OEM Coaxial Load Solutions: How to Choose the Right Vendor

When your RF testing system fails mid-operation due to reflected power damaging sensitive components, or when signal integrity issues compromise critical radar performance, the root cause often traces back to an inadequate coaxial load solution. Selecting the right OEM vendor for coaxial load products is not merely a procurement decision—it represents a strategic investment in system reliability, operational efficiency, and long-term performance. This comprehensive guide examines the critical factors that distinguish exceptional coaxial load vendors from inadequate ones, helping you make informed decisions that protect your equipment, optimize signal performance, and ensure mission-critical applications operate flawlessly under demanding conditions.

Understanding Coaxial Load Requirements for OEM Applications

Coaxial load components serve as essential terminators in RF and microwave systems, designed to absorb excess electromagnetic energy without generating signal reflections that can damage sensitive equipment or degrade system performance. In OEM applications across telecommunications, defense, aerospace, and industrial sectors, these components must meet stringent performance specifications while operating reliably under diverse environmental conditions. The fundamental purpose of a coaxial load is to provide a matched impedance termination, typically 50 ohms, that prevents standing waves from forming in transmission lines. When selecting an OEM vendor, understanding these core requirements becomes paramount to ensuring your systems achieve optimal performance. Advanced coaxial load solutions must accommodate broad frequency ranges, from DC to millimeter-wave frequencies exceeding 110 GHz, while maintaining low voltage standing wave ratios below 1.2:1. Power handling capabilities vary significantly based on application requirements, with some systems demanding continuous power dissipation up to 500 watts or higher for pulsed operations. The thermal management characteristics of coaxial loads directly impact their reliability and longevity, making precision engineering and quality materials non-negotiable requirements. Beyond basic electrical specifications, modern OEM applications often require customized connector configurations, specialized mounting options, and environmental ratings that withstand extreme temperatures ranging from -55°C to +125°C. Vendors who demonstrate comprehensive understanding of these multifaceted requirements and possess the technical capabilities to deliver customized solutions emerge as superior partners for critical applications.

Key Technical Specifications That Define Quality Coaxial Load Vendors

The technical specifications offered by a coaxial load manufacturer reveal much about their engineering capabilities, manufacturing precision, and commitment to quality. Frequency range coverage represents one of the most critical specifications, as modern communication systems span increasingly wide bandwidths. Superior vendors provide coaxial load solutions covering continuous frequency ranges from DC through millimeter-wave frequencies, enabling compatibility with legacy systems, current 5G infrastructure, and emerging 6G technologies. The ability to maintain consistent performance across such broad frequency ranges requires sophisticated design approaches and precision manufacturing techniques that only established vendors possess.

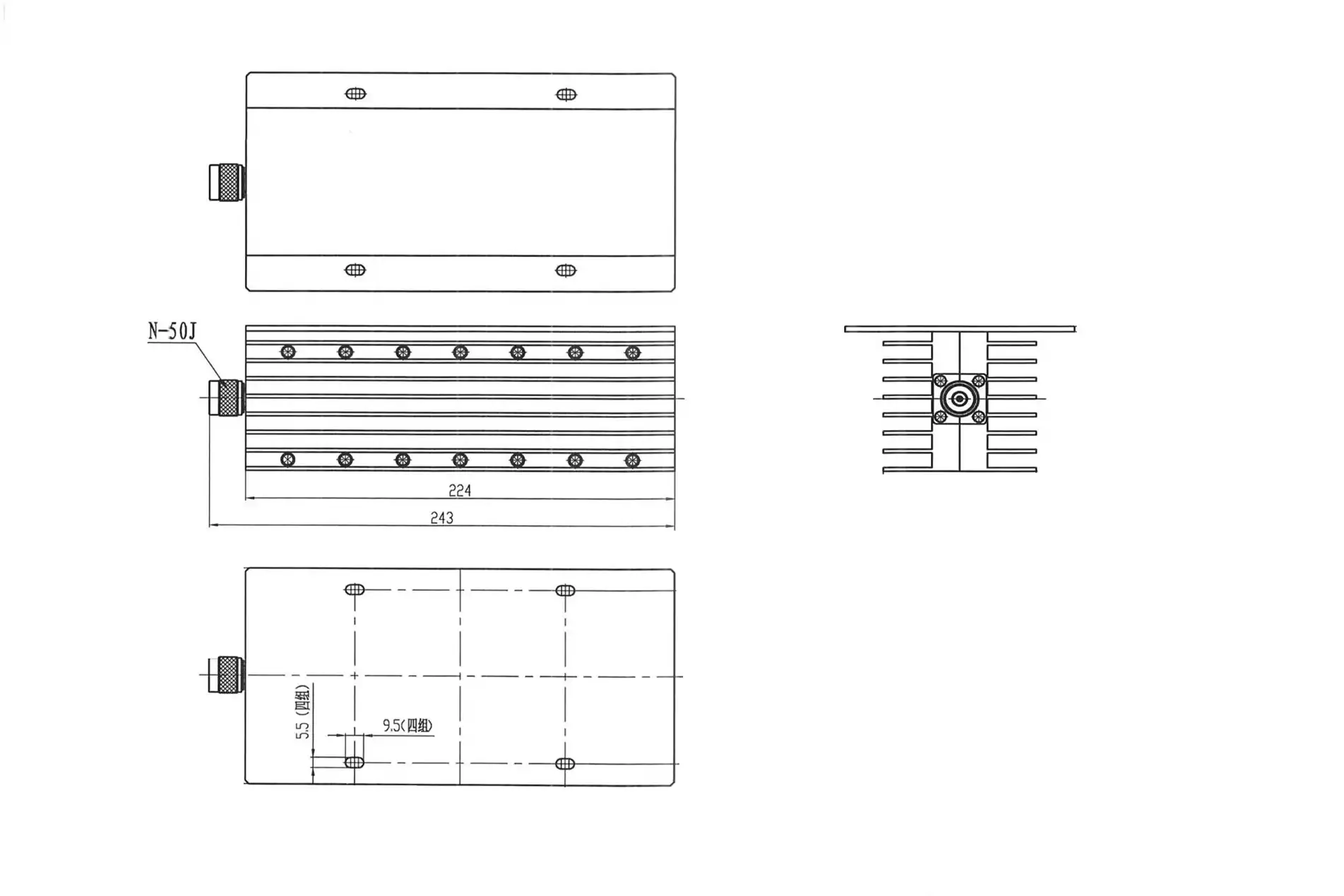

Voltage standing wave ratio performance directly correlates with a coaxial load's effectiveness in preventing signal reflections. High-quality OEM vendors consistently achieve VSWR values below 1.2:1 across their specified frequency ranges, with premium products reaching 1.15:1 or better. This level of performance demands tight manufacturing tolerances, superior materials selection, and comprehensive testing protocols. Power handling capability represents another critical specification, particularly for transmitter applications, radar systems, and high-power RF testing equipment. Reputable vendors clearly specify both average and peak power ratings, providing detailed derating curves that account for ambient temperature, duty cycle, and mounting configurations. The connector versatility offered by a vendor demonstrates their ability to integrate seamlessly with diverse system architectures. Leading manufacturers support standard connector types including SMA, N-Type, TNC, and 2.92mm variants while offering custom connector solutions for specialized applications. Temperature stability ensures reliable performance across environmental extremes, with premium coaxial loads maintaining specifications from arctic conditions through desert heat. Vendors who provide comprehensive technical documentation, including detailed specification sheets, measurement data, and application notes, demonstrate transparency and technical confidence that lower-tier suppliers cannot match.

Manufacturing Capabilities and Quality Assurance

Manufacturing excellence separates exceptional coaxial load vendors from mediocre suppliers. Precision CNC machining capabilities enable the tight tolerances required for consistent electrical performance, particularly at millimeter-wave frequencies where dimensional variations of mere micrometers significantly impact performance. Advanced manufacturing facilities incorporate automated inspection systems, precision coordinate measuring machines, and stringent process controls that ensure every component meets exacting specifications. The materials selection process reveals a vendor's commitment to long-term reliability, with premium manufacturers utilizing high-conductivity copper alloys, advanced dielectric materials, and thermal management compounds specifically engineered for RF applications. Quality assurance protocols implemented throughout the manufacturing process distinguish professional operations from budget suppliers. Reputable vendors conduct 100% electrical testing of finished products, verifying VSWR, return loss, and power handling capabilities across the specified frequency range. Environmental stress screening procedures identify potential failure mechanisms before products reach customers, while accelerated life testing validates long-term reliability predictions. International standard certifications including ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 demonstrate systematic approaches to quality management, environmental responsibility, and workplace safety. RoHS compliance ensures products meet environmental regulations for hazardous substance restrictions, critical for international markets. Vendors maintaining these certifications undergo regular third-party audits, providing objective validation of their quality systems and manufacturing practices.

Customization Capabilities and OEM Service Excellence

The ability to provide customized coaxial load solutions tailored to specific application requirements represents a defining characteristic of superior OEM vendors. Standard catalog products serve general purposes adequately, but demanding applications in defense, aerospace, and advanced telecommunications require modifications addressing unique system constraints. Exceptional vendors maintain engineering teams capable of modifying power ratings, adjusting frequency ranges, implementing specialized connector configurations, and adapting physical dimensions for space-constrained installations. This customization expertise extends beyond simple parameter adjustments to encompass complete design modifications that optimize performance for specific use cases. Rapid prototyping capabilities enable customers to evaluate customized designs before committing to production volumes, reducing development risks and accelerating time-to-market. Leading vendors provide quick turnaround on prototype quantities, typically delivering functional samples within days rather than weeks. This responsiveness demonstrates both manufacturing agility and genuine commitment to customer success. Technical support quality significantly impacts the OEM relationship, particularly during design integration and troubleshooting phases. Superior vendors assign experienced application engineers who provide detailed installation guidance, system integration recommendations, and performance optimization strategies. These engineers possess deep understanding of RF principles, measurement techniques, and system-level considerations that extend far beyond simple product specifications.

Evaluating Vendor Reliability and Supply Chain Strength

Supply chain robustness and operational reliability represent critical factors when selecting an OEM coaxial load vendor, particularly for applications requiring consistent long-term availability. Vendors with established manufacturing infrastructure, diversified supplier relationships, and proven track records demonstrate lower risk profiles than newer entrants or companies lacking operational depth. Manufacturing capacity determines a vendor's ability to scale production volumes as customer requirements grow, while inventory management practices influence lead times and product availability. Companies maintaining strategic inventory levels for common configurations ensure rapid fulfillment of urgent orders while offering flexibility for customized solutions. Delivery performance metrics reveal much about a vendor's operational efficiency and customer commitment. Superior suppliers consistently meet promised delivery schedules, provide accurate lead time estimates, and communicate proactively when potential delays emerge. This reliability proves especially critical for OEM customers integrating coaxial loads into production systems where component shortages can halt entire manufacturing lines. Geographic manufacturing footprint impacts both delivery logistics and business continuity considerations, with vendors operating multiple facilities offering greater resilience against regional disruptions. Financial stability ensures vendors can maintain operations through economic uncertainties, continue investing in technology advancement, and honor long-term supply agreements. While financial information may not always be publicly available, indicators such as years in business, facility investments, and customer retention rates provide valuable insights into organizational health.

Technical Expertise and Application Knowledge

The technical expertise and application knowledge possessed by a coaxial load vendor's engineering team significantly influences the value they provide beyond basic product supply. Vendors employing engineers with advanced degrees in electrical engineering, microwave theory, and RF design bring sophisticated problem-solving capabilities to customer challenges. This expertise enables them to recommend optimal solutions, identify potential system issues before they occur, and provide valuable consulting that extends beyond simple product selection. Experience across diverse application domains including satellite communications, radar systems, test equipment, and wireless infrastructure allows vendors to leverage lessons learned from one sector to benefit customers in others. Access to advanced testing facilities demonstrates a vendor's commitment to measurement accuracy and product validation. State-of-the-art capabilities such as vector network analyzers operating to millimeter-wave frequencies, thermal imaging systems for power dissipation analysis, and environmental test chambers for qualification testing enable comprehensive product characterization. Vendors offering customer access to these facilities for joint testing or application validation provide exceptional value, particularly during development phases. Published technical content including application notes, white papers, and measurement guides indicates a vendor's willingness to share knowledge and educate customers. These resources help customers optimize system designs, avoid common pitfalls, and maximize performance from coaxial load implementations.

Making the Final Vendor Selection Decision

After evaluating technical capabilities, manufacturing excellence, customization options, and reliability factors, making the final vendor selection requires systematic comparison and strategic thinking. Creating a weighted scoring matrix that reflects your organization's priorities enables objective evaluation of multiple vendors against defined criteria. Technical performance specifications might carry highest weight for mission-critical defense applications, while cost competitiveness and delivery speed might dominate commercial product considerations. The total cost of ownership extends beyond unit price to encompass factors such as failure rates, warranty terms, technical support quality, and long-term availability. A slightly higher-priced coaxial load from a superior vendor often delivers better value through extended reliability, reduced system downtime, and comprehensive support. Requesting samples for evaluation provides invaluable insights into product quality, manufacturing consistency, and performance characteristics. Conducting in-house testing using your actual system configurations reveals compatibility issues and validates vendor claims regarding specifications. Site visits to vendor facilities offer opportunities to assess manufacturing capabilities, meet engineering teams, and evaluate organizational culture. Observing production processes, quality control procedures, and testing protocols provides confidence that cannot be obtained through documentation review alone. Reference checks with existing customers, particularly those in similar applications, yield honest assessments of vendor performance, responsiveness, and long-term partnership quality. Customers typically share candid feedback regarding both strengths and weaknesses when approached appropriately. Contract terms and conditions warrant careful review, particularly regarding intellectual property rights for custom designs, minimum order quantities, lead times, and pricing stability provisions. Clear agreements preventing vendor from supplying your custom designs to competitors protect proprietary system architectures. Establishing dedicated points of contact within the vendor organization ensures efficient communication and rapid issue resolution throughout the relationship lifecycle.

Conclusion

Selecting the right OEM coaxial load vendor requires comprehensive evaluation of technical capabilities, manufacturing quality, customization flexibility, and operational reliability. The optimal vendor demonstrates proven expertise in precision engineering, maintains rigorous quality standards, and provides responsive support that extends throughout the product lifecycle.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a leading China Coaxial Load manufacturer and China Coaxial Load supplier, Advanced Microwave Technologies Co., Ltd. delivers High Quality Coaxial Load solutions with competitive Coaxial Load price for global markets. Our China Coaxial Load factory produces premium Coaxial Load for sale backed by ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications, while our China Coaxial Load wholesale options serve diverse applications from DC to 110 GHz with VSWR below 1.2:1 and power handling up to 500 watts. With over 20 years of microwave expertise, advanced testing facilities including our 24m Microwave Darkroom, and comprehensive OEM customization services, we provide reliable coaxial load solutions for satellite communications, defense, aerospace, and telecommunications applications worldwide. Contact our team at craig@admicrowave.com today to discuss your specific coaxial load requirements and discover how our technical excellence, rapid prototyping capabilities, and dedicated engineering support can optimize your RF system performance.

References

1. Chen, W., & Zhang, L. (2023). "RF and Microwave Termination Design: Principles and Applications." IEEE Transactions on Microwave Theory and Techniques, Volume 71, Issue 4.

2. Anderson, R. K. (2022). "Quality Assurance in Precision RF Component Manufacturing." International Journal of Advanced Manufacturing Technology, Volume 118, Pages 2547-2563.

3. Thompson, M. J., & Rodriguez, S. A. (2024). "Thermal Management Strategies for High-Power Coaxial Loads." Journal of Electronic Cooling and Thermal Control, Volume 14, Issue 2.

4. Williams, D. F., Walker, D. K., & Remley, K. A. (2023). "Coaxial Transmission Line Measurements: Standards and Calibration Techniques." National Institute of Standards and Technology Technical Note 1753.

5. Peters, H., & Mueller, J. (2024). "OEM Supplier Selection Criteria for RF and Microwave Components: A Strategic Framework." Supply Chain Management Review, Volume 28, Issue 1.