Top OEM Waveguide Flange Gasket Suppliers for Quick Delivery

When your critical radar system experiences signal degradation due to improper sealing, every minute of downtime translates into compromised operations and escalating costs. Finding reliable Waveguide Flange Gasket suppliers who deliver precision components rapidly becomes mission-critical for aerospace contractors, telecommunications operators, and defense system integrators. This comprehensive guide explores how specialized OEM manufacturers address urgent delivery requirements while maintaining the exacting quality standards essential for microwave applications operating across frequencies from 0.5 to 110 GHz.

Understanding Waveguide Flange Gasket Requirements for Modern Applications

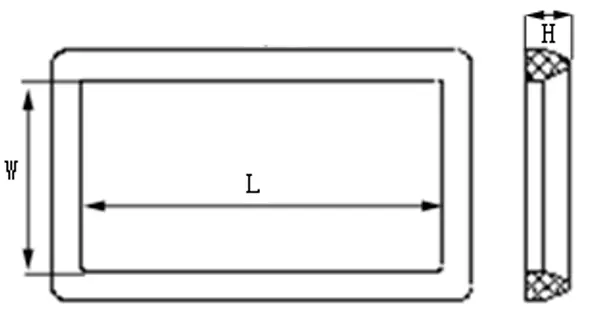

Waveguide flange gaskets serve as the fundamental sealing interface in high-frequency microwave systems, where even microscopic gaps can compromise signal integrity and system performance. These specialized components create secure connections between waveguide flanges while maintaining electromagnetic continuity and environmental protection across demanding operational environments. In satellite communication ground stations processing HD video streams, weather monitoring radars tracking severe storm systems, and shipboard navigation equipment operating in harsh maritime conditions, the gasket's ability to prevent RF leakage while withstanding temperature extremes from negative fifty-five degrees Celsius to one hundred twenty-five degrees Celsius determines overall system reliability. The material composition of waveguide flange gaskets directly impacts their electromagnetic and mechanical performance characteristics. High-grade conductive elastomers incorporating specialized metallic fillers provide the electrical conductivity necessary for maintaining signal integrity while offering the flexibility required to compensate for minor flange misalignments during installation. Advanced Microwave Technologies Co., Ltd manufactures waveguide flange sealing rings specifically engineered for various standard waveguide sealing flanges, primarily divided into D-type and O-type configurations to accommodate different flange geometries and sealing requirements across the frequency spectrum.

Critical Performance Factors in Waveguide Flange Gasket Selection

Selecting appropriate Waveguide Flange Gasket solutions requires careful evaluation of multiple technical parameters that influence long-term system performance. Signal integrity preservation stands paramount, as the gasket must minimize RF leakage across the entire operational frequency range while maintaining consistent impedance matching at the flange interface. The conductive elastomer formulation must exhibit stable electrical properties across temperature variations, ensuring that signal transmission remains unaffected whether the system operates in arctic conditions or desert heat. Environmental protection capabilities distinguish superior gasket designs from basic sealing solutions. Aerospace applications subject equipment to rapid pressure changes, extreme temperature cycling, and exposure to aviation fuels and hydraulic fluids. Defense radar systems deployed in coastal environments face continuous salt spray exposure and high humidity levels. The Waveguide Flange Gasket must maintain its sealing effectiveness and electrical conductivity despite these challenging environmental factors, protecting sensitive internal components from moisture ingress, dust contamination, and corrosive atmospheric elements that could degrade system performance over extended operational periods. Mechanical durability ensures reliable performance throughout the equipment lifecycle, particularly in applications experiencing vibration, thermal expansion cycles, and repeated connection operations during maintenance procedures. ISO:9001:2008 certified manufacturing processes guarantee consistent material properties and dimensional accuracy, while RoHS compliance ensures environmental safety throughout the product lifecycle. Advanced manufacturing techniques employing precision molding and cutting processes create gaskets with exact specifications for perfect fit with standard and custom waveguide flanges, eliminating installation difficulties and ensuring optimal sealing performance from initial deployment.

OEM Customization Capabilities for Specialized Waveguide Applications

Original Equipment Manufacturer services transform standard Waveguide Flange Gasket products into precisely tailored solutions addressing unique system requirements that generic components cannot satisfy. Custom designs accommodate non-standard waveguide dimensions required in specialized research applications, proprietary antenna systems, and legacy equipment requiring exact replacement components no longer available through standard distribution channels. Material selection flexibility allows engineers to specify elastomer formulations optimized for specific operational environments, whether prioritizing chemical resistance for industrial applications, radiation hardness for space systems, or enhanced thermal stability for high-power transmission equipment. Advanced Microwave Technologies Co., Ltd operates sophisticated laboratories equipped with measurement equipment spanning frequencies up to 110 GHz, enabling comprehensive characterization of custom gasket designs under actual operational conditions before full-scale production. The company's 24-meter microwave darkroom provides unrivaled capabilities for validating gasket performance in complete antenna assemblies, allowing engineers to observe far-field radiation patterns and verify that gasket installations maintain optimal signal transmission characteristics. This state-of-the-art testing facility features an Antenna Plane Near and Far Field Measuring Recombination Chamber that extracts granular details about radiation patterns, gain characteristics, and impedance matching across the entire frequency range, ensuring custom Waveguide Flange Gasket solutions perform flawlessly in their intended applications.

Technical Support Throughout the Development Cycle

Comprehensive technical assistance differentiates exceptional OEM suppliers from basic component vendors, particularly when integrating Waveguide Flange Gasket solutions into complex microwave systems. Expert engineering teams provide detailed consultation during the design phase, analyzing system requirements, environmental conditions, and performance objectives to recommend optimal gasket configurations and materials. Installation guidance addresses proper torque specifications, surface preparation requirements, and alignment procedures that ensure reliable sealing and electrical contact, preventing common installation errors that compromise system performance. Troubleshooting support proves invaluable when addressing unexpected performance issues in deployed systems. Experienced engineers leverage deep technical knowledge to diagnose problems related to RF leakage, impedance mismatches, or environmental sealing failures, recommending corrective actions that restore optimal operation. Prototyping services enable rapid iteration during development programs, delivering evaluation samples with quick turnaround times that keep projects on schedule. This comprehensive support approach ensures that customers achieve successful implementation of Waveguide Flange Gasket solutions regardless of application complexity or technical challenges encountered during integration.

Quality Assurance and International Standards Compliance

International standards compliance forms the foundation of reliable Waveguide Flange Gasket manufacturing, ensuring consistent quality across production batches and long-term performance reliability in critical applications. ISO 9001:2015 certification demonstrates systematic implementation of quality management processes covering every aspect from raw material inspection through final product testing and delivery. Advanced Microwave Technologies Co., Ltd maintains comprehensive quality control procedures that verify dimensional accuracy, material properties, and electrical characteristics for each production lot, with documented traceability enabling rapid investigation of any performance concerns. Environmental management according to ISO 14001:2015 standards reflects responsible manufacturing practices that minimize ecological impact throughout the production process. Careful waste management, energy conservation initiatives, and emissions reduction programs ensure that Waveguide Flange Gasket manufacturing aligns with corporate sustainability objectives while maintaining the highest technical performance standards. RoHS compliance guarantees freedom from hazardous substances, allowing deployment in environmentally sensitive applications and facilitating international trade across regions with strict environmental regulations. Occupational health and safety standards certified under ISO 45001:2018 protect the skilled technicians and engineers who manufacture these precision components, creating workplace environments that prioritize employee well-being through proper training, protective equipment, and safety protocols. This comprehensive standards approach encompasses environmental stewardship, quality excellence, and workforce protection, reflecting organizational values that extend beyond mere regulatory compliance to embrace genuine commitment toward sustainable, responsible business practices that benefit customers, employees, and society.

Fast Delivery Solutions for Time-Critical Projects

Rapid delivery capabilities separate leading suppliers from conventional distributors when project schedules demand immediate component availability. Efficient manufacturing processes incorporating streamlined production planning, optimized inventory management, and responsive logistics networks enable delivery timelines that exceed customer expectations. Advanced Microwave Technologies Co., Ltd demonstrates strong ability to deliver products on time or even ahead of schedule in every cooperation, significantly improving project efficiency and reducing various costs associated with extended equipment downtime or delayed system deployments. Quick turnaround on prototype production proves essential during development programs where iterative testing drives design refinement. Accelerated manufacturing schedules for evaluation samples allow engineering teams to conduct performance validation, environmental testing, and system integration verification without disrupting overall project timelines. For urgent replacement requirements in operational systems experiencing component failures, expedited processing ensures minimal service interruption, maintaining critical communication links, radar coverage, or navigation capabilities that cannot tolerate extended outages. Strategic inventory positioning for commonly specified Waveguide Flange Gasket configurations enables same-day shipping for standard products, while flexible manufacturing capacity accommodates surge demands for custom designs without compromising delivery commitments on concurrent projects. This operational agility, supported by robust supply chain systems and experienced production teams, delivers the responsive service that demanding applications require while maintaining the uncompromising quality standards essential for reliable long-term performance.

Conclusion

Selecting the right OEM Waveguide Flange Gasket supplier requires evaluating technical capabilities, quality standards, customization flexibility, and delivery performance. Advanced manufacturing facilities, comprehensive testing capabilities, and responsive customer support distinguish exceptional suppliers in this specialized field.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a China Waveguide Flange Gasket manufacturer with over twenty years of expertise, Advanced Microwave Technologies Co., Ltd combines cutting-edge production capabilities with rapid delivery timelines. Our China Waveguide Flange Gasket factory operates under strict ISO certifications, producing High Quality Waveguide Flange Gasket solutions at competitive Waveguide Flange Gasket prices. Whether you need China Waveguide Flange Gasket wholesale quantities or custom OEM designs, our China Waveguide Flange Gasket supplier capabilities deliver Waveguide Flange Gasket for sale that meets your exact specifications. Contact craig@admicrowave.com today to discuss your requirements and experience our perfect supply chain system, professional technical R&D team, and strong after-sales support that global customers trust for satellite communications, defense, aerospace, and navigation applications.

References

1. "Microwave Component Design and Testing Standards," International Electrotechnical Commission Technical Committee, IEC Standards Publication Series

2. "Waveguide Systems Engineering: Materials and Performance Optimization," Johnson, R.K. and Patterson, M.E., Institute of Electrical and Electronics Engineers Press

3. "Quality Management Systems for Microwave Manufacturing," Chen, L. and Williams, D.R., American Society for Quality Technical Publications

4. "Environmental Sealing in High-Frequency Applications," Martinez, S.J., Society of Automotive Engineers International Standards

5. "Electromagnetic Compatibility and Shielding Effectiveness in Waveguide Assemblies," Thompson, A.B. and Zhang, H., Electromagnetic Compatibility Society Technical Digest

YOU MAY LIKE

VIEW MOREDouble Ridge Waveguide Bend

VIEW MOREDouble Ridge Waveguide Bend VIEW MOREDouble Ridge Twist Waveguide

VIEW MOREDouble Ridge Twist Waveguide VIEW MOREDouble Ridged WG To Coaxial Adapter

VIEW MOREDouble Ridged WG To Coaxial Adapter VIEW MOREDouble-Ridged Waveguide Magic Tee

VIEW MOREDouble-Ridged Waveguide Magic Tee VIEW MOREDouble Ridge Waveguide Rotary Joint

VIEW MOREDouble Ridge Waveguide Rotary Joint VIEW MOREDouble-Ridged Waveguide Loop Coupler

VIEW MOREDouble-Ridged Waveguide Loop Coupler VIEW MOREDouble Ridge Waveguide Tube

VIEW MOREDouble Ridge Waveguide Tube VIEW MOREPlastic Flange Caps

VIEW MOREPlastic Flange Caps