Coaxial Power Detector

Product Introduction

Coaxial Power Detector is designed to address the demand for real-time, accurate, and stable power measurement of coaxial-transmitted RF/microwave signals. Unlike general-purpose power meters, this detector integrates a high-sensitivity power-sensing module, a coaxial interface adapter, and a digital signal processing unit, enabling direct connection to coaxial transmission lines without additional conversion compon ents. It supports both continuous-wave (CW) and pulsed signal measurement, with frequency ranges typically covering DC to 67GHz and power measurement ranges from -60dBm to +20dBm, meeting the testing needs of low-power signal monitoring and high-power signal detection. The device is available in three main types: benchtop precision type, handheld portable type, and rack-mounted integrated type, adapting to diverse application scenarios.

Product Specifications

Parameters | Details | ||||||

|---|---|---|---|---|---|---|---|

Frequency Range | 10MHz - 40GHz | ||||||

Power Measurement Range | -60dBm to +20dBm (average power) | ||||||

Measurement Accuracy | ±0.5dB | ||||||

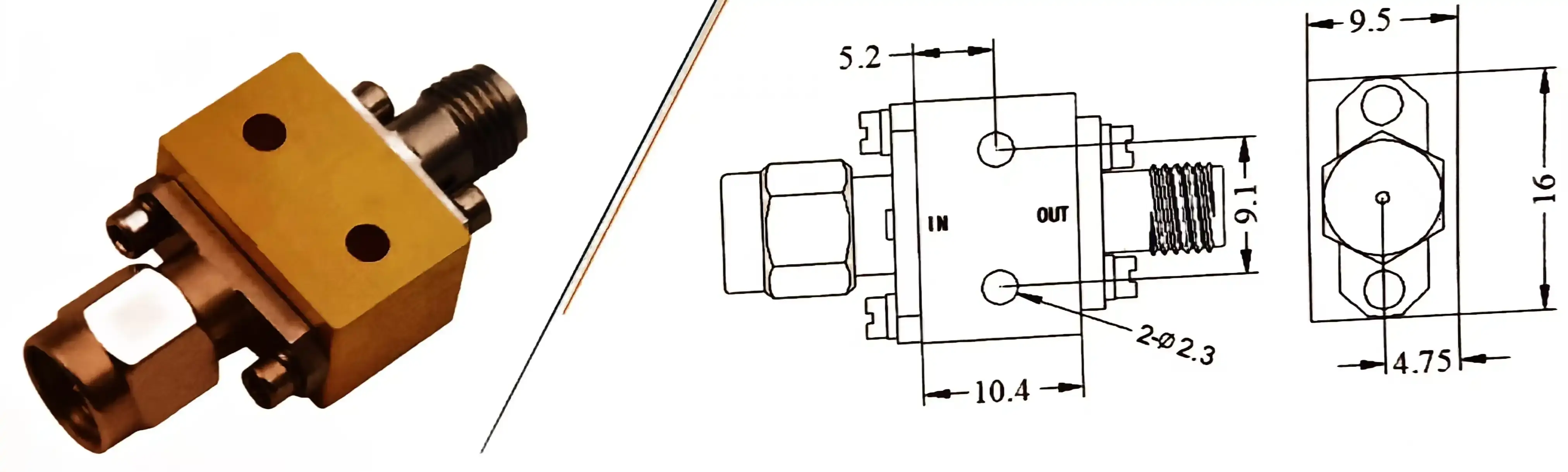

Input and output connectors | SMA-Female/SMA-Male | ||||||

Material | Aluminum | ||||||

Operating Temperature | -45°C to +85°C | ||||||

Product Benefits

- High measurement accuracy: Adopts a high-linearity thermoelectric power sensor and digital signal calibration algorithm, ensuring stable and reliable power data even in complex signal environments.

- Wide compatibility: Supports multiple coaxial interface types and covers a broad frequency/power range, eliminating the need for frequent interface replacement or tool switching when testing different coaxial systems.

- User-friendly operation: Equipped with an intuitive touchscreen interface, one-key measurement function, and preset test modes, reducing operation complexity for both professional and field operators.

- Real-time data analysis: Built-in data logging and power trend curve display, enabling real-time monitoring of signal power fluctuations and quick identification of abnormal signals.

- Strong environmental adaptability: Industrial-grade models feature dustproof and anti-drop designs; aerospace-grade models add anti-vibration and high-low temperature resistance, suitable for harsh outdoor, industrial, or aerospace scenarios.

- Cost-efficient integration: Integrates power measurement, data storage, and data transmission functions in one device, avoiding the cost of purchasing multiple separate instruments.

Technical Features

- High-sensitivity power sensing: Uses thermoelectric or Schottky barrier diode power sensors, with a minimum detectable power of -65dBm, enabling accurate measurement of weak RF signals in coaxial lines.

- Dynamic range extension technology: Adopts automatic gain control and multi-range sensor switching, achieving a wide dynamic range of 80dB, which can simultaneously measure weak and strong signals in the same coaxial system.

- Fast response speed: The signal processing unit supports a sampling rate of up to 1MHz, with a response time of ≤10μs, meeting the testing needs of high-speed pulsed signals.

- Calibration traceability: All Coaxial Power Detector units undergo factory calibration with national metrology standards, and support on-site recalibration via a standard signal source; a calibration certificate is provided to ensure data compliance with ISO/IEC standards.

- Anti-interference design: The internal circuit adopts double-shielded packaging, and the power supply module uses EMI filtering technology, reducing electromagnetic interference from external devices and ensuring measurement accuracy in high-noise environments.

- Smart connectivity: Supports remote control and data transmission via USB, Ethernet, or Wi-Fi; compatible with LabVIEW, MATLAB, and other test software, enabling integration into automated test systems.

Product Applications

- Communication infrastructure: Used in 5G/6G base stations to monitor the output power of coaxial jumper cables and antenna feed systems, ensuring signal coverage stability and avoiding damage to RF components caused by over-power.

- RF device manufacturing: Applied in the production of coaxial amplifiers, attenuators, and filters to test the input/output power of products, screening out defective products with abnormal power and improving production yield.

- Test & measurement laboratories: Essential for R&D of RF/microwave components; provides accurate power reference data for optimizing circuit design and verifying prototype performance.

- Field maintenance & troubleshooting: Used by telecom operators for on-site testing of coaxial cables in communication towers and indoor distributed systems, quickly locating issues such as power loss caused by cable aging or connector loosening.

- Aerospace & defense: Adopted in aircraft communication systems, missile guidance RF links, and satellite ground stations to measure the power of coaxial-transmitted signals; the anti-vibration and high-temperature resistance design ensures reliable operation in extreme environments.

- Industrial and medical equipment: Applied in microwave heating equipment, RF plasma generators, and medical RF ablation devices to monitor the power of coaxial transmission paths, preventing equipment failure or treatment risks caused by power deviations.

OEM

We provide professional OEM services for Coaxial Power Detector to meet the personalized testing needs of different customers and industries:

- Customized parameter configuration: Tailor the frequency range, power measurement range, and accuracy level according to customer-specific application scenarios.

- Interface & structural customization: Design non-standard coaxial interfaces or special structural forms; for handheld models, customize battery capacity or waterproof levels.

- Software & data customization: Develop dedicated test software with custom functions; support integration with customer’s MES/ERP systems for production data tracking or maintenance record management.

- Branding & packaging customization: Print customer logos on the device casing and packaging; design customized user manuals and quick-start guides to match the customer’s brand image and user habits.

- Technical collaboration & support: Offer pre-sales technical consultation and post-sales on-site training, ensuring customers can fully utilize the customized Coaxial Power Detector and interpret test data accurately.

FAQ

Q: What is the difference between Coaxial Power Detector and a general RF power meter?

A: A general RF power meter usually requires an external power sensor and connecting cables, which may introduce additional insertion loss and measurement errors. Coaxial Power Detector integrates a dedicated coaxial power sensor and interface, enabling direct connection to coaxial lines without extra components—this reduces loss, improves accuracy, and simplifies operation, making it more suitable for scenario-specific coaxial system testing.

Q: How often does Coaxial Power Detector need to be recalibrated?

A: The calibration interval depends on the usage frequency and environment: Benchtop precision models require recalibration every 6 months; Handheld and rack-mounted models can be recalibrated every 12 months. If the device is exposed to severe impact, high humidity, or extreme temperatures, it is recommended to shorten the interval and conduct a pre-use verification with a standard signal source.

Contact Us

If you need a high-precision, reliable Coaxial Power Detector to solve the challenges of inaccurate, inefficient, or incompatible power measurement in coaxial systems, contact us now to get customized solutions tailored to your project requirements!

📧 Email: [sales@admicrowave.com]