Why Choose a Conical Circular Polarization Horn Antenna OEM?

When satellite signals fail during critical missions or radar systems lose accuracy in harsh weather conditions, the underlying problem often traces back to one crucial component: the antenna. Choosing a Conical Circular Polarization Horn Antenna from a reliable OEM partner directly addresses these pain points by delivering precision-engineered solutions that maintain signal integrity regardless of environmental challenges. This specialized antenna technology combines conical geometry with circular polarization capabilities to ensure consistent, high-quality performance across applications ranging from aerospace defense systems to next-generation telecommunications infrastructure. Understanding why OEM partnerships matter in this highly technical field can mean the difference between system success and costly operational failures.

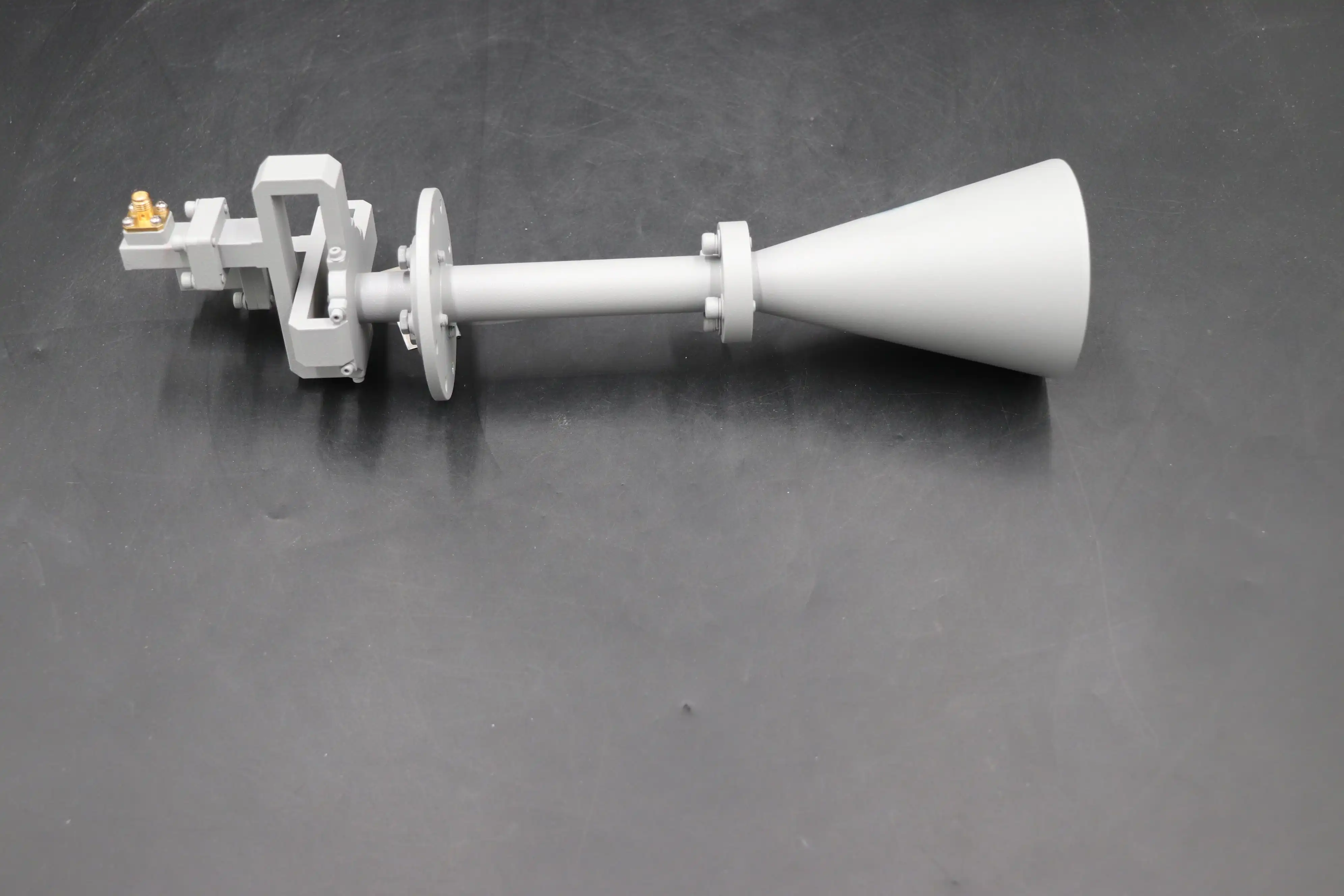

Understanding Conical Circular Polarization Horn Antenna Technology

The Conical Circular Polarization Horn Antenna represents a sophisticated fusion of electromagnetic theory and practical engineering design. At its core, this antenna type utilizes a conical structure that gradually transitions from a waveguide feed to a larger radiating aperture, creating an efficient pathway for electromagnetic wave propagation. The circular polarization aspect introduces a rotating electric field pattern that offers distinct advantages over traditional linear polarization systems. When electromagnetic waves travel through space with circular polarization, they maintain their orientation independence, meaning the receiving antenna does not require precise alignment with the transmitting source. This characteristic proves invaluable in mobile applications, satellite communications, and scenarios where maintaining exact antenna positioning becomes impractical or impossible. The engineering behind Conical Circular Polarization Horn Antenna designs involves carefully calculated flare angles, aperture dimensions, and feed structures that work together to produce optimal radiation patterns across wide frequency ranges. Advanced Microwave Technologies has developed manufacturing processes that ensure these critical dimensions maintain tolerances measured in fractions of millimeters, directly impacting the antenna's axial ratio and polarization purity. The conical geometry itself provides natural broadband capabilities, allowing a single antenna design to operate efficiently across multiple frequency bands without requiring complex matching networks or additional tuning components.

Technical Advantages of Circular Polarization in Horn Antennas

Circular polarization offers several technical benefits that make Conical Circular Polarization Horn Antenna solutions particularly attractive for demanding applications. The primary advantage emerges from the antenna's ability to mitigate multipath interference, a common problem in complex electromagnetic environments where signals reflect off multiple surfaces before reaching the receiver. Linear polarization systems suffer significant signal degradation under these conditions because reflected signals can arrive with phase shifts that cause destructive interference. Circular polarization maintains better signal integrity because the rotating field pattern inherently reduces the impact of reflected signals, as reflected waves typically reverse their polarization sense upon reflection from most surfaces. Weather conditions that severely impact linear polarization systems have minimal effect on Conical Circular Polarization Horn Antenna performance. Rain fade, a phenomenon where atmospheric water droplets attenuate electromagnetic signals, affects circularly polarized signals less severely than their linearly polarized counterparts. This robustness stems from the polarization diversity inherent in the circular field pattern, which distributes signal energy across multiple orientations simultaneously. For satellite ground stations, air traffic control radars, and military surveillance systems operating in all weather conditions, this reliability translates directly into operational availability and mission success rates. The Conical Circular Polarization Horn Antenna design from Advanced Microwave Technologies incorporates precision feed networks that maintain excellent axial ratios across the entire operational bandwidth from one gigahertz to forty gigahertz, ensuring consistent polarization purity even at frequency extremes.

Wide Frequency Coverage and Gain Characteristics

The frequency range capabilities of modern Conical Circular Polarization Horn Antenna designs address one of the most pressing challenges in contemporary wireless systems: the need to support multiple communication standards and frequency allocations within a single antenna platform. Operating from one gigahertz to forty gigahertz, these antennas encompass legacy communication bands, current cellular infrastructure frequencies, satellite communication uplink and downlink bands, radar applications, and emerging millimeter-wave technologies. This broad coverage eliminates the need for multiple specialized antennas in multi-band systems, reducing system complexity, installation costs, and maintenance requirements while improving overall reliability through component consolidation. Gain characteristics of Conical Circular Polarization Horn Antenna systems typically range from ten to twenty decibels isotropic, providing substantial directivity that concentrates radiated power in desired directions while minimizing interference with adjacent systems. The conical aperture design allows engineers to trade off between beamwidth and gain according to specific application requirements. Larger aperture antennas deliver higher gain but with narrower beamwidths, ideal for long-distance point-to-point links where precise beam control maximizes link budget efficiency. Smaller apertures provide wider coverage angles suitable for sector coverage in base station applications or wide-area surveillance systems. Advanced Microwave Technologies offers extensive customization options for Conical Circular Polarization Horn Antenna specifications, allowing customers to optimize these performance parameters for their unique operational requirements while maintaining the fundamental benefits of circular polarization and broadband frequency coverage.

Critical Factors in Selecting an OEM Partner

Choosing the right OEM manufacturer for Conical Circular Polarization Horn Antenna solutions requires careful evaluation of multiple technical and business factors that directly impact long-term project success. Manufacturing precision stands as perhaps the most critical selection criterion, as antenna performance depends heavily on maintaining tight dimensional tolerances throughout the fabrication process. The flare angle of the conical section, the aperture diameter, the feed probe positioning, and the waveguide transition dimensions must all be manufactured to specifications typically requiring precision measured in hundredths of millimeters. Deviations from design specifications directly degrade key performance parameters including return loss, axial ratio, gain, and beam pattern symmetry. Advanced Microwave Technologies operates state-of-the-art manufacturing facilities with computer-controlled machining centers and quality control processes that verify every critical dimension against design specifications before products ship to customers. Testing capabilities represent another essential evaluation factor when selecting a Conical Circular Polarization Horn Antenna OEM partner. Comprehensive antenna characterization requires specialized measurement equipment and facilities that many manufacturers simply do not possess. The twenty-four meter microwave darkroom at Advanced Microwave Technologies provides the controlled electromagnetic environment necessary for accurate far-field pattern measurements, gain calibration, and polarization purity verification. This facility operates across the full frequency spectrum from point five gigahertz to one hundred ten gigahertz, allowing complete characterization of Conical Circular Polarization Horn Antenna performance across all specified operating bands. The Antenna Plane Near and Far Field Measuring Recombination Chamber enables both near-field and far-field measurement techniques, providing flexibility to characterize antennas of various sizes and gain levels using the most appropriate measurement methodology for each design.

Quality Management and International Standards Compliance

Quality management systems and international standards compliance provide essential assurance that OEM manufacturing processes consistently deliver products meeting specified requirements. Advanced Microwave Technologies maintains ISO nine thousand one certification to the two thousand fifteen standard, demonstrating commitment to comprehensive quality management across all business operations from initial customer inquiry through design, manufacturing, testing, delivery, and after-sales support. This certification requires documented processes, regular internal audits, management review cycles, and continuous improvement initiatives that collectively ensure consistent product quality regardless of order size or customization complexity. For customers in regulated industries including aerospace, defense, and telecommunications, working with ISO certified Conical Circular Polarization Horn Antenna manufacturers simplifies their own compliance obligations and reduces supply chain risk.

Environmental management represents an increasingly important consideration in global supply chain decisions, with many organizations requiring suppliers to demonstrate environmental responsibility through formal management systems. The ISO fourteen thousand one certification to the two thousand fifteen standard held by Advanced Microwave Technologies confirms implementation of comprehensive environmental management practices covering waste minimization, energy conservation, emissions reduction, and materials selection throughout the product lifecycle. These environmental initiatives extend to Conical Circular Polarization Horn Antenna manufacturing processes, where materials selection prioritizes recyclable aluminum construction, manufacturing methods minimize waste generation, and packaging designs reduce transportation environmental impact. Occupational health and safety management certified to ISO forty-five thousand one standard demonstrates additional commitment to responsible business practices that protect workers while maintaining the skilled workforce essential for producing precision Conical Circular Polarization Horn Antenna products.

Customization Capabilities and Engineering Support

The ability to provide customized Conical Circular Polarization Horn Antenna solutions distinguishes truly capable OEM partners from vendors offering only standard catalog products. Real-world applications frequently present requirements that cannot be satisfied by off-the-shelf antenna designs, necessitating modifications to frequency coverage, gain specifications, mechanical interfaces, environmental protection levels, or integration features. Advanced Microwave Technologies maintains an engineering team with deep expertise in electromagnetic theory, antenna design, microwave measurement techniques, and manufacturing processes, enabling rapid development of custom Conical Circular Polarization Horn Antenna solutions optimized for specific customer applications. This engineering support extends beyond initial design to encompass prototyping, testing, design iteration based on measurement results, and production scaling to meet volume requirements. Technical support throughout the product lifecycle provides additional value that separates premium OEM partners from commodity suppliers. Customers implementing Conical Circular Polarization Horn Antenna solutions in complex systems benefit from ongoing access to engineering expertise for installation guidance, system integration troubleshooting, performance optimization, and field problem resolution. Advanced Microwave Technologies provides comprehensive technical documentation including detailed mechanical drawings, electromagnetic performance data, installation instructions, and handling guidelines that facilitate smooth system integration. When unexpected challenges arise during installation or operation, responsive technical support teams can quickly diagnose issues and recommend solutions, minimizing costly project delays. For applications requiring custom feed networks, specialized mounting arrangements, or integration with other microwave components, this engineering collaboration ensures all system elements work together optimally to achieve overall performance objectives.

Applications Driving Conical Circular Polarization Horn Antenna Demand

Satellite communication systems represent one of the largest application areas driving demand for high-performance Conical Circular Polarization Horn Antenna solutions. Ground stations communicating with orbiting satellites must maintain reliable links despite the constant motion of spacecraft across the sky, variations in atmospheric conditions, and potential interference from terrestrial sources. Circular polarization provides critical advantages in this environment by maintaining consistent signal reception regardless of satellite orientation changes, reducing susceptibility to interference from linearly polarized terrestrial systems, and minimizing signal degradation from atmospheric phenomena including rain, fog, and ice crystals. The Conical Circular Polarization Horn Antenna designs from Advanced Microwave Technologies deliver the wide bandwidth, high gain, and excellent axial ratio performance required for modern satellite communication applications spanning television broadcasting, internet connectivity, mobile backhaul, maritime and aeronautical communications, and government services.

Defense and aerospace applications demand the most rigorous performance specifications for Conical Circular Polarization Horn Antenna systems, where mission success and operational safety depend on absolute reliability under extreme conditions. Military radar systems utilize circular polarization to distinguish between actual targets and clutter, as most natural objects depolarize reflected signals while manufactured targets tend to preserve polarization characteristics. Air traffic control radars require exceptional beam quality and pattern stability to ensure accurate aircraft position tracking even during severe weather conditions that would impair lesser antenna systems. Unmanned aerial vehicle communication links rely on circular polarization to maintain connectivity despite platform motion and orientation changes during flight maneuvers. Advanced Microwave Technologies serves these demanding applications with Conical Circular Polarization Horn Antenna products manufactured to strict quality standards, tested comprehensively before delivery, and backed by detailed documentation supporting certification and qualification processes required in defense and aerospace procurement programs.

Telecommunications Infrastructure and Emerging Technologies

Telecommunications infrastructure continues evolving toward higher frequencies and wider bandwidths to support growing data traffic demands, creating opportunities for Conical Circular Polarization Horn Antenna technology in next-generation networks. Fifth-generation cellular systems and emerging sixth-generation research explore millimeter-wave frequencies where circular polarization offers advantages in challenging propagation environments including urban canyons with multiple reflection paths and rural areas requiring extended coverage. Base station antenna systems can leverage Conical Circular Polarization Horn Antenna elements in specific sectors where polarization diversity improves link reliability or where integration with existing linear polarization systems provides enhanced coverage. Backhaul links connecting cell sites to core networks benefit from the weather resilience and interference rejection inherent in circular polarization, particularly for long-distance links where link budget margins are tight and availability requirements are stringent. Industrial internet of things deployments and smart city infrastructure increasingly require wireless connectivity in electromagnetically complex environments where conventional antenna technology struggles to maintain reliable links. Factories with metal machinery creating multipath propagation, ports with shipping containers causing signal blockage and reflection, and transportation systems with constantly moving vehicles present challenging scenarios where Conical Circular Polarization Horn Antenna systems provide robust connectivity. The customization capabilities at Advanced Microwave Technologies enable development of specialized antenna solutions optimized for these emerging applications, incorporating features like compact form factors for space-constrained installations, ruggedized construction for harsh industrial environments, and custom frequency allocations matching specific regulatory requirements in different global markets.

Conclusion

Partnering with an experienced OEM for Conical Circular Polarization Horn Antenna solutions delivers technical performance, manufacturing quality, customization flexibility, and ongoing support essential for project success.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands ready as your trusted China Conical Circular Polarization Horn Antenna factory, offering unmatched expertise spanning over twenty years in precision microwave component manufacturing. Our comprehensive OEM services deliver High Quality Conical Circular Polarization Horn Antenna solutions at competitive Conical Circular Polarization Horn Antenna price points, backed by our advanced twenty-four meter microwave darkroom and ISO certified quality systems. Whether you need standard products or customized designs, our China Conical Circular Polarization Horn Antenna supplier capabilities ensure rapid prototyping and reliable production scaling. As a leading China Conical Circular Polarization Horn Antenna manufacturer and China Conical Circular Polarization Horn Antenna wholesale provider, we offer Conical Circular Polarization Horn Antenna for sale with comprehensive technical support from initial consultation through installation and beyond. Contact craig@admicrowave.com today to discuss your specific requirements and discover how our engineering team can optimize antenna solutions for your critical applications.

References

1. Balanis, Constantine A. "Antenna Theory: Analysis and Design." Fourth Edition. John Wiley & Sons, 2016.

2. Milligan, Thomas A. "Modern Antenna Design." Second Edition. IEEE Press, 2005.

3. Stutzman, Warren L. and Gary A. Thiele. "Antenna Theory and Design." Third Edition. John Wiley & Sons, 2012.

4. Love, Augustus W. "Electromagnetic Horn Antennas." IEEE Press Selected Reprint Series. Institute of Electrical and Electronics Engineers, 1976.

5. Olver, A. D., P. J. B. Clarricoats, A. A. Kishk, and L. Shafai. "Microwave Horns and Feeds." IEEE Press, 1994.

_1733738410152.webp)