Custom Waveguide to Coax Adapters | Get Multiple Quotes

When your microwave system experiences signal degradation, impedance mismatches, or installation delays due to incompatible waveguide-to-coaxial transitions, you face more than just technical challenges—you risk project timelines, budget overruns, and system performance failures. Finding the right Custom Waveguide to Coaxial Adapter that meets your exact specifications across frequency bands, power handling, and environmental requirements demands precision engineering and trusted manufacturing partners. This comprehensive guide addresses these critical pain points by exploring how custom solutions deliver seamless signal transitions, helping you navigate specifications, applications, and supplier selection to ensure your RF system operates at peak performance without compromise.

Understanding Custom Waveguide to Coaxial Adapter Technology

The Critical Role of Precision Signal Transitions

In modern microwave and radio frequency systems, the Custom Waveguide to Coaxial Adapter serves as the essential interface between two fundamentally different transmission mediums. Waveguides excel at handling high-power signals with minimal loss at microwave frequencies, while coaxial cables offer flexibility and ease of integration with standard RF equipment. The challenge lies in bridging these technologies without introducing signal reflections, insertion loss, or impedance discontinuities that compromise system performance. A well-engineered Custom Waveguide to Coaxial Adapter addresses this challenge through precise mechanical design, careful material selection, and rigorous electromagnetic field matching at the transition point. Engineers must consider mode conversion, where the dominant TE10 mode in rectangular waveguides transforms into the TEM mode of coaxial transmission lines, requiring sophisticated probe positioning and geometry optimization.

Frequency Coverage and Bandwidth Considerations

The operating frequency range represents one of the most critical specifications when selecting a Custom Waveguide to Coaxial Adapter. Different waveguide sizes correspond to specific frequency bands, from WR-650 covering 1.12 to 1.70 GHz for lower microwave applications, up to WR-10 operating at 75 to 110 GHz for millimeter-wave systems. Advanced Microwave Technologies Co., Ltd. offers Custom Waveguide to Coaxial Adapter solutions spanning 0.5 to 110 GHz, accommodating everything from legacy L-band satellite systems to cutting-edge W-band communications. The frequency response must remain flat across the entire operational bandwidth, with insertion loss typically maintained below 0.3 dB for standard adapters and even lower for precision laboratory-grade units. Their ADM-100WCAST21 model demonstrates this capability with a narrow 9.32 to 9.42 GHz frequency range, maximum VSWR of 1.1, and insertion loss not exceeding 0.15 dB, making it ideal for X-band applications requiring exceptional signal integrity.

Key Specifications and Performance Parameters

Electrical Performance Metrics That Matter

When evaluating Custom Waveguide to Coaxial Adapter options, several electrical parameters directly impact system performance. Voltage Standing Wave Ratio (VSWR) indicates how well the impedance is matched at the transition point, with lower values representing better performance. High-quality Custom Waveguide to Coaxial Adapter designs achieve VSWR values below 1.2 across full waveguide bands, while precision laboratory units can reach 1.05 or better. Insertion loss measures signal power dissipated within the adapter due to conductor losses and dielectric absorption, typically ranging from 0.1 to 0.5 dB depending on frequency and design complexity. Return loss, the inverse measurement of reflected power, should exceed 20 dB for reliable operation. Power handling capability varies significantly based on adapter configuration, connector type, and cooling provisions, ranging from a few watts for small coaxial connectors to hundreds of watts for specialized high-power designs with enhanced thermal management features.

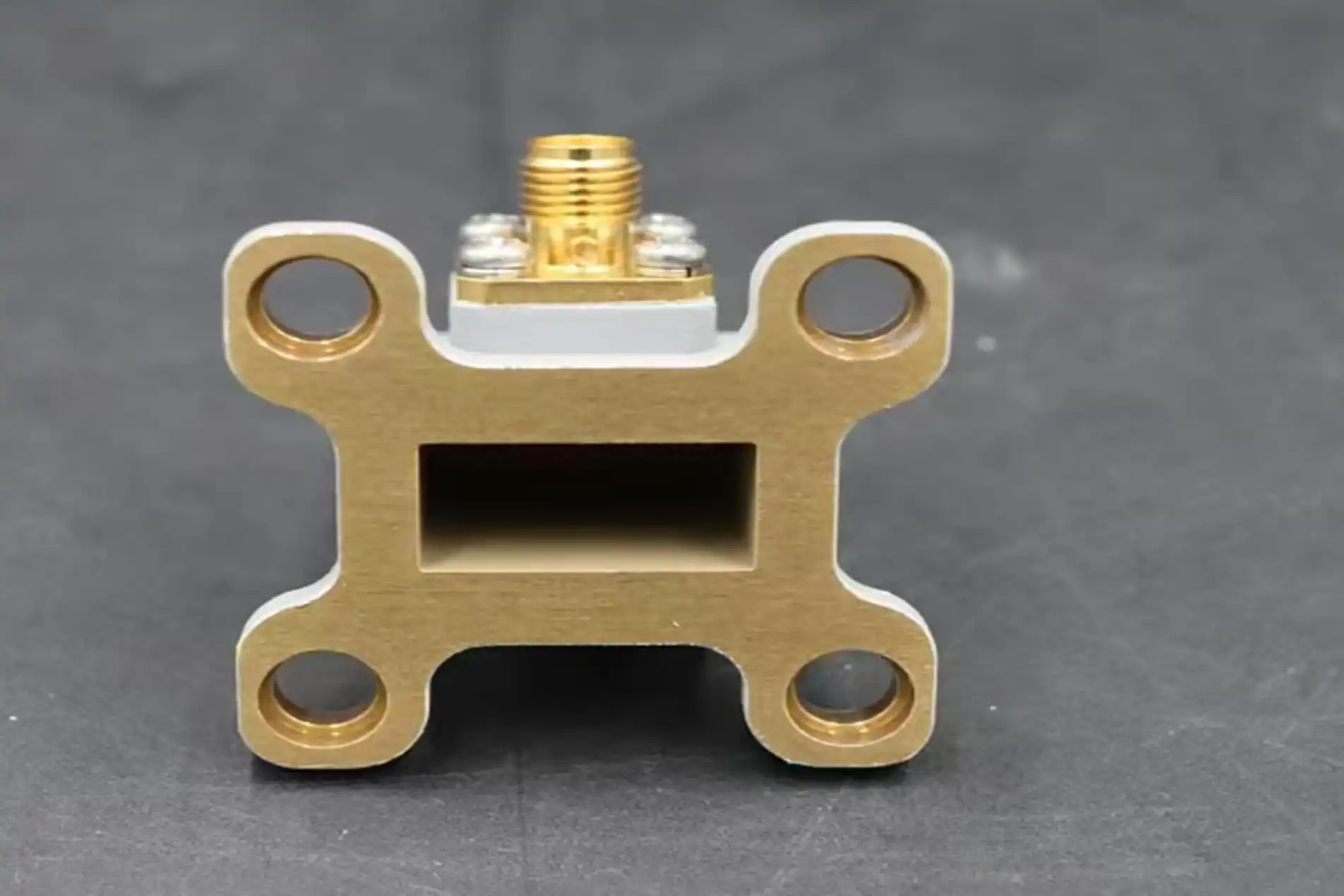

Mechanical Design and Interface Compatibility

The mechanical aspects of a Custom Waveguide to Coaxial Adapter prove equally critical as electrical performance. Waveguide flange options include standard types such as UG-style flanges, British Rectangular flanges, and custom mounting configurations tailored to specific installation requirements. The coaxial connector selection depends on frequency range and power handling needs, with N-type connectors dominating below 18 GHz, SMA connectors extending to 26.5 GHz, and precision 2.92mm or 2.4mm connectors reaching millimeter-wave frequencies. Material selection impacts both electrical performance and environmental durability, with copper providing excellent conductivity, aluminum offering weight reduction, and brass or stainless steel delivering enhanced corrosion resistance. Advanced Microwave Technologies Co., Ltd. constructs their Custom Waveguide to Coaxial Adapter products using copper bodies with silver plating on interior surfaces to minimize ohmic losses, while exterior surfaces receive anticorrosion grey paint for protection in harsh deployment environments.

Application Scenarios Across Industries

Communication Systems and Wireless Infrastructure

Custom Waveguide to Coaxial Adapter components play indispensable roles in modern communication infrastructure. In 5G base stations, these adapters enable efficient signal transfer between high-power transmitters operating through waveguide distribution networks and antenna elements fed via coaxial cables, maintaining signal integrity across frequencies ranging from 24 to 39 GHz. Satellite communication ground stations rely on Custom Waveguide to Coaxial Adapter interfaces to connect large reflector antennas, which naturally integrate with waveguide feeds, to receiver front-ends and signal processing equipment using standard coaxial interfaces. This transition must preserve the extremely low noise figures required for detecting weak signals from satellites positioned in geostationary orbit over 35,000 kilometers away. Advanced Microwave Technologies Co., Ltd. supports these applications through custom designs that accommodate specific frequency plans, polarization requirements, and environmental specifications demanded by commercial and military satellite operators worldwide.

Aerospace, Defense, and Radar Applications

Military and aerospace applications impose the most stringent requirements on Custom Waveguide to Coaxial Adapter performance. Airborne radar systems require lightweight, compact adapters that withstand extreme vibration, temperature cycling from minus 55 to plus 125 degrees Celsius, and altitude-induced pressure variations while maintaining electrical specifications without degradation. Defense surveillance radars employ Custom Waveguide to Coaxial Adapter arrays to interface waveguide distribution networks feeding phased array antennas with digital beamforming receivers, demanding exceptional amplitude and phase stability across adjacent channels to enable accurate target tracking and identification. Aircraft collision avoidance systems, weather radar installations, and ground-based air traffic control radars all depend on reliable waveguide-to-coaxial transitions. Advanced Microwave Technologies Co., Ltd. addresses these demanding applications through rigorous environmental testing, including vibration profiles matching MIL-STD-810, thermal cycling, and salt fog exposure, ensuring their Custom Waveguide to Coaxial Adapter products meet aerospace and defense qualification standards.

Testing, Measurement, and Laboratory Equipment

Research laboratories and calibration facilities require Custom Waveguide to Coaxial Adapter components with exceptional repeatability and stability for accurate measurements. Vector network analyzers measuring S-parameters of waveguide devices need precision adapters with verified electrical models to enable error correction and de-embedding of test fixtures. Antenna measurement ranges, including Advanced Microwave Technologies Co., Ltd.'s impressive 24-meter microwave darkroom, utilize Custom Waveguide to Coaxial Adapter interfaces to connect antennas under test to measurement instrumentation, demanding low insertion loss and high return loss to avoid corrupting measurement accuracy. Component characterization systems for filters, isolators, and amplifiers operating in waveguide must transition to coaxial interfaces for integration with automated test equipment. These laboratory-grade Custom Waveguide to Coaxial Adapter units undergo individual electrical testing and often include calibration data documenting measured S-parameters across frequency, enabling users to mathematically remove adapter effects from measurements and achieve traceable results referenced to national standards.

Customization Capabilities and Design Flexibility

Tailored Solutions for Specific Requirements

Off-the-shelf adapter offerings rarely meet every application need, making customization capabilities essential when sourcing Custom Waveguide to Coaxial Adapter components. Frequency range optimization allows manufacturers to design adapters for narrow operational bands, achieving superior electrical performance compared to broad-bandwidth designs by tailoring probe length, position, and coupling mechanisms to specific frequencies. Power handling enhancement addresses applications requiring operation at elevated power levels through larger coaxial connectors, improved thermal paths using copper or aluminum heat sinks, and specialized probe designs distributing current densities to prevent arcing and thermal damage. Environmental hardening customizes mechanical construction, connector sealing, and material selection for deployment in extreme conditions including maritime environments with salt spray exposure, outdoor installations experiencing wide temperature swings, and space applications facing vacuum conditions and radiation exposure. Advanced Microwave Technologies Co., Ltd. maintains comprehensive customization capabilities supported by experienced RF engineers who work directly with customers to translate application requirements into optimized Custom Waveguide to Coaxial Adapter designs.

Integration with Complete RF Systems

Modern RF systems increasingly demand integrated solutions rather than discrete components, driving evolution in Custom Waveguide to Coaxial Adapter offerings. Multi-port adapters combine several transitions into unified assemblies, reducing installation complexity and improving reliability by eliminating external interconnections. Integrated switching matrices incorporate PIN diode or MEMS switches directly within adapter housings, enabling automated signal routing between multiple waveguide ports and coaxial test equipment. Filtered transitions embed bandpass or band-reject filtering within the adapter structure, providing frequency selectivity without requiring separate external filters. Advanced Microwave Technologies Co., Ltd. extends beyond basic Custom Waveguide to Coaxial Adapter products to deliver complete RF subsystems including feed networks that distribute signals across multiple antenna elements, integrated assemblies combining adapters with rotary joints for antenna positioning systems, and custom test fixtures incorporating precisely characterized transitions for automated production testing environments.

Quality Standards and Manufacturing Excellence

ISO Certifications and Quality Management

Manufacturing excellence in Custom Waveguide to Coaxial Adapter production requires comprehensive quality management systems ensuring consistent performance and reliability. Advanced Microwave Technologies Co., Ltd. maintains ISO 9001:2015 certification, demonstrating systematic quality control throughout design, manufacturing, and delivery processes. This standard mandates documented procedures for product development, supplier qualification, manufacturing process control, and continuous improvement through corrective and preventive action systems. Their ISO 14001:2015 environmental management certification reflects commitment to sustainable manufacturing practices including waste reduction, energy conservation, and minimizing environmental impact of production operations. The ISO 45001:2018 occupational health and safety management system ensures employee well-being through comprehensive safety protocols, training programs, and hazard identification procedures. These internationally recognized certifications provide customers confidence that Custom Waveguide to Coaxial Adapter products meet stringent quality standards supported by auditable processes and traceability throughout the supply chain.

Advanced Testing and Measurement Facilities

Reliable performance of Custom Waveguide to Coaxial Adapter components depends on thorough testing using calibrated measurement equipment in controlled environments. Advanced Microwave Technologies Co., Ltd. operates laboratories equipped with vector network analyzers calibrated for measurements extending to 110 GHz, enabling complete electrical characterization of insertion loss, return loss, and phase response across entire operational frequency ranges. Their remarkable 24-meter microwave darkroom houses antenna near-field and far-field measurement capabilities, allowing comprehensive validation of antenna feed systems incorporating Custom Waveguide to Coaxial Adapter transitions. Environmental test chambers verify performance under temperature extremes, humidity exposure, thermal shock, and vibration loading matching customer specifications and military standards. Power handling validation subjects adapters to high-power RF signals while monitoring temperature rise and electrical performance degradation. This comprehensive test infrastructure ensures every Custom Waveguide to Coaxial Adapter meets documented specifications before shipment, backed by test data provided with each delivery.

Selecting the Right Supplier and Getting Competitive Quotes

Evaluation Criteria for Supplier Selection

Choosing a Custom Waveguide to Coaxial Adapter manufacturer requires careful evaluation beyond simple price comparison. Technical capability assessment should examine frequency range coverage, customization flexibility, and in-house design expertise evidenced by engineering staff qualifications and past project portfolios. Manufacturing capacity indicators include production volume capabilities, lead time commitments, and ability to scale production for large orders without compromising quality. Quality system certifications provide objective evidence of systematic process control and continuous improvement culture. Technical support availability proves critical when specifications require interpretation, application guidance demands expert input, or troubleshooting requires rapid manufacturer response. Advanced Microwave Technologies Co., Ltd. brings over twenty years of microwave manufacturing experience to Custom Waveguide to Coaxial Adapter production, supported by comprehensive laboratory facilities, ISO-certified quality systems, and engineering teams capable of addressing the most challenging application requirements across satellite communications, defense systems, aerospace platforms, and scientific research installations worldwide.

Optimizing Your Quote Request Process

Obtaining competitive quotations for Custom Waveguide to Coaxial Adapter requirements demands clear communication of specifications and performance expectations. Complete frequency range documentation should specify operating bandwidth, insertion loss limits, and VSWR or return loss requirements across that range. Interface definitions must detail waveguide size and flange type, coaxial connector specification, and orientation preference for end-launch versus right-angle configurations. Environmental requirements encompassing operating temperature range, storage temperature extremes, humidity tolerance, vibration specifications, and any special environmental exposures like salt fog or vacuum operation require explicit documentation. Quantity requirements including prototype needs, production volumes, and delivery schedule expectations enable suppliers to optimize pricing and manufacturing planning. Advanced Microwave Technologies Co., Ltd. welcomes detailed quote requests and provides responsive engineering support to help customers refine specifications, suggest alternative approaches when appropriate, and deliver competitive pricing backed by proven manufacturing capability and quality assurance processes. Their global customer base spanning satellite operators, defense contractors, research institutions, and commercial telecommunications providers demonstrates their ability to support diverse application needs.

Conclusion

Selecting the right Custom Waveguide to Coaxial Adapter demands careful consideration of electrical performance, mechanical specifications, quality standards, and supplier capabilities to ensure reliable system operation. By understanding key parameters and application requirements, engineers can confidently specify solutions meeting demanding technical and environmental challenges.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a leading China Custom Waveguide to Coaxial Adapter factory, China Custom Waveguide to Coaxial Adapter supplier, and China Custom Waveguide to Coaxial Adapter manufacturer, Advanced Microwave Technologies Co., Ltd. offers China Custom Waveguide to Coaxial Adapter wholesale solutions with competitive Custom Waveguide to Coaxial Adapter price and High Quality Custom Waveguide to Coaxial Adapter for sale. With over 20 years of experience, ISO certifications, and advanced 110 GHz testing capabilities, we deliver custom solutions backed by rapid prototyping, comprehensive technical support, and efficient delivery. Whether you need standard products or tailored designs for satellite communications, defense, aerospace, or testing applications, our expert engineers provide complete support from specification development through after-sales service. Contact us at craig@admicrowave.com to discuss your requirements, receive detailed quotations, and discover why global leaders trust our Custom Waveguide to Coaxial Adapter solutions. Bookmark this page for quick reference when planning your next RF project.

References

1. "Microwave Engineering" by David M. Pozar, Professor Emeritus at University of Massachusetts Amherst, published by John Wiley & Sons

2. "RF and Microwave Passive and Active Technologies" edited by Mike Golio, Chief Technology Officer at Rockwell Collins, published by CRC Press

3. "Waveguide Handbook" by Nathan Marcuvitz, Massachusetts Institute of Technology Radiation Laboratory Series, published by McGraw-Hill

4. "Microwave and RF Design: A Systems Approach" by Michael Steer, Professor at North Carolina State University, published by SciTech Publishing