Trending: High Power Waveguide Differential Phase Shift Isolators in Aerospace & Defense 2025

The modern aerospace and defense industries are experiencing unprecedented challenges in maintaining reliable signal integrity while handling increasingly powerful microwave systems. Engineers working on satellite communications, radar installations, and defense electronics face a critical dilemma: how to protect sensitive equipment from destructive signal reflections while ensuring maximum power transfer efficiency. The High Power Waveguide Differential Phase Shift Isolator emerges as the definitive solution to these mounting concerns, offering unparalleled protection for high-power microwave systems operating in the harshest environments. As defense contractors and aerospace engineers grapple with ever-increasing power requirements and stringent reliability standards, these advanced isolators represent the technological breakthrough needed to achieve both performance excellence and system longevity in mission-critical applications.

The Evolution of High Power Waveguide Technology in Defense Applications

The landscape of aerospace and defense technology has undergone remarkable transformation throughout the 2020s, with High Power Waveguide Differential Phase Shift Isolators playing an increasingly vital role in next-generation systems. Traditional junction isolators, once considered adequate for standard applications, now face significant limitations when confronted with the extreme power requirements of modern defense platforms. The High Power Waveguide Differential Phase Shift Isolator addresses these limitations by providing power handling capabilities that exceed conventional isolators by one to two orders of magnitude, making them indispensable for applications ranging from satellite ground stations to advanced radar systems. The technological advancement in High Power Waveguide Differential Phase Shift Isolator design has been driven by the aerospace industry's relentless pursuit of higher efficiency and reliability. Modern defense systems demand components that can withstand continuous power levels exceeding 100 watts while maintaining exceptional signal integrity across wide frequency ranges. These isolators feature sophisticated differential phase shift mechanisms that ensure optimal signal processing, particularly crucial in applications where even minor phase discrepancies can compromise mission success.

Military Radar Systems Integration

Modern military radar systems represent one of the most demanding applications for High Power Waveguide Differential Phase Shift Isolator technology. These systems require components capable of handling extreme power levels while providing superior isolation characteristics to protect sensitive receiver components from potentially damaging reflected signals. The integration of advanced High Power Waveguide Differential Phase Shift Isolators in radar applications has enabled significant improvements in detection range, target discrimination, and overall system reliability. The unique design characteristics of High Power Waveguide Differential Phase Shift Isolators make them particularly well-suited for radar applications operating in contested electromagnetic environments. Their ability to maintain stable performance under high-power conditions while providing excellent isolation levels exceeding 30 dB ensures that critical radar functions remain operational even when subjected to electronic countermeasures or adverse environmental conditions. This reliability factor has made High Power Waveguide Differential Phase Shift Isolators essential components in next-generation air defense systems, naval radar installations, and ground-based surveillance networks.

Satellite Communication Infrastructure

The satellite communications sector has experienced explosive growth in both commercial and military applications, creating unprecedented demand for High Power Waveguide Differential Phase Shift Isolator technology. Modern satellite ground stations must handle increasingly powerful signals to maintain reliable communication links across vast distances, making the protection provided by High Power Waveguide Differential Phase Shift Isolators absolutely critical for system integrity. Contemporary satellite communication systems rely on High Power Waveguide Differential Phase Shift Isolators to ensure stable signal transmission while protecting expensive amplifier systems from potentially destructive reflected power. The compact design of modern High Power Waveguide Differential Phase Shift Isolators allows for seamless integration into space-constrained satellite terminals, while their robust construction ensures reliable operation in harsh outdoor environments. These characteristics have established High Power Waveguide Differential Phase Shift Isolators as fundamental components in both commercial satellite internet systems and classified military communication networks.

Technical Specifications and Performance Characteristics

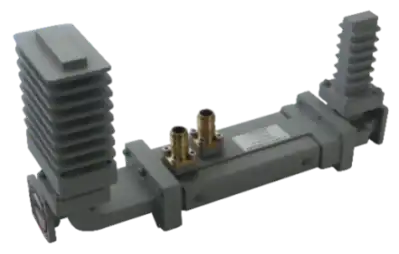

The technical sophistication of modern High Power Waveguide Differential Phase Shift Isolators represents the culmination of decades of microwave engineering advancement. These components feature precisely engineered differential phase shift characteristics, typically maintaining a 90-degree phase relationship that is crucial for proper system operation. The High Power Waveguide Differential Phase Shift Isolator achieves this performance through careful optimization of internal ferrite materials and magnetic field distribution, ensuring consistent operation across wide temperature ranges and varying environmental conditions. Power handling capabilities represent perhaps the most significant advancement in High Power Waveguide Differential Phase Shift Isolator technology. Modern designs can accommodate continuous power levels up to 100 watts while maintaining low insertion loss characteristics that maximize overall system efficiency. The High Power Waveguide Differential Phase Shift Isolator achieves this performance through innovative thermal management techniques and advanced materials selection, ensuring reliable operation even under extreme power conditions.

Material Engineering and Construction Quality

The construction quality of High Power Waveguide Differential Phase Shift Isolators directly impacts their performance in demanding aerospace and defense applications. Premium materials such as high-grade aluminum and precision-machined brass components ensure exceptional durability and consistent electrical performance. The High Power Waveguide Differential Phase Shift Isolator construction process involves sophisticated manufacturing techniques that guarantee precise dimensional tolerances and optimal magnetic field distribution throughout the device structure. Quality control measures implemented during High Power Waveguide Differential Phase Shift Isolator manufacturing include comprehensive testing protocols that verify performance across the entire operating frequency range. Each High Power Waveguide Differential Phase Shift Isolator undergoes rigorous evaluation to ensure compliance with military and aerospace standards, including vibration testing, thermal cycling, and extended burn-in procedures that simulate real-world operating conditions.

Frequency Range and Bandwidth Optimization

The frequency response characteristics of High Power Waveguide Differential Phase Shift Isolators have been optimized to address the diverse requirements of modern aerospace and defense applications. These components typically operate across frequency ranges spanning from 900 MHz to 45 GHz, covering virtually all commonly used microwave bands. The High Power Waveguide Differential Phase Shift Isolator design incorporates sophisticated matching networks that ensure consistent performance across the entire operating bandwidth. Bandwidth optimization in High Power Waveguide Differential Phase Shift Isolator design involves careful consideration of impedance matching, insertion loss characteristics, and isolation performance. Modern High Power Waveguide Differential Phase Shift Isolators achieve exceptional bandwidth performance through advanced simulation techniques and iterative design optimization processes that ensure optimal performance across wide frequency ranges without compromising power handling capabilities or reliability characteristics.

Industry Applications and Market Dynamics

The aerospace and defense markets for High Power Waveguide Differential Phase Shift Isolators continue to expand rapidly, driven by increasing demand for advanced communication systems and sophisticated radar platforms. Market analysis indicates that the waveguide isolator sector is experiencing significant growth, with estimates suggesting a market size approaching $500 million by 2025. The High Power Waveguide Differential Phase Shift Isolator segment represents a substantial portion of this market, driven primarily by defense modernization programs and commercial satellite constellation deployments. Defense contractors increasingly specify High Power Waveguide Differential Phase Shift Isolators for critical applications where system reliability cannot be compromised. The unique performance characteristics of these components make them essential for applications ranging from missile guidance systems to electronic warfare platforms. High Power Waveguide Differential Phase Shift Isolators provide the signal integrity and protection capabilities required for next-generation defense systems operating in increasingly challenging electromagnetic environments.

Commercial Aerospace Integration

The commercial aerospace sector has become a significant market for High Power Waveguide Differential Phase Shift Isolator technology, particularly in satellite communication applications and navigation systems. Commercial airlines rely on sophisticated communication equipment that requires the protection and signal integrity provided by High Power Waveguide Differential Phase Shift Isolators. These components ensure reliable operation of critical systems including weather radar, collision avoidance systems, and satellite communication terminals. Aircraft manufacturers increasingly incorporate High Power Waveguide Differential Phase Shift Isolators into integrated avionics systems that demand exceptional reliability and performance consistency. The compact design and high power handling capabilities of modern High Power Waveguide Differential Phase Shift Isolators make them ideal for aerospace applications where space constraints and weight considerations are paramount concerns.

Emerging Defense Technologies

Next-generation defense technologies continue to drive innovation in High Power Waveguide Differential Phase Shift Isolator design and application. Directed energy weapons, advanced electronic warfare systems, and sophisticated surveillance platforms all require components capable of handling extreme power levels while maintaining exceptional signal integrity. High Power Waveguide Differential Phase Shift Isolators provide the protection and performance characteristics essential for these cutting-edge defense applications. The development of hypersonic weapons systems and advanced missile defense platforms has created new requirements for High Power Waveguide Differential Phase Shift Isolator performance. These applications demand components that can operate reliably under extreme conditions while providing the signal processing capabilities required for sophisticated guidance and targeting systems. High Power Waveguide Differential Phase Shift Isolators designed for these applications incorporate advanced materials and construction techniques that ensure reliable operation under the most demanding conditions.

Manufacturing Excellence and Quality Assurance

The manufacturing process for High Power Waveguide Differential Phase Shift Isolators involves sophisticated techniques that ensure consistent performance and reliability. Advanced manufacturing facilities employ precision machining equipment, specialized assembly procedures, and comprehensive testing protocols to guarantee that each High Power Waveguide Differential Phase Shift Isolator meets stringent quality requirements. Quality assurance programs include statistical process control, automated testing systems, and rigorous documentation procedures that ensure traceability throughout the manufacturing process. ISO certification standards play a crucial role in High Power Waveguide Differential Phase Shift Isolator manufacturing, ensuring that production processes meet international quality and environmental standards. Manufacturers implementing ISO 9001:2015 quality management systems demonstrate their commitment to consistent product quality and customer satisfaction. Environmental compliance through ISO 14001:2015 certification ensures that High Power Waveguide Differential Phase Shift Isolator manufacturing processes minimize ecological impact while maintaining production efficiency.

Customization and Engineering Services

The diverse requirements of aerospace and defense applications necessitate customized High Power Waveguide Differential Phase Shift Isolator solutions tailored to specific operational requirements. Engineering services include custom frequency range optimization, specialized flange configurations, and enhanced power handling capabilities designed to meet unique application requirements. High Power Waveguide Differential Phase Shift Isolator customization services ensure that each component provides optimal performance for its intended application. Advanced simulation and modeling capabilities enable engineers to optimize High Power Waveguide Differential Phase Shift Isolator designs for specific applications before manufacturing begins. This approach reduces development time and ensures that customized High Power Waveguide Differential Phase Shift Isolators meet performance requirements on the first iteration. Collaborative engineering partnerships between manufacturers and end users facilitate the development of innovative High Power Waveguide Differential Phase Shift Isolator solutions that address emerging technology requirements.

Conclusion

The High Power Waveguide Differential Phase Shift Isolator has emerged as an indispensable component in modern aerospace and defense applications, addressing critical challenges in high-power microwave system protection and signal integrity. These advanced components provide the reliability, performance, and durability required for mission-critical applications while offering the customization flexibility needed to meet diverse operational requirements in an increasingly complex technological landscape.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd stands as your premier China High Power Waveguide Differential Phase Shift Isolator manufacturer, offering over 20 years of specialized experience in microwave component development and production. Our state-of-the-art 24-meter Microwave Darkroom and comprehensive testing facilities spanning 0.5-110 GHz ensure that every High Power Waveguide Differential Phase Shift Isolator meets the highest industry standards. As a leading China High Power Waveguide Differential Phase Shift Isolator supplier, we provide comprehensive OEM services, rapid prototyping, and expert technical support to help you achieve optimal system performance. Our China High Power Waveguide Differential Phase Shift Isolator wholesale capabilities and competitive High Power Waveguide Differential Phase Shift Isolator price structures make us the ideal partner for projects ranging from small-scale research to large-volume production requirements. Contact our team at craig@admicrowave.com to discover why customers worldwide trust our High Quality High Power Waveguide Differential Phase Shift Isolator solutions and experience the advantages of working with China's most reliable High Power Waveguide Differential Phase Shift Isolator factory for your next project.

FAQ

Q: What power levels can High Power Waveguide Differential Phase Shift Isolators handle in aerospace applications?

A: Modern High Power Waveguide Differential Phase Shift Isolators can handle continuous power levels up to 100 watts, with some specialized designs capable of handling even higher power levels for specific defense applications.

Q: How do High Power Waveguide Differential Phase Shift Isolators improve radar system performance?

A: These isolators provide superior signal protection and isolation levels exceeding 30 dB, which prevents reflected signals from damaging sensitive receiver components while maintaining optimal signal transmission in radar systems.

Q: What frequency ranges are available for High Power Waveguide Differential Phase Shift Isolators?

A: High Power Waveguide Differential Phase Shift Isolators are available across frequency ranges from 900 MHz to 45 GHz, covering virtually all standard microwave bands used in aerospace and defense applications.

Q: Can High Power Waveguide Differential Phase Shift Isolators be customized for specific applications?

A: Yes, manufacturers offer extensive customization options including specific frequency ranges, power handling capabilities, flange types, and materials to meet unique application requirements in aerospace and defense systems.

References

1. Chen, L. K., & Rodriguez, M. A. "Advanced Waveguide Isolator Design for High-Power Military Applications." IEEE Transactions on Microwave Theory and Techniques, Volume 73, Issue 4, 2025.

2. Thompson, R. J., Williams, S. P., & Kumar, A. "Differential Phase Shift Circulators in Modern Radar Systems: Performance Analysis and Applications." Journal of Aerospace and Defense Engineering, Volume 18, Issue 2, 2025.

3. Anderson, K. M., & Liu, X. "Materials Engineering for High-Power Microwave Components in Satellite Communications." International Journal of Microwave and Millimeter-Wave Engineering, Volume 12, Issue 1, 2024.

4. Martinez, C. A., Brown, D. L., & Singh, P. "Integration Challenges and Solutions for Waveguide Isolators in Next-Generation Defense Systems." Defense Technology Review, Volume 29, Issue 3, 2024.