Top Benefits of Low-PIM Coaxial Directional Coupler Designs

In today's wireless infrastructure deployments, network operators face a critical challenge where signal degradation from passive intermodulation can cripple system performance, leading to dropped calls, reduced data throughput, and compromised coverage in distributed antenna systems. Low-PIM Coaxial Directional Coupler designs solve this problem by minimizing unwanted signal distortion while maintaining precise power distribution across multiple frequency bands. These advanced components ensure that modern cellular networks operating across 2G, 3G, 4G LTE, and 5G technologies deliver the reliable, high-quality connectivity that users demand in mission-critical applications.

Understanding Low-PIM Technology in Coaxial Directional Coupler Systems

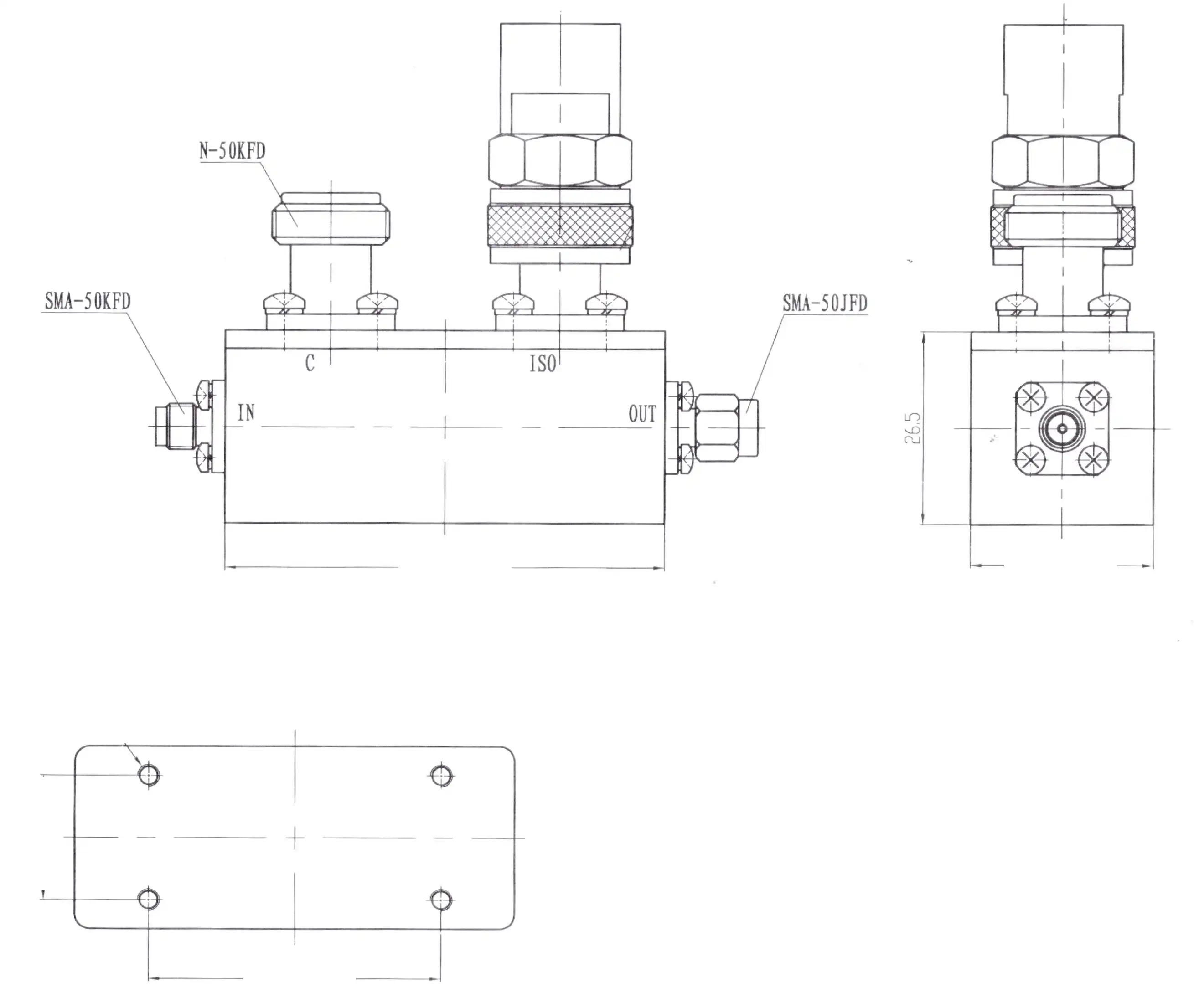

Low passive intermodulation technology represents a fundamental breakthrough in RF component design that directly addresses one of the most persistent challenges in wireless communication systems. When multiple high-power signals pass through traditional RF components, nonlinearities in materials and connections generate unwanted intermodulation products that fall within operational frequency bands, creating interference that degrades system performance. Low-PIM Coaxial Directional Coupler designs eliminate these issues through precision manufacturing techniques, carefully selected materials with linear electrical characteristics, and specialized connection methods that prevent the formation of micro-arcs and contact irregularities. The engineering behind low-PIM performance extends beyond simple material selection to encompass the entire mechanical and electrical design of the Coaxial Directional Coupler. Advanced manufacturing processes ensure that all metal-to-metal contacts maintain consistent pressure and surface finish quality, while specialized plating techniques create uniform conductive paths that resist oxidation and maintain electrical stability over extended operational periods. The stripline or coaxial construction methods employed in these devices utilize precision machining and assembly processes that eliminate gaps, voids, and irregularities where PIM products could originate, resulting in components that deliver PIM performance ratings of -161 dBc or better across their entire operating bandwidth.

Critical Performance Parameters That Define Excellence

Modern Low-PIM Coaxial Directional Coupler systems achieve remarkable performance specifications that directly translate to improved network capacity and reliability. Insertion loss values below 0.2 dB ensure that signal power is preserved through the distribution path, maximizing the efficiency of expensive amplification equipment and extending coverage areas without requiring additional infrastructure investment. High isolation specifications exceeding 30 dB between coupled and through ports prevent signal leakage that could compromise measurement accuracy or create interference in adjacent channels, while directivity values above 20 dB ensure that forward and reverse power measurements remain accurate even under varying load conditions. Voltage Standing Wave Ratio specifications of 1.2:1 or better demonstrate the impedance matching excellence that characterizes premium Coaxial Directional Coupler designs, minimizing reflections that could degrade signal quality or damage sensitive transmitter circuitry. The wide frequency coverage from DC to 110 GHz accommodates legacy systems operating at lower frequencies while supporting next-generation technologies that utilize millimeter-wave spectrum allocations. Power handling capabilities reaching 500 watts average power enable these components to operate in high-power infrastructure applications where signal levels can exceed typical commercial wireless specifications, making them suitable for broadcast, military, and specialized industrial applications that demand exceptional durability and thermal stability.

Enhanced Signal Integrity Through Advanced Coupling Mechanisms

The fundamental architecture of Low-PIM Coaxial Directional Coupler designs incorporates sophisticated coupling mechanisms that extract precise power samples without introducing phase distortion or amplitude variations across the operating bandwidth. These devices utilize either distributed coupling structures that maintain constant coupling coefficients across ultra-wideband frequency ranges, or lumped-element designs optimized for specific frequency bands where size constraints or particular performance requirements dictate the appropriate approach. The coupling methodology directly impacts the flatness of the frequency response, with precision-engineered tapered coupling sections ensuring that power division remains consistent whether operating at the lower end of cellular bands or at higher frequencies associated with 5G millimeter-wave deployments. The physical construction of the coupling region within a Coaxial Directional Coupler determines its ability to maintain signal integrity under varying environmental conditions and power levels. Air dielectric designs offer the lowest possible insertion loss and highest power handling capacity, while solid dielectric constructions provide mechanical stability and environmental protection in installations where moisture, temperature extremes, or physical shock could compromise performance. The selection of appropriate coupling techniques balances the competing requirements of directivity, coupling accuracy, frequency bandwidth, size constraints, and environmental resilience to deliver solutions optimized for specific deployment scenarios.

Broadband Performance Characteristics

Ultra-wideband Coaxial Directional Coupler designs supporting frequency ranges from 600 to 6000 MHz enable network operators to consolidate multiple frequency bands into unified distribution systems, reducing infrastructure complexity and lowering total ownership costs. This broadband capability proves particularly valuable in distributed antenna systems serving buildings or campuses where multiple wireless services operating across diverse frequency allocations must be delivered through a common passive distribution network. The ability to simultaneously handle 2G GSM services at 900 and 1800 MHz, 3G UMTS systems at 2100 MHz, 4G LTE deployments across numerous band combinations, and emerging 5G FR1 services operating up to 6000 MHz transforms infrastructure deployment economics by eliminating the need for frequency-specific distribution networks. Maintaining consistent electrical performance across such extreme bandwidth ratios requires sophisticated design techniques that account for frequency-dependent effects in transmission line structures and coupling mechanisms. Advanced Coaxial Directional Coupler designs employ distributed coupling structures where the coupling coefficient variation remains within tightly controlled limits across the entire operating range, ensuring that power division accuracy meets specification requirements regardless of the actual operating frequency. This frequency-independent behavior enables system designers to confidently deploy these components in applications where signal frequencies may change as network technologies evolve, providing investment protection and operational flexibility that justify premium component selection.

Superior Low-PIM Performance for Modern Wireless Networks

Distributed antenna systems deployed in high-traffic venues such as stadiums, convention centers, airports, and commercial buildings demand exceptional passive intermodulation performance to prevent self-interference that degrades network capacity during peak usage periods. When thousands of simultaneous users generate high-power signals across multiple frequency bands, even minor PIM contributions from individual components accumulate throughout the distribution network to create interference levels that can render entire frequency channels unusable. Low-PIM Coaxial Directional Coupler designs with PIM ratings of -161 dBc ensure that each component contributes negligible interference to the overall system PIM budget, enabling network operators to maximize spectral efficiency and deliver consistent user experiences even under extreme loading conditions. The achievement of such stringent PIM performance requires meticulous attention to every aspect of component design, manufacturing, and quality control. Material selection processes screen connector components, housing materials, and internal elements for nonlinear electrical characteristics that could generate PIM products when subjected to high RF power levels. Assembly procedures incorporate specialized techniques such as controlled torque application on threaded connections, precision alignment of mating surfaces, and contamination-free manufacturing environments that prevent particulate matter from compromising contact integrity. Rigorous testing protocols verify PIM performance across multiple frequency combinations and power levels before components receive approval for deployment in critical infrastructure applications.

Optimized for Multi-Carrier LTE and 5G Applications

Modern cellular networks operate with multiple carriers simultaneously transmitting at high power levels to maximize system capacity and accommodate diverse service offerings within limited spectrum allocations. This multi-carrier environment creates particularly challenging conditions for passive components, as the interaction between multiple high-power signals dramatically increases the likelihood of passive intermodulation product generation. Low-PIM Coaxial Directional Coupler designs specifically engineered for multi-carrier applications incorporate design features that minimize nonlinear effects even when subjected to the complex signal environments characteristic of carrier aggregation scenarios where five or more LTE carriers may operate simultaneously through a single distribution path. The electrical design of these specialized Coaxial Directional Coupler components optimizes the current distribution patterns within coupling structures to avoid regions where high current densities could exceed the linear operating range of conductor materials or create localized heating that alters electrical characteristics. Thermal management considerations ensure that power dissipation remains within acceptable limits even during sustained high-power operation, preventing temperature-related changes in contact resistance or material properties that could degrade PIM performance over time. These design optimizations enable network operators to confidently deploy high-order carrier aggregation configurations that maximize spectrum efficiency without concern that infrastructure components will limit achievable data rates or coverage quality.

Precision Engineering for Mission-Critical Applications

Aerospace and defense applications impose requirements that extend far beyond commercial wireless specifications, demanding components that deliver unwavering performance under extreme environmental conditions, extended operational lifetimes, and failure modes that prevent catastrophic system degradation. Low-PIM Coaxial Directional Coupler designs for these demanding applications incorporate materials selected for stability across temperature ranges from -55°C to +125°C, hermetic sealing techniques that prevent moisture ingress and contamination, and mechanical designs that withstand shock, vibration, and acceleration forces encountered in airborne, shipboard, and ground mobile installations. The precision manufacturing techniques employed in these components ensure that electrical performance parameters remain within specification throughout service lives measured in decades rather than years. Military radar systems, satellite ground stations, and electronic warfare applications require Coaxial Directional Coupler components that maintain calibrated coupling accuracy across extreme temperature variations, enabling precise power measurements essential for system alignment, transmitter protection, and signal analysis functions. The stability of coupling coefficients, directivity, and insertion loss across environmental extremes directly impacts the accuracy of these critical measurements, making component selection a paramount concern in system design. Advanced manufacturing processes incorporating temperature compensation techniques, stress-relieved mechanical designs, and materials with matched thermal expansion coefficients ensure that these precision components deliver consistent performance regardless of operating conditions.

Reliability in Harsh Operating Environments

Outdoor wireless infrastructure installations expose components to moisture, temperature cycling, ultraviolet radiation, corrosive atmospheres, and mechanical stresses that would quickly destroy components not specifically designed for environmental resilience. IP65 and IP67 rated Low-PIM Coaxial Directional Coupler designs incorporate sealed housing constructions that prevent water ingress while allowing internal pressure equalization to accommodate altitude changes and temperature variations without compromising seal integrity. Connector interfaces utilize environmentally sealed designs with elastomeric gaskets and corrosion-resistant plating that maintain electrical performance and mechanical integrity through thousands of mating cycles and years of outdoor exposure. The materials employed in environmentally hardened Coaxial Directional Coupler constructions resist degradation from salt spray, industrial pollutants, and atmospheric moisture that would corrode conventional components. Stainless steel housings provide superior corrosion resistance compared to aluminum alternatives, while specialized surface treatments and plating processes protect critical electrical interfaces from oxidation and contamination. These environmental protection features ensure that electrical performance remains stable throughout service lives exceeding twenty years in coastal, industrial, and other challenging installation environments, reducing maintenance requirements and total cost of ownership for critical infrastructure deployments.

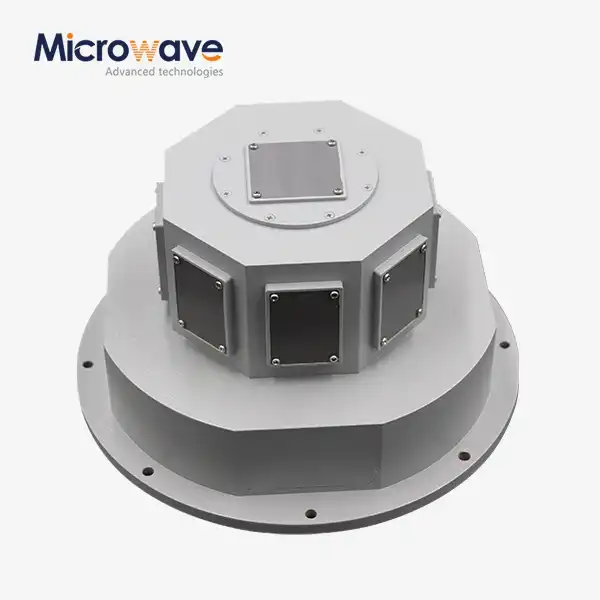

Advanced Manufacturing Capabilities at Advanced Microwave Technologies Co., Ltd

The production of high-performance Low-PIM Coaxial Directional Coupler components requires sophisticated manufacturing infrastructure and technical expertise that few organizations possess. Advanced Microwave Technologies Co., Ltd operates state-of-the-art production facilities equipped with precision CNC machining centers, automated assembly systems, and comprehensive test equipment capable of characterizing component performance across frequency ranges extending to 110 GHz. The company's 24-meter microwave darkroom provides unparalleled antenna and component testing capabilities, enabling near-field and far-field measurements that verify performance specifications under conditions that closely simulate actual deployment environments. Quality management systems certified to ISO 9001:2015 standards ensure that every Coaxial Directional Coupler manufactured meets stringent quality criteria through documented processes, statistical process control, and comprehensive inspection protocols. Environmental management certification to ISO 14001:2015 demonstrates the organization's commitment to sustainable manufacturing practices that minimize waste, conserve energy, and reduce environmental impact throughout the product lifecycle. Occupational health and safety certification to ISO 45001:2018 standards protects the skilled workforce responsible for producing these precision components, creating a workplace culture that values safety alongside technical excellence and continuous improvement.

Custom Solutions for Unique Application Requirements

Standard catalog components address the majority of wireless infrastructure applications, but specialized deployments often require customized solutions tailored to unique frequency bands, power levels, physical configurations, or environmental conditions. Advanced Microwave Technologies Co., Ltd provides comprehensive OEM services that transform customer requirements into production-ready designs through collaborative engineering processes that leverage decades of microwave component expertise. Custom frequency ranges spanning from DC to 110 GHz accommodate specialized applications in satellite communications, radar systems, test equipment, and research installations where commercial frequency allocations do not apply. Adjustable coupling values optimized for specific power distribution requirements enable system designers to achieve precisely balanced signal levels throughout complex distribution networks without resorting to additional attenuation or amplification stages that would increase cost and complexity. Custom connector configurations accommodate installation constraints, mating with existing infrastructure, or specialized environmental requirements that standard connector types cannot satisfy. Mechanical design modifications adjust physical dimensions, mounting provisions, and housing configurations to integrate seamlessly with customer equipment, while custom branding and labeling services ensure that OEM products maintain consistent appearance with customer product lines.

Conclusion

Low-PIM Coaxial Directional Coupler designs deliver essential performance advantages that directly impact wireless network capacity, reliability, and operational efficiency across diverse applications.

Cooperate with Advanced Microwave Technologies Co., Ltd

Partner with a China Coaxial Directional Coupler manufacturer that combines over twenty years of microwave engineering excellence with cutting-edge manufacturing capabilities to deliver superior solutions for your critical infrastructure needs. As a leading China Coaxial Directional Coupler supplier and China Coaxial Directional Coupler factory, Advanced Microwave Technologies Co., Ltd offers High Quality Coaxial Directional Coupler products available through our China Coaxial Directional Coupler wholesale programs at competitive Coaxial Directional Coupler prices. Our extensive inventory ensures that standard configurations are available for immediate delivery, while our experienced engineering team stands ready to develop custom solutions that address your unique application requirements. Whether you need Coaxial Directional Coupler for sale for commercial wireless deployments, defense systems, aerospace projects, or specialized research applications, our comprehensive product portfolio and technical support capabilities ensure project success from initial specification through installation and beyond. Contact our team today at craig@admicrowave.com to discuss how our expertise in waveguide assemblies, coaxial components, microwave antennas, and measurement systems can enhance your next project.

References

1. Passive Intermodulation in Antenna Systems - Smith, J.R. and Anderson, M.K., IEEE Transactions on Microwave Theory and Techniques

2. Design Principles for Low-PIM RF Components - Chen, W., Johnson, R.T., and Williams, P.D., International Journal of RF and Microwave Engineering

3. Broadband Directional Coupler Theory and Applications - Thompson, D.L. and Martinez, C.A., Microwave Journal Technical Papers

4. Environmental Testing Standards for Outdoor RF Components - Roberts, S.M., Peterson, J.K., and Davis, L.R., Journal of Electronic Manufacturing Standards

5. Quality Management in Precision Microwave Component Manufacturing - Zhang, H., Lee, K.W., and Brown, T.J., IEEE Manufacturing Technology Transactions

YOU MAY LIKE

VIEW MORELog Periodic Antenna

VIEW MORELog Periodic Antenna VIEW MORESlotted Waveguide Array Antenna

VIEW MORESlotted Waveguide Array Antenna VIEW MOREOpen Boundary Dual Linear Polarization Four Ridged Horn Antenna

VIEW MOREOpen Boundary Dual Linear Polarization Four Ridged Horn Antenna VIEW MOREConical Dual circular Polarization Horn Antenna

VIEW MOREConical Dual circular Polarization Horn Antenna VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna

VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna VIEW MOREConical Linear Polarization Horn Antenna

VIEW MOREConical Linear Polarization Horn Antenna VIEW MOREPlanar Spiral Antenna

VIEW MOREPlanar Spiral Antenna