Coaxial Directional Coupler Maintenance Checklist for OEMs

System failures in satellite communications or radar networks often trace back to one overlooked component: the Coaxial Directional Coupler. When these precision devices degrade unnoticed, OEMs face costly downtime, signal degradation, and customer complaints. This comprehensive maintenance checklist empowers OEMs to implement proactive strategies that extend component lifespan, maintain peak performance specifications, and prevent catastrophic failures in mission-critical RF systems across aerospace, defense, and telecommunications applications.

Understanding Coaxial Directional Coupler Fundamentals for Effective OEM Maintenance

The Coaxial Directional Coupler serves as a critical passive component in RF and microwave systems, designed to sample signal power with minimal disruption to the main transmission path. For OEMs integrating these components into satellite communication terminals, radar assemblies, or base station infrastructure, understanding their operational principles directly impacts maintenance planning effectiveness. These devices operate by electromagnetic coupling between transmission lines, transferring a predetermined fraction of RF power to monitoring or measurement ports while maintaining signal integrity through the primary path. Advanced Microwave manufactures directional couplers spanning DC to 40 GHz with superior performance characteristics including insertion losses below 0.2 dB and isolation exceeding 30 dB, making them ideal candidates for demanding applications where reliability cannot be compromised. The fundamental architecture of a Coaxial Directional Coupler typically includes four ports: input, output, coupled, and isolated terminals. Understanding how power flows through these ports helps OEMs diagnose performance degradation patterns. When RF energy enters the input port, the majority continues to the output with minimal attenuation, while a small, precisely controlled portion couples to the monitoring port. The coupling value, expressed in decibels, determines this power division ratio—common values include 10 dB, 20 dB, and 30 dB configurations. The isolated port ideally receives no power from forward-traveling signals, though real-world directivity limitations allow small leakage. Maintenance protocols must account for how environmental stressors, mechanical vibrations, and thermal cycling affect these delicate coupling relationships over operational lifespans that may extend decades in satellite or aerospace deployments.

Critical Performance Parameters Requiring Regular Monitoring

OEMs must establish baseline measurements for key performance indicators that directly reflect Coaxial Directional Coupler health status. Insertion loss represents the signal attenuation through the main transmission path and should remain consistently low throughout the device's service life. Any increase beyond specification tolerances signals potential connector degradation, dielectric contamination, or structural damage requiring immediate investigation. Directivity, measuring the coupler's ability to distinguish forward from reflected signals, becomes particularly critical in reflectometer applications where accurate return loss measurements depend on superior port-to-port isolation. Advanced Microwave's couplers achieve directivity specifications ensuring measurement accuracy in the most demanding test environments, but maintaining these levels requires vigilant monitoring and preventive maintenance. Voltage Standing Wave Ratio (VSWR) provides another essential health indicator that OEMs should track throughout operational deployment. VSWR values exceeding 1.2:1 at the specified frequency range indicate impedance mismatches that can arise from connector wear, moisture ingress, or thermal stress-induced dimensional changes. Coupling accuracy itself deserves regular verification, as the precise power division ratio forms the foundation for all downstream measurement and monitoring functions. Temperature-dependent variations in coupling value are normal within manufacturer specifications, but permanent shifts suggest internal degradation requiring replacement. Power handling capacity, rated up to 500 W in Advanced Microwave's high-power models, must be respected during operation and verified during maintenance intervals to prevent catastrophic failures from thermal runaway or dielectric breakdown.

Pre-Deployment Inspection Protocol for New Coaxial Directional Coupler Installations

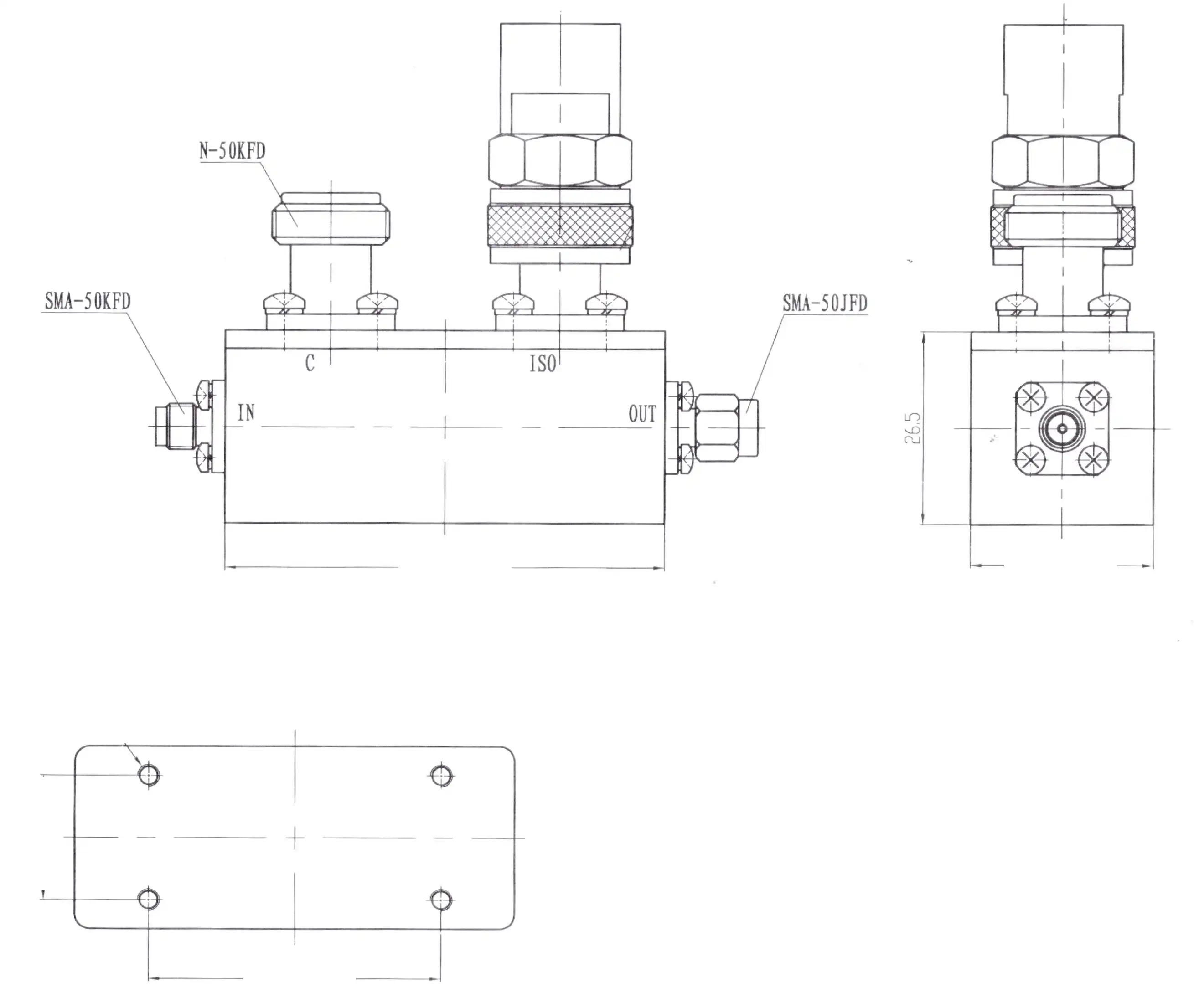

Before integrating Coaxial Directional Coupler units into production systems, OEMs should implement rigorous incoming inspection procedures that establish performance baselines and verify compliance with specification sheets. Visual examination forms the first line of defense against shipping damage or manufacturing defects. Inspect all connector interfaces for proper thread engagement, center conductor alignment, and dielectric integrity. SMA and N-Type connectors, commonly specified on Advanced Microwave products, should exhibit smooth threading action without binding or cross-threading tendencies. Examine the coupler housing for dents, scratches, or deformation that might indicate rough handling during transportation. Pay particular attention to the transition regions where connectors mate with the coupler body, as these stress concentration points are vulnerable to mechanical damage. Electrical characterization using calibrated network analyzer equipment provides quantitative verification of manufacturer specifications before installation. Sweep the full operating frequency range while measuring S-parameters that define insertion loss, return loss, coupling accuracy, and directivity performance. Compare measured values against datasheet specifications, allowing for reasonable measurement uncertainty but investigating any discrepancies exceeding ±0.5 dB for critical parameters. Document these baseline measurements in a comprehensive database that enables trend analysis throughout the component's operational lifetime. For high-reliability applications in aerospace or defense sectors, consider implementing 100% electrical testing rather than statistical sampling approaches. This upfront investment prevents field failures that exponentially exceed the cost of pre-deployment screening.

Environmental Stress Screening Before Critical Deployments

OEMs deploying Coaxial Directional Coupler assemblies in harsh environmental conditions should consider implementing accelerated stress screening protocols that reveal latent defects before they manifest as field failures. Thermal cycling across the specified operating temperature range, typically -40°C to +85°C for ruggedized designs, exposes workmanship defects and material incompatibilities that might not surface during room-temperature testing. Monitor key electrical parameters at temperature extremes to verify performance stability and identify units exhibiting excessive temperature coefficients. Advanced Microwave's products undergo extensive environmental qualification testing, but additional screening provides extra assurance for mission-critical applications where failure is not an option. Vibration testing according to relevant MIL-STD specifications helps identify mechanical weaknesses in connector assemblies or internal coupling structures. While Coaxial Directional Coupler designs are inherently robust due to their solid-state construction and absence of moving parts, high-frequency vibrations can induce fretting wear at connector interfaces or stress cracks in solder joints. Sine sweep and random vibration profiles representing typical aircraft, shipboard, or ground vehicle environments should be applied while monitoring for intermittent electrical discontinuities or parameter drift. Units passing these screening tests demonstrate enhanced reliability that justifies the additional qualification effort and expense in high-consequence applications.

Routine Maintenance Schedule Development for Operational Systems

Establishing appropriate maintenance intervals for Coaxial Directional Coupler installations requires balancing reliability requirements against operational constraints and resource availability. For satellite ground stations and telecommunications base stations where the couplers operate continuously in relatively benign indoor environments, annual comprehensive inspections typically suffice. These should include complete electrical characterization across the operating frequency range, visual inspection of all connectors and mounting hardware, and verification of environmental control systems maintaining appropriate temperature and humidity levels. Document all measurements in maintenance logs that enable statistical analysis of degradation trends, providing early warning of impending failures before they impact system availability. More aggressive maintenance schedules become necessary for harsh environment deployments including shipboard radar systems, airborne communication platforms, and outdoor telecommunication infrastructure. Quarterly inspections should focus on connector condition, examining for corrosion, moisture ingress, or mechanical wear resulting from thermal cycling and vibration exposure. Semi-annual full electrical testing verifies that performance parameters remain within acceptable tolerances despite environmental stressors. Military and aerospace applications often mandate even more frequent inspections per system-specific maintenance manuals that account for the critical nature of these platforms and the catastrophic consequences of RF system failures during mission execution.

Connector Interface Maintenance Procedures

The connector interfaces represent the most vulnerable elements in any Coaxial Directional Coupler installation, serving as the transition points where environmental contaminants can enter and mechanical stresses concentrate. Develop standardized cleaning procedures using appropriate solvents and lint-free wipes to remove accumulated dust, moisture, and oxidation products from threaded coupling surfaces and center conductor contacts. For threaded connectors, apply proper torque specifications during reassembly using calibrated torque wrenches—over-tightening damages dielectric materials while under-tightening compromises electrical contact and allows moisture penetration. Maintain detailed records of connector mating cycles, as repeated connections eventually wear gold plating and degrade contact resistance, ultimately necessitating connector replacement or refurbishment. Implement corrosion prevention strategies appropriate to the deployment environment. Coastal installations face accelerated degradation from salt spray exposure, requiring protective coatings or environmental sealing beyond standard specifications. Consider applying dielectric grease to connector threads in particularly hostile environments, though care must be taken to prevent contamination of the RF signal path. For critical installations, periodic removal and laboratory testing of representative connector samples provides objective data on degradation rates, enabling optimization of replacement intervals before failures occur. Advanced Microwave offers customizable connector options including stainless steel hardware for enhanced corrosion resistance in marine and tropical environments where standard aluminum construction proves inadequate.

Performance Verification Testing Methods for In-Service Components

Regular performance verification ensures that installed Coaxial Directional Coupler assemblies continue meeting specification requirements throughout their operational service life. Network analyzer testing provides the most comprehensive characterization capability, measuring full two-port S-parameters across the operating frequency range. This approach quantifies insertion loss, return loss, coupling accuracy, and directivity with precision sufficient to detect subtle degradation trends before they compromise system functionality. Establish test procedures that ensure repeatability through careful calibration practices, proper connector torquing, and environmental control during measurement sessions. Compare results against baseline data collected during initial installation to identify parameter drift that might indicate developing problems requiring corrective action. For OEMs lacking access to sophisticated network analyzer equipment at remote installation sites, simplified field testing procedures using calibrated power meters and signal sources provide adequate performance monitoring capabilities. Inject known power levels at the input port while measuring coupled and output port power levels to verify coupling accuracy and insertion loss. This approach lacks the frequency resolution and dynamic range of network analyzer testing but sufficiently identifies gross parameter shifts indicating component failure or system configuration problems. Portable directional power sensors specifically designed for field testing applications offer convenient solutions for telecommunications technicians performing routine maintenance on widely distributed base station infrastructure where transportable test equipment must be compact, rugged, and operable by personnel with limited RF expertise.

Troubleshooting Common Failure Modes

Understanding typical failure mechanisms helps OEMs develop effective diagnostic strategies when Coaxial Directional Coupler performance degrades. Increased insertion loss most commonly results from connector degradation, whether from corrosion, contamination, or mechanical wear reducing contact quality. Systematically evaluate each connector interface in the signal path, cleaning and retorquing connections before assuming internal coupler damage. If connector maintenance fails to restore specifications, internal dielectric damage or conductor oxidation likely requires component replacement. Advanced Microwave's robust construction minimizes internal failure modes, but no device is immune to extreme environmental stressors or electrical overload conditions exceeding design limits. Directivity degradation typically indicates problems at the isolated port termination. In three-port designs with internal terminations, this suggests potential moisture ingress or thermal damage to the termination resistor. Four-port configurations where OEMs provide external terminations should prompt inspection of the termination load and associated cabling for proper impedance matching. Intermittent performance fluctuations often trace to loose mounting hardware allowing mechanical vibrations to induce micro-movements at connector interfaces. Tighten all mechanical fasteners and implement vibration isolation measures if environmental conditions prove more severe than anticipated during system design. Document all troubleshooting activities and solutions in knowledge bases that accelerate future diagnosis and repair activities across the OEM's installed base.

Environmental Control and Protection Strategies for Extended Service Life

Maintaining appropriate environmental conditions dramatically extends Coaxial Directional Coupler operational lifetimes by minimizing exposure to degradation mechanisms. Temperature control prevents thermal cycling stresses that gradually damage solder joints, connector seals, and dielectric materials through differential thermal expansion. While Advanced Microwave's products are qualified across wide temperature ranges meeting aerospace and military requirements, maintaining stable moderate temperatures whenever possible reduces cumulative stress accumulation. Indoor installations should leverage climate control systems to maintain 15-30°C ambient temperatures, preventing condensation during cold periods and thermal degradation during heat waves. Outdoor installations require environmental enclosures with appropriate heating, cooling, and ventilation to protect components from temperature extremes. Humidity control proves equally critical, as moisture ingress into RF components causes multiple failure mechanisms including corrosion, dielectric breakdown, and power-dependent heating that accelerates degradation. Maintain relative humidity below 60% through climate control or desiccant systems in sealed enclosures. Periodically inspect enclosure seals and cable entry points for degradation that could permit moisture infiltration. Consider implementing humidity monitoring systems that alert maintenance personnel when environmental protection measures fail, enabling rapid intervention before significant damage occurs. The RoHS compliant materials used in Advanced Microwave's products provide enhanced resistance to environmental stressors compared to legacy designs, but cannot compensate for grossly inadequate environmental protection in hostile deployment locations.

Vibration Isolation and Mechanical Protection

Mechanical vibration represents a significant threat to long-term reliability, particularly in mobile platforms or installations near rotating machinery. Implement vibration isolation mounting systems using appropriate elastomeric isolators that attenuate vibration energy before it reaches sensitive RF components. Size isolation systems based on measured or predicted vibration spectra at the installation location, ensuring that isolation resonance frequencies fall well below the dominant excitation frequencies. For aerospace and shipboard applications subject to high shock loads, employ shock-rated mounting hardware and verify that the Coaxial Directional Coupler and associated cabling remain securely fastened under all anticipated loading conditions. Protect connector interfaces from mechanical damage during routine access and maintenance activities by implementing protective covers or guards that prevent accidental impacts. Train maintenance personnel on proper handling procedures emphasizing that RF connectors are precision components requiring careful manipulation. Even minor physical damage to connector threads or center conductors can dramatically degrade electrical performance and compromise long-term reliability. For high-traffic installation areas, consider protective enclosures that restrict unauthorized access while facilitating legitimate maintenance activities. Document all instances of mechanical damage in maintenance records to identify problem locations requiring enhanced protection measures or personnel retraining.

Calibration and Measurement Equipment Management for Accurate Testing

Maintaining measurement accuracy requires rigorous control of test equipment used to characterize Coaxial Directional Coupler performance during maintenance activities. Network analyzers, power meters, signal generators, and associated test cables constitute significant capital investments requiring periodic calibration against national standards laboratories to ensure traceability and accuracy. Establish calibration intervals based on manufacturer recommendations, typically annual for laboratory-grade equipment, though more frequent calibration may be necessary for instruments subjected to harsh field conditions or intensive usage patterns. Maintain comprehensive calibration records documenting measurement uncertainty and traceability chains, particularly important for aerospace and defense applications where test data must withstand regulatory scrutiny. Test cable assemblies and calibration standards themselves require periodic verification and replacement as they experience wear from repeated connection cycles and environmental exposure. Inspect phase-stable test cables for mechanical damage before each use, as damaged cable assemblies introduce measurement errors that can mask or simulate component degradation. Maintain multiple sets of calibration standards appropriate for different connector types and frequency ranges, and rotate standards to distribute wear across the inventory. When measuring high-power Coaxial Directional Coupler installations, ensure that test equipment power ratings exceed anticipated signal levels to prevent damage to measurement instruments that could cascade into erroneous test results and inappropriate maintenance decisions.

Measurement Repeatability Verification Procedures

Implement control procedures that verify measurement repeatability before attributing performance changes to component degradation rather than test system variability. Establish "golden standard" reference components with stable, well-characterized performance that undergo measurement during each test session. Tracking these reference measurements over time reveals test system drift or degradation requiring corrective action before proceeding with production testing. This approach prevents unnecessary component replacements based on illusory performance degradation actually resulting from uncalibrated or drifting test equipment. Statistical process control methodologies adapted from manufacturing quality control provide powerful frameworks for analyzing measurement data and distinguishing real component degradation from test system noise. Environmental factors during testing significantly impact measurement accuracy, particularly for sensitive parameters like directivity and coupling accuracy. Conduct testing in temperature-controlled laboratory environments whenever possible, and allow components to thermally stabilize before measurement when transitioning from field installation environments. Humidity variations affect dielectric properties and connector contact resistance, introducing measurement variability that complicates trend analysis. Document environmental conditions during each test session, and flag measurements conducted under non-standard conditions for special scrutiny during data analysis. Advanced Microwave's comprehensive test reports document measurements conducted under controlled conditions, providing reliable reference data for comparison against field measurements potentially compromised by environmental factors.

Documentation and Record-Keeping Best Practices for OEM Maintenance Programs

Comprehensive documentation transforms maintenance activities from reactive firefighting into proactive reliability engineering that optimizes lifecycle costs and maximizes system availability. Establish standardized data collection templates capturing all relevant information during maintenance inspections including measured performance parameters, visual observations, environmental conditions, and corrective actions implemented. Digital maintenance management systems enable powerful trend analysis capabilities impossible with paper records, identifying subtle degradation patterns that predict impending failures before they occur. For OEMs managing large installed bases of equipment containing multiple Coaxial Directional Coupler assemblies, database approaches tracking individual component serial numbers through their entire operational lifetime provide invaluable reliability data guiding design improvements for future product generations. Photographic documentation supplements numerical measurements by capturing visual evidence of component condition, connector wear patterns, and installation quality that might escape written descriptions. High-resolution images of connector interfaces reveal incipient corrosion, contamination, or mechanical damage invisible to cursory visual inspection. Time-series photographs document degradation progression, helping establish optimal maintenance intervals for similar installations. For critical aerospace and defense applications, comprehensive photographic records also provide forensic evidence valuable in failure analysis investigations when components do eventually fail despite preventive maintenance efforts. The modest investment in digital imaging equipment and storage infrastructure returns substantial dividends through improved diagnostics and accelerated problem resolution.

Failure Analysis and Continuous Improvement Processes

When Coaxial Directional Coupler failures occur despite preventive maintenance programs, rigorous root cause analysis identifies systemic issues requiring design changes, specification revisions, or enhanced maintenance procedures. Establish formal failure review boards bringing together engineering, manufacturing, and field service personnel to thoroughly investigate each failure and implement corrective actions preventing recurrence. Failed components should undergo detailed laboratory analysis including physical teardown, materials characterization, and electrical testing to definitively establish failure mechanisms. For high-value aerospace and defense programs, partner with specialized failure analysis laboratories possessing capabilities including scanning electron microscopy, energy-dispersive X-ray spectroscopy, and other advanced analytical techniques that reveal failure mechanisms at microscopic scales. Aggregate failure data across the installed base to identify population-level reliability trends that might escape notice when examining individual failures in isolation. Statistical analysis techniques including Weibull distribution modeling provide quantitative predictions of future failure rates, enabling optimization of spare parts inventories and maintenance scheduling. Share anonymized reliability data with component suppliers like Advanced Microwave Technologies Co., Ltd., fostering collaborative improvement programs that enhance future product generations. The most successful OEM maintenance programs embrace failures as learning opportunities rather than simply inconveniences, systematically capturing lessons learned and implementing corrective actions that progressively improve system reliability throughout the product lifecycle.

Conclusion

Effective Coaxial Directional Coupler maintenance demands systematic approaches balancing preventive inspection, performance verification, environmental protection, and comprehensive documentation. OEMs implementing these protocols maximize reliability while minimizing lifecycle costs across demanding applications.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands ready to support your OEM requirements with over 20 years of specialized expertise in RF and microwave components. Our ISO 9001:2015 certified manufacturing processes ensure consistent quality, while our state-of-the-art 24m Microwave Darkroom enables precision testing from 0.5 to 110 GHz. As a leading China Coaxial Directional Coupler manufacturer, China Coaxial Directional Coupler supplier, and China Coaxial Directional Coupler factory, we offer comprehensive OEM services including custom frequency ranges, coupling values, and connector configurations. Whether you need High Quality Coaxial Directional Coupler solutions with competitive Coaxial Directional Coupler price points or China Coaxial Directional Coupler wholesale programs, our technical team provides rapid prototyping and engineering support. With Coaxial Directional Coupler for sale spanning DC to 40 GHz and customizable specifications, we serve satellite communications, defense, aerospace, and telecommunications sectors globally. Contact our expert team at craig@admicrowave.com today to discuss your specific requirements and discover how our advanced manufacturing capabilities, rigorous quality control, and responsive customer support can accelerate your product development timelines while ensuring superior performance and reliability.

References

1. Institute of Electrical and Electronics Engineers, "IEEE Standard for Definitions of Terms for Radio Wave Propagation," IEEE Std 211-2018, Institute of Electrical and Electronics Engineers Standards Association.

2. Microwave Journal Editorial Staff, "Directional Coupler Design and Applications in Modern RF Systems," Microwave Journal Technical Publications, Horizon House Publications.

3. Pozar, David M., "Microwave Engineering, Fourth Edition," Chapter 7: Power Dividers and Directional Couplers, John Wiley & Sons, Inc.

4. Military Standards and Specifications, "MIL-HDBK-217F: Reliability Prediction of Electronic Equipment," United States Department of Defense.

5. Collin, Robert E., "Foundations for Microwave Engineering, Second Edition," IEEE Press Series on Electromagnetic Wave Theory, Wiley-IEEE Press.