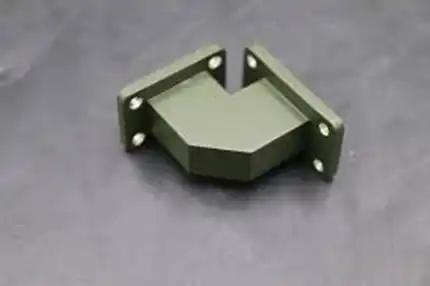

Miter Bend Waveguide

Product Introduction

Miter Bend Waveguide is designed to address the demand for compact, low-loss, and reliable signal redirection in high-frequency waveguide transmission scenarios. Traditional curved waveguide bends often suffer from large volume, high conductor loss, and inconsistent performance at broadband frequencies—issues that Miter Bend Waveguide overcomes through its optimized mitered structure and precision machining. It is available in standard angle configurations and supports waveguide sizes from WR-10 to WR-2300, covering frequency bands from 0.3GHz to 110GHz. The component is constructed with high-conductivity materials and features optional plating for enhanced corrosion resistance and electrical performance, making it suitable for both commercial and harsh-environment applications.

Product Specifications

Parameters | Details |

|---|---|

Frequency Range | 0.3GHz– 110GHz |

Angle Configurations | 45° (standard) |

Insertion Loss | ≤0.1dB |

Return Loss | ≥25dB |

Operating Temperature | -45°C to +85°C |

Product Benefits

- Compact & space-saving design: The mitered structure eliminates the large curvature of traditional bends, reducing volume by 30%-50% compared to curved waveguide bends—ideal for space-constrained systems.

- Low signal loss & high fidelity: Precision-machined mitered surfaces and high-conductivity materials minimize insertion loss and reflection, ensuring over 95% signal transmission efficiency across the operating band.

- Broad frequency & size compatibility: Supports frequencies from 0.3GHz to 110GHz and waveguide sizes from WR-10 to WR-2300, eliminating the need for multiple bend models in multi-band systems.

- High power & environmental robustness: Industrial/aerospace-grade models handle up to 5kW CW power and resist extreme temperatures, vibration, and moisture, maintaining performance in harsh outdoor or industrial environments.

- Easy system integration: Compatible with standard waveguide flanges and requires no additional matching components, enabling quick installation into existing waveguide circuits.

- Long service life: Corrosion-resistant plating and rugged material construction reduce wear from environmental factors, ensuring stable operation for over 15,000 hours.

Technical Features

- Precision mitered surface machining: Uses 5-axis CNC machining to achieve mitered cuts with ±0.01mm tolerance, ensuring uniform electromagnetic field distribution and minimizing signal reflection.

- High-conductivity material selection: Oxygen-free copper (OFC) body reduces conductor loss, while optional silver/gold plating lowers surface resistance and enhances corrosion resistance.

- Optimized chamfer & matching design: Integrated impedance matching chamfers at the mitered joint eliminate standing waves, improving return loss to ≥25dB across the full frequency range.

- Thermal management for high-power models: High-power Miter Bend Waveguide variants include integrated copper heat sinks or ceramic thermal pads, dissipating heat from high-power signals to prevent performance degradation from overheating.

- EMI shielding enhancement: The all-metal structure and flange gaskets provide >60dB EMI shielding, preventing external interference from entering the waveguide path and internal signal leakage.

Product Applications

- Radar systems: Used in airborne, naval, and ground-based radar to redirect microwave signals between antennas, transmitters, and receivers—its compact design saves space in radar modules, while low loss ensures long detection ranges.

- Satellite & space communication: Integrated into satellite transceivers and ground stations to route signals between waveguides and feed horns—aerospace-grade models resist extreme temperatures and radiation, ensuring reliable operation in space environments.

- Microwave heating & industrial processing: Applied in microwave ovens, plasma generators, and material processing equipment to redirect high-power microwave signals—high power handling and low loss maximize energy efficiency.

- Test & measurement setups: Used in RF/microwave test benches to adjust signal paths between signal generators, analyzers, and DUTs—high return loss ensures accurate measurement results.

- 5G/6G millimeter-wave systems: Deployed in mmWave base stations to redirect signals between active antenna arrays and waveguides—compact design fits into small base station enclosures, while low loss maintains signal strength.

- Aerospace & defense electronics: Used in avionics and defense equipment —compliance with MIL-STD-883 ensures durability in high-vibration, extreme-temperature environments.

OEM

We provide professional OEM services for Miter Bend Waveguide to meet the personalized needs of different industries and customers:

- Parameter customization: Tailor frequency range, angle (30°, 60°), and power handling according to customer application scenarios.

- Interface & form factor customization: Design non-standard waveguide sizes or flange types; optimize size for miniaturized devices.

- Performance optimization: Adjust insertion loss or temperature stability for special scenarios requiring ultra-high performance.

- Branding & packaging customization: Print customer logos on the component body, customize product labels with technical parameters, and design branded packaging/user manuals to align with the customer’s brand image.

- Technical collaboration & support: Provide pre-sales electromagnetic simulation to verify signal performance in the customer's system, post-sales on-site installation guidance, and performance testing training to ensure optimal integration of the customized Miter Bend Waveguide .

FAQ

Q: What is the difference between Miter Bend Waveguide and a curved waveguide bend?

A: A curved waveguide bend uses a gradual curve to redirect signals, which requires a large volume and may cause higher insertion loss. In contrast, Miter Bend Waveguide uses a precision-cut "mitered" joint to change direction, offering 30%-50% smaller volume, lower insertion loss, and more consistent performance across broadband frequencies. Curved bends are cheaper for low-frequency, low-precision applications, while Waveguide Miter Bend is preferred for high-frequency, space-constrained, or high-performance scenarios.

Q: Can Miter Bend Waveguide be used in outdoor or high-humidity environments?

A: Yes. Our industrial-grade Miter Bend Waveguide features IP65 waterproof design and can work stably in environments with relative humidity up to 95% and temperatures from -40°C to +85°C. For marine or coastal applications, we offer customized anti-salt spray versions to resist corrosion from saltwater vapor.

Contact Us

If you need a compact, low-loss Miter Bend Waveguide to solve signal redirection, space constraint, or performance challenges in your waveguide system, contact us now to get customized solutions tailored to your project requirements!

📧 Email: [sales@admicrowave.com]