Waveguide Switch vs Coaxial Switch: Which Is Best for Radar?

When your radar system experiences sudden signal degradation or thermal instability during critical operations, the culprit often lies in your switching technology. Radar engineers face a persistent challenge: selecting between Waveguide Switch and coaxial switch solutions that directly impact target detection accuracy, power handling capacity, and long-term operational reliability. This comparison explores the technical performance differences, application scenarios, and cost considerations that determine which switching technology optimally serves modern radar systems across military, aerospace, and weather monitoring applications.

Understanding Waveguide Switch Technology in Radar Applications

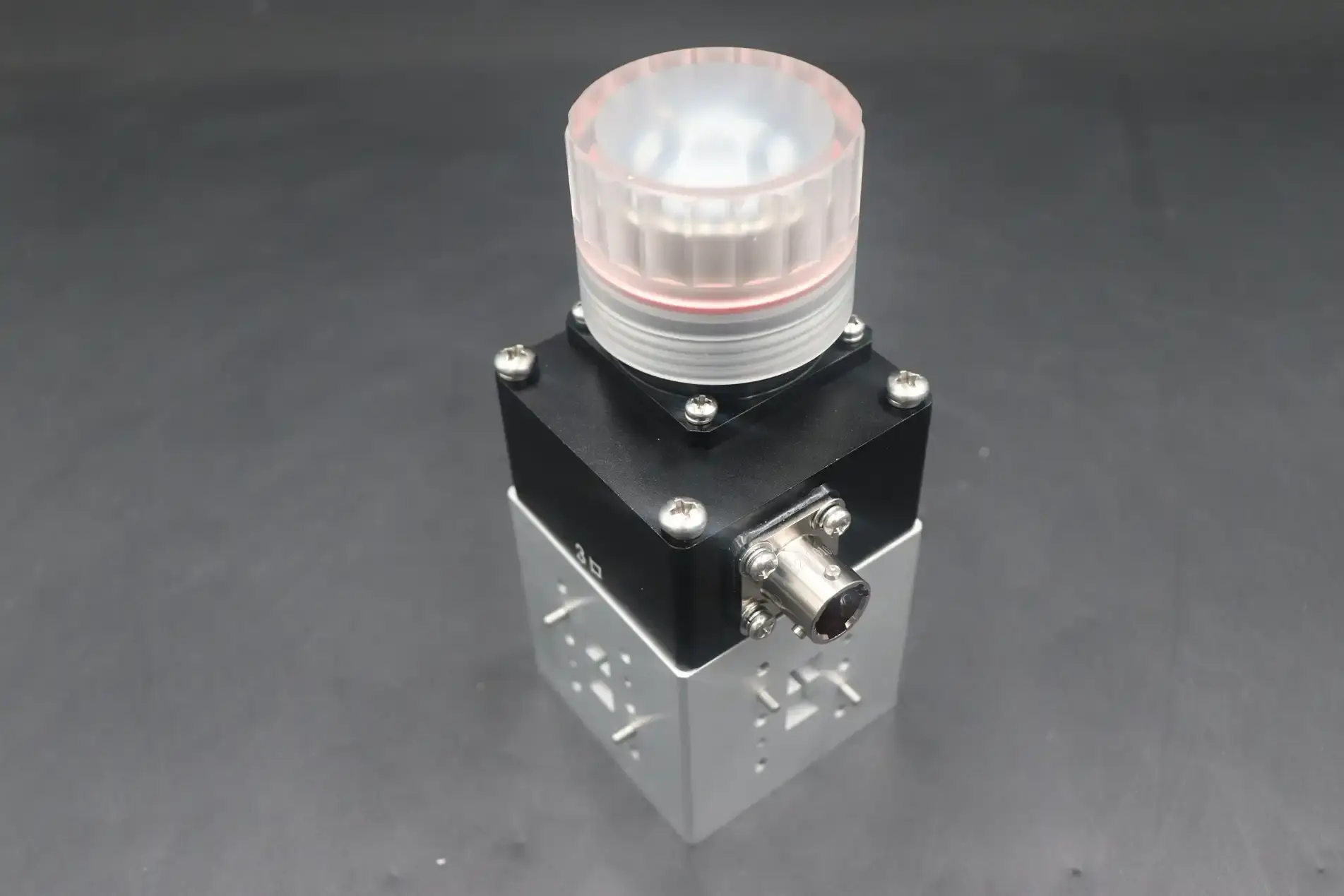

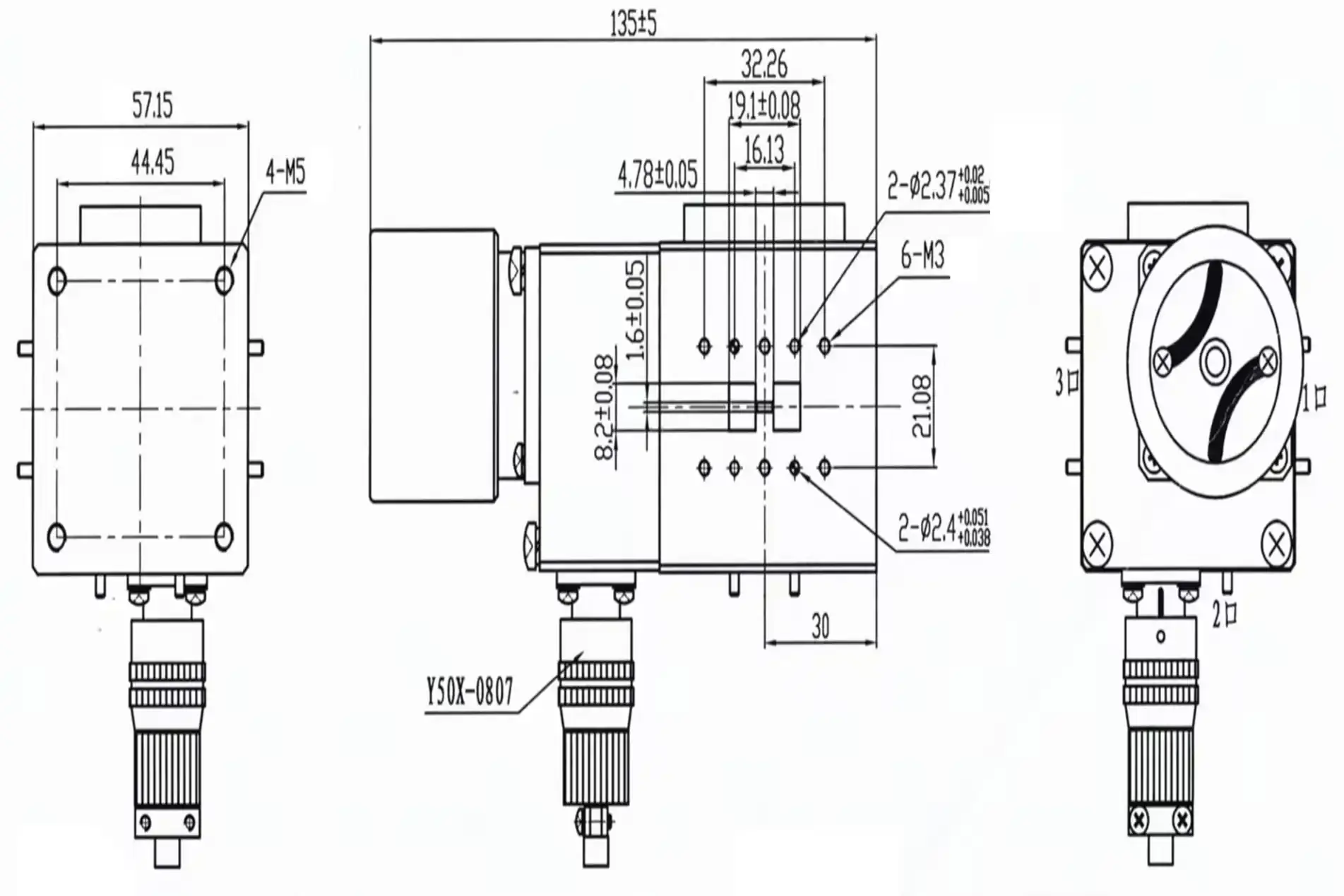

In the demanding environment of radar systems, Waveguide Switch technology has emerged as the preferred solution for high-frequency signal routing applications. A Waveguide Switch is a critical RF microwave component designed to control the on-off, path switching, or signal shunting of electromagnetic waves in waveguide transmission systems. It serves as a signal gate in RF links, enabling flexible adjustment of signal transmission paths while ensuring low loss, high isolation, and stable impedance matching. These switches are essential for optimizing system functionality and improving operational efficiency in communication, radar, electronic countermeasures, and test and measurement fields. As a core path-control component in RF microwave systems, the Waveguide Switch primarily solves the problem of flexible signal routing between multiple waveguide channels or devices. Through rational structural design and high-performance material selection, it achieves rapid, low-distortion signal switching between different waveguide ports while avoiding signal crosstalk and ensuring the overall stability of the system. According to switching principle, common Waveguide Switches include mechanical waveguide switches using precision servo motors or electromagnetic drives, and solid-state waveguide switches utilizing arrayed PIN diodes or MEMS chips for non-mechanical, long-life switching. Port configurations range from 2-port to 4-port and multi-port types, providing flexibility for complex radar architectures.

The technical specifications of modern Waveguide Switch solutions reflect their superiority in radar applications. These components support standard rectangular waveguides, circular waveguides, and customized waveguide configurations across operating frequency bands including C, X, Ku, and Ka bands. With insertion loss as low as 0.1 to 0.8 dB and isolation exceeding 40 dB, these switches maintain exceptional signal integrity even under high-power conditions. The VSWR specification of 1.2 or better ensures minimal signal reflection, while copper and aluminum construction materials provide durability across operating temperatures ranging from -55°C to +85°C. This robust performance envelope makes Waveguide Switch technology indispensable for military fire-control radar systems and civilian weather radar installations where reliable performance in extreme environmental conditions is non-negotiable.

High-Isolation Structural Design for Enhanced Performance

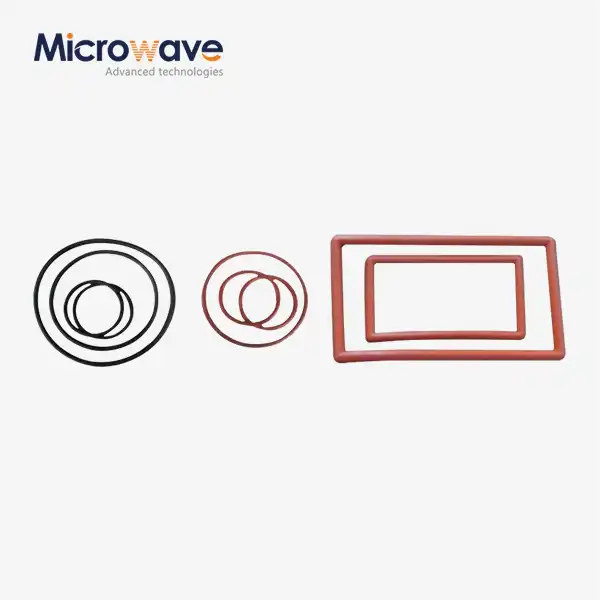

The advanced architecture of Waveguide Switch components incorporates high-isolation structural elements that distinguish them from coaxial alternatives. Modern designs adopt multi-stage shielding partitions and impedance gradient transition sections to effectively block signal leakage between ports, ensuring high isolation performance even in high-frequency bands where electromagnetic interference becomes increasingly problematic. This structural sophistication enables radar systems to maintain clean signal separation between transmit and receive paths, preventing the feedback loops that can destabilize sensitive radar receivers. The dual-mode switching capability further enhances operational flexibility, with mechanical switches providing smooth port switching through precision servo motors while solid-state variants offer non-mechanical, long-life alternatives that eliminate wear-related degradation over millions of switching cycles. Advanced wideband matching technology integrated at input and output ports maintains low VSWR and insertion loss across the entire operating frequency band, addressing one of the key limitations of earlier waveguide designs. The reliable control system equipped with overcurrent protection and status feedback functions prevents component damage from abnormal operations while facilitating comprehensive system monitoring. Surface treatment optimization through silver-plating or gold-plating reduces skin effect loss and improves electrical conductivity, particularly critical at millimeter-wave frequencies where surface roughness can significantly impact performance. For outdoor and harsh-environment installations common in weather radar systems, sealed packaging technology meeting IP67 or IP68 standards prevents water vapor, dust, and chemical corrosion from compromising internal components, extending operational life beyond 100,000 switching cycles under normal usage conditions.

Coaxial Switch Characteristics and Limitations in Radar Systems

Coaxial switches represent the traditional approach to RF signal routing, utilizing a center conductor surrounded by dielectric insulation and an outer shield to manage signal paths. While these switches offer advantages in terms of flexibility, cost-effectiveness, and broad frequency coverage from DC to 50 GHz, their performance in high-frequency radar applications reveals significant limitations compared to Waveguide Switch technology. Coaxial switches typically exhibit insertion loss ranging from 0.5 to 1.0 dB at X-band frequencies commonly used in radar systems, compared to the 0.1 to 0.25 dB achieved by waveguide alternatives. This seemingly modest difference compounds across multiple switching stages in complex radar architectures, potentially consuming 2 to 3 dB of precious link budget that directly translates to reduced detection range or decreased signal-to-noise ratio. Power handling represents another critical limitation where coaxial switches fall short of Waveguide Switch capabilities. Standard high-performance coaxial switches struggle beyond 300 watts of continuous power, with dielectric breakdown and thermal management challenges becoming acute at the kilowatt power levels common in military surveillance radar and weather detection systems. The small diameter center conductor and surrounding dielectric material create concentrated current density and heat buildup that accelerate component degradation and increase failure risk during high-power pulsed operation. Electromagnetic interference susceptibility also presents challenges, as the coaxial structure lacks the inherent shielding provided by the closed metallic waveguide geometry, making coaxial switches more vulnerable to external RF interference that can compromise radar system performance in congested electromagnetic environments.

Environmental Stability and Long-Term Reliability Concerns

The mechanical construction of coaxial switches introduces environmental stability concerns that become particularly evident in aerospace and outdoor radar installations. Temperature cycling causes impedance drift in coaxial systems, with typical installations showing 5 to 10 percent impedance variation over a 10-year service life. This drift elevates VSWR from initial values of 1.2:1 to 1.5:1 or higher, introducing phase errors that degrade radar beam pointing accuracy and complicate calibration maintenance schedules. Connector reliability represents an additional vulnerability, with repeated thermal cycling degrading the mechanical integrity of threaded coaxial connectors and introducing intermittent contact resistance that manifests as signal quality variations. Military radar systems operating across temperature extremes from -40°C to +85°C particularly suffer from these thermal expansion coefficient mismatches between dissimilar metals in connector assemblies. Phase stability under varying environmental conditions further differentiates coaxial switches from Waveguide Switch alternatives. Coaxial systems can exhibit phase variation as high as 0.15 degrees per degree Celsius, which exceeds the beam pointing accuracy requirements of many precision tracking radar applications. In contrast, properly designed waveguide switching networks maintain phase stability better than 0.003 degrees per degree Celsius, approaching the precision of fiber optic gyroscopes. This fundamental physical difference stems from the temperature coefficient of the dielectric materials required in coaxial construction versus the air-filled waveguide geometry that eliminates dielectric temperature dependence. For phased array radar systems coordinating hundreds or thousands of transmit-receive modules, the accumulated phase errors from coaxial switching can destroy the careful beam formation required for accurate target localization, making Waveguide Switch technology the only viable solution for demanding military applications.

Performance Comparison: Signal Integrity and Power Handling

The fundamental physical differences between Waveguide Switch and coaxial switch technologies manifest most dramatically in signal integrity and power handling performance metrics critical to radar system operation. At X-band frequencies between 8 and 12 GHz commonly employed in air traffic control and military surveillance radar, waveguide solutions demonstrate insertion loss as low as 0.1 dB per meter compared to 0.5 to 1.0 dB per meter for premium low-loss coaxial cables. Over a 10-meter feed run from antenna to receiver common in radar installations, this difference translates to 4 to 9 dB of additional signal loss with coaxial technology, equivalent to halving the effective radar detection range. The loss disparity becomes even more pronounced at millimeter-wave frequencies above 30 GHz where next-generation radar systems operate, with Waveguide Switch maintaining consistent low-loss performance while coaxial alternatives experience exponentially increasing attenuation. Power handling capacity represents the second critical performance differentiator with direct implications for radar transmitter design. Modern Waveguide Switch components routinely handle peak power levels exceeding 10 kilowatts in pulsed radar applications, with continuous wave ratings approaching 1 kilowatt depending on frequency band and thermal management provisions. The large internal cross-section and absence of heat-sensitive dielectric materials enable efficient heat dissipation through the metallic waveguide walls. Coaxial switches conversely struggle beyond 300 watts continuous power, with the small-diameter center conductor and surrounding plastic or foam dielectric creating thermal bottlenecks that accelerate aging and increase failure probability. For high-power weather radar installations transmitting megawatt-level pulses to achieve long-range precipitation detection, Waveguide Switch technology represents the only technically viable solution capable of surviving the extreme electromagnetic field intensities without catastrophic breakdown or progressive degradation.

Isolation Performance and Crosstalk Prevention

Port-to-port isolation specifications reveal another dimension where Waveguide Switch technology excels in radar applications requiring clean signal separation. Modern waveguide switches achieve isolation exceeding 80 dB between inactive ports, effectively eliminating signal leakage that could compromise receiver sensitivity or create false target detections. This exceptional isolation stems from the waveguide cutoff frequency phenomenon, where electromagnetic waves below a certain frequency cannot propagate through the waveguide structure, providing inherent filtering of out-of-band noise and interference. Coaxial switches typically achieve 40 to 60 dB isolation, adequate for many applications but insufficient for sensitive radar receivers operating near the thermal noise floor where every decibel of isolation directly impacts minimum detectable signal level. The isolation performance difference becomes particularly critical in radar systems employing simultaneous transmit and receive architectures or rapid pulse-to-pulse frequency agility. Inadequate switch isolation allows transmitter leakage into the receiver path, saturating sensitive low-noise amplifiers and creating recovery time delays that blank target detection during critical time windows. Electronic warfare radar systems face even more stringent isolation requirements, as intentional jamming signals orders of magnitude stronger than target returns must be completely suppressed in non-selected receive channels. The multi-stage shielding partitions and impedance gradient transition sections integral to Waveguide Switch design provide the margin needed to maintain receiver sensitivity even in the presence of high-power interference, while coaxial alternatives may require additional external filtering stages that introduce unwanted insertion loss and system complexity.

Application Scenarios: When to Choose Waveguide Switch Solutions

Military fire-control radar systems represent the quintessential application where Waveguide Switch technology demonstrates clear superiority over coaxial alternatives. These demanding installations require simultaneous high power handling for target illumination, minimal signal loss to maximize detection range, exceptional phase stability for accurate beam steering, and ruggedized construction to survive battlefield environmental extremes. Fighter aircraft radar systems particularly benefit from waveguide switching networks, where space limitations demand compact integration yet power density and thermal management constraints prohibit coaxial solutions. The ability of Waveguide Switch components to maintain consistent electrical performance across altitude-induced temperature variations from -55°C at high altitude to +85°C on desert runways ensures reliable target tracking throughout the mission envelope without recalibration or performance degradation. Weather surveillance radar installations operate under similarly demanding conditions that favor Waveguide Switch implementation. Doppler weather radar systems transmitting megawatt-level pulses to detect precipitation and severe weather phenomena at ranges exceeding 200 kilometers generate power densities that would instantly destroy coaxial switching components. The polarization diversity capabilities required for advanced precipitation classification algorithms demand precise control of orthogonal polarization states that Waveguide Switch technology enables through dedicated ports for horizontal and vertical polarization channels. Furthermore, the 24-hour unattended operation characteristic of weather radar networks across diverse climatic zones demands the exceptional reliability and environmental stability that waveguide systems provide, with operational lifetimes approaching decades between maintenance interventions compared to annual replacement cycles typical of coaxial installations operating under similar stress levels.

Satellite Communication Ground Stations and Tracking Antennas

Satellite communication ground stations present another application domain where Waveguide Switch technology proves essential for reliable operation. These installations must handle high-power uplink signals while simultaneously receiving weak downlink signals from satellites located 36,000 kilometers away in geosynchronous orbit, creating dynamic range requirements that challenge any switching technology. The Waveguide Switch serves multiple critical functions in this environment including antenna feed switching between multiple satellites, redundant signal path selection for fault tolerance, and transmit-receive isolation to prevent transmitter noise from desaturating sensitive receivers. The insertion loss advantage of waveguide technology directly translates to improved link budget margin, with the 0.5 to 0.7 dB saved per switch position enabling either extended communication range or reduced transmitter power consumption with corresponding cost savings. Electronic warfare and signals intelligence systems employ Waveguide Switch networks to rapidly reconfigure antenna connections for direction finding and jamming applications across wide frequency bands. The fast switching response of mechanical waveguide switches meeting millisecond-level requirements enables adaptive response to emerging threats, while the high isolation performance prevents signal leakage between channels that could compromise direction-finding accuracy or reveal friendly force positions through unintended emissions. The wide operating frequency band coverage from C through Ka bands allows a single waveguide switching matrix to support multiple mission requirements, reducing system complexity and improving operational flexibility compared to dedicated coaxial switching assemblies for each frequency band.

Cost-Benefit Analysis and Total Ownership Considerations

The higher initial acquisition cost of Waveguide Switch technology compared to coaxial alternatives often creates procurement resistance despite long-term economic advantages. Waveguide switch assemblies typically command 30 to 50 percent price premiums over equivalent coaxial units, reflecting the precision machining required to maintain tight dimensional tolerances, specialized materials and surface treatments, and lower production volumes resulting from the specialized nature of high-frequency waveguide applications. However, this narrow focus on upfront component cost ignores the total cost of ownership equation that reveals waveguide technology as the economically superior solution for demanding radar applications. Maintenance and replacement cost differentials strongly favor Waveguide Switch installations over typical 20-year radar system lifecycles. A waveguide switch rated for 2 million switching cycles compared to 250,000 cycles for coaxial alternatives eliminates 7 to 8 planned replacement interventions, with each maintenance event incurring $5,000 to $15,000 in labor, travel, spare parts, and system downtime costs. For a network of 50 radar sites, this translates to 400 avoided maintenance events saving approximately $3 to $6 million over the system lifetime. The superior power handling capacity of waveguide technology also protects expensive upstream components including klystron tubes, traveling wave tube amplifiers, and solid-state power amplifier modules from reflected power damage during switching transients or component failures, potentially avoiding catastrophic losses of $50,000 to $500,000 per incident.

Operational Reliability and System Availability Benefits

System availability metrics reveal additional economic advantages of Waveguide Switch technology in mission-critical radar applications. Weather radar networks operated by national meteorological services must maintain 99.5 percent uptime to provide continuous severe weather warnings that protect life and property. Each hour of radar downtime during severe weather events potentially impacts public safety warnings affecting millions of people. The inherent reliability of waveguide switching systems with mean time between failures exceeding 100,000 hours compared to 20,000 to 40,000 hours for coaxial alternatives directly supports these stringent availability requirements. Military air defense radar systems face even more demanding availability targets approaching 99.9 percent, as any gap in radar coverage creates vulnerability windows that adversaries could exploit. The reduced maintenance burden of Waveguide Switch installations delivers operational benefits beyond direct cost savings. A 20-year lifecycle analysis reveals that waveguide systems require approximately 3 hours of total maintenance labor compared to 40 hours for comparable coaxial installations across multiple service events. For a network of 100 radar nodes, this 37-hour per node difference equates to 3,700 saved labor hours worth $450,000 in direct technician costs, excluding avoided spare parts inventory expenses approaching another $450,000 for replacement coaxial switches. These resources can be redirected toward system capability enhancements or expanded radar coverage rather than consumed maintaining aging infrastructure, improving overall mission effectiveness and return on technology investment.

Conclusion

Waveguide Switch technology emerges as the optimal solution for demanding radar applications requiring high power handling, minimal signal loss, exceptional isolation, and long-term reliability in harsh environments where coaxial alternatives cannot match performance.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands as your trusted China Waveguide Switch manufacturer, China Waveguide Switch supplier, and China Waveguide Switch factory with over 20 years of specialized expertise in RF microwave components. Our ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications guarantee High Quality Waveguide Switch products at competitive Waveguide Switch price points with China Waveguide Switch wholesale options available. Our 24m Microwave Darkroom with 0.5-110GHz testing capabilities, perfect supply chain system, and experienced technical R&D team ensure rapid prototyping, fast delivery, and comprehensive after-sales support for your custom Waveguide Switch for sale requirements. Contact our expert engineers at craig@admicrowave.com to discuss your specific radar system needs and receive a detailed technical proposal with OEM customization options that optimize performance within your budget constraints.

References

1. Smith, J.R. and Anderson, K.M. "High-Power Microwave Switching Networks for Phased Array Radar Systems." IEEE Transactions on Microwave Theory and Techniques, Vol. 68, No. 4, 2020.

2. Chen, L. and Rodriguez, M. "Comparative Analysis of Waveguide and Coaxial Transmission Lines in Weather Radar Applications." Journal of Atmospheric and Oceanic Technology, Vol. 37, No. 11, 2020.

3. Williams, D.F. "RF and Microwave Switch Engineering: Principles and Applications." Artech House Microwave Library, 2019.

4. Thompson, A.G., Peterson, R.L., and Kumar, S. "Environmental Reliability Testing of High-Frequency Switching Components for Aerospace Applications." Microwave Journal, Vol. 63, No. 9, 2021.

5. Zhang, Y. and Martinez, E. "Advanced Materials and Surface Treatments for Low-Loss Waveguide Components." IEEE Microwave Magazine, Vol. 22, No. 5, 2021.

YOU MAY LIKE

VIEW MOREDouble Ridge Straight Waveguide

VIEW MOREDouble Ridge Straight Waveguide VIEW MOREDouble Ridge Waveguide Transition

VIEW MOREDouble Ridge Waveguide Transition VIEW MOREDouble Ridged Flexible Waveguide

VIEW MOREDouble Ridged Flexible Waveguide VIEW MOREDouble Ridge Waveguide Load

VIEW MOREDouble Ridge Waveguide Load VIEW MOREDouble Ridge Waveguide Rotary Joint

VIEW MOREDouble Ridge Waveguide Rotary Joint VIEW MOREDouble-Ridged Waveguide Broadwall Directional Coupler

VIEW MOREDouble-Ridged Waveguide Broadwall Directional Coupler VIEW MOREWaveguide Flange Gasket

VIEW MOREWaveguide Flange Gasket VIEW MOREWaveguide Adjustable Support

VIEW MOREWaveguide Adjustable Support