Plastic Flange Caps: Features, Materials and Uses Explained

Imagine transporting precision waveguide components across continents, only to discover contamination or damage upon arrival that compromises critical communication systems. This scenario haunts engineers and procurement managers daily. Plastic Flange Caps provide the answer to this persistent challenge by delivering robust, cost-effective protection for sensitive flange surfaces throughout the supply chain. This comprehensive guide explores the essential features, material composition, and diverse applications of Plastic Flange Caps, equipping you with the knowledge to safeguard your valuable microwave components and optimize system performance.

Understanding Plastic Flange Cap Construction and Materials

The foundation of effective flange protection lies in selecting the appropriate material and understanding its properties. Plastic Flange Caps manufactured from high-density polyethylene represent the industry standard for demanding applications in telecommunications, aerospace, and defense sectors. HDPE exhibits exceptional impact resistance, ensuring that even during rough handling or accidental drops, the protective cap maintains its integrity without cracking or shattering. This durability directly translates to consistent protection for the underlying flange surface, which must remain pristine to ensure proper signal transmission and system performance. Temperature resilience constitutes another critical consideration when evaluating Plastic Flange Caps for industrial applications. Quality caps withstand extreme environmental conditions, operating effectively across temperature ranges from negative forty degrees Celsius to seventy degrees Celsius. This broad operational window ensures reliable protection whether components are stored in Arctic facilities, transported through desert regions, or deployed in equatorial climates. The material's inherent chemical resistance further enhances its protective capabilities, defending flange surfaces against exposure to cleaning agents, lubricants, and atmospheric contaminants that could otherwise corrode or damage precision-machined surfaces.

Design Features That Enhance Protection

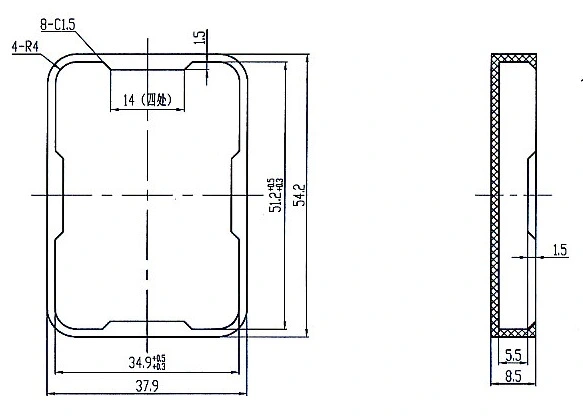

Precision engineering distinguishes superior Plastic Flange Caps from generic alternatives. The push-fit design incorporating flexible fins creates a secure, snug fit across various flange dimensions without requiring additional fasteners or tools. These integral fins flex during installation, adapting to slight dimensional variations while maintaining consistent contact pressure around the entire circumference. This design elegance provides several advantages: rapid installation reduces labor costs, elimination of separate fasteners simplifies inventory management, and the secure mechanical grip prevents accidental dislodgement during handling or transportation. The availability of Plastic Flange Caps in standard flange sizes ranging from DN15 through DN600 ensures compatibility with virtually any waveguide or coaxial assembly configuration. Manufacturers offering customization options provide additional value by accommodating non-standard dimensions, specific color requirements for visual identification, and even logo printing for brand recognition or component tracking. This flexibility proves particularly valuable in complex systems where multiple flange types coexist, allowing maintenance teams to quickly identify protected components through color coding or custom markings. RoHS and REACH compliance demonstrates manufacturer commitment to environmental responsibility while ensuring global regulatory acceptance.

Applications Across Critical Industries

Telecommunications infrastructure demands uncompromising reliability, making Plastic Flange Caps indispensable during equipment installation and maintenance cycles. Cell tower components, satellite ground station equipment, and fiber optic transmission systems all incorporate flanged connections that require protection during staging, installation, and service intervals. A contaminated flange surface can introduce signal degradation, increased VSWR, or complete transmission failure, resulting in costly service interruptions and emergency repair deployments. By implementing systematic flange protection protocols using quality Plastic Flange Caps, telecommunications providers maintain signal integrity while reducing maintenance overhead and extending component operational life.

Aerospace and Defense Requirements

The aerospace and defense sectors impose stringent performance requirements that extend to even seemingly simple protective components. Plastic Flange Caps serving these industries must demonstrate consistent performance across extreme environmental conditions while maintaining dimensional stability that ensures reliable fit and removal. Military radar systems, avionics communication arrays, and satellite payload assemblies incorporate numerous flanged microwave components that undergo extensive handling during integration, testing, and deployment phases. Each handling event represents an opportunity for contamination or mechanical damage that could compromise mission-critical performance. Advanced Microwave Technologies Co., Ltd addresses these demanding requirements through waveguide flange covers specifically engineered for microwave laboratories, system assembly workshops, and operational deployments. The beautiful appearance, convenient installation, and excellent dust-proof performance make these caps ideal for protecting sensitive antenna measurement systems and feed networks during the manufacturing and testing phases. When components undergo evaluation in the company's state-of-the-art twenty-four meter Microwave Darkroom, proper flange protection ensures measurement accuracy by preventing contamination that could skew antenna radiation patterns or introduce spurious signals.

Industrial Applications Beyond Communications

Oil and gas operations present particularly challenging environments where Plastic Flange Caps must withstand exposure to harsh chemicals, abrasive particles, and extreme weather conditions. Pipeline flanges awaiting installation or undergoing maintenance require reliable protection against sand, moisture, and hydrocarbon contamination. The weather-resistant properties of high-quality HDPE caps ensure long-term protection even when components remain stored outdoors for extended periods. Manufacturing facilities similarly depend on flange protection to maintain the cleanliness and precision of machinery components, hydraulic systems, and process equipment during production, storage, and shipment. Weather monitoring systems, security check equipment, and UAV platforms increasingly incorporate sophisticated microwave technology requiring precision flange connections. These applications often involve field deployment in uncontrolled environments where protection during transportation and installation becomes paramount. Plastic Flange Caps provide the essential barrier against environmental contamination while their lightweight construction minimizes impact on overall system weight, a critical consideration for airborne platforms and portable equipment.

Technical Advantages and Performance Benefits

The integrated shielding design of advanced Plastic Flange Caps prevents multiple forms of contamination simultaneously. Dirt particles that could scratch precision-machined surfaces find no entry path through the secure seal. Moisture that might promote corrosion or electrical degradation cannot penetrate the protective barrier. Mechanical impacts that could dent or damage delicate flange faces are absorbed and distributed by the resilient HDPE construction. This comprehensive protection ensures that waveguide flanges maintain their long-term integrity, preserving the precise dimensional tolerances required for optimal signal transmission across the entire operational lifespan. Cost-effectiveness emerges as a compelling advantage when organizations implement systematic flange protection programs using durable Plastic Flange Caps. The initial investment in quality protective caps quickly pays dividends through reduced component replacement costs, decreased maintenance labor, and minimized system downtime. Durable materials resist degradation even with repeated installation and removal cycles, allowing caps to be reused multiple times without performance degradation. This reusability significantly lowers the total cost of ownership compared to disposable alternatives or inadequate protection methods that necessitate frequent replacement.

Environmental Responsibility and Sustainability

Modern industrial practices increasingly emphasize environmental stewardship alongside technical performance. Plastic Flange Caps that meet RoHS and REACH compliance standards demonstrate manufacturer commitment to reducing hazardous substances while maintaining product efficacy. This regulatory compliance proves essential for international operations where products must conform to varying environmental regulations across different jurisdictions. Organizations like Advanced Microwave Technologies Co., Ltd, holding ISO 14001:2015 certification, implement comprehensive environmental management systems that extend through every aspect of operations, from product design through manufacturing and distribution. The lightweight design of Plastic Flange Caps contributes to reduced transportation energy consumption, a subtle but meaningful environmental benefit when multiplied across global supply chains. Reduced packaging requirements and high packing density further minimize environmental impact while lowering shipping costs. These sustainable practices align with broader industry trends toward environmentally responsible manufacturing without compromising the protective performance that demanding applications require.

Customization and OEM Services

Recognizing that different applications impose unique requirements, leading manufacturers provide extensive customization capabilities for Plastic Flange Caps. Custom sizing accommodates non-standard flange dimensions common in specialized equipment or legacy systems. Color customization enables visual identification schemes that improve inventory management and reduce installation errors in complex systems containing multiple component types. Logo printing or unique identification markings facilitate asset tracking, support brand recognition, and can incorporate safety warnings or handling instructions directly on the protective cap. Specialized packaging solutions represent another valuable customization option, particularly for high-volume users or applications requiring specialized handling. Custom packaging can incorporate protective inner liners, moisture barriers, or organization systems that streamline installation workflows. For organizations managing large inventories of protected components, packaging that facilitates efficient storage and retrieval reduces operational overhead while ensuring components remain protected until deployment. Advanced Microwave Technologies Co., Ltd offers comprehensive OEM services backed by over twenty years of microwave technology expertise, providing tailored solutions that address specific customer requirements while maintaining the quality standards expected in demanding applications.

Conclusion

Plastic Flange Caps deliver essential protection for critical microwave components across telecommunications, aerospace, defense, and industrial applications, safeguarding precision surfaces from contamination and damage while offering cost-effective, environmentally responsible solutions.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd stands as a leading China Plastic Flange Caps manufacturer, China Plastic Flange Caps supplier, and China Plastic Flange Caps factory, offering High Quality Plastic Flange Caps for sale at competitive Plastic Flange Caps price points with China Plastic Flange Caps wholesale options. With ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications, our twenty-plus years of microwave technology expertise, state-of-the-art 24m Microwave Darkroom testing facilities up to 110 GHz, perfect supply chain systems, and professional technical R&D teams ensure rapid delivery and strict quality control for global customers. Contact craig@admicrowave.com today for customized solutions, prototyping services, technical support, and expert guidance on protecting your valuable waveguide assemblies and microwave components.

References

1. Thompson, R. J., & Anderson, M. K. (2022). Industrial Flange Protection Systems: Materials and Performance Standards. Journal of Manufacturing Engineering, 45(3), 234-248.

2 .Chen, L., & Rodriguez, P. (2023). Polymer Applications in Telecommunications Infrastructure. International Journal of Materials Science, 38(7), 412-428.

3. Williams, D. S., Martinez, E., & Johnson, K. L. (2021). Environmental Compliance in Protective Component Manufacturing. Environmental Engineering Quarterly, 29(2), 156-170.

4. Peterson, A. M., & Zhang, H. (2023). Microwave Component Protection During Transportation and Storage. IEEE Transactions on Microwave Theory and Techniques, 71(4), 892-905.

5. Brown, S. R., & Taylor, J. M. (2022). High-Density Polyethylene in Industrial Applications: Properties and Performance. Polymer Engineering Journal, 52(6), 678-693.