Beyond Basic Waveguides: The Strategic Benefits of Double Ridged Flexible Design

When engineers face the challenge of routing high-frequency signals through complex geometries while maintaining signal integrity, traditional waveguides often fall short. The limitations become painfully apparent when dealing with tight spaces, vibrations, and demanding performance requirements across broad frequency ranges. This is where the revolutionary Double Ridged Flexible Waveguide technology emerges as a game-changing solution, offering unprecedented flexibility without compromising electrical performance, making it the ideal choice for modern microwave applications requiring both mechanical adaptability and superior signal transmission characteristics.

Revolutionary Design Principles of Double Ridged Flexible Waveguide Technology

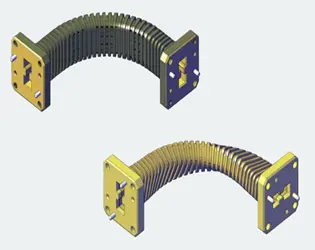

The fundamental innovation behind Double Ridged Flexible Waveguide lies in its sophisticated internal ridge structure that dramatically transforms electromagnetic field distribution patterns. The strategic placement of metallic ridges within the waveguide structure effectively modifies the electromagnetic field distribution and reduces the cutoff frequency, allowing for broader bandwidth operation. This design breakthrough enables engineers to achieve superior performance metrics that were previously impossible with conventional waveguide technologies. The double-ridged configuration creates a concentrated electric field between the ridges, significantly reducing the characteristic impedance compared to standard rectangular waveguides. This reduction in impedance facilitates better matching with external components and systems, eliminating the need for additional matching networks that would otherwise increase system complexity and insertion loss. The flexible construction materials are carefully selected to maintain these electrical properties even under mechanical stress, ensuring consistent performance throughout the operating envelope.

Enhanced Frequency Response and Bandwidth Capabilities

Double Ridged Flexible Waveguide technology delivers exceptional frequency response characteristics that extend well beyond traditional waveguide limitations. The principal effect of ridges is to lower the value of the cutoff wavelength, allowing a guide with smaller dimensions to be used for any given frequency. This fundamental advantage enables system designers to work with more compact form factors while achieving broader operational bandwidth in a single component. The enhanced bandwidth capabilities stem from the ridge geometry's ability to support multiple propagation modes across an extended frequency range. Unlike conventional waveguides that exhibit steep cutoff characteristics, Double Ridged Flexible Waveguides provide gradual transition zones that maintain consistent impedance matching across the entire operational spectrum. This characteristic proves invaluable in applications requiring wide instantaneous bandwidth, such as electronic warfare systems, broadband communication links, and multi-frequency radar installations.

Strategic Advantages in Modern Microwave Applications

The deployment of Double Ridged Flexible Waveguide technology offers compelling strategic advantages that directly address critical challenges in contemporary microwave system design. These advantages manifest across multiple dimensions, including mechanical flexibility, electrical performance, and system integration capabilities that collectively deliver superior value propositions for demanding applications.

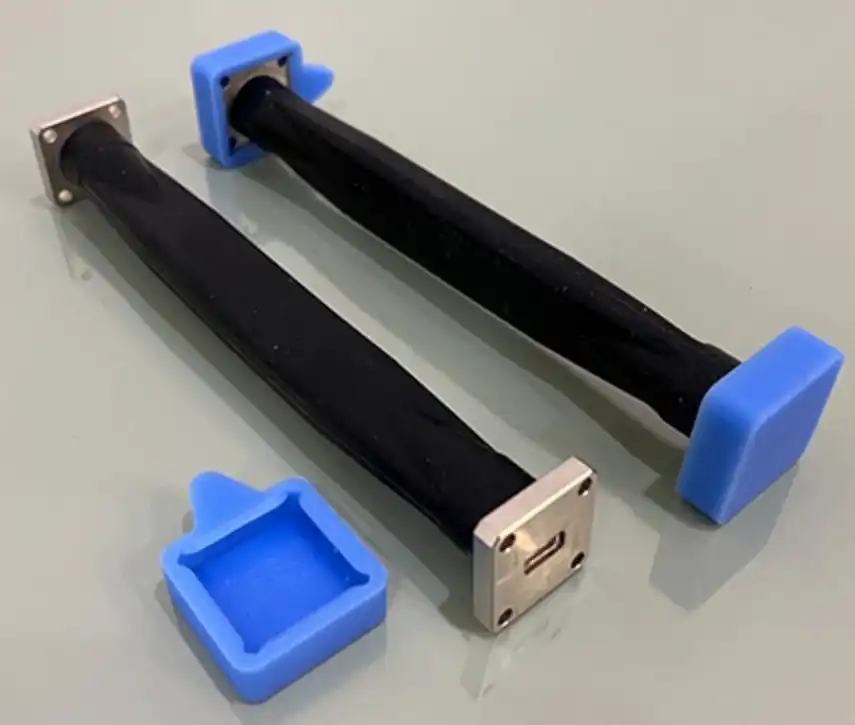

Superior Mechanical Flexibility and Installation Benefits

The flexible construction of Double Ridged Flexible Waveguide represents a paradigm shift in microwave system installation methodologies. Traditional rigid waveguides require precise mechanical alignment and often necessitate complex mounting structures to accommodate system geometry constraints. In contrast, flexible waveguide technology adapts to existing mechanical constraints, reducing installation time and eliminating the need for custom mechanical interfaces. In Satcom applications where movement is a factor, flexible waveguides give extra flexibility in space constraints, coupling with other waveguide flanges without altering electrical characteristics. This mechanical adaptability proves particularly valuable in mobile platforms, satellite ground stations, and shipboard installations where vibration, thermal expansion, and mechanical movement are constant considerations. The flexible design absorbs mechanical stresses that would otherwise be transmitted to sensitive electronic components, enhancing overall system reliability. The installation benefits extend beyond mechanical considerations to encompass significant cost savings in system integration. Flexible waveguides eliminate the need for precise mechanical tolerances and custom mounting hardware, reducing both material costs and labor requirements. The ability to route signals through complex paths without intermediate components simplifies system architecture and reduces potential failure points.

Electrical Performance Optimization Across Frequency Bands

Double Ridged Flexible Waveguide technology delivers exceptional electrical performance that surpasses conventional alternatives across multiple critical parameters. The double-ridge configuration optimizes field distribution to minimize losses while maintaining excellent voltage standing wave ratio (VSWR) characteristics throughout the operational frequency range. This performance optimization directly translates to improved system efficiency and enhanced signal quality in demanding applications. The ability of ridges to control waveguide impedance allows for impedance matching without additional components, greatly reducing design costs and complexity. This impedance control capability enables seamless integration with various system components, including antennas, amplifiers, and measurement equipment, without requiring external matching networks that would introduce additional losses and complexity. The low-loss characteristics of Double Ridged Flexible Waveguide technology prove particularly advantageous in high-frequency applications where signal attenuation becomes a critical design constraint. Advanced materials and precision manufacturing techniques ensure that insertion loss remains minimal even at millimeter-wave frequencies, enabling system designers to achieve performance specifications that would be impossible with alternative transmission line technologies.

Advanced Manufacturing and Customization Capabilities

Modern Double Ridged Flexible Waveguide manufacturing incorporates sophisticated production techniques that ensure consistent electrical and mechanical performance while enabling extensive customization to meet specific application requirements. These manufacturing capabilities represent the convergence of advanced materials science, precision machining, and electromagnetic design optimization.

Precision Engineering and Quality Control Processes

The manufacturing of Double Ridged Flexible Waveguide components demands exceptional precision in both dimensional control and material properties. Advanced manufacturing facilities utilize computer-controlled machining centers and specialized tooling to maintain tolerances that directly impact electrical performance. The ridge geometry must be manufactured to precise specifications to ensure consistent impedance characteristics and optimal field distribution patterns. Quality control processes encompass comprehensive electrical testing across the full operational frequency range, mechanical stress testing to verify flexibility and durability characteristics, and environmental testing to ensure reliable performance under extreme conditions. Each manufactured unit undergoes rigorous inspection procedures that validate both electrical specifications and mechanical performance parameters before shipment to customers. The integration of advanced measurement equipment, including vector network analyzers and specialized waveguide test fixtures, enables manufacturers to provide detailed characterization data for each product. This comprehensive testing approach ensures that customers receive components that meet or exceed specified performance requirements while providing the documentation necessary for system-level integration and verification.

Customization Options for Specialized Applications

The versatility of Double Ridged Flexible Waveguide technology enables extensive customization to address specific application requirements across diverse industries and use cases. Customization capabilities encompass dimensional modifications, material selection, flange configurations, and specialized protective coatings that enhance performance in challenging environments. Advanced Microwave Technologies offers comprehensive customization services that begin with detailed application analysis and requirements definition. Engineering teams work closely with customers to optimize waveguide designs for specific performance requirements, mechanical constraints, and environmental conditions. This collaborative approach ensures that the final product delivers optimal performance while meeting all system-level requirements. Customization extends to specialized configurations such as multi-port assemblies, integrated switching elements, and hybrid designs that combine flexible sections with rigid components. These advanced configurations enable system architects to implement complex signal routing schemes while maintaining the performance advantages of Double Ridged Flexible Waveguide technology throughout the signal path.

Industrial Applications and Market Impact

The adoption of Double Ridged Flexible Waveguide technology spans numerous industrial sectors, each benefiting from the unique combination of electrical performance and mechanical flexibility. These applications demonstrate the versatility and value proposition of advanced waveguide technology in addressing real-world engineering challenges.

Aerospace and Defense Applications

In aerospace and defense applications, Double Ridged Flexible Waveguide technology provides critical capabilities for radar systems, electronic warfare platforms, and satellite communication systems. The ability to maintain signal integrity while accommodating mechanical movement and vibration makes this technology indispensable for mobile and airborne platforms where traditional rigid waveguides would be impractical or impossible to implement. Military radar systems particularly benefit from the broad bandwidth capabilities of double-ridged designs, enabling simultaneous operation across multiple frequency bands without the complexity of switching networks. The flexible construction accommodates antenna positioning systems and rotating mechanisms while maintaining consistent electrical performance throughout the mechanical range of motion. Satellite communication ground stations utilize Double Ridged Flexible Waveguide technology to connect fixed equipment with tracking antennas that must continuously adjust position to maintain satellite links. The flexible design eliminates the need for rotary joints and slip rings that would introduce additional losses and potential failure modes.

Telecommunications and 5G Infrastructure

The deployment of 5G networks and advanced telecommunications infrastructure creates substantial demand for high-performance waveguide components that can operate across expanded frequency ranges while accommodating complex installation requirements. Double Ridged Flexible Waveguide technology addresses these requirements by providing reliable signal transmission capabilities across the millimeter-wave frequencies utilized by 5G systems. Base station installations particularly benefit from the flexible design, which simplifies the connection between RF equipment and antenna systems mounted on towers and rooftops. The ability to route signals through complex paths while maintaining low insertion loss enables more efficient system architectures and reduced installation costs. The broad bandwidth capabilities of double-ridged designs support the multi-band operation requirements of modern telecommunications systems, enabling single waveguide assemblies to handle multiple frequency allocations simultaneously. This capability reduces system complexity and improves overall reliability by minimizing the number of individual components required for multi-band operation.

Conclusion

Double Ridged Flexible Waveguide technology represents a fundamental advancement in microwave transmission line design, offering unprecedented combination of electrical performance and mechanical flexibility. The strategic benefits encompass enhanced bandwidth capabilities, superior impedance matching, reduced system complexity, and simplified installation procedures that collectively deliver exceptional value across diverse applications.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd stands as your premier China Double Ridged Flexible Waveguide factory, leveraging over 20 years of microwave expertise to deliver cutting-edge solutions. As a leading China Double Ridged Flexible Waveguide supplier and China Double Ridged Flexible Waveguide manufacturer, we provide comprehensive China Double Ridged Flexible Waveguide wholesale services with competitive Double Ridged Flexible Waveguide price points. Our state-of-the-art 24m Microwave Darkroom and ISO-certified manufacturing ensure High Quality Double Ridged Flexible Waveguide for sale that meets the most demanding specifications.

Our comprehensive OEM services include rapid prototyping, technical support, and global delivery capabilities, ensuring your project success from concept to deployment. With advanced measurement equipment spanning 0.5-110 GHz and strict quality control processes, we deliver reliable solutions for satellite communications, aerospace, defense, and telecommunications applications. Contact craig@admicrowave.com today to discuss your specific requirements and discover how our expertise can enhance your next project.

FAQ

Q: What frequency range do Double Ridged Flexible Waveguides support?

A: They typically operate from 0.5 to 110 GHz, covering microwave and millimeter-wave bands for diverse applications.

Q: How does flexible construction affect electrical performance?

A: Advanced materials maintain consistent impedance and low insertion loss even under mechanical stress and bending.

Q: Can Double Ridged Flexible Waveguides replace rigid alternatives?

A: Yes, they often provide superior bandwidth and flexibility while maintaining comparable or better electrical performance.

Q: What customization options are available for specific applications?

A: Extensive customization includes dimensions, materials, flanges, and specialized coatings for unique environmental requirements.

References

1. Pozar, David M. "Microwave Engineering, Fourth Edition" - Comprehensive analysis of waveguide design principles and ridge waveguide characteristics

2. Collin, Robert E. "Foundations for Microwave Engineering, Second Edition" - Advanced treatment of electromagnetic wave propagation in complex waveguide structures

3. Ramo, Simon, John R. Whinnery, and Theodore Van Duzer. "Fields and Waves in Communication Electronics, Third Edition" - Fundamental electromagnetic field theory applications in waveguide technology

4. IEEE Transactions on Microwave Theory and Techniques, Various Authors - "Double-Ridge Waveguide Analysis and Applications" - Peer-reviewed research on advanced waveguide design methodologies