How a Waveguide High Pass Filter Solves Your Low-Frequency Noise Problems?

In today's complex microwave and RF systems, engineers face a persistent challenge: low-frequency noise contaminating critical high-frequency signals, leading to degraded performance, signal distortion, and system failures. The Waveguide High Pass Filter emerges as the definitive solution to this pervasive problem, offering precision filtering capabilities that eliminate unwanted low-frequency interference while preserving essential high-frequency signal integrity. Understanding how these sophisticated components work and their transformative impact on system performance is crucial for engineers seeking to optimize their RF and microwave applications across satellite communications, radar systems, and defense technologies.

Understanding Waveguide High Pass Filter Fundamentals

Physical Principles Behind High Pass Filtering

The Waveguide High Pass Filter operates on fundamental electromagnetic principles where hollow metal conduits selectively transmit frequencies above a predetermined cutoff frequency while attenuating lower frequencies. This filtering action occurs because electromagnetic waves below the cutoff frequency cannot propagate through the waveguide structure, experiencing exponential decay instead of transmission. The waveguide dimensions directly determine the cutoff frequency, with larger cross-sectional areas supporting lower cutoff frequencies and smaller dimensions requiring higher frequencies for propagation. The filtering mechanism relies on the relationship between wavelength and waveguide geometry, where the half-wavelength of the electromagnetic wave must fit within the waveguide's cross-sectional dimensions for successful propagation. When frequencies fall below this threshold, the waveguide walls act as short circuits to the incident wave, preventing transmission and effectively creating a high-pass filtering characteristic. Advanced Microwave's Waveguide High Pass Filter designs leverage these principles to achieve exceptional filtering performance with minimal insertion loss and excellent return loss characteristics across frequency ranges from low GHz to high GHz applications.

Technical Architecture and Design Elements

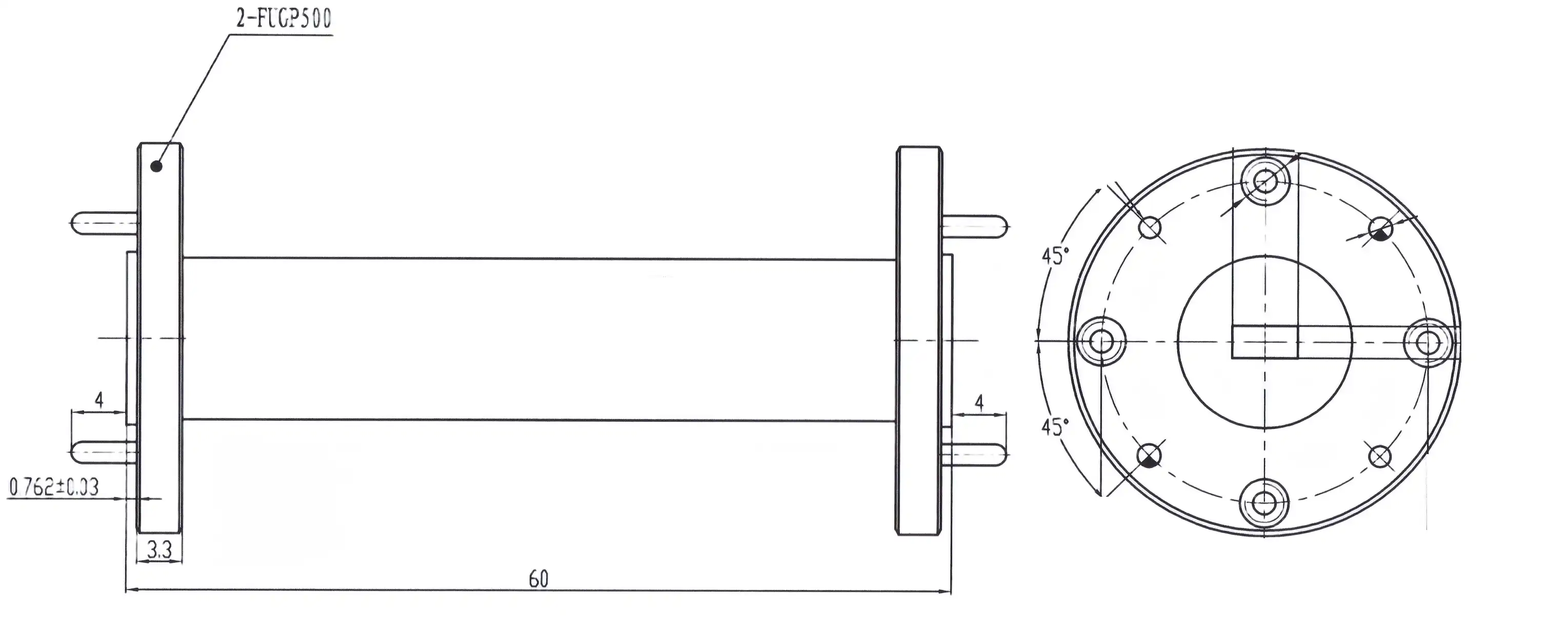

Modern Waveguide High Pass Filter construction employs precision-machined aluminum or copper materials to ensure optimal electrical conductivity and mechanical stability. The internal geometry features carefully calculated dimensions that create the desired cutoff frequency while maintaining impedance matching throughout the operational frequency range. These filters incorporate smooth transitions and optimized internal structures to minimize reflection losses and maintain signal integrity across the passband. The design process involves complex electromagnetic modeling and simulation to predict performance characteristics including insertion loss, return loss, and frequency response. Advanced manufacturing techniques ensure dimensional accuracy within tight tolerances, critical for maintaining consistent filtering performance across production units. The Waveguide High Pass Filter architecture often includes additional features such as flanged connections for easy integration, environmental sealing for harsh operating conditions, and customizable frequency ranges to meet specific application requirements.

Critical Applications Where Low-Frequency Noise Causes Problems

Satellite Communication System Challenges

Satellite communication systems operating in C, X, Ku, and Ka frequency bands frequently encounter low-frequency noise contamination that degrades signal quality and reduces communication reliability. This interference originates from various sources including terrestrial radio frequency interference, atmospheric noise, and internal system harmonics that fall outside the desired communication bands. The Waveguide High Pass Filter addresses these challenges by providing sharp frequency discrimination that eliminates unwanted low-frequency components while preserving the integrity of high-frequency satellite signals. In satellite ground stations, low-frequency noise can cause intermodulation distortion, reduced signal-to-noise ratios, and increased bit error rates that compromise data transmission quality. The implementation of precision Waveguide High Pass Filter solutions ensures clean signal separation, enabling satellite systems to achieve optimal performance even in electromagnetically challenging environments. These filters support wide frequency ranges and can be customized to meet specific satellite band requirements, providing essential signal conditioning for both uplink and downlink communications.

Radar and Defense System Applications

Military and civilian radar systems require exceptional signal purity to achieve accurate target detection, ranging, and tracking capabilities. Low-frequency noise and interference can mask weak target returns, create false targets, and reduce overall radar sensitivity, compromising mission-critical operations. The Waveguide High Pass Filter serves as a crucial front-end component that eliminates spurious low-frequency signals while preserving radar signal integrity across operational frequency bands. Defense applications demand the highest levels of filtering performance to ensure reliable operation in contested electromagnetic environments. Advanced radar systems operating at X-band, Ku-band, and higher frequencies rely on precision Waveguide High Pass Filter technology to maintain clear frequency separation between operational signals and unwanted interference. These filters must withstand harsh environmental conditions while maintaining consistent performance, making material selection and construction quality paramount considerations for defense contractors and system integrators.

Advanced Waveguide High Pass Filter Technologies and Benefits

Performance Characteristics and Technical Specifications

The modern Waveguide High Pass Filter delivers exceptional performance metrics that directly address the challenges of low-frequency noise contamination. Key specifications include minimal insertion loss typically below 0.5 dB across the passband, excellent return loss exceeding 20 dB, and sharp transition characteristics that provide effective stopband rejection. These performance parameters ensure that desired high-frequency signals pass through with minimal attenuation while unwanted low-frequency components experience significant suppression. Frequency response characteristics of advanced Waveguide High Pass Filter designs feature steep roll-off rates that provide clear separation between passband and stopband regions. The customizable nature of these filters allows engineers to specify exact cutoff frequencies, passband ripple, and stopband rejection levels to match specific application requirements. Broad frequency support capabilities enable single filter designs to address multiple frequency bands simultaneously, reducing system complexity and improving overall reliability.

Material Engineering and Construction Quality

High-performance Waveguide High Pass Filter construction utilizes premium-grade aluminum and copper materials selected for their excellent electrical conductivity, mechanical stability, and environmental resistance. Advanced manufacturing processes including precision CNC machining and electroplating ensure consistent dimensional accuracy and surface finish quality that directly impact electrical performance. The selection of appropriate materials and manufacturing techniques is crucial for achieving the low insertion loss and high return loss characteristics demanded by modern microwave systems. Environmental durability represents another critical aspect of Waveguide High Pass Filter design, particularly for aerospace, defense, and outdoor communication applications. These filters must maintain performance specifications across wide temperature ranges, humidity variations, and mechanical stress conditions. Advanced Microwave's filter designs incorporate environmental sealing, corrosion-resistant materials, and robust mechanical construction to ensure reliable operation throughout the product lifecycle.

Integration Strategies and System Implementation

Installation and Interface Requirements

Successful Waveguide High Pass Filter implementation requires careful consideration of mechanical interfaces, electrical connections, and system integration factors. Standard waveguide flanges provide secure mechanical connections while maintaining electrical continuity and impedance matching throughout the RF signal path. Proper installation techniques including torque specifications, alignment procedures, and environmental sealing ensure optimal filter performance and system reliability. System designers must account for the physical dimensions and mounting requirements of Waveguide High Pass Filter components during the design phase to ensure adequate space allocation and proper thermal management. The filter's position within the signal chain significantly impacts overall system performance, with optimal placement typically occurring at the front end of sensitive receiver systems or at critical interface points where frequency separation is essential.

Customization and Application-Specific Solutions

The diverse requirements of modern microwave systems necessitate customizable Waveguide High Pass Filter solutions that address specific frequency bands, power levels, and environmental conditions. Advanced Microwave Technologies offers comprehensive customization services including tailored frequency responses, specialized mounting configurations, and enhanced environmental ratings to meet unique application demands. This flexibility enables optimal filter performance across a wide range of applications from laboratory test equipment to field-deployed communication systems. Custom filter design processes involve detailed analysis of system requirements, electromagnetic modeling, and prototype validation to ensure performance specifications are met or exceeded. The ability to modify filter characteristics including cutoff frequency, passband width, and physical dimensions provides system designers with the flexibility needed to optimize overall system performance while addressing specific integration constraints and operational requirements.

Quality Assurance and Performance Validation

Testing and Measurement Protocols

Comprehensive testing and validation procedures ensure that every Waveguide High Pass Filter meets stringent performance specifications before deployment in critical applications. Advanced measurement systems utilizing vector network analyzers, signal generators, and spectrum analyzers provide detailed characterization of filter performance across the operational frequency range. These measurements include insertion loss, return loss, group delay, and power handling capabilities under various environmental conditions. Quality assurance protocols incorporate statistical process control methods, traceability systems, and environmental testing to validate long-term reliability and performance consistency. The testing procedures align with relevant industry standards and customer specifications, ensuring that delivered products meet or exceed performance expectations throughout their operational lifetime. Advanced Microwave's 24-meter microwave darkroom facility enables precision testing up to 110 GHz, providing unparalleled measurement accuracy for high-frequency filter characterization.

Compliance and Certification Standards

Modern Waveguide High Pass Filter products must comply with various international standards and regulations governing electromagnetic compatibility, environmental performance, and quality management systems. ISO 9001:2015 certification ensures consistent quality management practices throughout the design, manufacturing, and delivery processes. RoHS compliance guarantees that materials and manufacturing processes meet environmental protection requirements for electronic components. Additional certifications including ISO 14001:2015 for environmental management and ISO 45001:2018 for occupational health and safety demonstrate comprehensive commitment to sustainable manufacturing practices and employee welfare. These certifications provide customers with confidence in product quality, environmental responsibility, and manufacturing process integrity that supports long-term business relationships and system reliability.

Conclusion

The Waveguide High Pass Filter represents a critical technology solution for addressing low-frequency noise problems in modern microwave and RF systems. Through precise engineering, advanced materials, and proven design methodologies, these filters deliver exceptional performance that enables optimal system operation across diverse applications. The combination of technical excellence, customization flexibility, and comprehensive support services makes waveguide high pass filtering an essential component for engineers seeking to eliminate low-frequency interference while maintaining signal integrity in demanding operational environments.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd stands as your premier China Waveguide High Pass Filter factory, China Waveguide High Pass Filter supplier, and China Waveguide High Pass Filter manufacturer offering competitive Waveguide High Pass Filter price solutions. As a leading China Waveguide High Pass Filter wholesale provider, we deliver High Quality Waveguide High Pass Filter for sale backed by over 20 years of microwave expertise. Our ISO-certified facilities feature cutting-edge 24m measurement capabilities up to 110 GHz, ensuring superior product quality. Contact craig@admicrowave.com for custom solutions, prototyping services, and technical support that transforms your filtering challenges into competitive advantages.

FAQ

Q: What frequency ranges do Waveguide High Pass Filters typically cover?

A: Waveguide High Pass Filters operate across frequency ranges from 0.5 GHz to 110 GHz, supporting C, X, Ku, and Ka bands with customizable cutoff frequencies.

Q: How do these filters achieve low insertion loss performance?

A: Advanced materials like high-grade aluminum and copper, precision manufacturing, and optimized internal geometry minimize signal attenuation while maintaining filtering effectiveness.

Q: Can Waveguide High Pass Filters handle high power applications?

A: Yes, these filters are designed for high-power applications with robust construction and thermal management capabilities suitable for radar and defense systems.

Q: What customization options are available for specific applications?

A: Customization includes frequency range adjustment, mounting configurations, materials selection, and environmental specifications to match unique system requirements.

References

1. Pozar, D. M. "Microwave Engineering" - Comprehensive analysis of waveguide filter theory and applications in microwave systems

2. Collin, R. E. "Foundations for Microwave Engineering" - Fundamental principles of waveguide high-pass filter design and electromagnetic wave propagation

3. Matthaei, G. L., Young, L., and Jones, E. M. T. "Microwave Filters, Impedance-Matching Networks, and Coupling Structures" - Detailed filter design methodologies and performance optimization techniques

4. IEEE Transactions on Microwave Theory and Techniques - Various technical papers on advanced waveguide filter technologies and noise suppression applications