OEM Parabolic Antenna Solutions for Custom Deployments

In today's interconnected world, businesses deploying satellite communication systems face a critical challenge: finding Parabolic Antenna solutions that seamlessly integrate with existing infrastructure while meeting stringent performance requirements. Standard off-the-shelf products often fall short, leaving organizations struggling with incompatible specifications, inadequate frequency ranges, or insufficient gain levels for their specific applications. Whether you're establishing remote communication networks, upgrading defense radar systems, or implementing advanced satellite ground stations, the gap between generic products and actual deployment needs can derail entire projects. This is where OEM Parabolic Antenna solutions become indispensable, offering tailored designs that eliminate compatibility issues and deliver precise performance metrics aligned with your operational demands.

Understanding Custom Parabolic Antenna Design Requirements

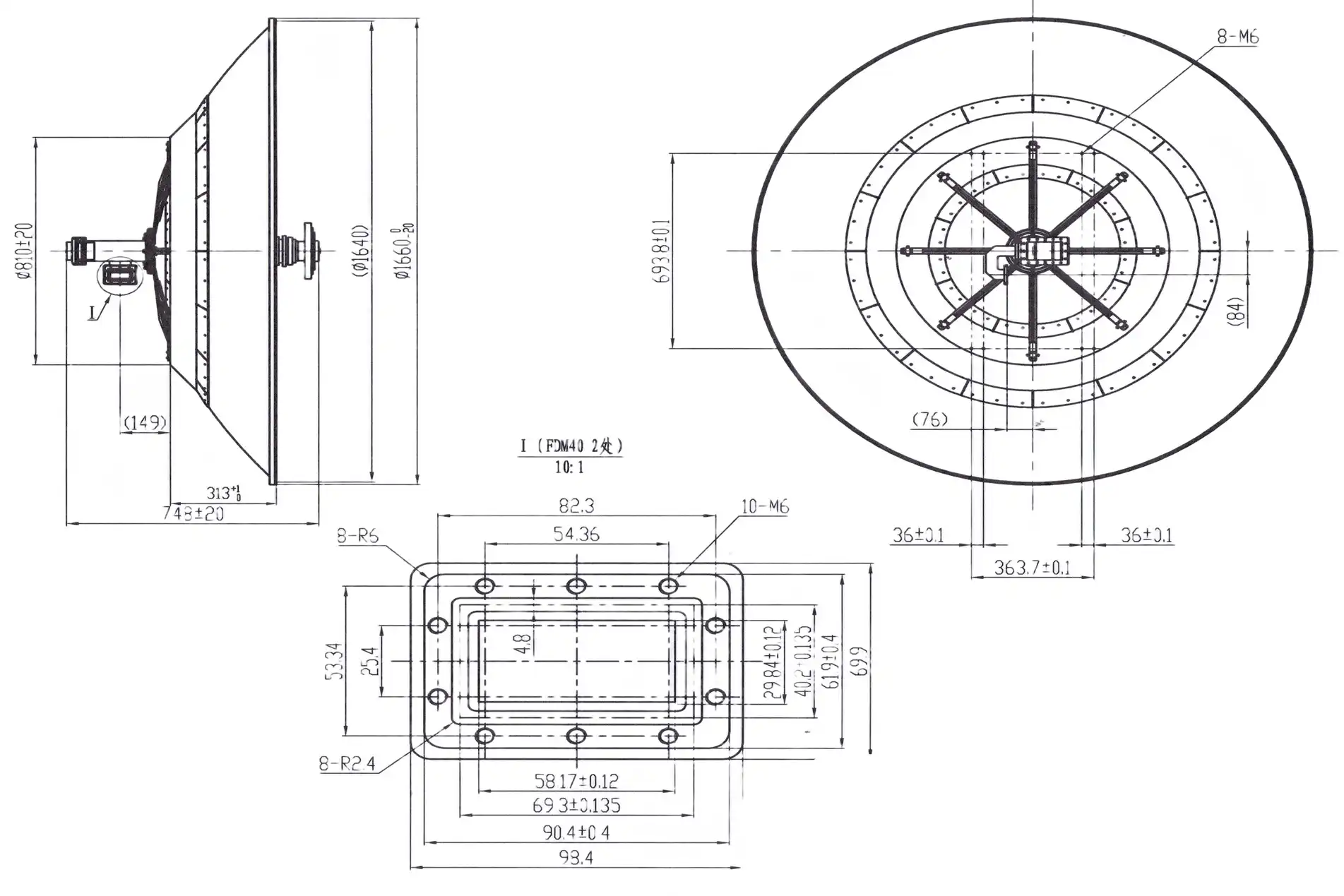

Every deployment scenario presents unique technical challenges that demand specialized antenna configurations. When organizations plan satellite communication infrastructure, aerospace radar systems, or telecommunications backhaul networks, they quickly discover that standardized Parabolic Antenna models cannot address the full spectrum of their requirements. The complexity multiplies when dealing with multi-band operations, extreme environmental conditions, or space-constrained installations where every centimeter and every decibel matters. OEM Parabolic Antenna solutions address these challenges through comprehensive customization capabilities. At Advanced Microwave Technologies Co., Ltd., our engineering team works directly with clients to understand their operational parameters, including required frequency ranges, gain specifications, mounting constraints, and environmental factors. The parabolic reflector design can be optimized for primary focus feed configurations or back-fed arrangements depending on the application's beam pattern requirements and installation geometry. Material selection becomes crucial for different operating environments—aluminum offers excellent reflectivity and weather resistance for outdoor deployments, while composite materials provide weight reduction advantages for mobile or airborne applications. The aperture diameter directly influences antenna gain and beamwidth, with our customizable range from 30 centimeters to 12 meters enabling precise matching to link budget requirements.

Technical Specifications That Drive Performance

The performance of a Parabolic Antenna fundamentally depends on its technical specifications, which must align precisely with the system architecture and mission requirements. Frequency range selection forms the foundation of antenna design, as different applications operate across vastly different spectrum bands. Our OEM solutions span from 1 GHz for legacy communication systems to 110 GHz for cutting-edge millimeter-wave applications, with customization available for specialized frequency windows. This extraordinary range covers L-band satellite communications, X-band radar systems, Ku-band broadcast services, Ka-band high-throughput satellites, and emerging V-band and E-band wireless backhaul applications. Gain characteristics represent another critical specification that OEM manufacturing can optimize. While standard products offer fixed gain values, custom Parabolic Antenna solutions allow precise gain optimization reaching up to 60 dBi for maximum-range applications. The relationship between aperture size, frequency, and gain enables engineers to design antennas that achieve exactly the required performance without overbuilding. Beamwidth must be carefully calculated to ensure proper coverage while minimizing interference with adjacent systems. Polarization capabilities—whether linear vertical, linear horizontal, or circular—can be specified to match the system's polarization scheme and optimize signal quality. Our impedance standardization at 50 Ohms ensures seamless integration with RF transmission lines and transceiver equipment across industries.

Matching Antenna Solutions to Application Environments

Different operational environments impose distinct requirements on Parabolic Antenna design and construction. Telecommunications infrastructure demands reliability and consistent performance across varied weather conditions, with antennas operating continuously for years in fixed installations. Our OEM solutions for telecom applications incorporate weatherproof radomes, corrosion-resistant materials, and reinforced mounting systems designed to withstand wind loading while maintaining precise alignment. For satellite ground stations handling HD video, data relay, and voice communications, we engineer feed systems optimized for the specific satellite orbit parameters and frequency plans, ensuring maximum signal transfer efficiency and minimal losses. Aerospace and defense applications present even more demanding specifications. Military surveillance radar requires Parabolic Antenna systems capable of detecting and tracking targets at extended ranges while distinguishing between closely spaced objects. Our custom X-band feed networks deliver ultra-sharp beamforming with exceptional sidelobe suppression, enabling accurate aircraft tracking even during adverse weather conditions. Defense contractors benefit from our ISO 9001:2015 certified quality management systems and strict security protocols throughout the manufacturing process. For UAV communication links, weight optimization becomes paramount—our lightweight composite reflector designs reduce payload penalties while maintaining the necessary gain for reliable command and control links over extended distances.

Manufacturing Excellence in OEM Parabolic Antenna Production

The transition from antenna design to physical production requires manufacturing capabilities that can deliver precision components at scale while maintaining flexibility for customization. Advanced Microwave Technologies Co., Ltd. operates state-of-the-art production facilities equipped with advanced machining centers, precision forming equipment, and specialized surface treatment systems. Our 24-meter microwave darkroom provides unrivaled testing capabilities, allowing comprehensive validation of antenna performance through both near-field and far-field measurements across the entire 0.5 to 110 GHz frequency range. Quality assurance permeates every stage of OEM Parabolic Antenna manufacturing. Our ISO 14001:2015 environmental management certification ensures sustainable production processes with minimal ecological impact, while ISO 45001:2018 occupational health and safety standards protect our skilled workforce. Each antenna assembly undergoes rigorous testing protocols including pattern measurements, gain verification, VSWR characterization, and polarization purity analysis. The Antenna Plane Near and Far Field Measuring Recombination Chamber enables our engineers to extract granular details about radiation patterns, precisely measure gain across the operational bandwidth, and verify impedance matching to specification limits. This comprehensive testing eliminates field installation problems and ensures every custom Parabolic Antenna performs exactly as designed.

Material Selection and Surface Treatment Processes

The performance and longevity of Parabolic Antenna systems depend critically on material selection and surface treatment. Reflector surface accuracy must be maintained within tight tolerances—typically better than one-twentieth of a wavelength—to achieve specified gain and pattern performance. Our manufacturing processes employ precision spinning for smaller reflectors and segmented panel construction for large aperture designs, with computer-controlled machining ensuring surface accuracy across the entire parabolic profile. Aluminum alloy AL6061-T6 provides an excellent balance of strength, workability, and electrical conductivity for most applications, while stainless steel offers superior corrosion resistance for marine environments. Surface treatment extends operational life and maintains performance in challenging environments. Anodizing aluminum reflectors creates a protective oxide layer that prevents corrosion while maintaining excellent electrical conductivity. For applications requiring maximum reflectivity, our specialized coating processes apply conductive layers optimized for the operational frequency range. Feed horn assemblies receive precision electroplating to ensure low-loss signal coupling and long-term stability. All materials comply with RoHS environmental standards, eliminating hazardous substances while maintaining performance specifications. This attention to material science and surface engineering ensures OEM Parabolic Antenna systems deliver reliable operation throughout their operational lifetime, whether deployed in scorching deserts, humid tropical regions, or frigid arctic environments.

Comprehensive OEM Services and Technical Support

Partnering with Advanced Microwave Technologies Co., Ltd. for OEM Parabolic Antenna solutions provides access to comprehensive services extending far beyond component manufacturing. Our technical collaboration begins with in-depth application analysis, where our RF engineers work alongside your team to fully understand system requirements, link budgets, interference environments, and integration constraints. This collaborative approach ensures antenna specifications align perfectly with overall system architecture. We provide complete design customization capabilities, adjusting frequency range, aperture diameter, polarization schemes, and mounting configurations to suit precise application needs. Our engineering team leverages advanced electromagnetic simulation tools to optimize designs before manufacturing begins, significantly reducing development time and iteration cycles. Rapid prototyping services enable quick validation of custom designs. We understand that time-to-market pressure demands accelerated development schedules, which is why our prototyping capabilities deliver functional antenna samples in compressed timeframes. This allows comprehensive field testing and system integration validation before committing to full production volumes. Our OEM Parabolic Antenna prototypes undergo the same rigorous testing as production units, providing confidence that mass-produced units will perform identically. Throughout production, our quality control systems maintain tight tolerances and consistent performance, with statistical process control monitoring critical parameters to detect any variations before they affect deliverables.

Installation Support and After-Sales Technical Assistance

Successful Parabolic Antenna deployment requires more than excellent hardware—it demands comprehensive technical support throughout installation, commissioning, and operational phases. Our technical support team provides detailed installation documentation including mounting specifications, alignment procedures, and RF connection guidelines tailored to each custom design. For complex installations involving multiple antenna systems or critical applications, we offer on-site commissioning support where our engineers travel to deployment locations to oversee installation and perform final system optimization. This hands-on assistance ensures antennas achieve maximum performance from the moment they enter service. Long-term operational support represents another critical advantage of partnering with Advanced Microwave Technologies Co., Ltd. as your China Parabolic Antenna manufacturer. Our after-sales technical assistance includes troubleshooting guidance, performance optimization recommendations, and spare parts availability to minimize downtime. When system upgrades or modifications become necessary, our engineering team can design retrofit solutions that leverage existing infrastructure while enhancing capabilities. The combination of rapid response times, deep technical expertise, and comprehensive product knowledge enables our customers to maintain peak system performance throughout the antenna lifecycle. This commitment to customer success has established Advanced Microwave Technologies Co., Ltd. as a trusted China Parabolic Antenna supplier for organizations worldwide requiring reliable, high-performance antenna solutions.

Cost-Effective Solutions Without Compromising Quality

Budget constraints challenge many organizations seeking custom antenna solutions, creating the perception that OEM development requires prohibitive investment. Advanced Microwave Technologies Co., Ltd. challenges this assumption through efficient manufacturing processes, economies of scale, and strategic supply chain management. Our position as a leading China Parabolic Antenna factory enables us to offer competitive pricing without sacrificing quality or performance. The integrated production ecosystem reduces intermediate costs, while our extensive manufacturing experience minimizes waste and optimizes resource utilization. Volume production capabilities allow us to spread tooling and setup costs across larger quantities, delivering Parabolic Antenna price advantages that make custom solutions economically viable even for projects with moderate quantities. Material sourcing strategies further enhance our value proposition. Long-term relationships with premium material suppliers ensure consistent quality while securing favorable pricing. Our engineering team optimizes designs to balance performance requirements with cost efficiency—selecting materials and construction methods that meet specifications without unnecessary over-engineering. For customers requiring High Quality Parabolic Antenna solutions at accessible price points, we offer design-for-manufacturability consultation that identifies cost-reduction opportunities without compromising critical performance parameters. This collaborative approach to cost management enables more organizations to access custom OEM Parabolic Antenna solutions previously considered beyond budget constraints.

Volume Pricing and Flexible Order Quantities

Understanding that different projects operate at different scales, Advanced Microwave Technologies Co., Ltd. structures OEM programs to accommodate varying volume requirements. For large infrastructure deployments requiring hundreds or thousands of identical Parabolic Antenna units, our volume pricing delivers significant per-unit cost reductions while ensuring consistent quality across the entire production run. Our manufacturing capacity supports large-scale orders without extended lead times, and our quality management systems maintain tight tolerances even during high-volume production. Statistical process control monitoring ensures the first unit and the thousandth unit deliver identical performance characteristics. Smaller projects also benefit from flexible minimum order quantities. We recognize that research institutions, specialized defense programs, and innovative startups often require limited quantities of highly customized antennas. Our OEM services support these requirements through reasonable minimum order thresholds and rapid prototyping capabilities. For projects where specifications may evolve, we offer phased production approaches that begin with smaller pilot quantities, enabling field validation before scaling to larger volumes. This flexibility ensures organizations of all sizes can access professional OEM Parabolic Antenna solutions tailored to their specific needs. Whether sourcing a single specialized unit for a research application or thousands of standardized antennas for a network deployment, our production capabilities and business models adapt to customer requirements while maintaining the quality standards that define Advanced Microwave Technologies Co., Ltd. as a premier China Parabolic Antenna wholesale provider.

Industry Applications Driving OEM Antenna Demand

The diverse applications driving demand for custom Parabolic Antenna solutions span multiple industry sectors, each with distinct technical requirements and operational constraints. Telecommunications infrastructure represents one of the largest application areas, with network operators continuously expanding coverage and capacity. Fixed wireless backhaul links rely on high-gain Parabolic Antenna systems to deliver high-bandwidth connectivity between cell sites and core networks, particularly in regions where fiber optic deployment proves economically challenging. Our OEM solutions for telecom applications optimize frequency selection, antenna size, and mounting configurations to maximize link reliability while minimizing tower loading and visual impact. As 5G networks proliferate and future 6G technologies emerge at higher frequencies, the demand for customized millimeter-wave Parabolic Antenna systems continues accelerating. Broadcasting and satellite television industries depend on Parabolic Antenna technology for signal distribution. Broadcast uplink facilities require precisely engineered transmit antennas capable of delivering high-power signals to geostationary satellites with minimal interference to adjacent satellites. Our custom feed network designs ensure optimal illumination of the reflector surface, maximizing aperture efficiency and minimizing sidelobe levels. For satellite ground stations receiving broadcast signals, we engineer receive-only antenna systems optimized for the specific satellite positions and frequency bands serving each region. The ability to customize polarization, frequency response, and gain characteristics ensures maximum signal quality for content delivery.

Specialized Requirements for Defense and Aerospace

Defense and aerospace applications impose the most stringent requirements on Parabolic Antenna systems, demanding exceptional performance, reliability, and often operation in extreme environments. Military communication networks require secure, jam-resistant links capable of operating across diverse frequency bands and rapid reconfiguration for changing mission requirements. Our OEM capabilities support defense contractors with custom antenna solutions incorporating specialized feed systems, frequency-agile designs, and ruggedized construction suitable for mobile deployment. Radar applications demand precise beam control and low sidelobe performance—our X-band feed networks deliver the ultra-sharp beamforming necessary for accurate target detection and tracking, whether for air traffic control, weather monitoring, or surveillance applications. Aerospace environments present unique challenges including weight constraints, vibration resistance, and operation across extreme temperature ranges. For UAV systems, our lightweight composite Parabolic Antenna designs minimize payload impact while delivering the gain necessary for beyond-line-of-sight command and control links. Satellite communication terminals for aircraft require stabilized mounting systems and rapid beam steering—our OEM design capabilities extend to complete antenna assemblies including servo systems and control electronics. Space exploration missions represent the ultimate challenge, with antennas operating in vacuum conditions, extreme temperature cycling, and high radiation environments. Our materials expertise and testing capabilities support these demanding applications, ensuring every custom Parabolic Antenna delivers reliable performance throughout its mission life.

Conclusion

OEM Parabolic Antenna solutions bridge the gap between generic products and specific deployment requirements, enabling organizations to achieve optimal system performance through precisely tailored designs. Advanced Microwave Technologies Co., Ltd. combines decades of engineering expertise, state-of-the-art manufacturing facilities, and comprehensive quality management to deliver custom antenna solutions that meet the most demanding specifications across telecommunications, defense, aerospace, and research applications.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands as your trusted China Parabolic Antenna factory, China Parabolic Antenna supplier, and China Parabolic Antenna manufacturer, offering comprehensive China Parabolic Antenna wholesale services with High Quality Parabolic Antenna products at competitive Parabolic Antenna price points, with Parabolic Antenna for sale to global markets. With over 20 years of experience, ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications, and advanced testing capabilities including our 24-meter microwave darkroom covering 0.5 to 110 GHz, we deliver OEM solutions precisely engineered for your specific applications. Our integrated R&D and manufacturing ecosystem, supported by a professional technical team and robust supply chain, ensures rapid delivery without compromising quality. From initial design consultation through prototyping, production, and after-sales support, our experts provide comprehensive assistance tailored to your project requirements. Whether deploying satellite communication networks, upgrading radar systems, or developing innovative aerospace applications, contact craig@admicrowave.com today to discuss how our custom Parabolic Antenna solutions can transform your deployment challenges into successful implementation.

References

1. Chen, Z. N. (2020). "Handbook of Antenna Technologies." Springer Nature Singapore, Second Edition.

2. Balanis, C. A. (2016). "Antenna Theory: Analysis and Design." John Wiley & Sons, Fourth Edition.

3. Stutzman, W. L., & Thiele, G. A. (2012). "Antenna Theory and Design." John Wiley & Sons, Third Edition.

4. Kraus, J. D., & Marhefka, R. J. (2002). "Antennas: For All Applications." McGraw-Hill Education, Third Edition.

5. International Telecommunication Union (2021). "Recommendation ITU-R S.465-6: Reference Radiation Pattern for Earth Station Antennas in the Fixed-Satellite Service for Use in Coordination and Interference Assessment." ITU Publications.