Are Plastic Flange Caps Safe for Long-Term Outdoor Use?

Picture this: you've invested thousands in precision waveguide components for your satellite communication system, carefully stored them outdoors during a project delay, only to discover months later that moisture has penetrated the flanges, causing corrosion that renders them unusable. This nightmare scenario haunts engineers across telecommunications, aerospace, and defense industries. The answer to whether Plastic Flange Caps can prevent such disasters during extended outdoor exposure depends critically on material quality, design engineering, and environmental conditions. High-density polyethylene Plastic Flange Caps, when properly specified and installed, provide reliable protection for waveguide flanges, coaxial assemblies, and antenna components even under challenging outdoor conditions, but only if you understand their capabilities and limitations.

Understanding Plastic Flange Caps for Outdoor Applications

Plastic Flange Caps serve as the first line of defense for sensitive microwave components exposed to outdoor environments. In the telecommunications and aerospace sectors, where equipment often waits months between manufacturing and installation, these protective covers must withstand temperature extremes, UV radiation, moisture infiltration, and mechanical stress without compromising the integrity of the underlying flange surfaces. The critical question is not whether plastic can survive outdoors, but rather which plastic formulations and designs deliver consistent protection over extended periods. The effectiveness of Plastic Flange Caps in outdoor settings fundamentally depends on material selection. High-density polyethylene stands out as the industry standard for outdoor flange protection due to its exceptional balance of properties. This thermoplastic polymer exhibits remarkable resistance to moisture absorption, preventing the caps themselves from degrading when exposed to rain, humidity, or condensation. Unlike lower-grade plastics that become brittle after UV exposure, quality HDPE formulations incorporate UV stabilizers that maintain material integrity even after years of direct sunlight. The chemical resistance of HDPE ensures that Plastic Flange Caps remain unaffected by industrial atmospheres, salt spray in coastal installations, or chemical exposure in petrochemical facilities. Temperature performance represents another critical consideration for outdoor deployment. Waveguide systems and antenna assemblies may be stored or installed in environments ranging from arctic conditions to desert heat. Advanced Plastic Flange Caps engineered from high-density polyethylene maintain their protective function across temperature ranges from negative forty degrees Celsius to seventy degrees Celsius. This thermal stability ensures that caps neither crack in freezing conditions nor soften and deform in extreme heat. For microwave measurement equipment and satellite ground station components that demand precision tolerance, maintaining flange face flatness during storage is paramount, and quality plastic caps deliver this protection regardless of ambient temperature fluctuations.

Material Composition and Weather Resistance

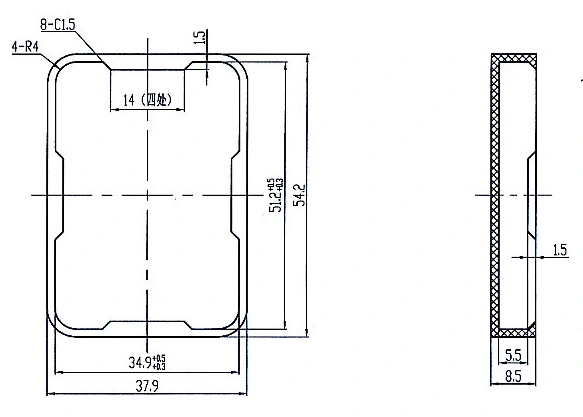

The molecular structure of high-density polyethylene provides inherent advantages for outdoor flange protection applications. HDPE's crystalline structure creates a material that resists environmental degradation while maintaining flexibility. This combination prevents the catastrophic failure modes seen in inferior plastic formulations. When lower-quality Plastic Flange Caps crack after several months outdoors, moisture and contaminants gain access to the protected surfaces, defeating the entire purpose of the protection system. Advanced manufacturing processes ensure that Plastic Flange Caps maintain consistent wall thickness and precision fit tolerances. The push-fit design common in quality flange caps creates mechanical interference that holds the cap securely in place even during transportation or when subjected to wind loading. This secure attachment prevents the common problem of caps blowing off during shipping or outdoor storage, a failure mode that leaves expensive components completely exposed. For waveguide assemblies used in weather monitoring systems or shipboard applications, where equipment may be stored outdoors for extended periods before installation, this reliability becomes absolutely essential. The RoHS and REACH compliance of modern Plastic Flange Caps addresses environmental responsibility concerns increasingly important to global organizations. These certifications confirm that the protective caps contain no hazardous substances that could leach into the environment during outdoor exposure or disposal. For defense contractors and aerospace manufacturers operating under strict environmental regulations, this compliance documentation provides necessary assurance that component protection methods align with corporate sustainability commitments.

Design Features That Enhance Outdoor Durability

Engineering design significantly impacts the long-term outdoor performance of Plastic Flange Caps beyond base material properties. Precision-engineered caps feature flexible fins or ribs that create positive sealing against the flange face while accommodating minor dimensional variations. This design ensures that each cap fits snugly across the range of standard flange sizes from DN15 through DN600, providing consistent protection whether protecting compact coaxial connectors or large waveguide flanges on antenna feed systems. The geometry of quality Plastic Flange Caps prevents water accumulation that could lead to corrosion of the protected surfaces. Proper design incorporates drainage features or shape profiles that shed rainwater rather than creating puddles on top of the cap. For microwave antennas and satellite communication equipment installed on towers or rooftops, where components face direct weather exposure, this water management becomes crucial. Even minor water infiltration can cause phase shifting in precision RF systems or corrosion in bolt holes, compromising system performance. Color coding serves both functional and organizational purposes in outdoor deployments. Standard yellow Plastic Flange Caps provide high visibility that aids in inventory management and installation verification. However, customization options allow users to specify colors that indicate equipment status, project phases, or component specifications. Red caps might designate components awaiting inspection, blue for approved inventory, creating visual management systems that reduce handling errors. For large-scale projects involving hundreds of waveguide assemblies and antenna components, this organization capability significantly improves logistics efficiency.

Performance Factors in Extended Outdoor Environments

Real-world outdoor exposure presents complex challenges that extend beyond simple material weathering. Plastic Flange Caps must maintain their protective function while subjected to thermal cycling, where daily temperature swings cause expansion and contraction. Quality HDPE formulations accommodate these dimensional changes without cracking or loosening. The thermal expansion coefficient of high-density polyethylene closely matches many metal flanges, preventing differential expansion that could break seals or create stress concentrations. UV degradation represents the primary long-term threat to outdoor plastic components. Unprotected polymers exposed to sunlight undergo photodegradation, where ultraviolet radiation breaks down molecular chains, causing embrittlement and surface chalking. However, modern Plastic Flange Caps incorporate UV stabilizer packages that absorb or reflect damaging wavelengths, dramatically extending outdoor service life. Independent testing demonstrates that properly formulated HDPE caps maintain over ninety percent of their mechanical properties after three years of continuous outdoor exposure in harsh climates.

Moisture and Contamination Barriers

The primary function of any flange cap is preventing moisture and contaminant ingress that could damage precision mating surfaces. For waveguide components operating at frequencies from 0.5 GHz through 110 GHz, even microscopic corrosion on flange faces can create signal reflections that degrade system performance. Plastic Flange Caps create physical barriers that block rain, dust, industrial pollutants, and airborne contaminants from reaching these critical surfaces. The sealing effectiveness of Plastic Flange Caps depends on proper installation and fit tolerance. Push-fit designs create mechanical interference that holds caps in place while forming a protective barrier. While not providing hermetic sealing like welded metal covers, quality plastic caps prevent the bulk moisture and particulate contamination that causes the majority of outdoor storage damage. For applications requiring absolute moisture exclusion, plastic caps can be supplemented with desiccants or sealed bags, but for typical outdoor storage periods of months rather than years, HDPE caps alone provide adequate protection. Chemical resistance becomes particularly important in industrial environments where flange-protected components may be exposed to airborne chemicals, cleaning agents, or process materials. High-density polyethylene demonstrates excellent resistance to acids, bases, and solvents commonly encountered in petrochemical, manufacturing, and aerospace facilities. This chemical stability ensures that Plastic Flange Caps themselves do not degrade or transfer contaminants to the protected surfaces, maintaining the purity essential for sensitive microwave measurement equipment and precision antenna systems.

Optimal Applications and Limitation Understanding

Plastic Flange Caps excel in numerous outdoor scenarios while having definable limitations that users must understand for proper application. These protective devices perform optimally for intermediate-term outdoor storage and transportation, typically spanning periods from several weeks to multiple years depending on environmental severity. For waveguide assemblies, coaxial components, and microwave antennas in storage yards, shipping containers, or construction sites, quality Plastic Flange Caps provide cost-effective protection that preserves component value. The telecommunications industry extensively utilizes Plastic Flange Caps during network infrastructure deployments. When installing cell towers, satellite ground stations, or microwave relay systems, components often arrive on site weeks or months before installation. During this storage period, equipment faces direct weather exposure, temperature extremes, and handling stress. HDPE flange caps protect antenna feeds, waveguide runs, and precision connectors throughout this vulnerable period, ensuring components remain installation-ready without requiring cleaning or refurbishment.

Industry-Specific Performance Requirements

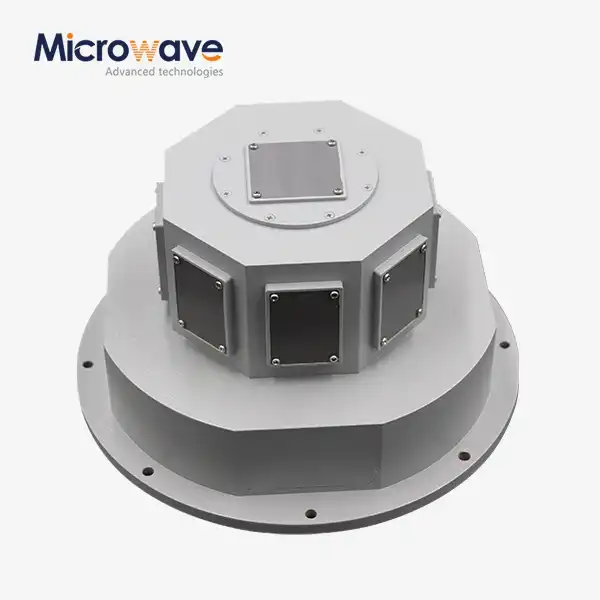

Aerospace and defense applications impose particularly stringent protection requirements due to the high value and critical performance demands of these systems. Surveillance radar components, satellite communication antennas, and navigation system elements cannot tolerate any contamination or damage that might compromise operational effectiveness. Plastic Flange Caps designed for these sectors feature enhanced sealing capabilities, impact resistance, and quality control documentation that traces materials and manufacturing processes. Advanced Microwave Technologies Co., Ltd manufactures Plastic Flange Caps specifically engineered for these demanding applications, with specifications that meet or exceed requirements for UAV systems, direction-finding equipment, and shipboard installations. Weather monitoring systems present unique challenges where equipment must function reliably in the most extreme conditions while being installed in exposed locations. Meteorological radar antennas and remote sensing equipment often undergo outdoor storage at installation sites before commissioning. During this period, Plastic Flange Caps protect sensitive microwave components from the very weather phenomena they will eventually measure. The dust-proof performance of well-designed caps prevents particulate accumulation in waveguide assemblies and connector interfaces that could cause signal attenuation or measurement errors. Security screening systems in airports and border crossings utilize precision microwave technology that requires careful protection during installation and maintenance. When these systems undergo upgrades or repairs, components may be temporarily removed and stored outdoors in secure areas. Plastic Flange Caps with tamper-evident features or security seals provide both physical protection and verification that components have not been accessed or compromised during storage periods.

Comparing Protection Methods and Selecting Appropriately

While Plastic Flange Caps offer numerous advantages for outdoor component protection, understanding alternative methods helps users make informed selection decisions. Metal flange covers provide superior impact resistance and can create hermetic seals when used with gaskets, but they add significant weight and cost compared to plastic alternatives. For applications where absolute moisture exclusion is critical, such as long-term preservation of spare parts, metal covers may justify their premium cost. However, for typical project storage and transportation scenarios, high-quality Plastic Flange Caps deliver equivalent protection at a fraction of the cost and weight. Adhesive tape or plastic wrap represents the simplest protection method but offers minimal durability in outdoor environments. UV exposure degrades adhesives, wind tears flexible wraps, and moisture can penetrate imperfect seals. These methods might suffice for very short-term indoor storage but prove inadequate for outdoor applications exceeding several days. The small incremental cost of proper Plastic Flange Caps provides dramatically superior protection that prevents expensive component damage or cleaning requirements.

Advanced Microwave's Solution for Outdoor Protection Challenges

Advanced Microwave Technologies Co., Ltd addresses the outdoor protection challenge through Plastic Flange Caps engineered specifically for demanding microwave component applications. Leveraging over twenty years of experience in waveguide assemblies, coaxial components, and antenna systems, the company understands the precise protection requirements these components demand. Their flange cap designs incorporate features directly informed by field experience across satellite communications, defense, aerospace, and navigation applications. The company's Plastic Flange Caps utilize premium high-density polyethylene formulated for extended outdoor durability. Material selection goes beyond standard industrial-grade HDPE to include UV stabilizer packages proven effective in accelerated weathering tests equivalent to years of outdoor exposure. This material specification ensures caps maintain protective integrity throughout typical project timelines without requiring replacement due to degradation.

Manufacturing precision ensures that Advanced Microwave's Plastic Flange Caps provide consistent fit across the complete range of waveguide flange standards used in microwave systems. From compact coaxial connectors to large rectangular waveguide flanges, precision molding creates caps that install easily while forming effective seals against contamination. The push-fit installation requires no tools or fasteners, enabling rapid protection of components during manufacturing, warehousing, shipping, and field installation workflows. Customization capabilities allow Advanced Microwave to address specific customer requirements beyond standard catalog products. Custom sizing accommodates non-standard flange geometries, alternative colors support inventory management systems, and logo printing enables brand identification or project tracking. For high-volume OEM applications, the company develops dedicated cap designs optimized for specific equipment models, potentially incorporating features like tether attachments, stacking lugs, or identification marking areas that streamline manufacturing and logistics processes. The environmental compliance of Advanced Microwave's Plastic Flange Caps reflects the company's commitment to sustainable manufacturing practices. Full compliance with RoHS and REACH regulations ensures the caps contain no restricted substances, allowing use in environmentally sensitive applications and facilitating responsible disposal or recycling at end of life. This compliance documentation, combined with ISO 9001:2015 quality management system certification, provides customers with confidence that component protection methods align with corporate environmental and quality objectives.

Conclusion

High-quality Plastic Flange Caps engineered from UV-stabilized HDPE provide reliable outdoor protection for waveguide, coaxial, and antenna components across telecommunications, aerospace, and defense applications when properly selected and deployed for appropriate durations and conditions.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd., a leading China Plastic Flange Caps manufacturer and China Plastic Flange Caps supplier, offers High Quality Plastic Flange Caps at competitive Plastic Flange Caps prices. As a trusted China Plastic Flange Caps factory with China Plastic Flange Caps wholesale capabilities and Plastic Flange Caps for sale globally, we provide complete OEM services backed by ISO certifications and over two decades of microwave expertise. Our perfect supply chain system, professional R&D team, and strict quality control ensure fast delivery and exceptional after-sales support for satellite communications, aerospace, and defense applications. Contact craig@admicrowave.com today to request specifications, samples, or custom solutions that protect your valuable microwave components throughout storage, shipping, and installation.

References

1. Massingill, J.L., "Polyethylene UV Stabilization for Long-Term Outdoor Applications," Plastics Engineering Handbook, Society of Plastics Engineers

2. Thompson, R.K. and Davis, M.E., "Environmental Degradation of High-Density Polyethylene in Industrial Applications," Journal of Materials Science and Engineering

3. Williams, P.A., "Flange Protection Systems for Microwave and RF Components," IEEE Transactions on Microwave Theory and Techniques

4. Anderson, H.B., "Material Selection for Outdoor Equipment Protection in Telecommunications Infrastructure," International Journal of Communications Systems

5. Mitchell, S.R., "Quality Assurance Standards for Protective Caps and Covers in Aerospace Applications," Aerospace Materials and Processes Quarterly

YOU MAY LIKE

VIEW MORELog Periodic Antenna

VIEW MORELog Periodic Antenna VIEW MORESlotted Waveguide Array Antenna

VIEW MORESlotted Waveguide Array Antenna VIEW MOREOpen Boundary Dual Linear Polarization Four Ridged Horn Antenna

VIEW MOREOpen Boundary Dual Linear Polarization Four Ridged Horn Antenna VIEW MOREConical Dual circular Polarization Horn Antenna

VIEW MOREConical Dual circular Polarization Horn Antenna VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna

VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna VIEW MOREConical Linear Polarization Horn Antenna

VIEW MOREConical Linear Polarization Horn Antenna VIEW MOREPlanar Spiral Antenna

VIEW MOREPlanar Spiral Antenna