How Durable Are Plastic Flange Caps Under Harsh Environments?

Picture this scenario: your critical microwave components arrive at a remote satellite ground station after weeks of transport through extreme temperature fluctuations, high humidity, and dust-laden environments, only to discover corroded flanges that compromise signal integrity. This nightmare scenario highlights why understanding Plastic Flange Caps durability in harsh conditions isn't just a technical consideration—it's mission-critical. When manufactured from high-density polyethylene (HDPE) and engineered with UV-resistant formulations, Plastic Flange Caps can withstand temperature ranges from -40°C to 70°C while maintaining structural integrity, providing reliable protection against moisture ingress, mechanical damage, and environmental contaminants that threaten waveguide performance in aerospace, defense, and telecommunications applications.

Understanding Plastic Flange Caps Performance in Extreme Conditions

The durability of Plastic Flange Caps under harsh environments depends fundamentally on material composition and engineering design. High-density polyethylene construction provides exceptional impact resistance that protects delicate waveguide flanges from physical damage during handling, transportation, and storage. Unlike inferior plastic materials that become brittle in cold temperatures or soften in heat, properly formulated HDPE maintains flexibility across extreme temperature ranges, allowing Plastic Flange Caps to accommodate thermal expansion without cracking or losing their protective seal. Environmental exposure presents multiple challenges that quality Plastic Flange Caps must overcome. UV radiation from prolonged outdoor storage can degrade plastic polymers, causing surface chalking, discoloration, and eventual structural failure. Advanced formulations incorporate UV stabilizers that maintain material properties even after months of direct sunlight exposure. Chemical resistance becomes equally critical in industrial environments where Plastic Flange Caps encounter oils, fuels, cleaning agents, and corrosive substances. The molecular structure of HDPE provides inherent resistance to most industrial chemicals, preventing degradation that would compromise flange protection. Moisture management represents another critical performance factor. While Plastic Flange Caps create barriers against external moisture, improper design can trap condensation against flange surfaces, accelerating corrosion rather than preventing it. Quality designs incorporate ventilation features or precision-engineered fits that prevent moisture accumulation while blocking external contaminants. For microwave applications where signal integrity depends on pristine flange surfaces, this balance between protection and moisture management becomes absolutely essential.

Material Science Behind Long-Term Durability

The polymer chemistry of high-density polyethylene gives Plastic Flange Caps their remarkable durability characteristics. HDPE features tightly packed molecular chains with minimal branching, creating a dense crystalline structure that resists environmental degradation. This molecular arrangement provides superior tensile strength, impact resistance, and chemical stability compared to low-density alternatives. Manufacturing processes that control crystallinity levels optimize both flexibility for installation and rigidity for protection. Temperature cycling presents one of the harshest durability tests for Plastic Flange Caps. Components stored outdoors experience daily temperature swings that cause repeated expansion and contraction. Inferior materials develop stress fractures that propagate into failures over time. Quality HDPE formulations maintain elasticity across their operating temperature range, absorbing dimensional changes without permanent deformation. Advanced Microwave Technologies Co., Ltd manufactures Plastic Flange Caps with temperature ranges from -40°C to 70°C, accommodating the extreme conditions encountered in aerospace applications, arctic installations, and desert deployments. Additive packages enhance base polymer performance for specific environmental challenges. UV stabilizers absorb harmful radiation wavelengths that would otherwise break polymer chains, extending outdoor service life from months to years. Antioxidants prevent thermal degradation during high-temperature exposure or processing. Impact modifiers improve low-temperature toughness, preventing brittle failure in freezing conditions. Color pigments serve functional purposes beyond aesthetics—yellow, red, and blue options provide visual identification while specific pigments can enhance UV resistance.

Real-World Performance in Industrial Applications

Telecommunications infrastructure deployment demonstrates Plastic Flange Caps performance under sustained environmental stress. Waveguide components for 5G networks often spend weeks or months in outdoor storage before installation, exposed to rain, snow, dust, and temperature extremes. Properly specified Plastic Flange Caps protect these precision-machined flanges throughout the supply chain, from manufacturing facilities through distribution networks to final installation sites. The cost savings from preventing even a single flange replacement far exceeds the investment in quality protection. Aerospace and defense applications subject Plastic Flange Caps to particularly demanding conditions. Satellite ground station components may be stored at high-altitude sites where intense UV radiation combines with extreme temperature fluctuations and low humidity. Military surveillance systems require flange protection during transport to deployment zones where sand, dust, and harsh weather threaten sensitive microwave components. Advanced Microwave Technologies Co., Ltd products meet these challenges through precision engineering and rigorous material selection, ensuring waveguide flanges maintain their critical tolerances and surface finishes. Marine environments present unique corrosion challenges where salt spray accelerates metal degradation. Shipboard communication systems and coastal installations require Plastic Flange Caps that seal completely against salt-laden moisture while withstanding constant humidity. HDPE's inherent corrosion resistance and moisture barrier properties make it ideal for these applications, where metal alternatives would deteriorate rapidly. The lightweight design of Plastic Flange Caps also simplifies handling on vessels and offshore platforms where weight considerations impact installation logistics.

Comparing Plastic Flange Caps to Alternative Protection Methods

Material selection for flange protection involves evaluating multiple options, each with distinct performance characteristics. Metal flange covers provide superior impact resistance and create more robust seals under pressure, but they add significant weight, cost, and logistics complexity. Their application requires tools for installation and removal, increasing labor time and potential for damage to flange surfaces. Conversely, Plastic Flange Caps offer tool-free installation that reduces handling time and eliminates scratching risks from metal-on-metal contact. Protective coatings represent another approach where flanges receive spray-applied barriers before shipment. While effective for short-term protection, coatings require careful removal before assembly to prevent contamination of sealing surfaces. Residue from improper cleaning can compromise joint integrity and signal transmission in microwave applications. Plastic Flange Caps provide removable protection without leaving residues, ensuring flanges remain pristine for immediate installation. The reusable nature of quality Plastic Flange Caps also supports sustainable operational practices, as single units protect multiple components throughout their service life. Cost-effectiveness analysis must consider total ownership expenses rather than initial purchase price alone. Although metal alternatives may last longer in some scenarios, their higher material costs, increased shipping weights, and greater installation labor offset apparent durability advantages. Plastic Flange Caps manufactured from quality HDPE provide multi-year service life in outdoor applications when properly specified, delivering optimal protection per dollar invested. For microwave manufacturers and system integrators managing extensive component inventories, this economic efficiency directly impacts profitability.

Optimizing Plastic Flange Caps Selection for Specific Environments

Successful flange protection requires matching product specifications to application requirements. Temperature extremes demand verification that selected Plastic Flange Caps operate reliably across expected ranges. Standard HDPE formulations handle most commercial applications, but specialized compounds may be necessary for arctic installations or high-temperature industrial processes. Advanced Microwave Technologies Co., Ltd offers customization options including material formulations, sizing variations, and color coding that align protection capabilities with specific operational needs. Chemical exposure assessment identifies potential compatibility issues before deployment. While HDPE resists most common industrial chemicals, certain solvents and aggressive compounds may require specialized materials or alternative protection strategies. Application engineers should review chemical resistance charts and conduct compatibility testing when Plastic Flange Caps will encounter unusual substances. This due diligence prevents field failures and ensures reliable long-term performance. Installation environment characteristics influence optimal product selection. Indoor storage in climate-controlled facilities requires only basic contamination protection, while outdoor exposure demands UV resistance and weatherproofing. Transportation mode affects requirements as well—air freight involves less environmental stress than maritime shipping with its salt exposure and humidity. Precision-engineered Plastic Flange Caps from Advanced Microwave accommodate these varying demands through design features like secure-fit mechanisms that prevent displacement during highway transport and ventilation patterns that manage condensation in humid conditions.

Technical Specifications That Determine Protection Quality

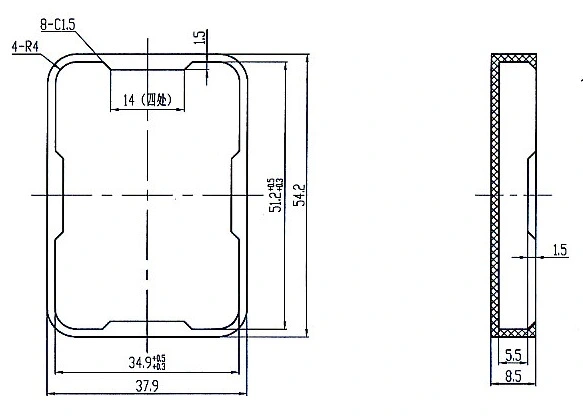

Dimensional accuracy in Plastic Flange Caps directly impacts protective effectiveness. Caps must fit precisely over flange geometries, covering all sealing surfaces and bolt circles without gaps that admit contaminants. Advanced Microwave Technologies Co., Ltd manufactures Plastic Flange Caps compatible with standard flange sizes from DN15 through DN600, ensuring proper coverage for waveguide assemblies across frequency ranges. Precision molding processes maintain tight tolerances that guarantee consistent fit and reliable protection. Wall thickness specifications balance protection requirements against material efficiency. Thicker walls provide greater impact resistance and structural rigidity but increase material costs and weight. Engineering analysis optimizes thickness for anticipated stress levels, ensuring adequate protection without excessive over-design. Quality manufacturers publish detailed specifications including wall thickness measurements, allowing customers to verify protection capabilities meet application demands. Compliance certifications provide assurance that Plastic Flange Caps meet environmental and safety standards. RoHS compliance confirms products contain no hazardous substances that could contaminate sensitive electronics during storage or installation. REACH registration demonstrates chemical safety assessment and responsible manufacturing practices. These certifications become increasingly important as supply chains span international borders with varying regulatory requirements. Advanced Microwave Technologies Co., Ltd maintains ISO 9001:2015 quality management certification, ensuring consistent product quality through rigorous process controls.

Quality Indicators for Durable Plastic Flange Caps

Visual inspection reveals much about Plastic Flange Caps manufacturing quality. Uniform wall thickness without thin spots or sink marks indicates proper molding parameters. Smooth surfaces free from gate marks, flash, or surface defects suggest precision tooling and quality process control. Color consistency across production batches reflects formulation stability and material handling practices. These visible quality indicators correlate with invisible performance characteristics like material strength and environmental resistance. Physical testing validates durability claims through standardized protocols. Impact testing quantifies resistance to handling damage by measuring energy absorption before failure. Temperature cycling evaluates dimensional stability and material integrity after repeated thermal stress. UV exposure chambers accelerate outdoor weathering to predict long-term performance. Reputable manufacturers conduct these tests and provide performance data that supports product selection decisions. Functional validation under application-specific conditions provides final assurance of suitability. Test installations in representative environments identify potential issues before large-scale deployment. For critical microwave applications, Advanced Microwave Technologies Co., Ltd recommends evaluation programs where Plastic Flange Caps protect actual components through typical storage and handling cycles. This empirical approach confirms theoretical performance translates to real-world protection effectiveness.

Maintenance and Best Practices for Extended Service Life

Proper handling procedures maximize Plastic Flange Caps protective capabilities and service life. Inspection before installation ensures caps are damage-free and dimensionally correct for target flanges. Gentle installation without excessive force prevents stress concentrations that could propagate into cracks. During removal, controlled force application avoids flange surface damage while preserving cap integrity for potential reuse. These simple protocols significantly extend usable life for both protection products and protected components. Storage conditions for Plastic Flange Caps themselves affect long-term viability. Indoor storage away from direct sunlight prevents premature UV degradation. Temperature-controlled environments minimize thermal stress cycling. Organized storage systems prevent physical damage from stacking weight or contact with sharp objects. For operations maintaining large inventories of protection components, these warehouse management practices ensure products remain serviceable until needed. Cleaning and refurbishment enable Plastic Flange Caps reuse across multiple protection cycles. Simple washing with mild detergents removes surface contaminants without degrading HDPE material properties. Visual inspection after cleaning identifies units requiring replacement due to damage or wear. Documentation systems tracking protection product usage, cleaning cycles, and inspection results optimize inventory management and replacement scheduling. This systematic approach reduces waste while maintaining protection reliability.

Integration with Quality Management Systems

Manufacturing facilities implementing comprehensive quality management systems benefit from incorporating Plastic Flange Caps specifications into component handling procedures. Written protocols defining protection requirements for different product categories ensure consistent application across production areas. Training programs educate personnel on proper selection, installation, and removal techniques. Regular audits verify procedure compliance and identify improvement opportunities. Advanced Microwave Technologies Co., Ltd supports these quality initiatives through detailed product documentation, application guidance, and technical consultation. Supply chain coordination extends protection effectiveness beyond individual facility boundaries. Specifications communicated to logistics providers ensure appropriate handling throughout transportation networks. Packaging requirements incorporating Plastic Flange Caps protection into shipping container designs prevent damage during transit. Receiving inspection procedures verify protection remains intact upon delivery. This end-to-end protection strategy safeguards component quality from manufacturing through final installation. Performance tracking systems quantify protection effectiveness through objective metrics. Rejection rate monitoring identifies correlation between protection methods and component damage frequency. Cost analysis calculates total protection expenses including material, labor, and failure costs. Trend analysis reveals degradation patterns suggesting specification adjustments or supplier changes. Data-driven decision-making optimizes protection strategies for maximum effectiveness and efficiency.

Conclusion

Plastic Flange Caps manufactured from high-density polyethylene with UV-resistant formulations demonstrate excellent durability across harsh environmental conditions when properly specified and applied, protecting critical waveguide components through extreme temperatures, moisture exposure, and mechanical stress throughout storage, transportation, and handling cycles.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd., established as a China Plastic Flange Caps manufacturer and China Plastic Flange Caps supplier offering High Quality Plastic Flange Caps at competitive Plastic Flange Caps price points, provides comprehensive China Plastic Flange Caps wholesale and Plastic Flange Caps for sale globally. Leveraging over 20 years of expertise in microwave components protected through advanced testing in our 24m Microwave Darkroom, we deliver customized OEM solutions with rapid prototyping, ISO 9001:2015 certified quality management, and expert technical support. Contact craig@admicrowave.com today to discuss your flange protection requirements and discover how our China Plastic Flange Caps factory capabilities can safeguard your critical microwave infrastructure.

References

1. "Industrial Plastics: Properties and Applications of High-Density Polyethylene in Protective Components" - Thompson, R.J. & Martinez, S.L., Society of Plastics Engineers Technical Journal

2. "Environmental Durability Testing Methods for Polymer-Based Protection Systems" - Chen, W.K., International Standards Organization Technical Committee 61

3. "Flange Protection Best Practices for Waveguide and Microwave Components" - Anderson, P.M. & Williams, K.R., Institute of Electrical and Electronics Engineers Microwave Theory and Techniques Society

4. "Material Selection for Harsh Environment Applications: Comparative Analysis of Protection Methods" - Rodriguez, A.C., American Society for Testing and Materials Special Technical Publication

5. "UV Degradation Mechanisms in Polyethylene and Stabilization Strategies" - Nakamura, T. & Singh, B.P., Polymer Degradation and Stability Research Institute