How does a fixed attenuator work?

Signal distortion in RF systems can destroy critical data transmission, compromise radar accuracy, and lead to costly equipment failures in aerospace and defense applications. When engineers face impedance mismatches, excessive signal power, or measurement inaccuracies, they need reliable solutions that deliver consistent performance. A Coaxial Fixed Attenuator provides the answer by reducing signal power levels with precision while maintaining signal integrity across wide frequency ranges. Understanding how fixed attenuators work is essential for anyone dealing with RF circuit design, telecommunications infrastructure, or microwave measurement systems where controlled signal management determines system success or failure.

Understanding the Core Principles of Coaxial Fixed Attenuator Operation

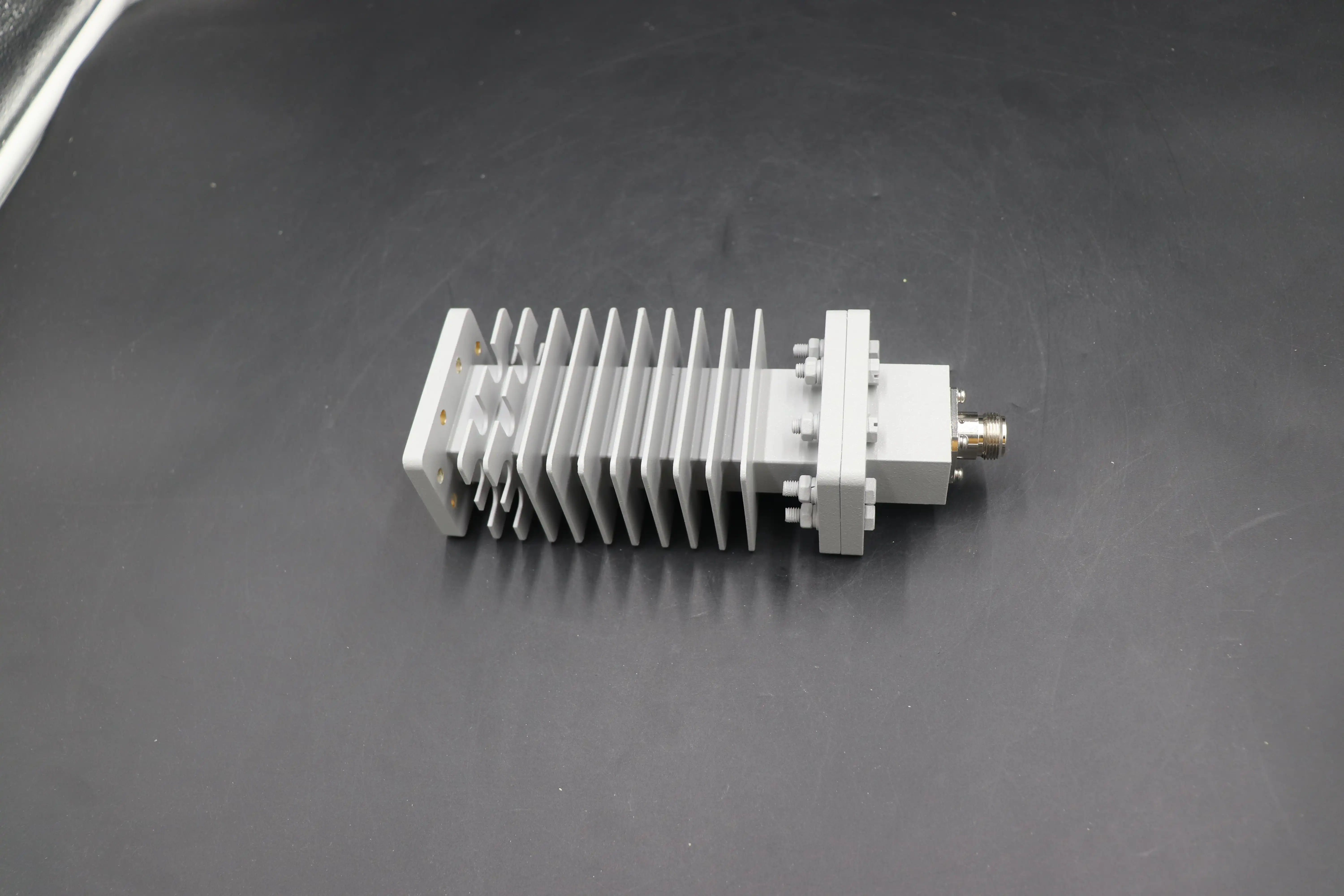

Fixed attenuators work by dissipating a portion of the signal energy in the form of heat. A fixed attenuator is essentially a resistor network that provides a fixed loss between the input and output ports. The fundamental operating principle relies on precisely engineered resistive networks that convert electrical energy into thermal energy while maintaining impedance matching throughout the signal path. These devices utilize carefully calculated resistance values arranged in specific circuit configurations to achieve predetermined attenuation levels measured in decibels. The physical construction of a Coaxial Fixed Attenuator involves multiple resistive elements strategically positioned within the signal path. When RF energy enters the attenuator, it encounters these resistance elements that absorb a calculated portion of the signal power. When the signal is reduced (i.e. attenuated) it is converted into heat. The greater the dB value, the hotter the attenuator will run because it is converting more of the signal into heat. This energy conversion process ensures that the output signal maintains the same characteristics as the input signal, just at a reduced amplitude level. Modern Coaxial Fixed Attenuators incorporate advanced materials and manufacturing techniques to ensure consistent performance across wide frequency ranges. The resistive elements are typically fabricated using thin-film or thick-film technologies that provide excellent stability and repeatability. Temperature coefficients are carefully controlled to minimize performance variations across operating temperature ranges, ensuring reliable operation in demanding environmental conditions.

Resistive Network Configurations in Fixed Attenuators

Fixed value attenuators make use of these core topologies realized with resistors in thin film and thick film hybrid technologies to provide fixed levels of attenuation. The three primary circuit configurations used in fixed attenuators are T-type, π-type, and bridged-T networks. Each configuration offers specific advantages depending on the application requirements and desired performance characteristics. The T-type configuration places resistors in both series and shunt positions, providing excellent impedance matching while achieving the desired attenuation level. The π-type network configuration utilizes two shunt resistors connected by a series resistor, creating a structure that resembles the Greek letter π. This arrangement is particularly effective for applications requiring high attenuation values while maintaining low VSWR performance. The bridged-T configuration combines elements from both T-type and π-type designs, offering enhanced isolation and improved frequency response characteristics for critical applications. Each resistive network configuration must be precisely calculated to maintain the characteristic impedance of the transmission line while providing the specified attenuation. The resistance values are determined using complex mathematical formulas that consider the desired attenuation level, characteristic impedance, and frequency response requirements. Advanced electromagnetic simulation software is often employed during the design process to optimize performance and minimize unwanted reflections.

Signal Power Management and Heat Dissipation

Effective thermal management is crucial for reliable Coaxial Fixed Attenuator operation, particularly in high-power applications. The conversion of RF energy to heat creates thermal stress that must be properly managed to prevent performance degradation or component failure. Advanced attenuator designs incorporate heat-spreading materials, thermal interfaces, and optimized mechanical structures to efficiently dissipate generated heat away from the active resistive elements. Power rating specifications define the maximum continuous power levels that an attenuator can handle without exceeding safe operating temperatures. These ratings are typically specified for specific ambient temperatures and may require derating at elevated operating temperatures. Understanding power handling capabilities is essential for proper application of fixed attenuators in high-power RF systems where thermal management directly impacts system reliability and component longevity. The relationship between attenuation value and power handling capability creates important design considerations. Higher attenuation values require greater energy dissipation, resulting in increased thermal stress and potentially reduced power handling capability. System designers must carefully balance attenuation requirements with power handling needs to ensure optimal performance in their specific applications.

Technical Specifications and Performance Characteristics of Coaxial Fixed Attenuator Designs

Modern Coaxial Fixed Attenuator designs must meet stringent performance requirements across multiple parameters including frequency response, VSWR, power handling, and environmental stability. For higher frequencies precisely matched low voltage standing wave ratio (VSWR) resistance networks are used. The frequency response characteristics determine how consistently the attenuator performs across its specified operating bandwidth, with advanced designs maintaining flat attenuation and low VSWR across multi-octave frequency ranges. VSWR performance is a critical specification that indicates how well the attenuator matches the characteristic impedance of the connected transmission line. Low VSWR values ensure minimal signal reflections, which could otherwise cause measurement errors, signal distortion, or system instability. High-quality Coaxial Fixed Attenuators typically achieve VSWR values of 1.25:1 or better across their entire operating frequency range, ensuring excellent signal integrity in demanding applications. Power handling specifications encompass both average power and peak power capabilities. Average power ratings define the continuous power levels that can be safely handled without exceeding thermal limits, while peak power ratings specify the maximum instantaneous power levels that can be accommodated. These specifications must consider factors such as pulse width, duty cycle, and ambient temperature conditions to ensure reliable operation across the full range of expected operating conditions.

Frequency Response and Bandwidth Considerations

The frequency response characteristics of a Coaxial Fixed Attenuator determine its suitability for specific applications and operating environments. Broadband designs must maintain consistent attenuation levels across wide frequency ranges while minimizing variations that could affect system performance. Advanced manufacturing techniques and careful material selection enable modern attenuators to achieve excellent frequency response characteristics from DC to millimeter-wave frequencies. Frequency-dependent effects such as skin effect, dielectric losses, and parasitic reactances become increasingly significant at higher frequencies. Careful design optimization and advanced simulation techniques are employed to minimize these effects and maintain consistent performance across the specified operating bandwidth. The use of high-quality substrate materials and precise manufacturing tolerances ensures that theoretical performance predictions are realized in actual production units. Temperature stability across the operating frequency range is another critical consideration for Coaxial Fixed Attenuator designs. Temperature coefficients of the resistive materials must be carefully matched to minimize performance variations across the specified operating temperature range. Advanced designs incorporate temperature compensation techniques that maintain consistent performance from -55°C to +125°C, enabling reliable operation in extreme environmental conditions.

Impedance Matching and VSWR Performance

Fixed attenuators also known as a "pad" are used to "match" unequal impedances. Impedance matching is fundamental to proper RF system operation, and fixed attenuators play a crucial role in maintaining system impedance integrity while providing signal level control. The resistive network design must present the correct impedance to both the source and load while providing the specified attenuation level. VSWR performance directly impacts signal integrity and measurement accuracy in RF systems. High VSWR values indicate poor impedance matching, which can cause signal reflections, standing wave patterns, and measurement uncertainties. Professional-grade Coaxial Fixed Attenuators are designed to maintain VSWR values well below 1.5:1 across their entire operating frequency range, ensuring minimal impact on overall system performance. The relationship between attenuation value and VSWR performance requires careful consideration during attenuator selection. Higher attenuation values may provide better impedance matching between mismatched source and load impedances, but they also introduce additional insertion loss that must be accounted for in system link budgets. System designers must optimize the balance between impedance matching improvement and acceptable signal level reduction.

Applications and Use Cases for Advanced Coaxial Fixed Attenuator Solutions

Fixed attenuators are used to improve the impedance matching in circuits. These are used to protect the circuits from damages caused by high voltage values. The versatility of Coaxial Fixed Attenuators makes them indispensable components in numerous RF and microwave applications. In telecommunications infrastructure, these devices ensure proper signal levels between different system components while maintaining signal integrity across long transmission paths. Base station applications utilize fixed attenuators to optimize transmitter power levels and prevent receiver overload conditions. Aerospace and defense applications demand the highest levels of reliability and performance from Coaxial Fixed Attenuator components. Radar systems employ these devices to control signal levels in both transmit and receive paths, ensuring optimal system sensitivity while preventing damage from high-power transmissions. Navigation systems rely on precise signal level control to maintain accuracy and reliability in critical positioning applications where signal integrity directly impacts mission success. Test and measurement applications represent another major market for high-performance Coaxial Fixed Attenuators. Vector network analyzers, spectrum analyzers, and signal generators require precise signal level control to achieve accurate measurement results. The use of calibrated attenuators with known insertion loss values enables precise power measurements and system calibration procedures essential for maintaining measurement traceability and accuracy.

Telecommunications and 5G Infrastructure Applications

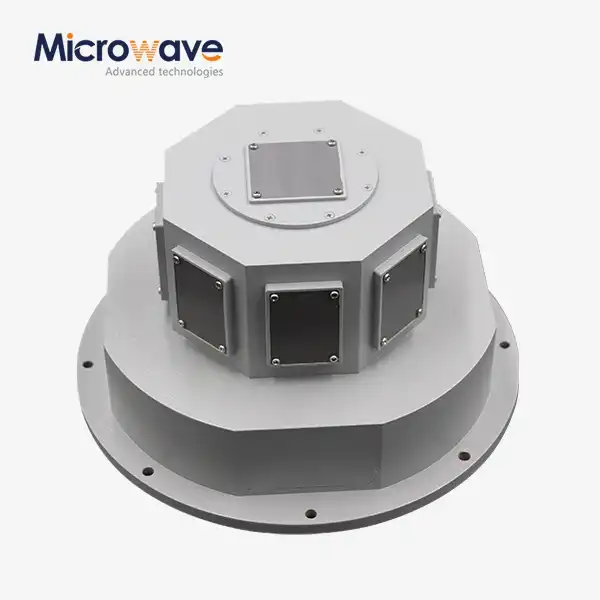

The deployment of 5G networks and advanced telecommunications infrastructure creates demanding requirements for Coaxial Fixed Attenuator performance. These systems operate across wide frequency ranges with stringent signal quality requirements that demand exceptional component performance. Fixed attenuators in 5G applications must maintain consistent performance across millimeter-wave frequencies while handling the high power levels associated with advanced antenna systems. Massive MIMO antenna systems utilize multiple Coaxial Fixed Attenuators to balance signal levels between different antenna elements and optimize overall system performance. The ability to maintain consistent attenuation values across large numbers of identical components is essential for achieving the precise amplitude and phase control required for optimal beamforming performance. Advanced manufacturing techniques and strict quality control procedures ensure that production attenuators meet the demanding specifications required for these applications. Small cell deployments and distributed antenna systems rely on fixed attenuators to optimize signal distribution and prevent interference between different coverage zones. The compact size requirements and wide operating temperature ranges associated with these installations demand robust component designs that can maintain consistent performance in challenging environmental conditions while providing long-term reliability.

Defense and Aerospace System Integration

Defense and aerospace applications place extraordinary demands on Coaxial Fixed Attenuator performance and reliability. Military radar systems operate in harsh environmental conditions while requiring precise signal control for target detection and tracking applications. The ability to maintain consistent performance across extreme temperature ranges, humidity conditions, and mechanical vibration is essential for mission-critical applications where component failure could have serious consequences. Satellite communication systems utilize fixed attenuators in both ground-based and space-based applications. Ground station equipment requires high-power handling capability and excellent long-term stability, while satellite-based components must withstand the extreme environmental conditions of space including temperature cycling, radiation exposure, and vacuum conditions. Specialized designs and qualification procedures ensure that these critical components meet the demanding requirements of space applications. Electronic warfare applications require Coaxial Fixed Attenuators with exceptional performance characteristics including wide frequency coverage, high dynamic range, and excellent isolation properties. The ability to maintain consistent performance across wide frequency ranges while providing precise signal level control is essential for effective countermeasure systems and signal intelligence applications.

Manufacturing Excellence and Quality Assurance at Advanced Microwave Technologies

Advanced Microwave Technologies Co., Ltd leverages over 20 years of experience in microwave component manufacturing to produce industry-leading Coaxial Fixed Attenuator solutions. The company's state-of-the-art 24m Microwave Darkroom provides unparalleled measurement capabilities for characterizing attenuator performance across the complete 0.5-110GHz frequency range. This advanced facility enables precise validation of theoretical performance predictions and ensures that production components meet the most demanding application requirements. The manufacturing process incorporates advanced thin-film and thick-film hybrid technologies to achieve the precise resistance values required for optimal performance. Automated assembly equipment and computer-controlled testing systems ensure consistent quality and repeatability across large production volumes. Every attenuator undergoes comprehensive swept-frequency testing to verify performance across its entire operating bandwidth, with calibration data provided on individual nameplate charts attached to each unit. Quality management systems certified to ISO 9001:2015 standards ensure consistent processes and continuous improvement throughout all manufacturing operations. Environmental management practices certified to ISO 14001:2015 standards demonstrate the company's commitment to sustainable manufacturing practices. Occupational health and safety programs certified to ISO 45001:2018 standards ensure safe working conditions for all personnel while maintaining the highest levels of product quality and reliability.

Advanced Testing and Calibration Capabilities

The comprehensive testing capabilities at Advanced Microwave Technologies enable thorough characterization of Coaxial Fixed Attenuator performance across all critical parameters. Network analyzer measurements verify insertion loss accuracy, VSWR performance, and frequency response characteristics across the full operating bandwidth. High-power testing validates power handling capabilities and thermal performance under realistic operating conditions. Environmental testing programs subject production components to extreme temperature cycling, humidity exposure, vibration testing, and shock testing to verify compliance with demanding military and aerospace specifications. Salt spray testing and other corrosion resistance evaluations ensure long-term reliability in marine and other harsh environments. These comprehensive testing programs provide confidence that components will perform reliably throughout their intended service life. Calibration services provide traceable measurement standards that enable customers to maintain measurement accuracy and comply with quality system requirements. The company's measurement standards are traceable to national metrology institutes, ensuring the highest levels of measurement accuracy and international recognition of calibration certificates.

Custom Design and OEM Services

Advanced Microwave Technologies provides comprehensive custom design services to meet unique application requirements that cannot be satisfied by standard catalog products. The experienced engineering team utilizes advanced electromagnetic simulation software and extensive component libraries to develop optimized designs that meet specific performance requirements while minimizing size, weight, and cost constraints. Prototyping services enable rapid evaluation of custom designs before committing to full-scale production. Quick turnaround times and flexible manufacturing capabilities support both small-quantity specialized applications and high-volume production requirements. Technical support throughout the design and manufacturing process ensures that custom solutions meet all performance requirements and integrate seamlessly into customer systems. OEM branding services enable customers to maintain their corporate identity while leveraging Advanced Microwave Technologies' manufacturing expertise and quality systems. Flexible packaging and marking options accommodate specific customer requirements while maintaining the high-quality standards expected from professional RF components.

Conclusion

Understanding how fixed attenuators work is fundamental for engineers designing RF systems that require precise signal control and impedance matching. These essential components utilize resistive networks to reduce signal power while maintaining excellent VSWR performance and signal integrity across wide frequency ranges. Advanced Coaxial Fixed Attenuator designs from industry leaders like Advanced Microwave Technologies provide the reliability and performance required for demanding telecommunications, aerospace, and defense applications where consistent operation is critical for system success.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Partner with Advanced Microwave Technologies Co., Ltd, a leading China Coaxial Fixed Attenuator manufacturer and China Coaxial Fixed Attenuator supplier with over 20 years of industry expertise. Our comprehensive product line includes high-quality Coaxial Fixed Attenuator solutions backed by ISO-certified quality systems and cutting-edge 24m Microwave Darkroom testing capabilities. Whether you need standard catalog products or custom OEM solutions, we provide competitive Coaxial Fixed Attenuator wholesale pricing and High Quality Coaxial Fixed Attenuator performance. As your trusted China Coaxial Fixed Attenuator factory partner, we offer fast delivery, expert technical support, and Coaxial Fixed Attenuator for sale at competitive Coaxial Fixed Attenuator price points. Contact craig@admicrowave.com today for quotes and technical consultations.

FAQ

Q: What is the difference between fixed and variable attenuators?

A: Fixed attenuators provide a constant, predetermined attenuation value that cannot be changed, while variable attenuators allow adjustment of attenuation levels during operation.

Q: How do I calculate the required attenuation value for my application?

A: Subtract the desired output power level from the input power level. The difference represents the required attenuation in decibels (dB).

Q: What happens to the power that is attenuated in a fixed attenuator?

A: The attenuated power is converted to heat energy and dissipated through the attenuator's thermal management system and housing materials.

Q: Can fixed attenuators improve impedance matching between components?

A: Yes, fixed attenuators can help improve impedance matching by providing a resistive buffer between mismatched source and load impedances.

References

1. "RF Circuit Design: Theory and Practice" by Reinhold Ludwig and Gene Bogdanov - Comprehensive coverage of RF attenuator theory and applications in modern communication systems.

2. "Microwave Engineering" by David M. Pozar - Detailed analysis of passive microwave components including fixed attenuators and their role in RF system design.

3. "RF and Microwave Circuit Design for Wireless Communications" by Lawrence E. Larson - Practical guidance on implementing fixed attenuators in wireless communication systems and their impact on overall system performance.

4. "Electronic Components and Technology" by Institute of Electrical and Electronics Engineers - Technical standards and specifications for fixed attenuator components used in professional RF applications and measurement systems.

YOU MAY LIKE

VIEW MORELog Periodic Antenna

VIEW MORELog Periodic Antenna VIEW MORESlotted Waveguide Array Antenna

VIEW MORESlotted Waveguide Array Antenna VIEW MOREOpen Boundary Dual Linear Polarization Four Ridged Horn Antenna

VIEW MOREOpen Boundary Dual Linear Polarization Four Ridged Horn Antenna VIEW MOREConical Dual circular Polarization Horn Antenna

VIEW MOREConical Dual circular Polarization Horn Antenna VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna

VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna VIEW MOREConical Linear Polarization Horn Antenna

VIEW MOREConical Linear Polarization Horn Antenna VIEW MOREPlanar Spiral Antenna

VIEW MOREPlanar Spiral Antenna