What is a Waveguide Tube, and how does it differ from ordinary coaxial cables in signal transmission?

When your satellite communication system experiences severe signal degradation at high frequencies, or your radar installation suffers from excessive power loss over long distances, the culprit often lies in choosing the wrong transmission technology. A Waveguide Tube is a hollow metallic pipe designed to guide electromagnetic waves at microwave and millimeter-wave frequencies with minimal loss, fundamentally different from coaxial cables that use a central conductor surrounded by insulation and shielding to transmit signals through current flow.

Understanding Waveguide Tube Fundamentals and Operating Principles

The Waveguide Tube represents a revolutionary approach to electromagnetic signal transmission that becomes essential at frequencies above several gigahertz. Unlike conventional transmission lines that rely on conductor-to-conductor current flow, a Waveguide Tube operates by containing and directing electromagnetic waves within its hollow metallic structure through internal reflection principles. The waveguide's rectangular or circular cross-section is precisely engineered to support specific electromagnetic field patterns known as propagation modes, with the most common being Transverse Electric (TE) and Transverse Magnetic (TM) modes where either the electric or magnetic field component remains perpendicular to the direction of wave travel. This fundamental difference in operation means that Waveguide Tubes only function effectively above a critical cutoff frequency determined by their physical dimensions, typically the width of the broader wall in rectangular configurations. For instance, a standard WR-90 Waveguide Tube with internal dimensions of twenty-two point eight-six millimeters by ten point one-six millimeters has a cutoff frequency around six point five-six gigahertz, below which electromagnetic waves cannot propagate efficiently through the structure. The absence of a central conductor and dielectric insulation eliminates many loss mechanisms that plague coaxial cables at high frequencies, making Waveguide Tubes the preferred solution for applications demanding maximum signal integrity and power handling capability in the microwave spectrum.

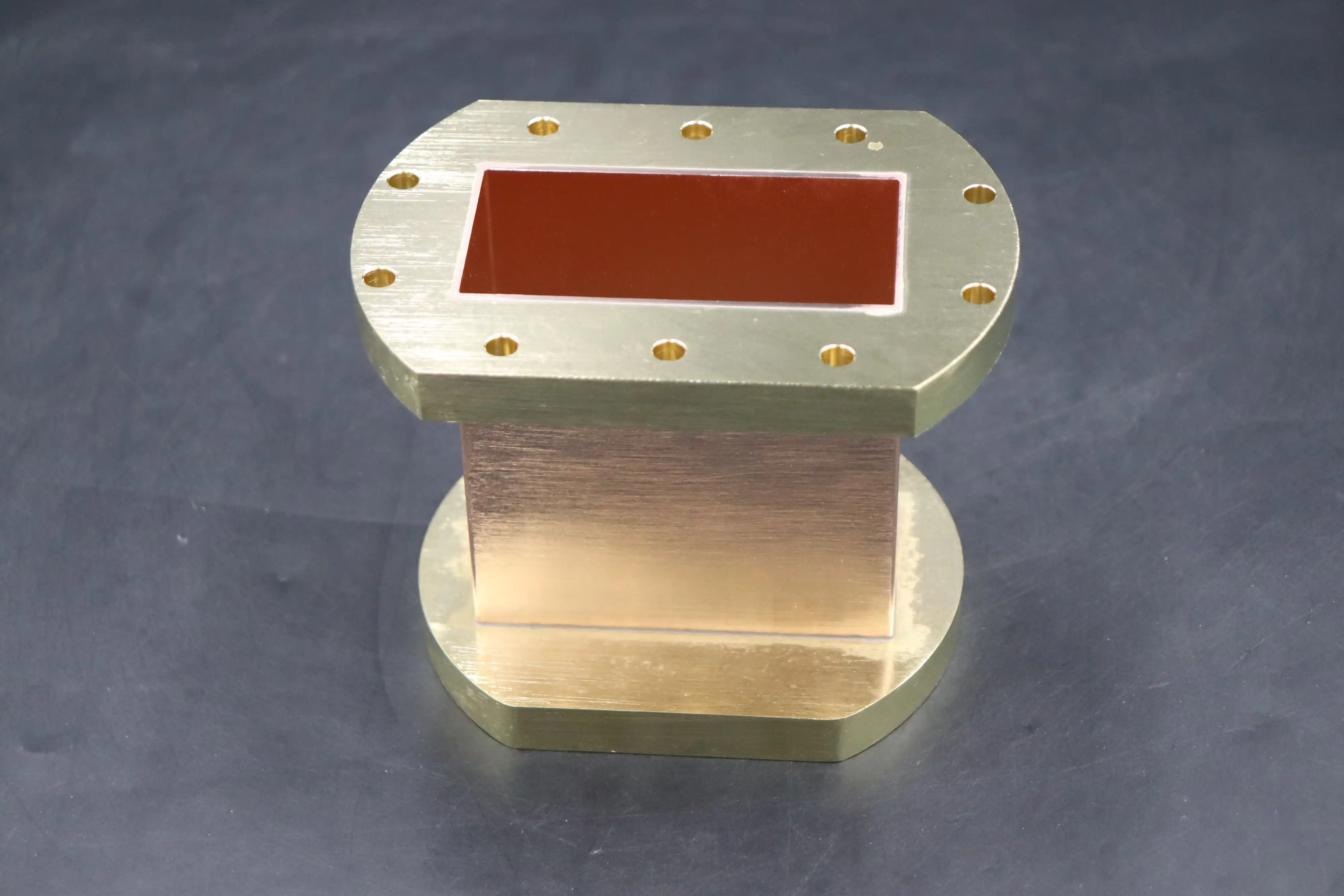

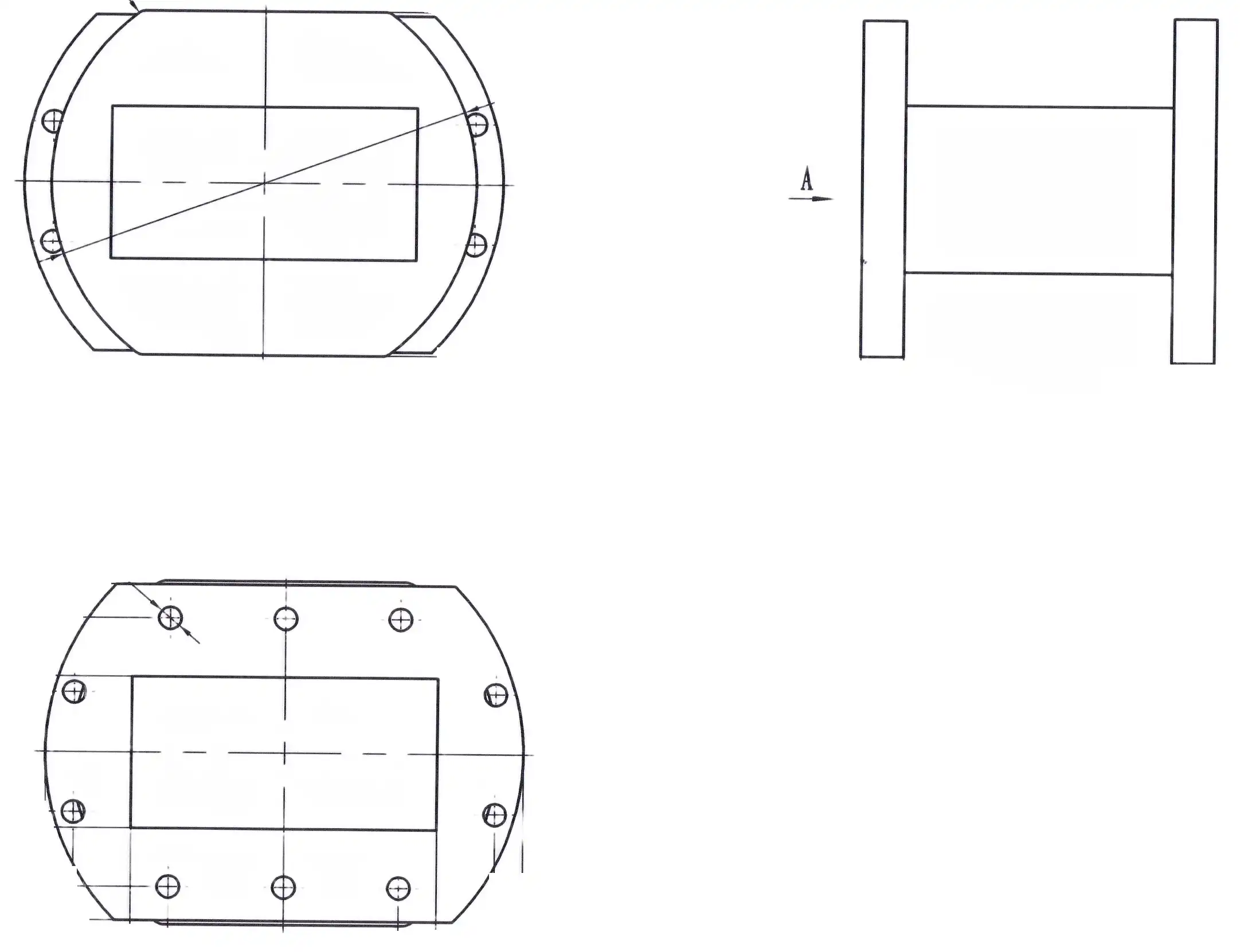

Physical Construction and Material Specifications

The construction of a Waveguide Tube involves precision manufacturing of hollow metallic tubes from high-conductivity materials such as copper, aluminum, or brass, with internal surface treatments like silver or gold plating to further minimize resistive losses. Advanced Microwave Technologies Co., Ltd. manufactures Waveguide Tubes in various wall thicknesses including standard, thin-wall, and thick-wall configurations to accommodate different mechanical strength and weight requirements across applications. The dimensional accuracy of Waveguide Tube manufacturing is critical, as deviations of even fractions of a millimeter can cause impedance mismatches, mode conversion, or excessive signal reflection that degrades system performance. Our product range spans from WR2300 down to WR10, covering frequency bands from approximately zero point three-two gigahertz up to three hundred twenty-five gigahertz, with each size designation indicating the broader internal dimension in hundredths of an inch. The rectangular geometry provides superior mechanical rigidity compared to circular designs, while offering predictable single-mode operation within specified frequency ranges that ensures consistent, reliable signal transmission for mission-critical applications in satellite communications, defense radar systems, and aerospace navigation equipment.

Electromagnetic Wave Propagation Mechanisms

The electromagnetic wave propagation mechanism within a Waveguide Tube differs fundamentally from the TEM (Transverse ElectroMagnetic) mode that dominates in coaxial cable transmission. In a Waveguide Tube, electromagnetic energy travels as waves that bounce off the inner walls at specific angles determined by the operating frequency and guide dimensions, creating standing wave patterns across the cross-section while propagating longitudinally down the tube. This wave propagation exhibits fascinating characteristics including phase velocity that exceeds the speed of light in free space, though the actual energy transmission velocity remains below this fundamental limit. The dominant TE10 mode in rectangular Waveguide Tubes features electric field lines that span from one broad wall to the opposite side, with maximum field intensity at the center and zero field strength at the metallic surfaces where currents flow to sustain the electromagnetic field pattern. Understanding these propagation characteristics becomes essential when designing microwave systems, as the field distribution influences power handling capability, insertion loss, and coupling efficiency to antennas or other system components. Advanced Microwave's engineering expertise in Waveguide Tube design ensures optimal field distribution and minimal higher-order mode excitation across the entire operational bandwidth, delivering superior performance compared to improvised or poorly designed alternatives that suffer from mode conversion losses and unpredictable transmission characteristics.

Key Differences Between Waveguide Tubes and Coaxial Cables in Signal Transmission

The operational disparities between Waveguide Tubes and ordinary coaxial cables create distinct performance profiles that make each technology optimal for specific application domains and frequency ranges. Coaxial cables employ a central conductor surrounded by a dielectric insulator and outer conducting shield, transmitting electromagnetic energy through current flow in the conductors with the electromagnetic fields confined to the dielectric region between them. This construction permits broadband operation from direct current up to several gigahertz, providing flexibility and ease of installation with bend radii measured in inches rather than feet. However, as operating frequencies increase beyond three gigahertz, the limitations of coaxial cable technology become increasingly problematic. The dielectric material supporting the center conductor introduces frequency-dependent losses that escalate dramatically with increasing frequency, while skin effect phenomena concentrate current flow in progressively thinner surface layers of the conductors, increasing resistive losses proportionally to the square root of frequency. At ten gigahertz, even premium coaxial cables like LMR-900 exhibit attenuation exceeding zero point four decibels per meter, meaning a fifty-meter cable run would lose over eighty-seven percent of the transmitted power before reaching the destination. In stark contrast, a WR-90 Waveguide Tube operating at the same frequency demonstrates losses below zero point one decibels per meter, retaining more than ninety-five percent of signal power over equivalent distances.

Attenuation Characteristics and Frequency Response

The attenuation performance comparison between Waveguide Tubes and coaxial cables reveals the dramatic advantages of waveguide technology at microwave frequencies. Coaxial cable losses arise from multiple mechanisms including dielectric losses in the insulating material, skin effect resistance in both center and outer conductors, and radiation losses from imperfect shielding, with all these factors increasing with frequency. At one gigahertz, typical RG-58 coaxial cable suffers approximately six point nine decibels of loss per hundred feet, but this escalates to completely impractical levels above ten gigahertz where losses can exceed two decibels per meter. The Waveguide Tube architecture eliminates the dielectric loss component entirely since electromagnetic waves propagate through air or vacuum within the hollow structure, while the distributed current flow across broad metallic surfaces minimizes skin effect resistance compared to the concentrated current density in coaxial cable conductors. Advanced Microwave Technologies Co., Ltd. Waveguide Tubes maintain remarkably low attenuation across broad frequency ranges, with our aluminum and copper constructions delivering performance that makes long-distance high-frequency transmission practical where coaxial alternatives would be completely unworkable. The frequency response of Waveguide Tubes exhibits a characteristic where attenuation actually decreases as frequency increases above the cutoff point, contrary to the monotonic increase seen in coaxial cables, providing optimal performance at the upper end of each waveguide size's operational band where system designers most need efficient, low-loss transmission capability.

Power Handling Capability and Breakdown Voltage

Power handling represents another critical distinction where Waveguide Tubes demonstrate overwhelming superiority over coaxial cable alternatives, particularly for high-power radar, satellite uplink, and industrial microwave applications. The power limitation in coaxial cables stems from voltage breakdown in the dielectric material between center and outer conductors, which occurs at relatively modest field strengths in solid or foam dielectric materials commonly used in cable construction. Even high-quality coaxial cables typically limit continuous power handling to a few hundred watts at microwave frequencies, with higher power levels causing dielectric heating, thermal expansion, and eventual catastrophic failure. A standard WR-90 Waveguide Tube, by comparison, can handle continuous power exceeding five kilowatts at ten gigahertz, with peak power capability reaching into the megawatt range for pulsed radar applications. This remarkable power handling stems from the air dielectric within the Waveguide Tube, which exhibits breakdown voltage around thirty kilovolts per centimeter - substantially higher than solid dielectric materials - combined with the distributed electromagnetic field that spreads energy across the entire cross-sectional area rather than concentrating it in the small volume around a central conductor. Our Waveguide Tube products incorporate precision manufacturing and optional pressurization capabilities that further enhance power handling by increasing the breakdown threshold and preventing moisture ingress that could degrade performance or cause arcing in high-field regions. For applications requiring reliable high-power transmission such as military surveillance radars, weather monitoring systems, and satellite ground stations, the Waveguide Tube provides the only viable solution that combines low loss with the robust power handling capability demanded by modern high-performance systems.

Technical Advantages of Advanced Microwave's Waveguide Tube Solutions

Advanced Microwave Technologies Co., Ltd. brings over twenty years of specialized experience in Waveguide Tube design and manufacturing, delivering products that meet the most demanding performance requirements across satellite communications, aerospace, defense, and telecommunications sectors. Our Waveguide Tubes benefit from state-of-the-art manufacturing facilities equipped with precision machining centers capable of maintaining dimensional tolerances within thousandths of an inch, ensuring optimal electromagnetic performance and mechanical fit compatibility with industry-standard flange connections. The material selection for our Waveguide Tube products reflects careful engineering tradeoffs between electrical conductivity, mechanical strength, weight considerations, and corrosion resistance appropriate for each application environment. Aluminum Waveguide Tubes provide excellent conductivity-to-weight ratios ideal for aerospace and mobile applications where mass reduction directly impacts system performance, while copper constructions deliver maximum conductivity for ultra-low-loss requirements in laboratory and fixed-installation scenarios. Our advanced surface treatment options including silver plating enhance conductivity and power handling, while gold plating provides superior corrosion resistance for harsh environmental exposures in marine and outdoor installations. The frequency range coverage from our comprehensive product line spanning WR2300 through WR10 ensures that system designers can select the optimal Waveguide Tube size for any application frequency, maximizing performance while minimizing unnecessary size and weight compared to using oversized waveguide sections.

Customization Capabilities and Engineering Support

Understanding that modern microwave systems present unique challenges requiring tailored solutions, Advanced Microwave Technologies Co., Ltd. offers extensive customization services for Waveguide Tube products beyond our standard catalog offerings. Our engineering team collaborates directly with customers to develop Waveguide Tubes with specialized dimensions, custom flange configurations, integrated transitions, and application-specific features that optimize system integration and performance. Whether your project requires non-standard lengths up to three meters for minimizing connection count in long transmission runs, specialized alloy materials for extreme temperature environments, or hybrid assemblies combining Waveguide Tube sections with transitions to coaxial or other interface types, our design and manufacturing capabilities can deliver precisely engineered solutions. The customization process begins with detailed technical consultation where our experienced RF engineers analyze your specific requirements including frequency range, power levels, environmental conditions, mechanical interfaces, and system integration constraints. We then develop prototype designs utilizing advanced electromagnetic simulation tools to verify performance before committing to production tooling, ensuring the final Waveguide Tube product meets or exceeds all specifications. Our ISO 9001:2015 certified quality management systems govern every aspect of the customization process from initial design through final testing and delivery, providing confidence that custom Waveguide Tube solutions will perform reliably in your critical applications. This comprehensive engineering support extends beyond product delivery to include installation guidance, system integration assistance, and ongoing technical consultation ensuring optimal long-term performance of Waveguide Tube-based microwave systems.

Quality Certifications and Performance Validation

Quality and reliability stand as fundamental requirements for Waveguide Tube products deployed in mission-critical applications where failure could compromise entire system functionality or create safety hazards. Advanced Microwave Technologies Co., Ltd. maintains comprehensive quality certifications including ISO 9001:2015 for quality management, ISO 14001:2015 for environmental management, and ISO 45001:2018 for occupational health and safety, demonstrating organizational commitment to excellence across all operational dimensions. Our Waveguide Tube manufacturing processes incorporate rigorous in-process inspection protocols and final verification testing that validates electrical performance parameters including insertion loss, return loss, and power handling capability across the specified frequency range. The advanced measurement equipment in our laboratories, supporting frequencies up to one hundred ten gigahertz, enables precise characterization of Waveguide Tube products ensuring they meet published specifications and customer requirements. Our twenty-four-meter microwave darkroom provides unparalleled capabilities for far-field antenna pattern measurements when Waveguide Tubes feed radiating elements, while the Antenna Plane Near and Far Field Measuring Recombination Chamber allows detailed characterization of radiation patterns, gain, and impedance characteristics critical for system performance optimization. RoHS compliance across our Waveguide Tube product line ensures environmental responsibility and regulatory conformance for international deployment, while our quality traceability systems maintain complete documentation from raw material certification through final test results for every manufactured unit. This commitment to quality and performance validation means that customers can specify Advanced Microwave Waveguide Tubes with confidence for demanding applications in aviation and aerospace systems, shipboard installations, weather monitoring radars, security screening equipment, unmanned aerial vehicles, and direction-finding systems where reliability directly impacts mission success.

Application Domains and System Integration Considerations

The unique performance characteristics of Waveguide Tubes make them indispensable components across numerous high-frequency microwave applications where ordinary coaxial cables simply cannot meet performance requirements. Satellite communication ground stations represent a prime application where Waveguide Tubes connect high-power transmitters to parabolic dish antennas, transmitting uplink signals at frequencies typically ranging from four to thirty gigahertz with power levels from tens to hundreds of watts continuous, or kilowatts for broadcast applications. The low insertion loss of Waveguide Tubes ensures maximum transmitted power reaches the antenna aperture rather than being dissipated in the transmission line, directly improving link margin and system reliability. In radar systems spanning weather monitoring, air traffic control, military surveillance, and navigation applications, Waveguide Tubes route microwave energy between transmitter/receiver electronics and antenna elements with minimal loss and maximum power handling capability essential for long-range detection and accurate target tracking. Advanced Microwave's Waveguide Tube products support these demanding radar applications across X-band, Ku-band, Ka-band, and millimeter-wave frequencies where the combination of low loss, high power capability, and excellent shielding effectiveness proves critical for achieving required system performance specifications. Telecommunications infrastructure increasingly employs microwave frequencies for backhaul connections and point-to-point links, with Waveguide Tubes providing the low-loss interconnections between radio equipment and tower-mounted antennas that maximize link distance and minimize signal regeneration requirements.

Defense and Aerospace Applications

Military and aerospace applications present the most demanding operational requirements for Waveguide Tube products, combining needs for maximum performance, extreme environmental resilience, and absolute reliability under conditions where failure could compromise mission success or personnel safety. Advanced Microwave Technologies Co., Ltd. serves defense contractors and aerospace manufacturers with Waveguide Tube solutions engineered specifically for these challenging applications. Military radar systems for surveillance, fire control, missile guidance, and countermeasures rely on Waveguide Tubes to deliver transmit power to phased array antennas and route received signals to sensitive detection electronics with minimal degradation of the weak echoes returned from distant targets. Our Waveguide Tube products withstand the shock, vibration, temperature extremes, and humidity variations encountered in mobile military installations, naval vessels, and aircraft while maintaining electrical performance across mission-critical frequency bands. Aerospace applications including satellite payload feed networks, aircraft weather radar systems, and navigation aids require Waveguide Tubes that combine minimum weight with maximum reliability, meeting stringent qualification requirements for space flight or aviation certification. The material expertise and manufacturing precision at Advanced Microwave enables delivery of lightweight aluminum Waveguide Tube assemblies that satisfy aerospace mass constraints while providing the low loss and power handling required for spacecraft communication systems operating in the harsh space environment. Our experience supplying defense and aerospace customers ensures understanding of unique requirements including specialized testing protocols, documentation standards, supply chain security, and configuration management necessary for these regulated market segments.

Industrial and Research Applications

Beyond traditional defense and communications domains, Waveguide Tube technology finds extensive application in industrial processes and scientific research where high-frequency electromagnetic energy serves specialized purposes. Industrial microwave heating systems for materials processing, chemical reactions, and food treatment employ Waveguide Tubes to efficiently deliver megawatts of microwave power from magnetron or solid-state generators to applicator cavities where the energy interacts with materials being processed. The power handling capability and low loss of Waveguide Tubes proves essential for achieving the energy efficiency required to make industrial microwave processes economically viable. Plasma generation systems for semiconductor manufacturing and materials research utilize Waveguide Tubes to couple microwave energy into vacuum chambers where it ionizes gases creating the plasma environment necessary for thin film deposition, etching, or surface treatment processes. Scientific research facilities studying high-frequency electromagnetic phenomena, testing microwave components, or developing next-generation communication technologies require precision Waveguide Tube assemblies and test fixtures that enable accurate measurements and characterization. Advanced Microwave Technologies Co., Ltd. supports research and development organizations with standard and custom Waveguide Tube products complemented by our measurement system capabilities including network analyzers, power meters, and antenna test ranges that provide comprehensive characterization services. Our twenty-four-meter microwave darkroom represents a world-class facility for antenna and propagation research, while our technical staff's expertise assists researchers in optimizing experimental setups and interpreting measurement results, advancing the state of microwave engineering knowledge that drives future technology development.

Conclusion

Waveguide Tubes provide superior high-frequency signal transmission through hollow metallic structures with dramatically lower loss and higher power handling than coaxial cables, making them essential for satellite communications, radar, aerospace, and defense applications above several gigahertz where conventional transmission lines cannot meet performance requirements.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Partner with Advanced Microwave Technologies Co., Ltd., the leading China Waveguide Tube factory, China Waveguide Tube supplier, and China Waveguide Tube manufacturer offering High Quality Waveguide Tube products at competitive Waveguide Tube price with Waveguide Tube for sale through China Waveguide Tube wholesale channels. Our perfect supply chain system, rich production experience spanning over twenty years, professional technical R&D team, fast delivery capabilities, competitive pricing, strict quality control under ISO certifications, and strong after-sales support ensure your microwave system success. Whether you need standard catalog products or custom Waveguide Tube solutions, our OEM services provide prototyping, technical support, and quick turnaround to meet your unique specifications. Contact craig@admicrowave.com today for technical consultation and quotations that will optimize your high-frequency transmission systems.

References

1. Pozar, David M. "Microwave Engineering" Fourth Edition. John Wiley & Sons, 2012. Chapter 3: Transmission Lines and Waveguides.

2. Collin, Robert E. "Foundations for Microwave Engineering" Second Edition. IEEE Press, 2001. Sections on Rectangular Waveguides and Transmission Line Theory.

3. Marcuvitz, Nathan. "Waveguide Handbook" MIT Radiation Laboratory Series Volume 10. McGraw-Hill Book Company, 1951. Comprehensive reference on waveguide theory and design.

4. Montgomery, C. G., Dicke, R. H., and Purcell, E. M. "Principles of Microwave Circuits" MIT Radiation Laboratory Series Volume 8. McGraw-Hill Book Company, 1948. Chapters on waveguide transmission and propagation modes.