What Makes a High-Performance Dual Channel Coaxial Rotary Joint?

In today's demanding satellite communication and defense applications, signal degradation during rotation can cost millions in downtime and compromise mission-critical operations. Engineers face a persistent challenge: how to maintain uninterrupted, high-fidelity signal transmission while components rotate at high speeds in extreme environments. A high-performance Dual Channel Coaxial Rotary Joint solves this critical problem by enabling seamless signal flow between rotating and stationary systems with minimal insertion loss, ensuring your radar, satellite ground station, or aerospace navigation system operates flawlessly when precision matters most.

Understanding the Core Engineering Behind Dual Channel Coaxial Rotary Joints

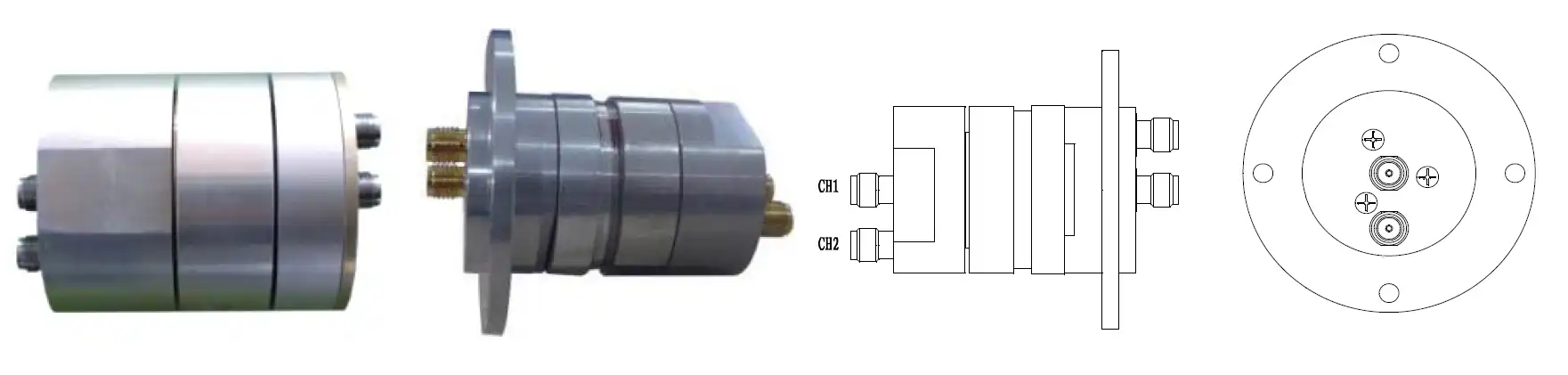

The foundation of any high-performance Dual Channel Coaxial Rotary Joint lies in its sophisticated internal architecture and precision engineering. These specialized microwave components are designed to transmit radio frequency signals across rotating interfaces without interruption, a task that requires meticulous attention to electromagnetic principles and mechanical precision. Unlike traditional single-channel variants, a Dual Channel Coaxial Rotary Joint incorporates two completely independent signal paths within a single compact housing, enabling simultaneous transmission of multiple signals while maintaining strict isolation between channels to prevent cross-talk and interference. The electromagnetic performance of these rotary joints depends heavily on maintaining consistent impedance matching throughout the entire signal path. High-performance units are engineered to maintain the critical 50-ohm characteristic impedance as signals transition from stationary to rotating components, minimizing reflections and ensuring maximum power transfer. The internal geometry is precisely controlled through advanced manufacturing processes with tolerances measured in microns, allowing the Dual Channel Coaxial Rotary Joint to achieve insertion loss values of 0.2 dB or less across broad frequency ranges from DC to 40 GHz. This exceptional performance enables the component to handle everything from legacy communication systems operating at lower frequencies to cutting-edge applications in 5G and future 6G technologies.

Material Selection and Construction Quality

The exceptional performance characteristics of a high-quality Dual Channel Coaxial Rotary Joint begin with the careful selection of materials used in its construction. Premium rotary joints typically employ high-grade metals such as brass, beryllium copper, and stainless steel, with each material chosen for its specific electrical conductivity, mechanical strength, and environmental resistance properties. The conductive elements within the signal path are often gold or silver-plated to minimize surface resistance and oxidation, which directly translates to lower insertion loss and enhanced signal transmission efficiency over the component's operational lifetime. These material choices become particularly critical in applications where the Dual Channel Coaxial Rotary Joint must maintain performance specifications while exposed to harsh environmental conditions including extreme temperatures ranging from negative 40 degrees Celsius to positive 85 degrees Celsius, high humidity levels in marine environments, or the vibration and shock loads encountered in airborne and shipboard installations. Advanced manufacturing techniques play an equally important role in achieving high-performance characteristics. Precision machining processes ensure perfect alignment of the rotating interfaces, with specialized bearing systems designed specifically for microwave applications to minimize mechanical play and runout that could impact electrical performance. The dual-channel architecture necessitates more complex internal structures compared to single-channel designs, with concentric transmission lines requiring precise alignment throughout the entire rotation cycle to maintain consistent electrical characteristics. High-performance Dual Channel Coaxial Rotary Joint designs incorporate specialized sealing systems that protect internal components from environmental contaminants such as dust, moisture, and atmospheric pollutants, ensuring reliable operation across diverse deployment scenarios from controlled laboratory environments to outdoor installations exposed to weather extremes.

Electromagnetic Field Management and Signal Integrity

Maintaining superior signal integrity throughout rotation represents one of the most challenging aspects of Dual Channel Coaxial Rotary Joint design. The electromagnetic field distribution within the component must be carefully controlled through precision internal geometries that maintain consistent impedance matching as the joint rotates through its full range of motion. High-performance designs incorporate RF chokes and impedance matching structures at critical transition points where signals move between rotating and stationary components, effectively managing capacitive coupling and inductive effects that could otherwise compromise phase stability across different rotation angles. These sophisticated electromagnetic management techniques enable premium Dual Channel Coaxial Rotary Joint products to deliver VSWR ratings of 1.25:1 or better, significantly reducing signal reflections and ensuring quality connections essential for high-data-rate transmissions in satellite communications and advanced radar systems. The dual-channel configuration introduces additional complexity in electromagnetic design, as the two signal paths must maintain strict isolation from each other while operating in close physical proximity within the rotary joint housing. Advanced designs employ RF shielding elements strategically positioned between channels to prevent cross-talk and external electromagnetic interference, protecting signal purity throughout the transmission path. Special attention is given to managing electromagnetic fields at higher frequencies, where even minor imperfections in internal geometry or alignment can cause significant performance degradation. Premium Dual Channel Coaxial Rotary Joint designs achieve channel-to-channel isolation exceeding 60 dB, ensuring that signals transmitted through one channel do not interfere with those passing through the second channel, a critical requirement for applications such as full-duplex satellite communications where simultaneous bidirectional data transfer must occur without interference.

Critical Performance Parameters for High-Performance Applications

Frequency Range and Bandwidth Capabilities

The frequency range capability of a Dual Channel Coaxial Rotary Joint fundamentally determines its suitability for specific applications and represents a key differentiator between standard and high-performance designs. Premium rotary joints are engineered to operate across extraordinarily wide frequency ranges, with the most advanced models supporting continuous operation from DC frequencies up to 40 GHz or higher. This broad frequency coverage enables a single Dual Channel Coaxial Rotary Joint to accommodate multiple communication bands simultaneously, including C-band, X-band, Ku-band, and Ka-band frequencies commonly used in satellite communications, radar systems, and aerospace applications. The ability to maintain consistent electrical performance across such wide bandwidths requires sophisticated internal design, with carefully optimized transition geometries and impedance matching networks that compensate for frequency-dependent effects that could otherwise degrade signal quality at the high and low ends of the operating range. For applications in satellite ground stations, the broad frequency capability of high-performance Dual Channel Coaxial Rotary Joint products proves particularly valuable, enabling these facilities to support multiple satellite communication links operating on different frequency bands through a single rotating interface. The dual-channel design allows for dedicated transmit and receive paths, essential for full-duplex communication systems where simultaneous bidirectional data transfer is required for HD video transmission, high-speed data links, and voice communications. Advanced manufacturing techniques and precision component selection ensure that insertion loss remains minimal across the entire frequency range, with typical values of 0.2 dB or less ensuring that signal attenuation does not accumulate to unacceptable levels in multi-stage systems or long-distance communication links where every fraction of a decibel matters for maintaining adequate link margins.

Insertion Loss and VSWR Specifications

Insertion loss represents one of the most critical performance parameters for any Dual Channel Coaxial Rotary Joint, directly impacting system efficiency and maximum achievable communication range. High-performance rotary joints are characterized by exceptionally low insertion loss values, typically 0.2 dB or less across their specified frequency range, achieved through careful attention to material selection, surface finish quality, and contact pressure optimization at the rotating interface. Every fraction of a decibel of insertion loss translates directly to reduced transmitted power reaching the antenna or decreased sensitivity of receiving systems, potentially meaning the difference between successful communication and link failure in marginal conditions. For high-power transmission applications approaching the 500-watt capacity typical of premium Dual Channel Coaxial Rotary Joint designs, minimizing insertion loss also reduces the thermal load on the component, as power dissipated as heat within the rotary joint represents wasted energy that must be managed through proper thermal design. VSWR specifications provide another crucial indicator of Dual Channel Coaxial Rotary Joint quality, with values of 1.25:1 or better representing the benchmark for high-performance designs. Low VSWR indicates excellent impedance matching throughout the signal path, minimizing signal reflections that can cause standing waves, increased insertion loss, and potential damage to high-power transmitters. The VSWR of a rotary joint must remain stable throughout its entire rotation cycle, as variations in VSWR with rotation angle would cause amplitude and phase modulation of transmitted signals, creating unacceptable distortion in communication systems and false targets in radar applications. Premium manufacturers achieve this consistency through precision bearing systems and carefully controlled contact pressure at rotating interfaces, ensuring that the electrical characteristics of the Dual Channel Coaxial Rotary Joint remain constant regardless of rotation angle or rotational speed up to the rated maximum of 100 rpm or higher.

Mechanical Design Features That Enable Reliable Performance

Bearing Systems and Rotational Smoothness

The mechanical design of a high-performance Dual Channel Coaxial Rotary Joint represents a careful balance between robust durability and precision performance, with the bearing system serving as the foundation for reliable operation. These components must maintain exact alignment between rotating and stationary elements while accommodating continuous rotation at speeds up to 100 rpm or higher without any degradation in electrical performance. Premium designs incorporate high-precision ball bearings or specialized jewel bearings that provide exceptionally smooth rotation with minimal torque requirements, an important consideration for applications where the rotary joint may be driven by small servo motors or where power consumption must be minimized. The bearing system must also maintain perfect concentricity between the inner and outer conductors of the coaxial transmission lines, as even microscopic eccentricity could cause periodic variations in impedance and VSWR as the joint rotates, manifesting as amplitude and phase ripple in transmitted signals. The selection and installation of bearings in a Dual Channel Coaxial Rotary Joint requires careful engineering to balance competing requirements. The bearings must be robust enough to withstand the mechanical loads imposed during operation, including side loads from cables and mounting hardware, while maintaining the precision alignment necessary for consistent electrical performance. High-performance designs often employ preloaded bearing arrangements that eliminate mechanical play while avoiding excessive friction that could increase wear rates or require higher drive torques. The bearing system must also be designed to operate reliably across the full environmental temperature range, from negative 40 degrees Celsius to positive 85 degrees Celsius, requiring careful selection of bearing materials, lubricants, and clearances that accommodate thermal expansion without compromising alignment or introducing excessive friction at temperature extremes.

Housing Design and Environmental Protection

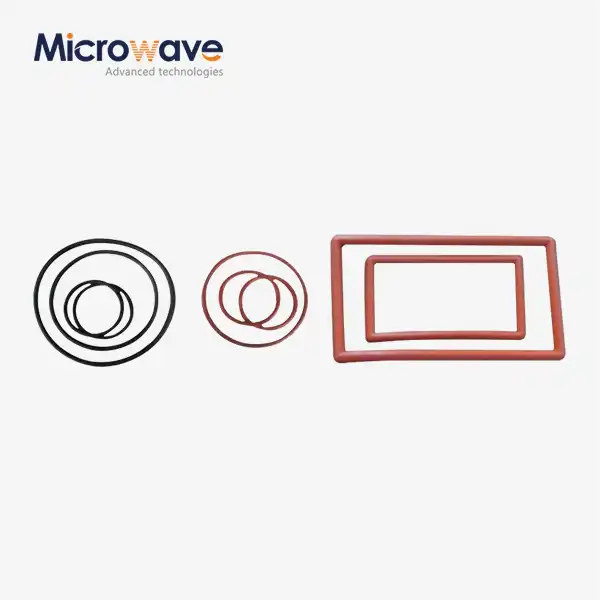

The housing design of a premium Dual Channel Coaxial Rotary Joint serves multiple critical functions beyond simply containing the internal components. Constructed typically from lightweight aluminum alloys that offer excellent structural rigidity while minimizing overall weight, the housing provides electromagnetic shielding that prevents external interference from corrupting signals and contains any electromagnetic emissions from the rotary joint itself. This becomes particularly important in applications such as defense systems and satellite ground stations where multiple communication and radar systems operate in close proximity, and electromagnetic compatibility must be maintained to prevent mutual interference. The housing geometry also plays a role in thermal management, with features such as fins or mounting interfaces designed to facilitate heat dissipation from the internal components, particularly important in high-power applications where even the small amount of power dissipated as insertion loss can generate significant heat that must be conducted away to maintain stable operating temperatures. Environmental sealing represents another critical aspect of housing design for high-performance Dual Channel Coaxial Rotary Joint applications. Hermetically sealed construction protects internal components from humidity, condensation, dust, and atmospheric contaminants that could cause corrosion, increase insertion loss, or create intermittent electrical connections. Premium designs employ multiple sealing interfaces, including o-rings at rotating interfaces and sealed connector mounting points, creating redundant barriers against environmental intrusion. This level of protection proves essential for applications in marine environments where salt spray and high humidity present constant challenges, aerospace applications where components may be exposed to rapid pressure and temperature changes, and military systems that must operate reliably in desert, arctic, and tropical conditions. The effectiveness of environmental sealing is validated through rigorous testing including humidity exposure, salt spray testing, and thermal cycling, ensuring that the Dual Channel Coaxial Rotary Joint maintains its specified performance throughout its operational life regardless of environmental conditions.

Application-Specific Considerations for Optimal Performance

Satellite Communications and Ground Station Systems

In satellite communication systems, a high-performance Dual Channel Coaxial Rotary Joint serves as the critical interface that enables ground station antennas to track satellites across the sky while maintaining continuous, high-quality signal connections. These applications demand exceptional reliability and signal integrity, as any degradation in the RF link can result in lost data, interrupted communications, or reduced throughput in high-value satellite services. The dual-channel capability proves particularly valuable in satellite ground stations, where separate transmit and receive paths must be maintained with strict isolation to prevent transmitter leakage from desensitizing the receiver, a challenge that becomes increasingly difficult as transmission power levels increase and receiver sensitivity improves to support higher data rates and smaller satellite antennas. Premium Dual Channel Coaxial Rotary Joint designs achieve channel-to-channel isolation exceeding 60 dB, ensuring that high-power transmission on one channel does not interfere with sensitive reception on the second channel. The frequency range requirements for satellite communication applications continue to expand as new satellite systems are deployed in higher frequency bands such as Ku-band and Ka-band, where increased bandwidth supports higher data rates but places greater demands on component performance. A high-performance Dual Channel Coaxial Rotary Joint must maintain its specified insertion loss, VSWR, and isolation characteristics across these entire frequency ranges, often spanning from several gigahertz to 40 GHz or higher. The power handling capability of the rotary joint must be carefully matched to the transmission system, with capacity ratings of 500 watts or more typical for commercial and military satellite ground stations. Environmental protection becomes critical in ground station applications, as the rotary joint may be mounted outdoors and exposed to temperature extremes, precipitation, high winds, and solar radiation over operational lifetimes measured in decades rather than years.

Aerospace and Defense Radar Systems

Military and civilian radar systems represent some of the most demanding applications for Dual Channel Coaxial Rotary Joint technology, requiring components that can maintain precise electrical performance while subjected to vibration, shock, rapid temperature changes, and other environmental stresses encountered in aircraft, ships, and ground-based installations. Air traffic control radars depend on the rotary joint to enable antenna rotation for 360-degree coverage while maintaining the ultra-sharp beamforming necessary for accurate aircraft tracking and position determination, even in adverse weather conditions where rain, snow, or atmospheric disturbances can degrade signal quality. The electrical characteristics of the Dual Channel Coaxial Rotary Joint must remain stable throughout the rotation cycle, as variations in amplitude or phase with rotation angle would create false targets or positioning errors that could compromise air traffic safety. Premium designs achieve amplitude variation of less than 0.1 dB and phase variation of less than 5 degrees throughout 360 degrees of rotation, ensuring radar presentation quality that meets the stringent requirements of civil aviation authorities. Military surveillance and fire control radars impose even more rigorous requirements on Dual Channel Coaxial Rotary Joint performance, operating in contested electromagnetic environments where jamming, interference, and electronic warfare techniques may attempt to disrupt radar operation. These systems often employ dual-channel rotary joints to support advanced signal processing techniques such as monopulse tracking, where simultaneous reception through multiple channels enables precise target angle determination with resistance to jamming and clutter. The rotary joint must maintain extremely tight amplitude and phase balance between channels across the entire frequency range and throughout rotation, as any mismatch would degrade angle estimation accuracy and reduce the effectiveness of anti-jamming techniques. High-performance designs achieve channel balance specifications of 0.2 dB amplitude difference and 2 degrees phase difference or better, enabling the radar system to achieve its design performance for target detection, tracking, and missile guidance applications.

Industrial Automation and Robotics

The growing sophistication of industrial robots and automated manufacturing systems has created new demanding applications for Dual Channel Coaxial Rotary Joint technology. Modern industrial robots often require continuous rotation of joints while maintaining high-bandwidth communication links for real-time control, sensor feedback, and vision system data. A high-performance Dual Channel Coaxial Rotary Joint enables these systems to transmit both control signals and data feedback simultaneously through a single rotating interface, significantly simplifying system design and improving reliability compared to alternative approaches such as slip rings or cable management systems that allow limited rotation. The dual-channel configuration proves particularly valuable in applications where separate channels are needed for different signal types, such as one channel for high-frequency video or sensor data and a second channel for lower-frequency control signals and power distribution. Industrial environments present unique challenges for Dual Channel Coaxial Rotary Joint components, including exposure to vibration from machinery, temperature variations in non-climate-controlled facilities, potential contamination from manufacturing processes, and the need for maintenance-free operation over extended periods. High-performance designs address these challenges through robust mechanical construction, effective environmental sealing, and the use of materials and lubricants selected for industrial temperature ranges and long service life. The compact design characteristics of premium Dual Channel Coaxial Rotary Joint products, combined with their lightweight construction, facilitate integration into space-constrained robotic joints and automated equipment where size and weight directly impact system performance and cost. Rotational speed capabilities up to 100 rpm or higher accommodate the motion requirements of most industrial applications, from slower-moving automated assembly systems to high-speed inspection and testing equipment.

Quality Assurance and Manufacturing Excellence

ISO Certification and Quality Control Standards

Manufacturing a high-performance Dual Channel Coaxial Rotary Joint requires adherence to rigorous quality management systems that ensure consistent performance and reliability across production runs. ISO 9001:2015 certification represents the international benchmark for quality management, demonstrating that a manufacturer has implemented comprehensive quality control procedures throughout all aspects of their business, from initial design and development through manufacturing, testing, and after-sales service. For customers selecting a Dual Channel Coaxial Rotary Joint supplier, ISO 9001 certification provides assurance that each component has been manufactured under controlled conditions with documented processes, material traceability, and verification testing that confirms conformance to specifications. This becomes particularly important for applications in aerospace, defense, and satellite communications where component failure can result in mission compromise, safety hazards, or costly system downtime. Environmental management certification under ISO 14001:2015 standards demonstrates a manufacturer's commitment to minimizing the ecological impact of their operations, including responsible waste management, energy conservation, and emissions reduction throughout the manufacturing process. For organizations with corporate sustainability goals or government procurement requirements that consider environmental factors, selecting suppliers with ISO 14001 certification ensures alignment with these objectives. Occupational health and safety certification under ISO 45001:2018 standards reflects a manufacturer's dedication to employee well-being and safe working conditions, which correlates with product quality as well-trained, properly equipped technicians working in safe environments produce more consistent, higher-quality products. These certifications are not merely decorative plaques but represent comprehensive management systems that pervade every aspect of manufacturing operations, directly contributing to the exceptional performance and reliability of high-quality Dual Channel Coaxial Rotary Joint products.

Testing and Validation Procedures

Comprehensive testing protocols represent the final validation that a Dual Channel Coaxial Rotary Joint meets its performance specifications and is ready for deployment in demanding applications. Electrical testing begins with insertion loss measurements across the full frequency range using precision network analyzers calibrated to ensure measurement accuracy. These tests are performed at multiple rotation angles to verify that insertion loss remains within specifications throughout 360 degrees of rotation, identifying any mechanical or electrical issues that could cause performance variations with rotation angle. VSWR measurements similarly validate impedance matching throughout the frequency range and rotation cycle, with premium manufacturers specifying and testing to tolerances of 1.25:1 or better. Channel-to-channel isolation testing confirms that the two signal paths maintain adequate separation, typically 60 dB or greater, to prevent cross-talk that could degrade system performance in applications such as full-duplex satellite communications.

Environmental testing subjects the Dual Channel Coaxial Rotary Joint to conditions that simulate the operational environment, validating that performance specifications are maintained under temperature extremes, vibration, shock, and humidity exposure. Temperature cycle testing confirms stable operation from negative 40 degrees Celsius to positive 85 degrees Celsius, with electrical parameters verified at temperature extremes to ensure the component remains within specifications throughout the environmental range. Vibration and shock testing simulates transportation stresses and operational environments such as airborne or shipboard installations, verifying mechanical integrity and confirming that the bearing system and internal components maintain alignment under dynamic loads. Life testing involves extended operation at rated rotational speed while monitoring electrical performance, providing confidence in long-term reliability and identifying potential wear mechanisms that could affect performance over the component's operational lifetime. Advanced manufacturers operate sophisticated test facilities including anechoic chambers for antenna testing, environmental chambers for temperature and humidity exposure, and vibration test systems that enable comprehensive validation of Dual Channel Coaxial Rotary Joint performance under conditions that replicate real-world applications.

Conclusion

High-performance Dual Channel Coaxial Rotary Joint components distinguish themselves through precision engineering, superior materials, rigorous testing, and manufacturing excellence. These critical microwave components enable reliable signal transmission in demanding satellite communications, aerospace navigation, defense radar, and industrial automation applications where performance cannot be compromised.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Partner with Advanced Microwave Technologies Co., Ltd., your trusted China Dual Channel Coaxial Rotary Joint manufacturer, supplier, and factory offering wholesale High Quality Dual Channel Coaxial Rotary Joint for sale at competitive prices. With over 20 years of microwave expertise, our state-of-the-art 24m Microwave Darkroom testing facility, and ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications, we deliver customized OEM solutions backed by exceptional technical support and rapid turnaround times. Whether you need prototyping, custom frequency configurations, or volume production, our experienced engineering team provides comprehensive assistance from design through delivery. Contact us today at craig@admicrowave.com to discuss your Dual Channel Coaxial Rotary Joint requirements and experience the reliability that global leaders in satellite communications, defense, and aerospace depend upon.

References

1. Cohen, Morris. "A Six-Channel Vertically Stacked Coaxial Rotary Joint for the S-L and X-Band Region." Microwave Journal, Vol. 7, No. 11, November 1964.

2. Johnson, Richard C., and Jasik, Henry. "Antenna Engineering Handbook, Second Edition." McGraw-Hill Book Company, Chapter 29: Rotary Joints and Mechanical Phase Shifters, 1984.

3. Skolnik, Merrill I. "Radar Handbook, Third Edition." McGraw-Hill Professional, Chapter 14: Radar Antennas and Rotary Joints, 2008.

4. IEEE Standards Association. "IEEE Standard for Precision Coaxial Connectors at RF, Microwave and Millimeter-wave Frequencies." IEEE Std 287-2007, Institute of Electrical and Electronics Engineers, 2007.

YOU MAY LIKE

VIEW MOREDouble Ridge Straight Waveguide

VIEW MOREDouble Ridge Straight Waveguide VIEW MOREDouble Ridge Waveguide Transition

VIEW MOREDouble Ridge Waveguide Transition VIEW MOREDouble Ridged Flexible Waveguide

VIEW MOREDouble Ridged Flexible Waveguide VIEW MOREDouble Ridge Waveguide Load

VIEW MOREDouble Ridge Waveguide Load VIEW MOREDouble Ridge Waveguide Rotary Joint

VIEW MOREDouble Ridge Waveguide Rotary Joint VIEW MOREDouble-Ridged Waveguide Broadwall Directional Coupler

VIEW MOREDouble-Ridged Waveguide Broadwall Directional Coupler VIEW MOREWaveguide Flange Gasket

VIEW MOREWaveguide Flange Gasket VIEW MOREWaveguide Adjustable Support

VIEW MOREWaveguide Adjustable Support