Best Double‑Ridged Waveguide Loop Coupler for Radar & 5G Systems

In today's high-frequency communication landscape, engineers and system designers face a critical challenge: finding a coupling solution that delivers exceptional performance across ultra-wide frequency ranges while maintaining signal integrity in demanding radar and 5G applications. Signal degradation, increased insertion loss, and coupling inconsistencies can cripple system performance, leading to unreliable data transmission and costly system failures. The Double-Ridged Waveguide Loop Coupler emerges as the optimal solution, combining precision engineering with versatile design to ensure minimal power loss, superior directivity, and stable operation across frequencies spanning from sub-GHz to millimeter-wave bands—making it the preferred choice for next-generation wireless infrastructure and advanced radar systems.

Understanding Double-Ridged Waveguide Loop Coupler Technology

The Double-Ridged Waveguide Loop Coupler represents a significant advancement in microwave coupling technology, engineered specifically to address the bandwidth limitations inherent in traditional waveguide components. This innovative design incorporates two opposing ridge structures within the waveguide cavity, fundamentally altering the electromagnetic field distribution and enabling operation across exceptionally wide frequency ranges. The ridge configuration effectively lowers the cutoff frequency while maintaining compact physical dimensions, allowing a single coupler to cover frequency bands that would typically require multiple conventional waveguide components. This architecture proves particularly valuable in modern communication systems where spectrum efficiency and component consolidation are paramount considerations for system designers. The coupling mechanism employs a loop structure that interacts precisely with the modified electromagnetic field created by the double-ridged waveguide geometry. This loop responds to both electric and magnetic field components, extracting a proportional sample of the propagating signal while maintaining excellent isolation between coupled and direct transmission paths. The position, diameter, and orientation of the coupling loop are critical parameters that determine the coupling coefficient and directivity characteristics. Advanced electromagnetic simulation and precision manufacturing techniques ensure that each Double-Ridged Waveguide Loop Coupler achieves the specified coupling values with minimal deviation across the entire operating bandwidth. The multi-port configuration typically includes input, output, coupled, and isolated ports, each optimized for specific impedance matching and power handling requirements essential for high-performance RF systems.

Key Performance Characteristics for Radar Applications

Modern radar systems demand coupling components that can handle high power levels while maintaining measurement accuracy across wide instantaneous bandwidths. The Double-Ridged Waveguide Loop Coupler excels in these applications through its robust construction and carefully engineered coupling characteristics. Air traffic control radars, weather monitoring systems, and defense surveillance platforms all benefit from the coupler's ability to extract signal samples without introducing significant insertion loss into the main transmission path. The typical insertion loss of less than 0.5 dB ensures that precious transmitted power reaches the antenna system efficiently, while the coupled port provides an accurate representation of the transmitted signal for monitoring and calibration purposes. Directivity performance represents another critical parameter for radar applications, where distinguishing forward and reverse power flow enables sophisticated system diagnostics. High-quality Double-Ridged Waveguide Loop Couplers achieve directivity values exceeding 15 dB across their specified frequency range, with premium designs reaching 20 dB or higher. This exceptional directivity allows radar system operators to accurately measure reflected power from targets or antenna mismatches while minimizing measurement errors. The coupling flatness specification, typically maintained within ±1.0 dB across the full bandwidth, ensures consistent performance during frequency-agile radar operation. Temperature stability is equally important, as radar systems often operate in challenging environmental conditions where ambient temperatures can vary significantly. Premium Double-Ridged Waveguide Loop Couplers incorporate thermal compensation techniques and utilize materials with matched thermal expansion coefficients to maintain coupling stability across temperature extremes.

Optimizing 5G Infrastructure with Advanced Couplers

The rollout of 5G networks presents unique challenges for RF component designers, particularly in millimeter-wave frequency bands where traditional waveguide technologies face significant limitations. Double-Ridged Waveguide Loop Couplers provide an elegant solution for 5G base station applications, supporting the wide channel bandwidths required for multi-gigabit data transmission. The frequency range capability extending from sub-6 GHz pioneer bands through Ka-band millimeter-wave allocations allows network operators to deploy standardized coupling solutions across diverse spectrum assignments. This component versatility reduces inventory complexity and simplifies maintenance procedures for telecommunications infrastructure providers managing large-scale network deployments. Signal integrity maintenance becomes increasingly critical at millimeter-wave frequencies where even minor impedance discontinuities can cause significant reflections and standing wave patterns. The precision-machined transitions within Double-Ridged Waveguide Loop Couplers minimize voltage standing wave ratio to values typically below 1.20:1, ensuring efficient power transfer and reducing the potential for thermal hotspots that could degrade component reliability. The low VSWR characteristic also contributes to improved power amplifier stability and efficiency, as the source sees a well-matched load impedance across all operating frequencies. For massive MIMO implementations requiring dozens or hundreds of antenna elements, the compact footprint of double-ridged designs enables dense packaging while the excellent port-to-port isolation prevents crosstalk between adjacent signal paths. The power handling capability, often exceeding several kilowatts for continuous wave applications, accommodates the high transmit powers necessary for extended cell coverage in rural and suburban deployments.

Technical Specifications and Design Features

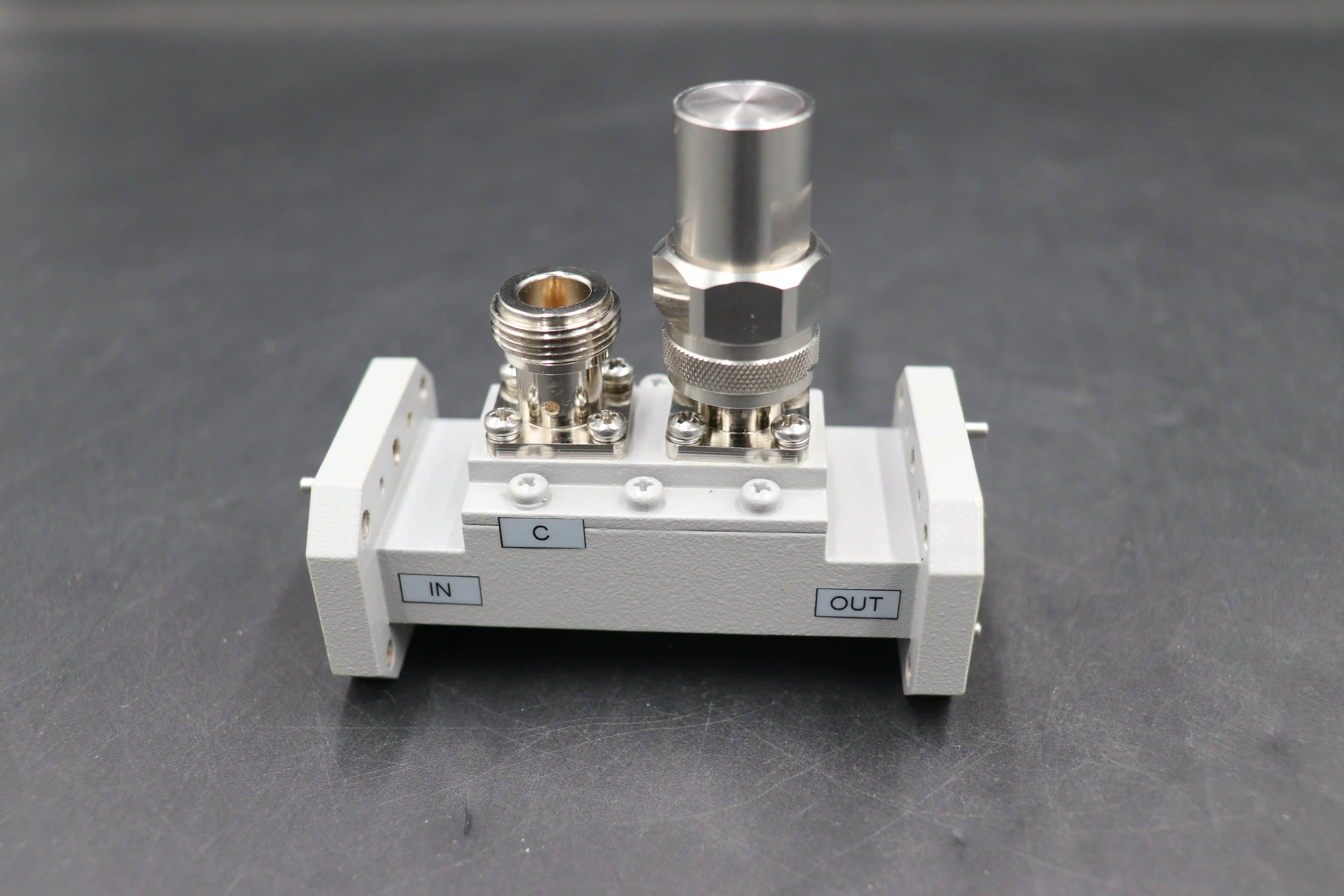

Advanced Microwave Technologies manufactures Double-Ridged Waveguide Loop Couplers with meticulous attention to electromagnetic performance and mechanical reliability. The structural design begins with precision-machined waveguide bodies, typically fabricated from aerospace-grade aluminum alloys that provide excellent electrical conductivity while maintaining low weight for tower-mounted installations. The ridge elements are formed through either precision milling or electrical discharge machining processes, achieving the tight dimensional tolerances necessary for consistent electromagnetic performance. Surface finishes receive particular attention, with electroplated silver or gold coatings applied to minimize conductor losses at high frequencies. These precious metal finishes also provide superior oxidation resistance compared to bare aluminum, ensuring stable performance throughout the component's operational lifetime even in corrosive coastal or industrial environments. The coupling loop assembly represents the heart of the component, where electromagnetic coupling between the main waveguide channel and the secondary measurement port occurs. Manufacturing techniques have evolved to enable extremely precise loop positioning and orientation, with dimensional control maintained to within micrometers. The loop material selection balances electrical conductivity requirements against mechanical strength considerations, as the loop must maintain its geometric configuration despite vibration, thermal cycling, and handling stresses encountered during installation and operation. Connector interfaces typically employ industry-standard coaxial connectors such as Type-N, SMA, or precision 2.92mm designs for millimeter-wave applications. These connectors undergo rigorous testing to verify their electrical performance and mechanical durability, with particular emphasis on maintaining low VSWR and high return loss across the specified frequency range.

Frequency Range and Bandwidth Considerations

The remarkable bandwidth capability of Double-Ridged Waveguide Loop Couplers stems directly from the ridge geometry's influence on waveguide propagation characteristics. Standard rectangular waveguides exhibit a practical bandwidth of approximately 40 percent due to mode purity requirements and dispersion considerations. In contrast, double-ridged configurations routinely achieve octave bandwidths (2:1 frequency ratio) and in some designs approach triple-octave coverage. This expanded bandwidth capability fundamentally changes system architecture possibilities, allowing designers to cover multiple communication bands or radar modes with a single coupling component. The frequency range spanning 0.5 GHz to 110 GHz available from specialized manufacturers like Advanced Microwave Technologies encompasses virtually all practical microwave and millimeter-wave applications encountered in telecommunications, defense, and scientific instrumentation. Waveguide size selection determines the specific frequency range for each Double-Ridged Waveguide Loop Coupler variant. The WRD-series designations indicate standardized double-ridged waveguide dimensions, with smaller cross-sections supporting higher frequency operation. WRD-180 components cover approximately 8 to 40 GHz, making them ideal for Ka-band satellite communications and vehicular radar systems. Larger WRD-650 variants operate from 1 to 4 GHz, serving applications in air traffic control radar and mobile communication systems. The ability to customize frequency coverage through ridge dimension optimization enables manufacturers to tailor components precisely to customer specifications, whether the application requires coverage of specific allocated spectrum bands or continuous operation across unusually wide frequency spans. Coupling value selection typically ranges from 20 dB for applications requiring strong signal sampling to 60 dB where minimal main-line interference is essential.

Power Handling and Thermal Management

High-power radar transmitters and communication amplifiers demand coupling components capable of withstanding substantial RF power levels without degradation or failure. Double-Ridged Waveguide Loop Couplers achieve impressive power handling through several design features. The relatively large waveguide cross-section compared to coaxial transmission lines provides lower current density on conductor surfaces, reducing ohmic heating even at multi-kilowatt power levels. The loop coupling element is designed with adequate conductor cross-section to handle the coupled power without excessive temperature rise. Premium designs incorporate heat-sinking features such as extended metal fins or provisions for forced-air cooling in extreme power applications. The dielectric materials used at port transitions and mounting hardware are selected for low loss tangent and high thermal conductivity, further enhancing power dissipation capabilities. Average power ratings for typical Double-Ridged Waveguide Loop Couplers range from several hundred watts for compact millimeter-wave designs to multiple kilowatts for lower-frequency, larger cross-section variants. Peak power handling for pulsed radar applications often exceeds average power ratings by an order of magnitude or more, limited primarily by voltage breakdown considerations rather than thermal constraints. The careful selection of internal air gaps and surface finishes minimizes the risk of multipaction or corona discharge phenomena that can cause sudden component failure in high-power applications. Testing protocols verify power handling capabilities through extended duration operation at rated power levels, with thermal imaging used to identify potential hotspots requiring design modifications. Environmental sealing techniques protect internal surfaces from moisture ingress and contamination that could reduce breakdown thresholds or increase insertion loss.

Applications Across Critical Industries

The versatility of Double-Ridged Waveguide Loop Couplers has led to their adoption across diverse industrial sectors where reliable RF coupling is essential. Satellite communication ground stations utilize these components for signal monitoring in both transmit and receive paths, enabling operators to verify link quality and quickly diagnose system malfunctions. The wide frequency coverage proves particularly valuable in commercial satellite operations where multiple frequency bands must be supported using shared infrastructure. The low insertion loss characteristic maximizes link budget efficiency, critical for geostationary satellite links where signal path losses exceed 200 dB. The coupled port provides convenient access for spectrum analyzers and other test equipment, facilitating routine maintenance and troubleshooting procedures without requiring service interruptions. Defense and aerospace applications impose particularly stringent requirements on RF components, and Double-Ridged Waveguide Loop Couplers have proven their reliability in these demanding environments. Military radar systems employ these couplers for transmitter power monitoring, receiver protection, and built-in test equipment integration. The rugged mechanical construction withstands shipboard shock and vibration environments, while corrosion-resistant finishes ensure reliable operation in maritime conditions. Airborne radar installations benefit from the compact size and low weight of double-ridged designs compared to conventional waveguide components achieving similar bandwidth. Electronic warfare systems leverage the wide instantaneous bandwidth to simultaneously monitor and analyze signals across multiple threat bands. The precision coupling characteristics enable accurate power measurements essential for evaluating radar cross-section during test range operations.

Telecommunications and Cellular Infrastructure

Modern cellular base stations increasingly rely on Double-Ridged Waveguide Loop Couplers as mobile networks migrate toward higher frequencies and wider channel bandwidths. The massive MIMO antenna arrays deployed for 5G services require signal distribution networks that can split and combine dozens of independent signal paths with minimal loss and excellent isolation. Loop couplers integrated into these distribution networks enable monitoring of individual transmitter outputs, facilitating fault detection and performance optimization in real-time. The ability to extract signal samples without interrupting main path operation proves invaluable for remote monitoring systems that track base station performance across geographically dispersed networks. Maintenance costs decrease as technicians can remotely identify failing components before service interruptions occur, improving network availability and customer satisfaction. Backhaul microwave links connecting cell sites to core network infrastructure also benefit from Double-Ridged Waveguide Loop Coupler technology. These point-to-point radio systems operate at frequencies ranging from 6 GHz through millimeter-wave E-band allocations, often employing automatic transmit power control to compensate for rain fade and atmospheric absorption. The coupled port signals enable the transmit power control loop to accurately measure output power and adjust amplifier drive levels accordingly. The wide frequency coverage of double-ridged designs accommodates network operators who deploy multi-band backhaul radios, reducing equipment complexity and improving system reliability. The excellent return loss characteristics minimize interference between transmit and receive chains in frequency-division duplex systems, preserving sensitivity and maximizing throughput.

Test and Measurement Equipment Integration

The precision coupling characteristics and broad frequency coverage of Double-Ridged Waveguide Loop Couplers make them essential components in microwave test equipment and measurement systems. Vector network analyzers employ these couplers in test set configurations, enabling accurate measurement of device reflection and transmission characteristics across wide frequency spans. The high directivity ensures that forward and reverse traveling waves can be distinguished with minimal uncertainty, critical for precise S-parameter measurements. Calibration procedures account for the coupler's own insertion loss and directivity specifications, with measurement uncertainty budgets improved through the use of premium components exhibiting exceptional stability and repeatability. The power handling capability allows testing of active devices and amplifiers at realistic operating power levels. Antenna test ranges utilize Double-Ridged Waveguide Loop Couplers to sample radiated signals for pattern measurement and gain calibration procedures. The compact design facilitates integration into test fixture assemblies where space constraints often limit component selection. The stable coupling characteristics across temperature variations ensure measurement repeatability even as environmental conditions change throughout test campaigns. Research laboratories investigating new wireless technologies and spectrum allocations rely on the wide bandwidth coverage to prototype systems operating across unconventional frequency ranges. The availability of custom frequency variants from manufacturers like Advanced Microwave Technologies enables research groups to access precisely the frequency coverage needed for their specific investigations without paying for unnecessary bandwidth or accepting compromised performance from general-purpose components.

Manufacturing Excellence and Quality Assurance

Advanced Microwave Technologies brings over two decades of specialized experience to Double-Ridged Waveguide Loop Coupler production, combining traditional craftsmanship with modern manufacturing technologies. The design process begins with electromagnetic simulation using industry-leading software tools that model the complex field distributions within ridged waveguide structures. Parametric optimization algorithms explore vast design spaces to identify configurations that meet specified electrical requirements while maintaining manufacturability. Prototype fabrication follows successful simulation, with components subjected to comprehensive network analyzer testing to verify performance against predictions. This iterative refinement process continues until measured performance meets or exceeds design targets across all critical parameters including coupling value, directivity, VSWR, and insertion loss. Production manufacturing employs computer numerically controlled machining centers capable of achieving the dimensional precision necessary for consistent electrical performance. In-process quality control includes dimensional verification using coordinate measuring machines and visual inspection of critical features such as ridge geometry and surface finishes. Plating processes receive particular attention, with thickness and uniformity measurements ensuring adequate conductivity and oxidation protection. Assembly operations join waveguide sections, coupling elements, and connector interfaces using precision brazing or bolted flanges depending on design requirements. Each completed coupler undergoes full electrical characterization across its specified frequency range, with test data archived for traceability and future reference. Environmental screening tests may include thermal cycling, vibration exposure, and humidity conditioning to verify reliability in challenging operating environments.

ISO Certification and Standards Compliance

The quality management system at Advanced Microwave Technologies maintains certification to ISO 9001:2015 standards, ensuring consistent processes and continuous improvement across all operations. This certification demonstrates the organization's commitment to meeting customer requirements and applicable regulatory standards. The ISO 14001:2015 environmental management certification reflects responsible manufacturing practices that minimize ecological impact through waste reduction, energy conservation, and emission controls. These environmental initiatives extend beyond mere compliance to encompass proactive measures such as selecting low-impact materials, optimizing manufacturing processes for energy efficiency, and implementing comprehensive recycling programs for metal scrap and chemical waste streams. Occupational health and safety receives equal priority through ISO 45001:2018 certification, which establishes comprehensive protocols for employee protection. Engineering and manufacturing personnel receive thorough training in safe handling of precision equipment, chemical processes, and electrical test systems. Personal protective equipment and engineered safety controls minimize exposure to potential hazards. The combination of these three ISO certifications positions Advanced Microwave Technologies as a responsible manufacturing partner committed to quality, environmental stewardship, and employee welfare. The certifications also facilitate business relationships with major corporations and government agencies whose procurement policies mandate supplier adherence to international standards.

Customization and OEM Services

Recognizing that standard catalog products cannot address every application requirement, Advanced Microwave Technologies offers extensive customization capabilities for Double-Ridged Waveguide Loop Coupler specifications. The engineering team collaborates closely with customers to understand specific performance requirements, physical constraints, and environmental conditions influencing design parameters. Custom frequency ranges can be optimized to cover precisely the spectrum allocations relevant to particular applications, whether that involves cellular bands, radar allocations, or proprietary wireless systems. Coupling values can be tailored anywhere within the technically feasible range, accommodating applications requiring strong signal sampling for monitoring purposes or weak coupling for minimal main-line interference. Material selection customization addresses special requirements such as extreme temperature operation, weight-sensitive aerospace applications, or corrosive industrial environments. Alternative alloys, exotic platings, and specialized surface treatments can be incorporated based on specific needs. Flange configurations adapt to mate with existing system components, whether that involves standard waveguide flanges, proprietary mounting interfaces, or integrated support brackets for simplified installation. Connector types and orientations can be modified to accommodate particular equipment layouts or cable routing requirements. The OEM service philosophy extends beyond simple component customization to encompass collaborative system-level problem solving, where Advanced Microwave Technologies engineers contribute their specialized expertise to help customers optimize complete RF architectures.

Technical Support and Rapid Prototyping

The OEM services include comprehensive technical support throughout the product development cycle. Initial consultation helps customers articulate requirements and identify potential design challenges early in the process. Electromagnetic analysis services can evaluate how proposed Double-Ridged Waveguide Loop Coupler specifications will integrate into complete system designs, identifying potential issues such as spurious mode generation or unexpected coupling effects. Rapid prototyping capabilities enable quick fabrication of sample units for customer evaluation, with typical turnaround times measured in weeks rather than months. This fast prototyping cycle allows iterative refinement of specifications based on actual measured performance rather than relying solely on theoretical predictions. Installation guidance and troubleshooting support ensure successful field deployment of custom components. Detailed technical documentation accompanies each delivery, including dimensional drawings, test data, handling precautions, and recommended integration practices. The technical support team remains available to address questions arising during system integration or operational deployment. This ongoing relationship distinguishes Advanced Microwave Technologies from vendors who simply ship products without maintaining customer engagement. The combination of manufacturing flexibility, engineering expertise, and responsive support makes the company an ideal partner for organizations developing sophisticated RF systems where standard off-the-shelf components prove inadequate.

Conclusion

The Double-Ridged Waveguide Loop Coupler stands as the definitive solution for modern radar and 5G systems requiring exceptional bandwidth, minimal insertion loss, and unwavering performance reliability across demanding operational environments.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Partner with Advanced Microwave Technologies Co., Ltd., your trusted China Double-Ridged Waveguide Loop Coupler manufacturer, supplier, and factory offering High Quality Double-Ridged Waveguide Loop Coupler for sale at competitive Double-Ridged Waveguide Loop Coupler price points with China Double-Ridged Waveguide Loop Coupler wholesale options. With over 20 years of expertise, ISO-certified manufacturing, and a state-of-the-art 24m Microwave Darkroom testing facility supporting frequencies up to 110 GHz, we deliver customized OEM solutions with rapid prototyping, expert technical support, and global export capabilities. Contact our engineering team at craig@admicrowave.com to discuss your specific requirements and experience the perfect supply chain system, strict quality control, and strong after-sales support that sets us apart. Save this page for quick reference whenever you need reliable waveguide solutions.

References

1. Shams, Shoukry I., and Ahmed A. Kishk. "Design of 3-dB Hybrid Coupler Based on RGW Technology." IEEE Transactions on Microwave Theory and Techniques, vol. 65, no. 10, 2017, pp. 3849-3855.

2. Ali, Mohamed M. M., Omar M. Haraz, Ibrahim Afifi, Abdel-Razik Sebak, and Tayeb A. Denidni. "Ultra-Wideband Compact Millimeter-Wave Printed Ridge Gap Waveguide Directional Couplers for 5G Applications." IEEE Access, vol. 10, 2022, pp. 90706-90714.

3. Zhao, Zheng, and Tarek A. Denidni. "Millimeter-Wave Printed-RGW Hybrid Coupler with Symmetrical Square Feed." IEEE Microwave and Wireless Components Letters, vol. 30, no. 2, 2020, pp. 156-159.

4. Shen, Dan, Ke Wang, and Xiao Zhang. "A Substrate Integrated Gap Waveguide Based Wideband 3-dB Coupler for 5G Applications." IEEE Access, vol. 6, 2018, pp. 66798-66806.

5. Schmidt, Robert V., and Ivan P. Kaminow. "Metal-Diffused Optical Waveguide Devices in LiNbO₃." Applied Physics Letters, vol. 25, no. 8, 1974, pp. 458-460.