Your Partner for Custom Waveguide Channel Rotary Joint Solutions

When critical microwave systems fail due to signal degradation in rotating assemblies, the cost extends far beyond component replacement. Satellites lose communication links, radar systems compromise defense capabilities, and aerospace navigation becomes unreliable. The Waveguide Channel Rotary Joint represents the crucial bridge between stationary and rotating microwave systems, ensuring seamless signal transmission where traditional connections fail. This comprehensive guide explores how Advanced Microwave Technologies Co., Ltd. delivers custom Waveguide Channel Rotary Joint solutions that maintain signal integrity under the most demanding conditions, addressing the specific challenges faced by engineers in satellite communications, defense systems, aerospace applications, and telecommunications infrastructure.

Understanding Custom Waveguide Channel Rotary Joint Technology

The Waveguide Channel Rotary Joint stands as one of the most sophisticated electromechanical devices in microwave engineering, designed specifically to transfer high-frequency signals between stationary and rotating structures without compromising signal quality. These precision-engineered components operate on the fundamental principle of maintaining electromagnetic field continuity while accommodating mechanical rotation, a challenge that has driven decades of innovation in microwave technology. Modern Waveguide Channel Rotary Joint designs incorporate advanced materials and manufacturing techniques to achieve minimal insertion loss and maximum isolation between channels. The electromagnetic performance depends critically on precise mechanical tolerances, typically measured in micrometers, and sophisticated bearing systems that ensure smooth rotation over millions of cycles. Advanced Microwave Technologies Co., Ltd. manufactures these components using rigorous electrical and mechanical design principles, ensuring each Waveguide Channel Rotary Joint meets the exacting standards required for mission-critical applications.

Core Design Principles of Waveguide Channel Rotary Joints

The fundamental architecture of a Waveguide Channel Rotary Joint relies on maintaining electromagnetic field patterns while allowing continuous rotation. This requires careful consideration of waveguide dimensions, bearing systems, and coupling mechanisms that preserve signal characteristics across the rotary interface. Advanced manufacturing techniques ensure that the internal surfaces maintain the precise geometry necessary for optimal microwave propagation, while specialized materials provide the durability required for long-term operation in harsh environments. The electrical design of each Waveguide Channel Rotary Joint involves complex field analysis to minimize reflection and maximize power transfer efficiency. Engineers must carefully balance mechanical requirements with electromagnetic performance, ensuring that bearing systems do not interfere with RF characteristics while providing the mechanical reliability necessary for continuous operation. This balance represents one of the most challenging aspects of rotary joint design, requiring extensive simulation and testing to achieve optimal results.

Advanced Models and Specifications for Custom Applications

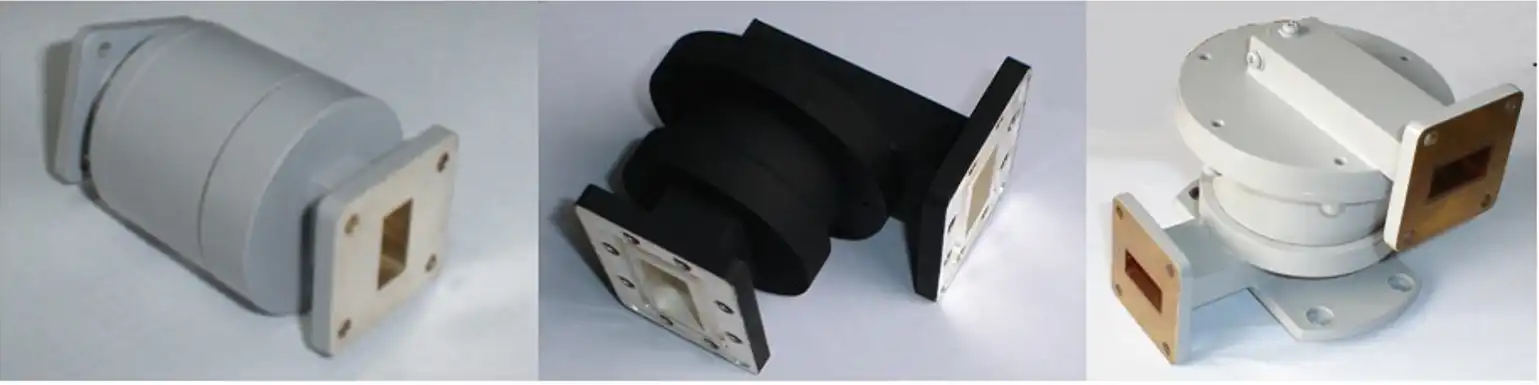

Advanced Microwave Technologies Co., Ltd. offers three primary Waveguide Channel Rotary Joint configurations, each designed to meet specific application requirements. The UI model represents a dual-channel U+I type configuration, providing channel isolation exceeding 50dB for applications requiring minimal crosstalk between signal paths. This configuration proves particularly valuable in radar systems where multiple signals must remain completely isolated to prevent interference patterns that could compromise target detection accuracy. The UL model delivers dual-channel U+L type functionality with identical isolation performance, optimized for satellite communication systems requiring simultaneous transmission and reception capabilities. This Waveguide Channel Rotary Joint variant enables continuous rotation of satellite dish assemblies while maintaining separate signal paths for uplink and downlink communications, ensuring reliable data transfer regardless of antenna positioning requirements.

Technical Performance Characteristics

The UU model provides dual-channel U+U type operation, specifically designed for applications requiring two identical waveguide channels with superior isolation characteristics. Each Waveguide Channel Rotary Joint model delivers channel isolation greater than or equal to 50dB, ensuring minimal signal bleed-through even in the most demanding electromagnetic environments. This performance level enables deployment in sensitive military applications where signal security and integrity represent critical operational requirements. All three Waveguide Channel Rotary Joint configurations support operation across the full frequency range from 0.5 to 110 GHz, accommodating everything from legacy communication systems to cutting-edge millimeter-wave applications. The wide bandwidth capability ensures compatibility with current and future communication standards, including 5G and anticipated 6G technologies that will operate at increasingly higher frequencies.

Product Benefits and Performance Advantages

The primary advantage of Advanced Microwave Technologies' Waveguide Channel Rotary Joint designs lies in their exceptionally low transmission loss characteristics. Signal attenuation remains minimal even at the highest operating frequencies, crucial for maintaining data integrity in long-range communication systems and sensitive radar applications. This performance stems from precision manufacturing techniques and careful attention to internal surface finishes that minimize electromagnetic losses. Wide frequency range support represents another critical benefit, with each Waveguide Channel Rotary Joint capable of handling signals up to 110 GHz. This versatility enables deployment across diverse applications, from traditional microwave communication systems operating at lower frequencies to advanced millimeter-wave radar and communication systems that demand performance at the highest frequency ranges. The broad bandwidth capability ensures long-term viability as communication standards evolve toward higher frequencies.

Durability and Environmental Resistance

Each Waveguide Channel Rotary Joint incorporates design features that provide exceptional resistance to environmental factors and mechanical stress. Advanced bearing systems and protective coatings enable reliable operation in harsh conditions, including extreme temperatures, vibration, and electromagnetic interference that could compromise lesser components. This durability ensures consistent performance throughout extended operational lifetimes, reducing maintenance requirements and total cost of ownership. Customization options allow each Waveguide Channel Rotary Joint to be tailored for specific application requirements, including material selection for extreme environments, dimensional modifications for space-constrained installations, and frequency range optimization for specialized applications. This flexibility enables optimal performance in unique deployment scenarios while maintaining the fundamental reliability and performance characteristics that define professional-grade rotary joints.

Precision Engineering and Technical Features

The manufacturing process for each Waveguide Channel Rotary Joint incorporates precision engineering techniques that guarantee stable and accurate signal transmission across the rotary interface. Computer-controlled machining ensures dimensional accuracy within tight tolerances, while specialized surface treatments minimize insertion loss and maximize power handling capability. Quality control procedures verify performance parameters at multiple stages throughout the manufacturing process, ensuring consistent results across production runs. Wideband capability represents a fundamental design characteristic, enabling each Waveguide Channel Rotary Joint to support complex signal formats and multiple communication standards simultaneously. This versatility proves particularly valuable in modern communication systems that must handle diverse signal types and rapidly evolving modulation schemes. The broad bandwidth performance ensures compatibility with both current and future communication standards, protecting investment value over extended operational periods.

Compact Design for Integration Flexibility

Despite their sophisticated internal mechanisms, Waveguide Channel Rotary Joint designs maintain compact external dimensions that facilitate integration into space-constrained systems. The optimized packaging enables installation in aircraft, spacecraft, and mobile communication systems where size and weight considerations represent critical design constraints. This compact form factor does not compromise performance, maintaining full specifications while minimizing system impact. Environmental compliance ensures that each Waveguide Channel Rotary Joint meets RoHS standards, guaranteeing that all materials remain free of harmful substances. This environmental responsibility extends throughout the manufacturing process, incorporating sustainable practices that minimize ecological impact while maintaining the quality and performance standards required for professional applications.

Critical Applications Across Industries

Satellite communication systems represent one of the most demanding applications for Waveguide Channel Rotary Joint technology, where signal transmission through rotating antenna assemblies requires absolute reliability. These systems must maintain continuous communication links while tracking satellites across the sky, requiring rotary joints that can handle high power levels while preserving signal quality over millions of rotation cycles. Advanced Microwave Technologies' designs meet these stringent requirements through careful engineering and extensive testing. Radar systems, particularly those used in military and defense applications, rely on Waveguide Channel Rotary Joint technology to enable antenna rotation while maintaining precise signal characteristics. These applications demand exceptional isolation between channels to prevent interference that could compromise target detection and tracking accuracy. The high isolation performance of Advanced Microwave Technologies' designs ensures reliable operation in these critical applications where system failure could have serious consequences.

Aerospace and Defense Integration

Aerospace applications present unique challenges for Waveguide Channel Rotary Joint implementations, requiring components that can withstand extreme environmental conditions while maintaining consistent performance. Aircraft navigation systems, weapon guidance systems, and communication equipment all depend on reliable signal transmission through rotating interfaces, making rotary joint reliability a critical factor in overall system performance. Telecommunications infrastructure increasingly relies on Waveguide Channel Rotary Joint technology to enable mobile antenna systems and base station installations that require continuous rotation capability. These applications demand components that can operate reliably for years with minimal maintenance while handling the high data rates and complex modulation schemes used in modern communication systems. The robust design and long-term reliability of Advanced Microwave Technologies' products make them ideal for these demanding applications.

Comprehensive OEM Services and Customization

Advanced Microwave Technologies Co., Ltd. provides extensive OEM services to ensure that each Waveguide Channel Rotary Joint perfectly matches specific application requirements. The customization process begins with detailed consultation to understand unique system requirements, environmental constraints, and performance objectives. Engineering teams work closely with customers to develop optimized solutions that address specific technical challenges while maintaining cost-effectiveness and delivery schedules. Dimensional customization enables Waveguide Channel Rotary Joint integration into systems with unique space constraints or mounting requirements. Material selection options accommodate extreme environmental conditions, from arctic cold to desert heat, ensuring reliable operation regardless of deployment location. Frequency range optimization allows performance tuning for specific applications, maximizing efficiency within the required operating bandwidth.

Prototyping and Technical Support Services

Rapid prototyping services enable customers to evaluate Waveguide Channel Rotary Joint performance in their specific applications before committing to full-scale production. This approach reduces development risk while ensuring optimal performance in the final application. Prototype units undergo the same rigorous testing procedures as production units, providing confidence in scalability and manufacturability. Technical support extends beyond initial delivery, with expert engineers providing installation guidance, troubleshooting assistance, and performance optimization recommendations throughout the product lifecycle. This comprehensive support ensures that each Waveguide Channel Rotary Joint achieves its full performance potential while minimizing operational disruptions and maintenance requirements.

Conclusion

The Waveguide Channel Rotary Joint represents a critical enabling technology for modern microwave systems that require reliable signal transmission through rotating interfaces. Advanced Microwave Technologies Co., Ltd. delivers comprehensive solutions that combine precision engineering, advanced materials, and extensive customization capabilities to meet the most demanding application requirements across satellite communications, radar systems, aerospace applications, and telecommunications infrastructure.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a leading China Waveguide Channel Rotary Joint manufacturer and China Waveguide Channel Rotary Joint supplier, Advanced Microwave Technologies Co., Ltd. brings over 20 years of microwave expertise to every project. Our China Waveguide Channel Rotary Joint factory operates under ISO 9001:2015 certification, ensuring High Quality Waveguide Channel Rotary Joint products that meet international standards. Whether you need Waveguide Channel Rotary Joint for sale or require China Waveguide Channel Rotary Joint wholesale quantities, our competitive Waveguide Channel Rotary Joint price structure and quick turnaround times deliver exceptional value. Our 24m Microwave Darkroom facility, equipped with measurement capabilities up to 110 GHz, provides comprehensive testing and validation for every product. From prototyping to full-scale production, our technical support team provides in-depth assistance including installation guidance and troubleshooting support. Contact us today at craig@admicrowave.com to discuss your specific requirements and experience why industry leaders choose Advanced Microwave Technologies as their preferred partner for custom waveguide solutions.

FAQ

Q: What is the typical channel isolation performance of your Waveguide Channel Rotary Joint?

A: All our models (UI, UL, UU) provide channel isolation ≥50dB, ensuring minimal crosstalk between signal paths.

Q: What frequency range do your Waveguide Channel Rotary Joint products support?

A: Our rotary joints operate across 0.5-110 GHz, covering microwave to millimeter-wave applications including 5G and future 6G systems.

Q: Can you customize Waveguide Channel Rotary Joint dimensions for space-constrained applications?

A: Yes, we offer complete dimensional customization, material selection, and frequency optimization through our comprehensive OEM services.

Q: What quality certifications apply to your Waveguide Channel Rotary Joint manufacturing?

A: Our products are ISO 9001:2015 certified and RoHS compliant, manufactured in our state-of-the-art facility with advanced testing capabilities up to 110 GHz.

References

1. "Microwave Engineering: Passive Circuits" - David M. Pozar, Department of Electrical and Computer Engineering, University of Massachusetts

2. "Waveguide Rotary Joint Design Principles" - IEEE Transactions on Microwave Theory and Techniques - Robert E. Collin, Department of Electrical Engineering, Case Western Reserve University

3. "RF and Microwave Passive and Active Technologies" - Mike Golio, Advanced Microwave Engineering Department, Motorola Corporation

4. "Handbook of Microwave Component Measurements" - Joel P. Dunsmore, Agilent Technologies Microwave Technology Center

YOU MAY LIKE

VIEW MORERight Angle Double Ridged WG To Coaxial Adapter

VIEW MORERight Angle Double Ridged WG To Coaxial Adapter VIEW MORERight Angle Waveguide to Microstrip Adapter

VIEW MORERight Angle Waveguide to Microstrip Adapter VIEW MOREEnd Launch Waveguide to Microstrip Adapter

VIEW MOREEnd Launch Waveguide to Microstrip Adapter VIEW MOREWG Termination

VIEW MOREWG Termination VIEW MOREDouble Ridge Waveguide Termination

VIEW MOREDouble Ridge Waveguide Termination VIEW MOREWaveguide Power Divider

VIEW MOREWaveguide Power Divider VIEW MOREE-Plane Tee

VIEW MOREE-Plane Tee VIEW MORECrossguide Directional Coupler

VIEW MORECrossguide Directional Coupler