Waveguide Fixed Attenuators: High-Power RF Solutions

In high-frequency microwave systems, engineers constantly face a critical challenge: how to precisely control signal strength without introducing distortion, excessive noise, or system instability—especially when dealing with high-power applications that can reach kilowatt levels. Whether you're designing a satellite ground station that must maintain signal integrity across millions of miles, developing radar systems for defense applications, or calibrating precision measurement equipment in research laboratories, the wrong attenuation solution can lead to equipment damage, signal degradation, and costly system failures. This is where the Waveguide Fixed Attenuator becomes an indispensable component, offering engineers a reliable, high-power solution that maintains consistent performance across broad frequency ranges while withstanding the demanding conditions of modern RF applications.

Understanding Waveguide Fixed Attenuator Technology

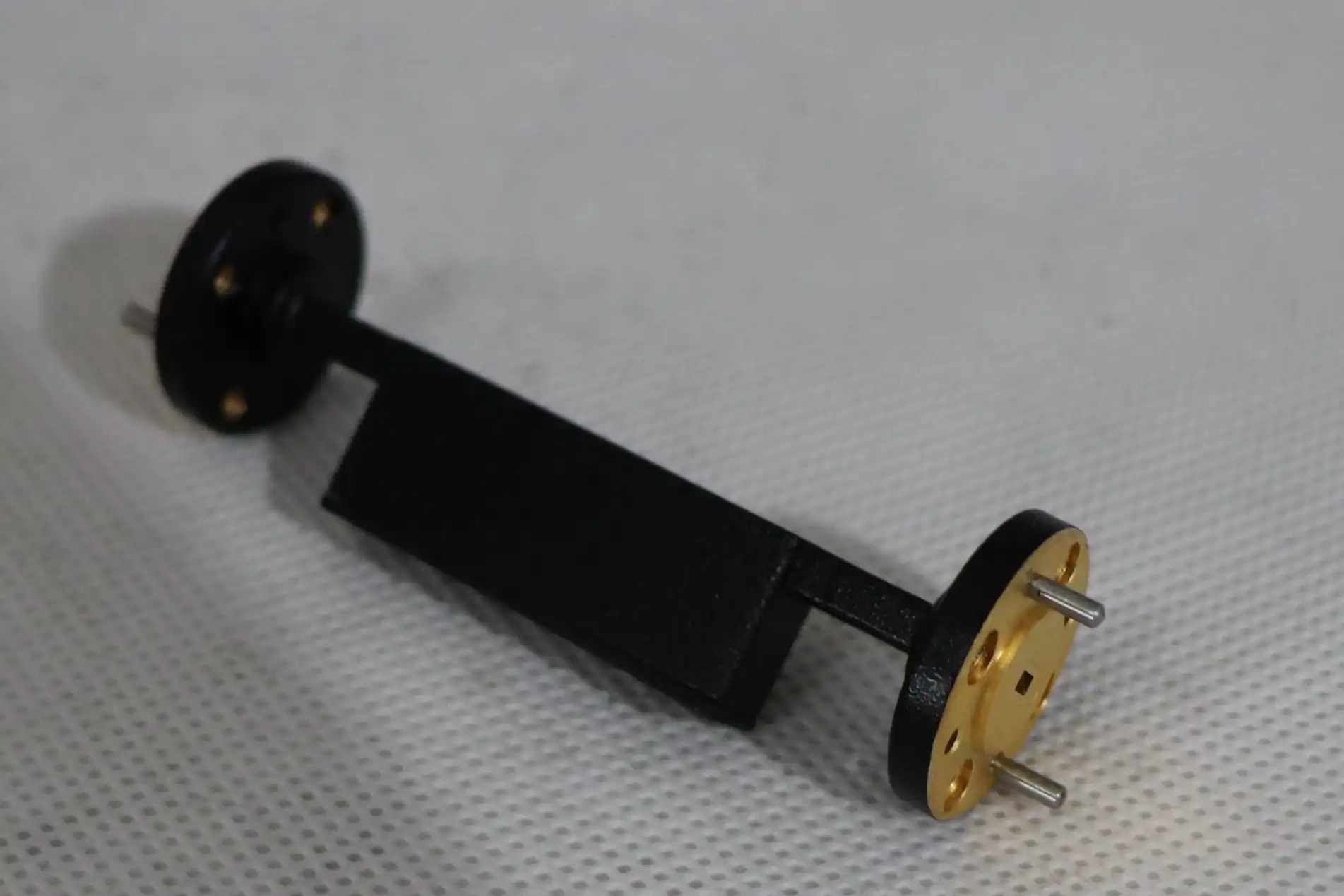

The Waveguide Fixed Attenuator represents a sophisticated solution in microwave engineering, designed specifically to reduce signal power levels in a controlled and predictable manner without compromising signal quality. Unlike coaxial attenuators that face power handling limitations and thermal management challenges, waveguide-based designs leverage the inherent advantages of rectangular waveguide structures to manage high-power RF signals effectively. The fundamental operating principle involves introducing precisely calibrated resistive elements within the waveguide structure, which absorb electromagnetic energy in a controlled fashion while maintaining the characteristic impedance of the transmission line. The engineering excellence behind these components lies in their construction methodology. Advanced manufacturing techniques position precision-engineered absorbing elements at optimal locations within the waveguide cross-section, ensuring uniform attenuation across the operating bandwidth while minimizing reflections and standing wave ratios. These absorbing materials are carefully selected for their thermal stability, power handling capabilities, and consistent electrical properties across temperature variations. The result is a passive component that delivers reliable performance in environments ranging from cryogenic research facilities to high-temperature aerospace applications.

Key Performance Parameters

When evaluating waveguide fixed attenuator performance, several critical parameters determine system compatibility and operational reliability. Voltage Standing Wave Ratio (VSWR) serves as a primary indicator of impedance matching quality—low VSWR values below 1.10:1 across the operating bandwidth ensure minimal signal reflection and maximum power transfer efficiency. Attenuation accuracy represents another crucial specification, with precision attenuators maintaining tolerances within ±0.1 dB or 1% of the nominal value. Power handling capacity varies significantly based on construction methodology and materials selection, with standard units accommodating average power levels from hundreds of milliwatts to several watts, while specialized high-power variants can withstand continuous power levels exceeding 100 watts and peak powers reaching kilowatt ranges. Frequency response characteristics define the operational envelope for specific applications. The Waveguide Fixed Attenuator must maintain consistent attenuation values across the entire specified frequency band, typically covering 10% to 40% fractional bandwidth depending on the waveguide size and design approach. Temperature stability becomes particularly critical in outdoor installations and aerospace applications, where ambient conditions can vary dramatically. Premium attenuators incorporate temperature-compensated materials and mechanical designs that maintain electrical performance across temperature ranges from -55°C to +85°C or wider.

Applications Across Critical Industries

Satellite Communication Systems

In satellite communication infrastructure, the Waveguide Fixed Attenuator plays an essential role in both ground station equipment and payload systems. Ground station operators utilize these components to protect sensitive low-noise amplifiers (LNAs) from excessive signal levels during antenna pointing operations or when tracking satellites at close approach distances. The high-power handling capability becomes crucial in transmit chains, where attenuators enable precise output power adjustment without forcing expensive high-power amplifiers to operate in backed-off conditions that compromise efficiency. Uplink power control systems incorporate waveguide attenuators to compensate for atmospheric variations and ensure compliant EIRP (Effective Isotropic Radiated Power) levels. During rain fade conditions, operators can bypass attenuation to maintain link margins, while clear-sky conditions require precise power reduction to avoid satellite transponder saturation. The reliability and repeatability of Waveguide Fixed Attenuator performance directly impacts communication quality and operational costs, as unstable attenuation characteristics could necessitate frequent system recalibration or emergency maintenance interventions.

Aerospace and Defense Applications

Military radar systems demand uncompromising performance from every component, and waveguide attenuators are no exception. High-power surveillance radars operating in X-band and Ku-band frequencies utilize these components for calibration procedures, receiver protection, and signal chain optimization. The ability to withstand high peak power levels while maintaining low insertion loss and excellent return loss characteristics makes the Waveguide Fixed Attenuator ideally suited for pulsed radar applications where instantaneous power levels can reach megawatt ranges. Electronic warfare systems incorporate precision attenuators in signal processing chains for threat emulation and countermeasure development. Test ranges and evaluation facilities rely on calibrated waveguide attenuators to create realistic electromagnetic environments for system validation. The rugged construction and environmental sealing capabilities of military-grade attenuators ensure reliable operation in aircraft, shipboard, and ground mobile platforms subject to shock, vibration, temperature extremes, and humidity exposure.

Telecommunications Infrastructure

Modern telecommunications networks, particularly those supporting 5G deployment and future 6G development, require sophisticated test and measurement capabilities. The Waveguide Fixed Attenuator enables accurate characterization of base station components, antenna systems, and backhaul equipment operating at millimeter-wave frequencies. Network operators utilize these components in interference testing scenarios, where precise signal level control is essential for validating receiver selectivity and dynamic range specifications. Fiber-optic system manufacturers employ waveguide attenuators in the development of radio-over-fiber solutions that extend wireless coverage into buildings, tunnels, and remote locations. The low VSWR characteristics minimize signal distortion in these complex hybrid systems, while the broad frequency coverage accommodates multi-band and carrier aggregation scenarios. As telecommunications continue evolving toward higher frequencies and wider bandwidths, the role of precision waveguide components becomes increasingly critical for ensuring network performance and reliability.

Technical Specifications and Performance Advantages

Precision Engineering and Manufacturing Quality

Advanced Microwave Technologies Co., Ltd. manufactures Waveguide Fixed Attenuator solutions using state-of-the-art fabrication processes that ensure consistent electrical performance and mechanical reliability. The product portfolio encompasses rectangular waveguide sizes from WR-650 through WR-28, covering frequency ranges from below 1 GHz to beyond 110 GHz. Standard attenuation values include 3dB, 6dB, 10dB, 20dB, and 30 dB configurations, with custom attenuation levels available for specialized applications requiring non-standard specifications. The assembled construction incorporates precision resistive elements positioned for optimal electrical performance through computer-aided electromagnetic simulation and empirical testing. Manufacturing processes maintain tight dimensional tolerances on waveguide cross-sections and flange mounting surfaces, ensuring excellent mate-ability with standard waveguide components and minimal insertion loss variation between units. Quality control procedures include full electrical characterization across the operating frequency range, with data recorded and supplied with each shipped unit for customer verification and system integration purposes.

Material Selection and Thermal Management

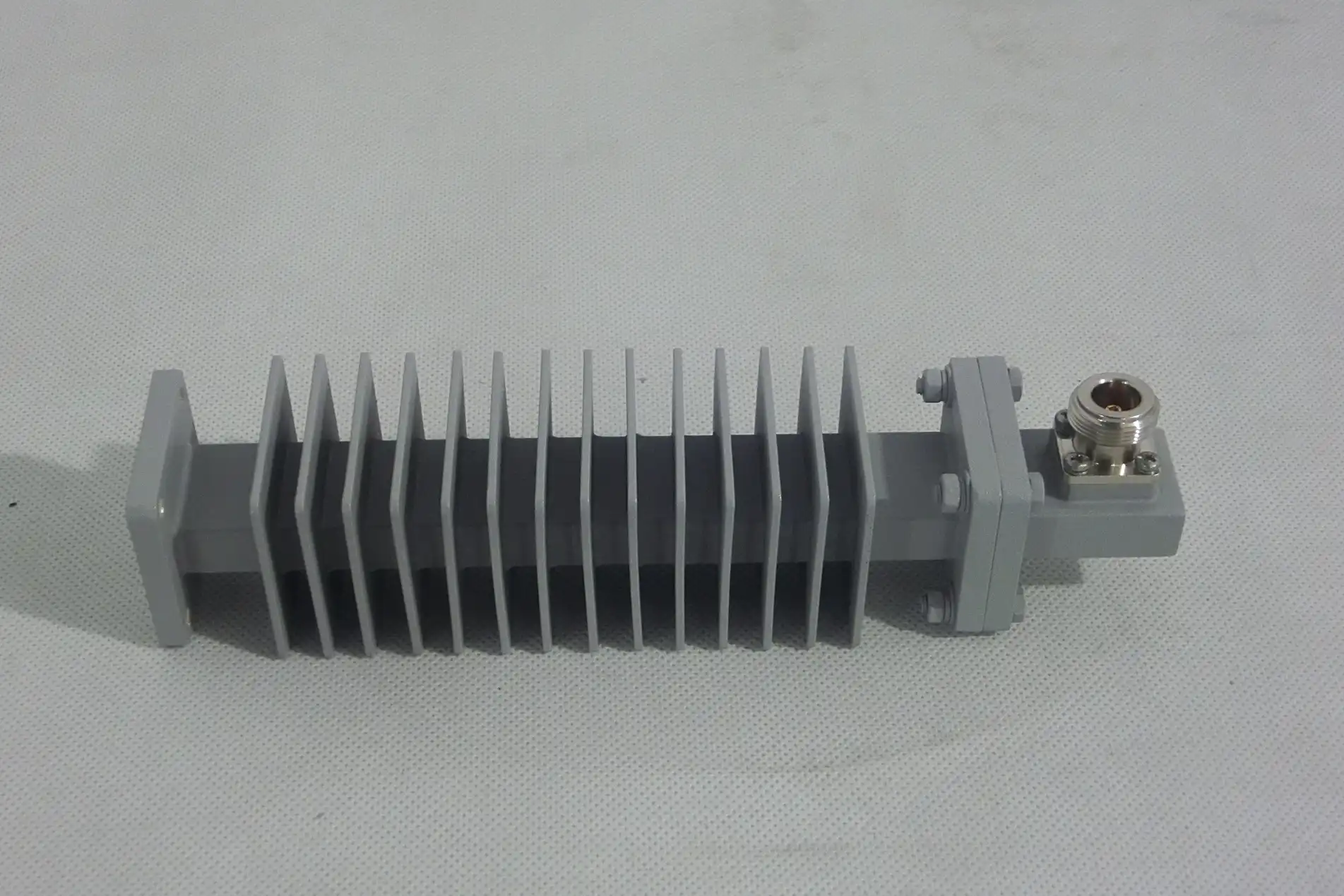

High-power Waveguide Fixed Attenuator designs require careful material selection to ensure long-term reliability under demanding operating conditions. The resistive elements utilize advanced ceramics and metal composites engineered for stable electrical properties across wide temperature ranges and high dissipated power levels. Waveguide body construction employs aluminum alloys for weight-sensitive aerospace applications or copper alloys where maximum thermal conductivity and electromagnetic shielding are priorities. Surface treatments including silver plating reduce ohmic losses and prevent corrosion in harsh environmental conditions. Thermal management becomes particularly critical in high-power applications where significant RF energy converts to heat within the attenuator structure. Advanced designs incorporate heat sinking features, mounting interfaces compatible with forced-air or liquid cooling systems, and thermal monitoring provisions for temperature-sensitive installations. The compact design philosophy ensures easy integration into crowded equipment layouts while maintaining adequate thermal dissipation pathways. These thermal considerations enable continuous operation at rated power levels without performance degradation or accelerated aging effects that could compromise system reliability.

Customization and OEM Services

Tailored Solutions for Unique Requirements

Advanced Microwave Technologies Co., Ltd. recognizes that many applications require customized specifications beyond standard catalog offerings. Our engineering team collaborates with customers to develop China Waveguide Fixed Attenuator solutions optimized for specific frequency bands, power levels, mechanical interfaces, and environmental conditions. The customization process begins with detailed technical discussions to understand application requirements, followed by electromagnetic simulation and mechanical design activities that result in optimized component configurations. Rapid prototyping capabilities enable quick turnaround on development units for customer evaluation and system integration testing. This iterative approach ensures that final production units meet all performance specifications and interface requirements before committing to volume manufacturing. As a leading China Waveguide Fixed Attenuator manufacturer, we maintain flexible production capabilities that accommodate both small-quantity specialized requirements and large-volume programs requiring consistent quality across thousands of units. Our China Waveguide Fixed Attenuator factory operates under ISO 9001:2015 quality management systems that ensure process control and continuous improvement initiatives.

Comprehensive Technical Support

From initial design consultation through product lifetime, Advanced Microwave Technologies Co., Ltd. provides comprehensive technical support services. Our experienced RF engineers assist with component selection, system integration guidance, and troubleshooting support when unexpected challenges arise during development or deployment phases. Installation documentation includes detailed mechanical drawings, electrical specifications, handling procedures, and application notes that facilitate successful integration into customer systems. For high-volume programs, we offer dedicated engineering resources, customized testing protocols, and supply chain management services that ensure on-time delivery and consistent quality. As a trusted China Waveguide Fixed Attenuator supplier, we understand the critical importance of reliable component availability and performance consistency in mission-critical applications. Our China Waveguide Fixed Attenuator wholesale programs provide cost-effective solutions for OEM customers requiring multiple component types across various frequency bands and specifications, with volume pricing structures that support competitive system-level economics.

Conclusion

Waveguide Fixed Attenuators deliver unmatched performance for high-power RF applications requiring precision signal control, reliability, and broad frequency coverage. These essential components enable engineers to optimize system performance across satellite communications, aerospace defense, telecommunications, and research environments while maintaining signal integrity and protecting sensitive equipment from damage.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Partner with Advanced Microwave Technologies Co., Ltd., your premier China Waveguide Fixed Attenuator factory with over 20 years of microwave component expertise. Our ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certified manufacturing facilities feature advanced measurement capabilities up to 110 GHz, including our remarkable 24m Microwave Darkroom for precise antenna and component characterization. As a leading China Waveguide Fixed Attenuator supplier and China Waveguide Fixed Attenuator manufacturer, we offer High Quality Waveguide Fixed Attenuator solutions at competitive Waveguide Fixed Attenuator prices, with extensive Waveguide Fixed Attenuator for sale inventory and rapid prototyping services. Our perfect supply chain system, professional R&D team, strict quality control, and strong after-sales support ensure your project succeeds. Contact craig@admicrowave.com today for customized solutions, technical specifications, and pricing information—bookmark this resource for future reference when RF challenges arise!

References

1. Rizzi, Peter A. "Microwave Engineering: Passive Circuits." Prentice Hall, 1988.

2. Pozar, David M. "Microwave Engineering, 4th Edition." John Wiley & Sons, 2011.

3. Saad, Theodore S. "Microwave Engineers' Handbook, Volume 1." Artech House Publishers, 1971.

4. Baden Fuller, A.J. "An Introduction to Microwave Theory and Techniques, 2nd Edition." Pergamon Press, 1979.

YOU MAY LIKE

VIEW MOREDouble Ridge Straight Waveguide

VIEW MOREDouble Ridge Straight Waveguide VIEW MOREDouble Ridge Waveguide Transition

VIEW MOREDouble Ridge Waveguide Transition VIEW MOREDouble Ridged Flexible Waveguide

VIEW MOREDouble Ridged Flexible Waveguide VIEW MOREDouble Ridge Waveguide Load

VIEW MOREDouble Ridge Waveguide Load VIEW MOREDouble Ridge Waveguide Rotary Joint

VIEW MOREDouble Ridge Waveguide Rotary Joint VIEW MOREDouble-Ridged Waveguide Broadwall Directional Coupler

VIEW MOREDouble-Ridged Waveguide Broadwall Directional Coupler VIEW MOREWaveguide Flange Gasket

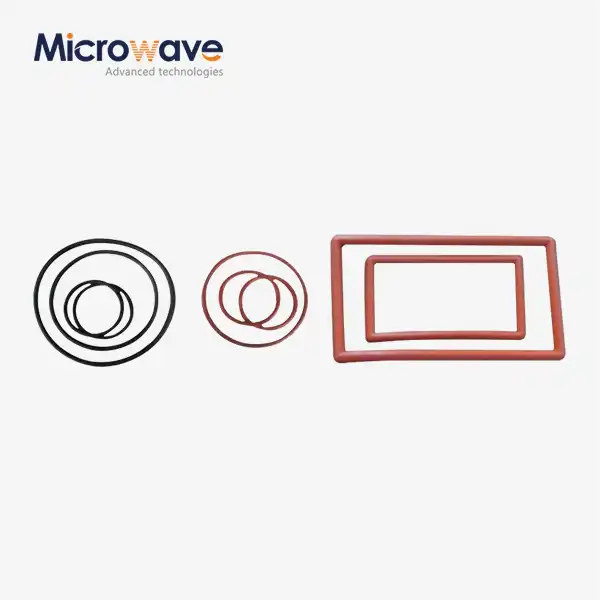

VIEW MOREWaveguide Flange Gasket VIEW MOREWaveguide Adjustable Support

VIEW MOREWaveguide Adjustable Support