Double Ridged Coupler | Waveguide Couplers

When your high-frequency communication system demands precise signal monitoring without degrading transmission quality, choosing the right directional coupler becomes mission-critical. The Double-Ridged Waveguide Broadwall Directional Coupler represents a breakthrough solution for engineers struggling with bandwidth limitations, power handling constraints, and measurement accuracy in demanding microwave applications across satellite communications, defense radar systems, and aerospace platforms.

Understanding the Fundamentals of Double-Ridged Waveguide Broadwall Directional Couplers

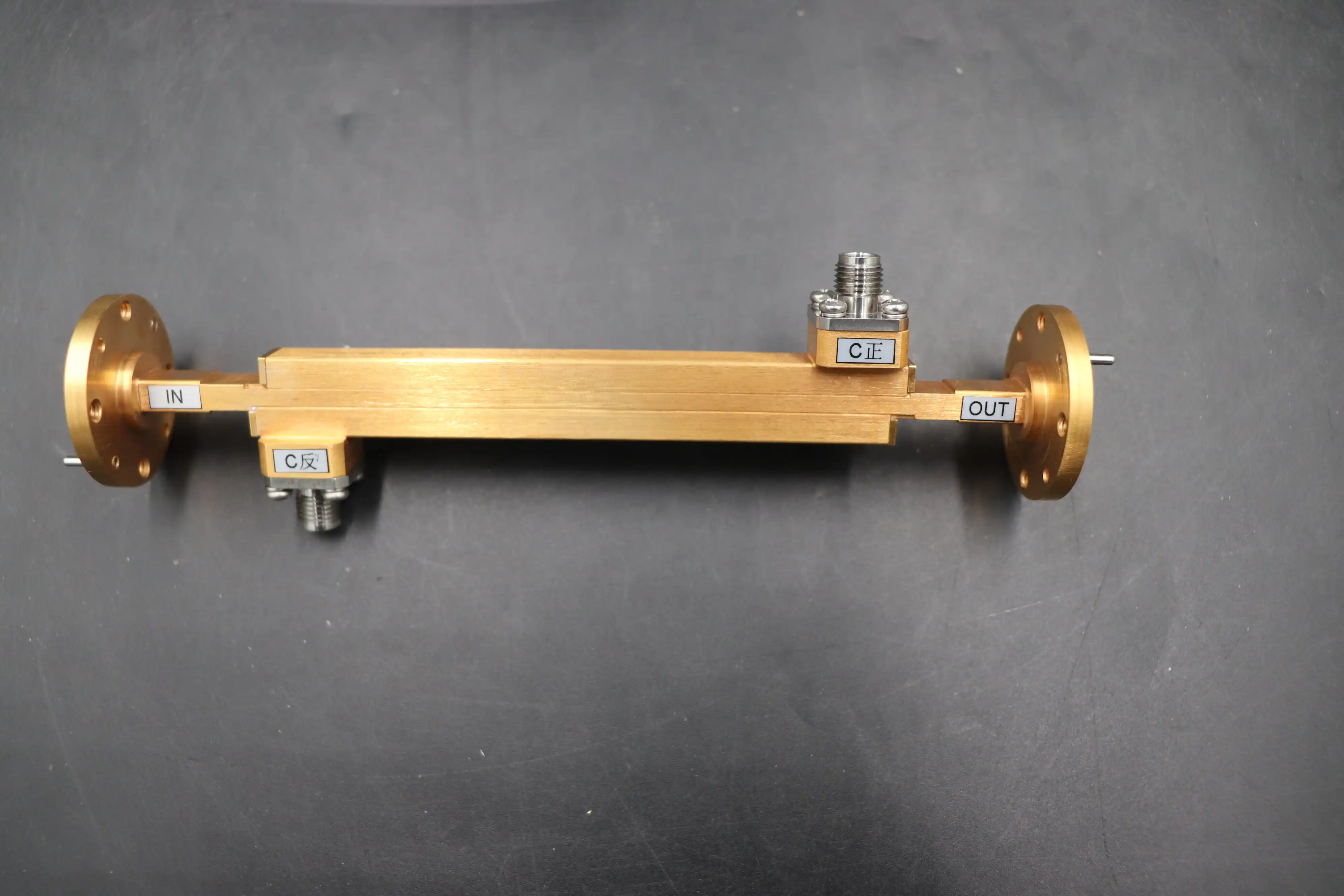

The Double-Ridged Waveguide Broadwall Directional Coupler stands as a sophisticated microwave component engineered with distinctive structural characteristics that set it apart from conventional waveguide solutions. This specialized device features two opposing ridge-like protrusions precisely machined into its broad wall, creating a unique electromagnetic field distribution that fundamentally alters wave propagation characteristics. When electromagnetic energy enters through one port, it travels along the double-ridge waveguide structure where the ridge geometry creates controlled coupling on the broad wall surface. During this propagation process, a carefully calculated portion of the electromagnetic wave couples to the secondary port through precisely designed coupling apertures, achieving directional signal transmission with exceptional precision. This coupling mechanism enables system designers to monitor transmitted power levels, perform signal sampling, and implement measurement protocols without disrupting the primary signal path or introducing significant insertion losses that would compromise system performance in bandwidth-intensive applications.

The engineering excellence behind Advanced Microwave Technologies' Double-Ridged Waveguide Broadwall Directional Coupler reflects over two decades of microwave expertise and continuous innovation in high-frequency component design. The company's specialized manufacturing capabilities leverage state-of-the-art precision machining, advanced electromagnetic simulation tools, and rigorous testing protocols within their remarkable 24-meter Microwave Darkroom facility. This expansive measurement environment enables comprehensive characterization of antenna radiation patterns, coupling flatness verification, and directivity measurements across the entire specified frequency range. Engineers at Advanced Microwave utilize sophisticated near-field and far-field measurement techniques through their Antenna Plane Near and Far Field Measuring Recombination Chamber, ensuring every Double-Ridged Waveguide Broadwall Directional Coupler meets stringent performance specifications before shipment. The testing infrastructure supporting these components spans from 0.5 GHz through 110 GHz, providing unparalleled verification capabilities that guarantee reliable performance in the most demanding operational environments where signal integrity cannot be compromised.

The Technical Architecture Driving Superior Performance

The structural design of the Double-Ridged Waveguide Broadwall Directional Coupler incorporates advanced electromagnetic principles that enable octave and multi-octave bandwidth performance unattainable with standard rectangular waveguide couplers. The ridge geometry reduces the cutoff frequency while maintaining compact physical dimensions, allowing broader frequency coverage without increasing waveguide size or weight. This characteristic proves invaluable for aerospace applications where every gram matters and for multi-band communication systems requiring a single component to serve multiple frequency allocations. The broad wall coupling technique employed in these directional couplers utilizes carefully positioned apertures or slots that extract a controlled fraction of the propagating electromagnetic energy. Advanced Microwave's design methodology ensures these coupling elements maintain consistent coupling coefficients across wide frequency ranges, typically achieving coupling flatness within plus or minus one decibel across octave bandwidths. This level of performance consistency enables accurate power monitoring in systems where signal levels vary dynamically, such as satellite transponders handling multiple carrier frequencies simultaneously or radar systems employing frequency-agile waveforms for improved target detection and tracking capabilities.

The mechanical construction of the Double-Ridged Waveguide Broadwall Directional Coupler emphasizes durability and environmental resilience through careful material selection and precision fabrication techniques. Advanced Microwave manufactures these components from high-grade aluminum alloys, stainless steel, or brass depending on application requirements, with all materials selected for excellent electrical conductivity, corrosion resistance, and mechanical stability across wide temperature ranges. The internal ridge structures undergo precision CNC machining to tolerances measured in micrometers, ensuring the critical dimensional accuracy required for predictable electromagnetic performance. Surface treatments including chromate conversion coatings, nickel plating, or specialized corrosion-resistant finishes protect the components during long-term deployment in harsh environments encountered in shipboard radar systems, ground-based satellite terminals, and airborne communication platforms. Flange interfaces feature precision-ground mating surfaces with standardized mounting patterns that facilitate seamless integration with existing waveguide infrastructure, reducing installation time and ensuring reliable electrical contact that minimizes reflections and maintains system voltage standing wave ratio specifications.

Key Performance Specifications and Technical Advantages

The Double-Ridged Waveguide Broadwall Directional Coupler delivers exceptional electrical performance across a comprehensive frequency spectrum spanning from 1 GHz through 40 GHz, accommodating legacy communication bands, modern cellular infrastructure frequencies, and emerging millimeter-wave applications. This extraordinarily wide bandwidth capability stems from the fundamental electromagnetic properties of the double-ridge waveguide structure, which supports propagation at frequencies significantly below the cutoff frequency of equivalently-sized rectangular waveguides. System designers benefit from this extended frequency range by implementing fewer coupler variants across multi-band installations, reducing inventory complexity, simplifying spare parts management, and accelerating field maintenance procedures when component replacement becomes necessary. The broad frequency coverage proves particularly valuable in software-defined radio architectures, spectrum monitoring systems, and research laboratories where experimental flexibility and rapid reconfiguration capability drive operational requirements and justify premium component specifications.

Advanced Microwave's Double-Ridged Waveguide Broadwall Directional Coupler excels in high-power applications through robust design elements that enable reliable operation at power levels reaching one kilowatt continuous wave and substantially higher peak power levels in pulsed radar applications. The generous internal dimensions of double-ridge waveguide structures provide increased surface area for current distribution compared to higher-frequency rectangular waveguides, reducing current density and minimizing resistive losses that would otherwise generate problematic heat accumulation. The coupling aperture design incorporates careful attention to field concentration effects, ensuring electric field intensities remain below breakdown thresholds even during maximum power transmission conditions. This high-power capability makes these directional couplers ideal for radar transmitter monitoring, where accurate measurement of multi-kilowatt output power enables precise system calibration, transmitter fault detection, and regulatory compliance verification. Defense applications particularly benefit from this power handling capacity, as military radar systems frequently operate at elevated power levels to achieve required detection ranges against low-radar-cross-section targets in electronically contested environments where jamming resistance and signal-to-noise ratio maximization prove operationally critical.

Insertion Loss Optimization and Signal Integrity Preservation

One of the most compelling advantages of the Double-Ridged Waveguide Broadwall Directional Coupler lies in its remarkably low insertion loss characteristics, typically measuring 0.5 decibels or less across the specified operating bandwidth. This minimal signal attenuation proves crucial in communication system budgets where every fraction of a decibel impacts link margins, maximum communication range, and data throughput capacity. In satellite ground station applications, where received signal levels arrive at the antenna already weakened by millions of kilometers of free-space path loss, preserving signal strength through low-loss components directly translates to improved bit error rates, higher-order modulation support, and increased revenue-generating bandwidth capacity. The low insertion loss stems from the efficient electromagnetic coupling mechanism employed in broad wall couplers, where energy extraction occurs through carefully designed apertures that minimize disruption to the primary signal path. Advanced Microwave's manufacturing precision ensures consistent insertion loss performance across production runs, with rigorous quality control procedures verifying electrical parameters on every unit before shipping to customers worldwide.

The directivity specification of the Double-Ridged Waveguide Broadwall Directional Coupler typically exceeds fifteen decibels, providing excellent discrimination between forward and reverse power flow directions. This directivity performance enables accurate standing wave measurements, reflected power monitoring, and transmitter-to-load mismatch detection in applications where antenna impedance varies with environmental conditions or mechanical pointing angles. High directivity proves particularly valuable in antenna measurement systems where precise characterization of radiation patterns requires discrimination between antenna-radiated signals and reflections from nearby structures or test equipment. Advanced Microwave's testing infrastructure includes comprehensive directivity verification across temperature ranges and throughout the specified frequency band, ensuring these critical parameters maintain specifications during actual field deployment conditions. The company's engineers provide detailed directivity versus frequency curves for each coupler model, empowering system designers with the detailed information necessary for accurate link budget calculations and measurement uncertainty analysis in precision test applications.

Strategic Applications Across Critical Industries

Satellite communication systems represent a primary application domain for the Double-Ridged Waveguide Broadwall Directional Coupler, where these components enable essential signal monitoring, power measurement, and system protection functions. In satellite ground stations, directional couplers sample transmitted signals for spectrum analyzer monitoring, enabling operators to verify modulation quality, carrier frequency accuracy, and spurious emission compliance with international telecommunications regulations. The broad bandwidth capability of double-ridge couplers allows single components to serve multiple transponder frequencies, simplifying ground station architecture and reducing equipment costs in multi-band facilities serving commercial, government, and military satellite constellations. Advanced Microwave's directional couplers support both uplink and downlink frequency bands used in C-band, X-band, Ku-band, and Ka-band satellite services, providing versatile solutions that accommodate the diverse frequency allocations employed in modern satellite communication networks spanning fixed satellite services, mobile satellite services, and emerging high-throughput satellite architectures delivering broadband connectivity to underserved geographic regions.

Defense and aerospace applications demand the most stringent performance specifications, and the Double-Ridged Waveguide Broadwall Directional Coupler meets these challenging requirements through military-qualified design, manufacturing, and testing procedures. Radar systems employ these couplers for transmitter power monitoring, enabling continuous verification of output power levels that directly impact detection range and tracking accuracy against hostile targets. The high directivity of these components allows radar systems to distinguish between transmitted power and reflected power from antenna mismatches, preventing false alarms and ensuring accurate threat assessment in complex electromagnetic environments. Electronic warfare systems utilize directional couplers for signal intercept, analysis, and countermeasure generation, where the wide bandwidth capability enables single-component coverage of multiple threat emitter frequency bands. Advanced Microwave's defense customers rely on the company's ISO 9001:2015 quality certification and rigorous configuration management procedures to ensure consistent performance and long-term availability of replacement components supporting weapons systems with multi-decade operational lifespans that extend far beyond typical commercial product cycles.

Telecommunications Infrastructure and 5G Network Deployment

Modern telecommunications infrastructure increasingly incorporates Double-Ridged Waveguide Broadwall Directional Couplers in base station architectures, particularly in millimeter-wave 5G deployments where high-frequency signal distribution requires precise power division and monitoring capabilities. The directional couplers enable base station monitoring systems to verify transmitter output power across multiple antenna sectors, ensuring regulatory compliance and optimal network coverage patterns. In distributed antenna systems serving large venues, shopping centers, and transportation hubs, these couplers facilitate signal splitting and combining operations that distribute cellular signals throughout coverage areas while maintaining signal quality and minimizing interference between sectors. The low insertion loss characteristic of Advanced Microwave's directional couplers preserves precious transmitter power in spectrum-efficient 5G networks where massive MIMO antenna arrays, beamforming techniques, and carrier aggregation strategies demand maximum power efficiency to achieve the promised multi-gigabit data rates and ultra-low latency performance that enable transformative applications including autonomous vehicles, remote surgery, and immersive augmented reality experiences.

Research and development laboratories utilize Double-Ridged Waveguide Broadwall Directional Couplers extensively in antenna measurement systems, material characterization equipment, and communications protocol development testbeds. The broad bandwidth and precise coupling characteristics enable researchers to conduct sweeping frequency measurements without repeatedly changing test equipment configurations, accelerating experimental procedures and improving measurement repeatability. Universities and corporate research facilities rely on these components when developing next-generation wireless technologies, studying electromagnetic propagation phenomena, and validating simulation models against measured data. Advanced Microwave supports the research community through customized coupler designs accommodating unique frequency ranges, specialized coupling factors, and custom flange configurations that facilitate integration with existing test setups. The company's engineering team collaborates with researchers to develop innovative solutions addressing emerging measurement challenges in fields including millimeter-wave imaging, automotive radar development, and wireless power transfer systems that push the boundaries of electromagnetic engineering knowledge and commercial technology capabilities.

Customization Capabilities and OEM Service Excellence

Advanced Microwave Technologies Co., Ltd. recognizes that demanding applications often require specialized component specifications beyond standard catalog offerings, and the company's comprehensive OEM services provide tailored solutions meeting unique system requirements. Custom frequency range development allows customers to specify directional couplers optimized for proprietary frequency allocations, experimental spectrum bands, or multi-band applications requiring specific coupling characteristics at discrete frequency points. The engineering team employs advanced electromagnetic simulation tools including full-wave finite element analysis and method-of-moments solvers to design coupling structures achieving target performance specifications while maintaining manufacturability and cost effectiveness. Custom coupling factor selection enables precise power sampling ratios ranging from loose coupling at 60 decibels for high-power transmitter monitoring down to tight coupling at 10 decibels for signal distribution applications requiring substantial power extraction from the main transmission line. Advanced Microwave's design flexibility extends to physical dimensions, allowing scaled couplers accommodating installation envelope constraints in space-limited equipment racks or providing extended coupling sections for applications requiring exceptionally flat coupling response across ultra-wide frequency spans.

Material selection customization addresses specific environmental requirements including extreme temperature ranges encountered in arctic installations and desert deployments, corrosive maritime atmospheres aboard naval vessels, and high-altitude aerospace applications where pressure differentials and ultraviolet exposure challenge conventional materials. Advanced Microwave works with customers to select optimal materials balancing electrical performance, mechanical properties, corrosion resistance, and weight constraints specific to each application domain. Specialized surface finishes including gold plating for low passive intermodulation in sensitive receiver applications, nickel plating for enhanced corrosion protection in marine environments, and conductive coating for electromagnetic interference shielding in densely packaged electronic warfare systems demonstrate the company's capability to address diverse operational requirements. The OEM services extend to connector selection and placement, accommodating customer preferences for N-type, SMA, precision millimeter connectors, or WR-series waveguide flanges at coupling ports. Advanced Microwave maintains extensive connector inventories and established relationships with leading connector manufacturers, ensuring rapid prototyping and production of customized configurations meeting delivery schedules that align with customer project timelines and system integration milestones.

Rapid Prototyping and Production Scalability

Advanced Microwave's prototyping services enable rapid design iteration and performance verification before committing to volume production, reducing development risk and accelerating time-to-market for customers developing innovative microwave systems. The company's engineering team provides design consultation services helping customers define optimal coupler specifications based on system requirements, installation constraints, and performance priorities. Initial electromagnetic simulations predict electrical performance and identify potential design challenges before fabrication begins, while the company's extensive measurement capabilities enable comprehensive prototype characterization including frequency response, directivity, voltage standing wave ratio, and power handling verification. Customers receive detailed test reports documenting prototype performance against specifications, providing confidence in design maturity and supporting internal design reviews and customer acceptance procedures. The rapid turnaround on prototype fabrication, typically measured in weeks rather than months, enables agile development methodologies where iterative design refinement produces optimized solutions addressing challenging application requirements that exceed off-the-shelf component capabilities.

Production scalability represents another strength of Advanced Microwave's manufacturing infrastructure, with flexible capacity supporting order quantities ranging from small-batch custom productions for specialized defense programs through high-volume manufacturing serving telecommunications equipment integrators. The company's quality management system compliant with ISO 9001:2015 standards ensures consistent manufacturing processes, rigorous inspection procedures, and comprehensive traceability documentation that satisfies customer quality requirements and supports long-term product support obligations. Advanced manufacturing equipment including multi-axis CNC machining centers, automated inspection systems, and environmentally controlled assembly areas enables efficient production of complex waveguide components while maintaining the tight tolerances necessary for predictable electromagnetic performance. The company's supply chain management ensures reliable availability of materials and components even during periods of market constraint, protecting customers from disruptions that could jeopardize project schedules or operational readiness. Advanced Microwave's commitment to delivery excellence, demonstrated through consistent on-time shipment performance and proactive communication of schedule status, establishes the company as a dependable partner for critical programs where delays carry significant operational or financial consequences.

Ensuring Quality Through Comprehensive Testing and Certification

Advanced Microwave Technologies Co., Ltd. maintains an unwavering commitment to quality assurance through comprehensive testing protocols that verify electrical performance, mechanical integrity, and environmental resilience of every Double-Ridged Waveguide Broadwall Directional Coupler produced. The company's state-of-the-art 24-meter Microwave Darkroom provides an ideal environment for precise antenna and component measurements free from external interference and multipath reflections that compromise measurement accuracy in conventional test facilities. This specialized chamber enables far-field antenna pattern measurements, coupling flatness characterization across wide frequency spans, and directivity verification under controlled environmental conditions replicating operational deployment scenarios. The testing infrastructure includes vector network analyzers calibrated to national standards, power meters with traceable accuracy, and specialized measurement fixtures designed to minimize measurement uncertainty and ensure results reflect true component performance rather than test setup artifacts that could mask design deficiencies or manufacturing variations.

The comprehensive certification portfolio held by Advanced Microwave Technologies demonstrates the company's commitment to international quality standards and environmental responsibility. ISO 9001:2015 certification validates the company's quality management system, encompassing all aspects of operations from initial customer inquiry through product design, manufacturing, testing, and after-sales support. This certification provides customers with confidence that documented procedures govern all activities affecting product quality, with regular internal audits and management reviews ensuring continuous improvement and consistent adherence to quality objectives. ISO 14001:2015 environmental management system certification underscores the company's dedication to minimizing environmental impact through responsible waste management, energy conservation, and emissions reduction initiatives integrated throughout manufacturing operations. This environmental stewardship aligns with the sustainability objectives of customers in industries including telecommunications and aerospace where corporate responsibility initiatives increasingly influence procurement decisions and supplier selection criteria. ISO 45001:2018 occupational health and safety certification demonstrates the company's concern for employee wellbeing through comprehensive safety programs, training initiatives, and workplace hazard identification procedures that create a secure working environment fostering employee engagement and operational excellence.

Conclusion

The Double-Ridged Waveguide Broadwall Directional Coupler delivers unmatched performance for demanding microwave applications requiring broad bandwidth, high power handling, and exceptional signal integrity preservation. Advanced Microwave Technologies' expertise ensures reliable solutions for satellite communications, defense systems, aerospace platforms, and telecommunications infrastructure where precision and dependability prove mission-critical.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands ready as your trusted China Double-Ridged Waveguide Broadwall Directional Coupler manufacturer, China Double-Ridged Waveguide Broadwall Directional Coupler supplier, and China Double-Ridged Waveguide Broadwall Directional Coupler factory offering premium Double-Ridged Waveguide Broadwall Directional Coupler for sale at competitive Double-Ridged Waveguide Broadwall Directional Coupler price points. Our China Double-Ridged Waveguide Broadwall Directional Coupler wholesale options and High Quality Double-Ridged Waveguide Broadwall Directional Coupler inventory serve global customers with rapid delivery, comprehensive OEM customization, and expert engineering support backed by ISO certifications and over twenty years of microwave expertise. Contact craig@admicrowave.com today to discuss your specific requirements and experience the Advanced Microwave advantage through our perfect supply chain system, professional R&D capabilities, and strong after-sales support ensuring your project success.

References

1. Matthaei, George L., Young, Leo, and Jones, E.M.T. "Microwave Filters, Impedance-Matching Networks, and Coupling Structures." Artech House Books, 1980.

2. Levy, Ralph and Cohn, Seymour B. "A History of Microwave Filter Research, Design, and Development." IEEE Transactions on Microwave Theory and Techniques, Volume 32, Issue 9, 1984.

3. Pozar, David M. "Microwave Engineering." Fourth Edition, John Wiley & Sons, 2011.

4. Collin, Robert E. "Foundations for Microwave Engineering." Second Edition, IEEE Press Series on Electromagnetic Wave Theory, 2001.