From DC to 110 GHz: How Our Waveguide Cable Assemblies Maintain Superior Signal Integrity

When critical communications fail at 110 GHz frequencies, the consequences can be catastrophic. Imagine a defense radar system losing target acquisition during a critical mission, or a satellite communication link dropping vital data transmission precisely when it's needed most. These scenarios highlight the paramount importance of maintaining exceptional signal integrity across the entire frequency spectrum from DC to 110 GHz. In today's demanding high-frequency applications, engineers face the constant challenge of preserving signal quality while minimizing loss, crosstalk, and interference. Our Waveguide Cable Assembly solutions address these critical pain points by delivering uncompromising performance that ensures your most sensitive applications maintain reliable, crystal-clear signal transmission even under the most demanding conditions.

Understanding Waveguide Cable Assembly Technology for High-Frequency Applications

The Science Behind Superior Signal Integrity

Waveguide Cable Assembly technology represents the pinnacle of high-frequency signal transmission engineering. At its core, this technology combines the exceptional low-loss characteristics of waveguides with the flexibility and connectivity options of coaxial cables. The fundamental principle behind maintaining superior signal integrity lies in controlling electromagnetic wave propagation through precisely engineered transmission paths. Each Waveguide Cable Assembly is designed to minimize insertion loss, reduce return loss, and eliminate signal reflections that can degrade performance in critical applications. The electromagnetic field confinement within our Waveguide Cable Assembly structures ensures that signal energy remains focused and protected from external interference. This is particularly crucial when operating across the broad frequency spectrum from DC to 110 GHz, where even minor impedance mismatches can result in significant signal degradation. Our assemblies utilize advanced materials and precision manufacturing techniques to maintain consistent 50-ohm impedance throughout the entire transmission path, ensuring optimal power transfer and minimal signal distortion.

Advanced Materials and Construction Techniques

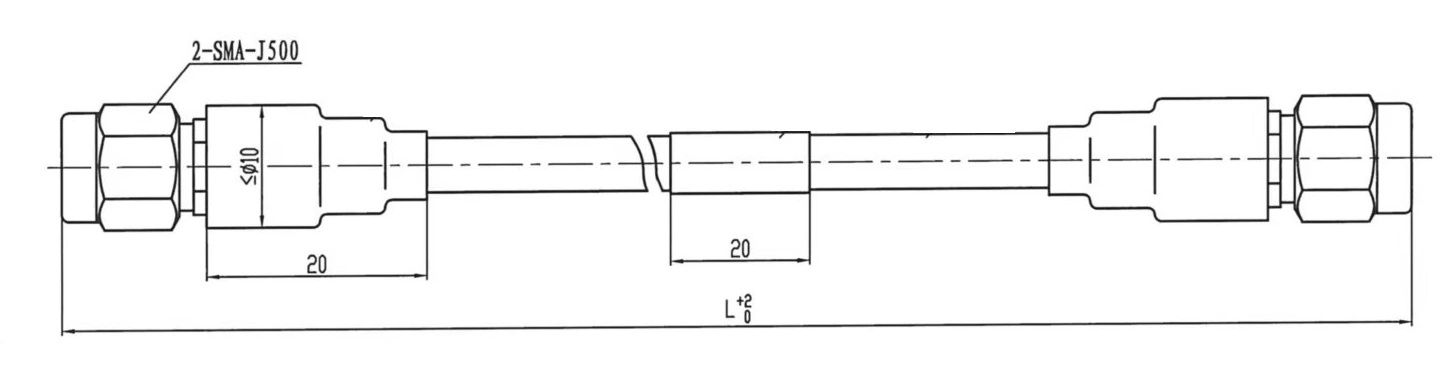

The construction of high-performance Waveguide Cable Assembly units requires careful selection of materials that can maintain their electrical properties across extreme frequency ranges and environmental conditions. Our assemblies incorporate premium conductors including aluminum, copper, stainless steel, and brass, each chosen for specific performance characteristics. The dielectric materials are selected for their low loss tangent and stable permittivity across the entire operating frequency range. The mechanical precision required for these assemblies cannot be overstated. Manufacturing tolerances must be maintained within micrometers to ensure consistent electrical performance. Our Waveguide Cable Assembly production utilizes advanced CNC machining and precision forming techniques to achieve the dimensional accuracy required for optimal signal integrity. The connector interfaces are manufactured to exact specifications, ensuring reliable mating and unmating cycles while maintaining electrical continuity and mechanical stability.

Critical Performance Parameters of Professional Waveguide Cable Assembly Solutions

Insertion Loss Optimization Across the Frequency Spectrum

Insertion loss represents one of the most critical performance parameters in any Waveguide Cable Assembly. The new cable assemblies offer engineers and technicians reliable off-the-shelf solutions for high frequency testing with optimized loss characteristics. Our assemblies are specifically engineered to minimize signal attenuation across the entire DC to 110 GHz frequency range through careful impedance matching and conductor geometry optimization. The challenge of maintaining low insertion loss becomes increasingly difficult as frequency increases. At millimeter-wave frequencies approaching 110 GHz, conductor losses and dielectric losses become significant factors that must be carefully managed. Our Waveguide Cable Assembly designs incorporate advanced loss compensation techniques and utilize materials with exceptionally low loss tangent values to maintain superior signal transmission characteristics even at the highest operating frequencies. Temperature stability is another crucial factor affecting insertion loss performance. Our Waveguide Cable Assembly products are designed to maintain consistent electrical characteristics across a wide temperature range from -40°C to +85°C, ensuring reliable operation in diverse environmental conditions from arctic installations to desert deployments.

Return Loss and VSWR Characteristics

Return loss and Voltage Standing Wave Ratio (VSWR) are fundamental indicators of impedance matching quality in Waveguide Cable Assembly systems. Poor impedance matching results in signal reflections that can cause standing waves, reducing power transfer efficiency and potentially damaging transmitter equipment. Our assemblies are engineered to maintain VSWR values below 1.5:1 across the entire operating frequency range, ensuring optimal power transfer and minimal signal reflection. The achievement of excellent return loss characteristics requires precise control of every impedance discontinuity within the Waveguide Cable Assembly. This includes the connector transitions, cable-to-waveguide interfaces, and any bends or twists within the assembly. Our design methodology utilizes advanced electromagnetic simulation tools to optimize these transitions and minimize reflections throughout the signal path.

Power Handling and Environmental Durability

High-power applications demand Waveguide Cable Assembly solutions that can handle significant RF power levels without degradation or failure. Our assemblies are designed with robust conductor cross-sections and advanced cooling considerations to handle high-power RF signals safely. The power handling capability is maintained across the entire frequency range through careful thermal management and conductor sizing optimization. Environmental durability is equally important, particularly for outdoor installations and mobile applications. Our Waveguide Cable Assembly products are constructed with corrosion-resistant materials and protective coatings that ensure long-term reliability in harsh environmental conditions. The assemblies meet stringent MIL-STD specifications for shock, vibration, and environmental exposure, making them suitable for the most demanding aerospace and defense applications.

Advanced Applications Demanding Superior Waveguide Cable Assembly Performance

Satellite Communication Systems and Ground Station Infrastructure

Modern satellite communication systems operate across increasingly broad frequency ranges, from traditional C-band and Ku-band frequencies up to Ka-band and beyond. These systems require Waveguide Cable Assembly solutions that can maintain signal integrity across multiple frequency bands while providing the flexibility needed for tracking antenna systems and ground station installations. Our assemblies support seamless signal transmission for high-definition video, voice communications, and data services that form the backbone of global telecommunications infrastructure. The demanding requirements of satellite communications include not only broad frequency coverage but also exceptional phase stability and low noise figure characteristics. Our Waveguide Cable Assembly designs incorporate advanced phase-matched configurations and low-noise materials to support the most sophisticated modulation schemes and high-data-rate applications. The assemblies are engineered to maintain consistent electrical length and phase characteristics across temperature variations and mechanical flexing.

Defense and Aerospace Radar Applications

Military radar systems represent some of the most demanding applications for Waveguide Cable Assembly technology. These systems require exceptional signal fidelity, high power handling capability, and absolute reliability in critical situations. From air traffic control radar systems that must maintain accurate target tracking in adverse weather conditions to missile guidance systems that demand precision targeting capability, our assemblies provide the performance foundation for mission-critical defense applications. The frequency agility requirements of modern radar systems place additional demands on Waveguide Cable Assembly performance. These systems must maintain consistent characteristics across rapid frequency changes while providing the dynamic range needed for both long-range detection and close-range tracking. Our assemblies are designed to support these requirements through optimized broadband performance and excellent group delay characteristics.

Test and Measurement Laboratory Equipment

Precision test and measurement applications require Waveguide Cable Assembly solutions that provide traceable accuracy and exceptional repeatability. With operable frequency of DC to 110 GHz, the W1 components generate metrology-grade quality results with high repeatability. Laboratory instrumentation demands assemblies that can maintain calibrated performance over extended periods while providing the mechanical stability needed for automated test equipment and precision measurements. The measurement uncertainty requirements for laboratory applications often exceed those of operational systems by orders of magnitude. Our Waveguide Cable Assembly products are manufactured to meet the most stringent specifications for electrical and mechanical stability. Each assembly undergoes comprehensive testing and characterization to ensure compliance with metrology standards and traceability requirements.

Manufacturing Excellence and Quality Assurance in Waveguide Cable Assembly Production

Precision Manufacturing and Advanced Quality Control

The manufacturing of high-performance Waveguide Cable Assembly products requires an integrated approach combining advanced manufacturing techniques with comprehensive quality assurance protocols. Our production facility utilizes state-of-the-art CNC machining centers, precision forming equipment, and automated assembly systems to ensure consistent quality and dimensional accuracy. Each assembly undergoes multiple inspection stages throughout the manufacturing process to verify compliance with design specifications and performance requirements. Quality control extends beyond dimensional verification to include comprehensive electrical testing of each Waveguide Cable Assembly. Our test capabilities span the entire DC to 110 GHz frequency range, utilizing advanced vector network analyzers and precision test fixtures to verify insertion loss, return loss, and impedance characteristics. The test data for each assembly is permanently recorded and traceable to NIST standards, ensuring complete documentation of performance characteristics.

ISO Certification and Environmental Compliance

Our commitment to quality excellence is demonstrated through our ISO 9001:2015 certification, which encompasses all aspects of Waveguide Cable Assembly design, manufacturing, and testing. The quality management system ensures consistent processes, continuous improvement, and customer satisfaction across all product lines. Additionally, our ISO 14001:2015 environmental management certification demonstrates our commitment to sustainable manufacturing practices and environmental responsibility. RoHS compliance is maintained throughout our product line, ensuring that all Waveguide Cable Assembly products meet the most stringent environmental regulations for hazardous substance restrictions. This compliance is particularly important for products destined for European markets and applications where environmental considerations are paramount.

Customization and Engineering Support for Specialized Waveguide Cable Assembly Requirements

Tailored Solutions for Unique Applications

Every high-frequency application presents unique challenges that often require customized Waveguide Cable Assembly solutions. Our engineering team works closely with customers to develop assemblies that meet specific mechanical, electrical, and environmental requirements. This includes custom connector configurations, specialized materials, non-standard cable lengths, and unique environmental specifications that exceed standard product offerings. The customization process begins with a thorough analysis of application requirements, including frequency range, power levels, environmental conditions, and mechanical constraints. Our engineers utilize advanced electromagnetic simulation tools to optimize the assembly design for the specific application requirements. Prototype assemblies are manufactured and tested to verify performance before proceeding to production quantities.

Comprehensive Technical Support and OEM Services

Our technical support capabilities extend far beyond product delivery to include comprehensive engineering assistance throughout the project lifecycle. This includes design consultation, prototype development, performance verification testing, and ongoing technical support. Our OEM services provide customers with complete turnkey solutions including custom packaging, labeling, and documentation to support their specific requirements. The technical support team includes experienced RF engineers with deep expertise in high-frequency applications and Waveguide Cable Assembly technology. This expertise enables us to provide valuable guidance on system integration, performance optimization, and troubleshooting support. Customer training programs are available to ensure proper installation, operation, and maintenance of our assemblies in customer applications.

Conclusion

From DC to 110 GHz, maintaining superior signal integrity requires the perfect combination of advanced materials, precision manufacturing, and expert engineering. Our Waveguide Cable Assembly solutions deliver uncompromising performance across the entire frequency spectrum, supporting critical applications in satellite communications, defense systems, and precision test equipment. With over two decades of manufacturing excellence and comprehensive quality assurance, we provide the reliability and performance that modern high-frequency applications demand.

Cooperate with Advanced Microwave Technologies Co., Ltd.

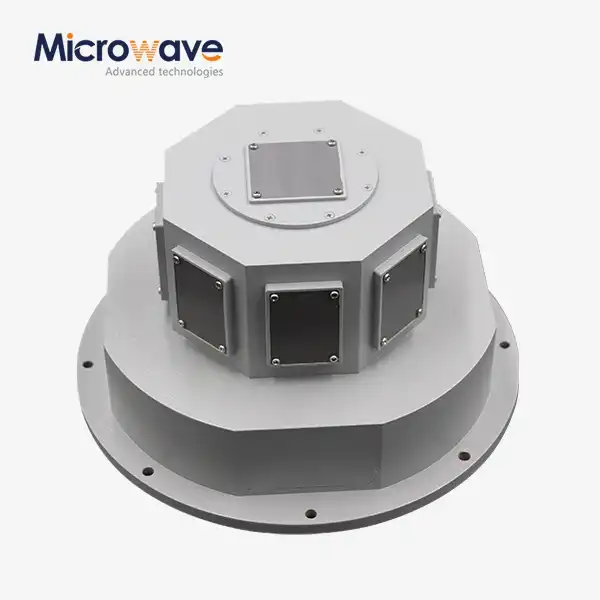

Advanced Microwave Technologies Co., Ltd stands as your trusted partner for high-performance Waveguide Cable Assembly solutions. Established in the 2000s, we bring over 20 years of specialized experience in microwave technology manufacturing. Our state-of-the-art 24m Microwave Darkroom facility enables precise testing across the full DC to 110 GHz frequency range, ensuring every product meets the highest performance standards.

As a leading China Waveguide Cable Assembly manufacturer and China Waveguide Cable Assembly supplier, we offer comprehensive OEM services with quick prototyping turnaround and expert technical support. Our China Waveguide Cable Assembly factory maintains ISO 9001:2015 and RoHS compliance, ensuring High Quality Waveguide Cable Assembly products for global markets. Whether you need Waveguide Cable Assembly for sale in standard configurations or require completely customized solutions, our engineering team provides competitive Waveguide Cable Assembly price quotes and China Waveguide Cable Assembly wholesale options to meet your specific requirements. Contact craig@admicrowave.com today to discuss your project needs and experience our exceptional service and technical expertise.

FAQ

Q: What frequency range do your Waveguide Cable Assemblies support?

A: Our assemblies operate from DC to 110 GHz, covering the complete spectrum for modern high-frequency applications.

Q: How do you ensure signal integrity across such a wide frequency range?

A: Through precision impedance matching, advanced materials selection, and rigorous quality control testing at every frequency point.

Q: Can you provide customized Waveguide Cable Assembly solutions?

A: Yes, we offer comprehensive OEM services with custom connectors, lengths, materials, and specifications tailored to your requirements.

Q: What quality certifications do your products maintain?

A: All products are ISO 9001:2015 certified and RoHS compliant, with full traceability and performance documentation provided.

References

1. "Microwave Engineering" by David M. Pozar - Comprehensive analysis of waveguide technology and signal integrity principles for high-frequency applications.

2. "RF and Microwave Engineering: Fundamentals of Wireless Communications" by Frank Gustrau - Detailed examination of cable assembly design and performance optimization techniques.

3. "High-Frequency Structure Simulator Design Guide" by Agilent Technologies Engineering Staff - Technical specifications and testing methodologies for precision RF assemblies.

4. "Waveguide Handbook" by Nathan Marcuvitz - Authoritative reference on waveguide theory, design principles, and practical implementation considerations.

YOU MAY LIKE

VIEW MORELog Periodic Antenna

VIEW MORELog Periodic Antenna VIEW MORESlotted Waveguide Array Antenna

VIEW MORESlotted Waveguide Array Antenna VIEW MOREOpen Boundary Dual Linear Polarization Four Ridged Horn Antenna

VIEW MOREOpen Boundary Dual Linear Polarization Four Ridged Horn Antenna VIEW MOREConical Dual circular Polarization Horn Antenna

VIEW MOREConical Dual circular Polarization Horn Antenna VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna

VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna VIEW MOREConical Linear Polarization Horn Antenna

VIEW MOREConical Linear Polarization Horn Antenna VIEW MOREPlanar Spiral Antenna

VIEW MOREPlanar Spiral Antenna