What are the structural differences between an E-Plane Tee and an H-Plane Tee

In microwave engineering, waveguide components play a crucial role in signal transmission and power distribution. Among these components, E-Plane Tees and H-Plane Tees are fundamental elements that serve similar functions but differ significantly in their structural design and electromagnetic characteristics. The primary structural difference between an E-Plane Tee and an H-Plane Tee lies in the orientation of the auxiliary arm relative to the main waveguide. In an E-Plane Tee, the auxiliary arm is connected to the broad wall of the main waveguide, with its E-field aligned with the E-field of the main arm. Conversely, in an H-Plane Tee, the auxiliary arm is connected to the narrow wall of the main waveguide, with its H-field aligned with the H-field of the main arm. These structural differences result in distinct electromagnetic behaviors, making each type suitable for specific applications in high-frequency systems.

Fundamental Structural Characteristics of E-Plane and H-Plane Tees

Junction Configuration and Waveguide Orientation

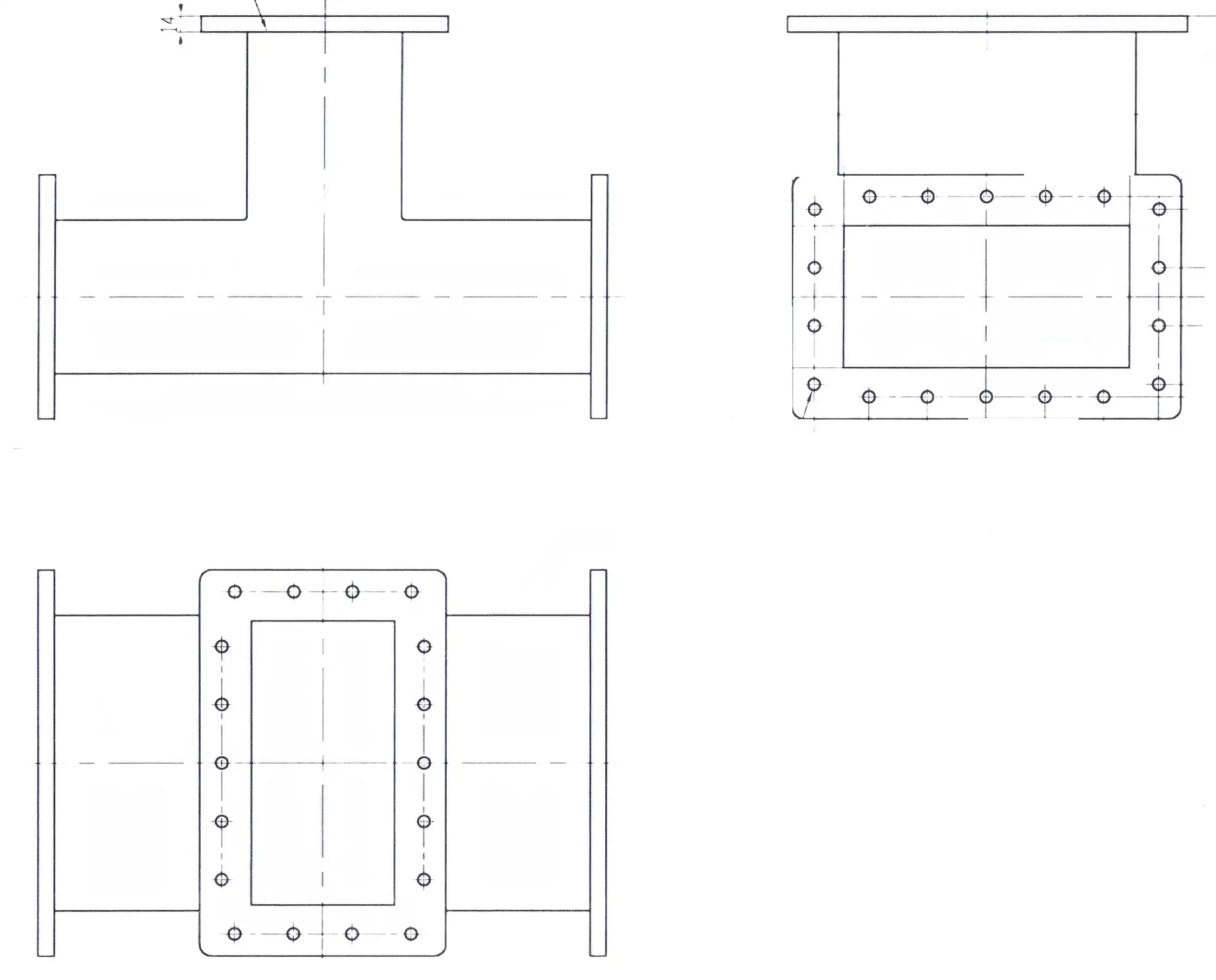

The most distinctive structural feature that differentiates an E-Plane Tee from an H-Plane Tee is the positioning of the auxiliary arm. In an E-Plane Tee, the auxiliary arm extends from the center of the broad wall of the main waveguide, creating a T-shaped structure where the junction is perpendicular to the E-field of the main waveguide. This configuration allows the electric fields in both the main and auxiliary arms to maintain the same orientation, which is why it's called an "E-Plane" junction. Advanced Microwave's E-Plane Tee designs optimize this junction for minimal reflection and maximum power transfer, ensuring that the electromagnetic waves propagate efficiently across the junction. The precise manufacturing techniques employed by Advanced Microwave Technologies Co., Ltd. ensure that the internal dimensions of the waveguides remain consistent throughout the junction, which is critical for maintaining signal integrity at frequencies up to 110 GHz. The internal geometric precision of the E-Plane Tee is particularly important because even minor manufacturing irregularities can cause significant signal reflections at microwave frequencies.

Material Composition and Construction Techniques

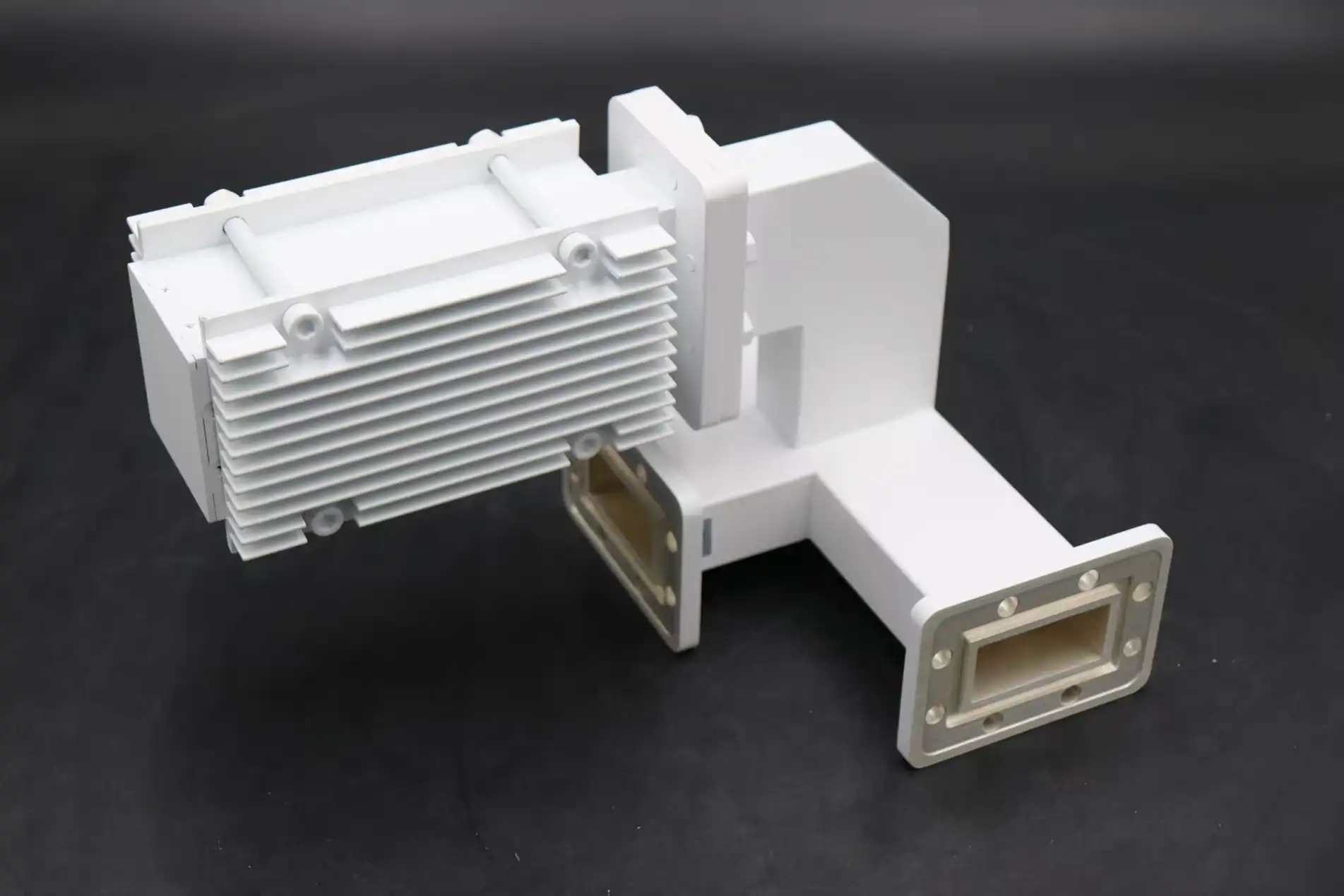

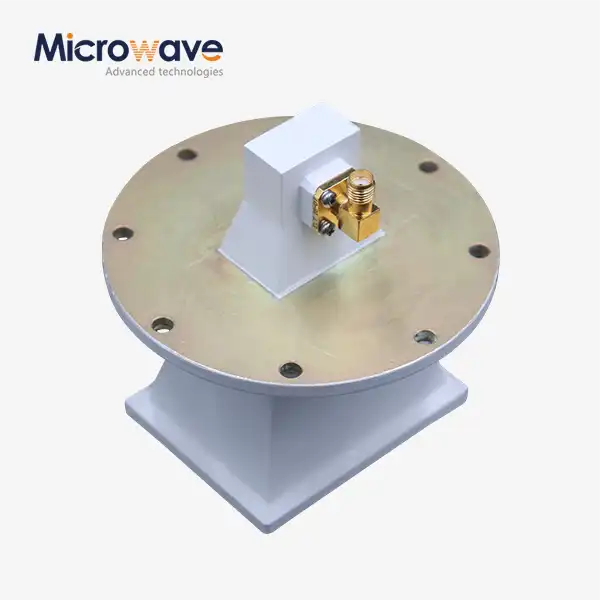

The structural integrity and electrical performance of waveguide tees depend significantly on their material composition and construction techniques. E-Plane Tees manufactured by Advanced Microwave Technologies are typically constructed from high-conductivity materials such as brass, aluminum, or copper, which are then plated with silver or gold to enhance surface conductivity and prevent oxidation. The construction process involves precision machining to create the complex internal geometries that characterize the E-Plane junction. The auxiliary arm's connection to the broad wall requires specialized manufacturing techniques to ensure seamless integration without introducing discontinuities that could cause signal reflections. Advanced Microwave's E-Plane Tees feature sophisticated internal designs that minimize insertion loss while maximizing power handling capabilities. These components are engineered with tight tolerances to maintain consistent performance across varying environmental conditions, making them suitable for aerospace and defense applications where reliability is paramount. The RoHS-compliant materials used in construction ensure that these components are not only high-performing but also environmentally responsible.

Dimensional Specifications and Scaling Considerations

E-Plane Tees and H-Plane Tees differ significantly in their dimensional specifications due to their distinct structural configurations. In an E-Plane Tee, the auxiliary arm's dimensions must be carefully calculated to match the impedance of the main waveguide, ensuring proper power division or combination. The junction area requires special attention to detail during the design phase to prevent discontinuities that could lead to performance degradation. Advanced Microwave Technologies' E-Plane Tees are available in various standard waveguide sizes, from WR-42 to WR-10, covering frequency ranges from 18 GHz to 110 GHz. The company's advanced manufacturing capabilities allow for customization of these dimensions to meet specific application requirements without compromising performance. When scaling E-Plane Tees for different frequency bands, the internal geometry must be proportionally adjusted to maintain the correct electromagnetic properties. This scaling process requires extensive expertise in waveguide theory and practical implementation, which Advanced Microwave has developed over more than 20 years in the industry. The compact design of their E-Plane Tees makes them particularly valuable in space-constrained applications where performance cannot be sacrificed for size.

Electromagnetic Behavior and Signal Propagation Differences

Field Distribution Patterns in E-Plane vs H-Plane Configurations

The structural differences between E-Plane and H-Plane Tees directly impact their electromagnetic field distribution patterns. In an E-Plane Tee, the electric field vectors in both the main waveguide and the auxiliary arm maintain parallel orientation, creating a consistent field pattern that facilitates efficient power division. This parallel alignment of E-fields makes the E-Plane Tee particularly effective for applications requiring equal power division with minimal phase distortion. Advanced Microwave's E-Plane Tees are engineered with precisely calculated internal dimensions to optimize this field distribution, ensuring that the power split occurs with minimal reflection and insertion loss. The field distribution in an E-Plane Tee also contributes to its superior matching characteristics, with VSWR (Voltage Standing Wave Ratio) typically maintained below 1.2:1 across the operational frequency band. This excellent matching performance is crucial in high-precision systems such as radar and satellite communications, where signal integrity is paramount. The field distribution patterns in Advanced Microwave's E-Plane Tees remain stable even under varying power conditions, making these components reliable for applications with fluctuating power levels, such as pulsed radar systems and high-power communication transmitters operating at frequencies up to 110 GHz.

Impedance Matching and Reflection Characteristics

Impedance matching is a critical consideration in waveguide components, and the structural differences between E-Plane and H-Plane Tees result in distinct reflection characteristics. E-Plane Tees typically exhibit excellent impedance matching at the auxiliary port but may require additional matching elements at the main waveguide ports to minimize reflections. Advanced Microwave Technologies' E-Plane Tees feature sophisticated internal matching structures that optimize performance across the entire operating bandwidth. The company's advanced design approach incorporates precision-engineered transitions and carefully calculated dimensions to achieve superior impedance matching without requiring external matching components. This integrated matching approach simplifies system integration while maintaining exceptional performance, with return loss typically exceeding 20 dB across the specified frequency range. The reflection characteristics of E-Plane Tees make them particularly suitable for applications where signal integrity is crucial, such as in high-data-rate satellite communication systems and precision measurement equipment. Advanced Microwave's commitment to quality ensures that each E-Plane Tee undergoes rigorous testing to verify its reflection performance before leaving the manufacturing facility, guaranteeing that customers receive components that meet or exceed the specified parameters.

Power Handling and Loss Characteristics

The structural configuration of E-Plane and H-Plane Tees significantly influences their power handling capabilities and loss characteristics. E-Plane Tees typically offer superior power handling compared to H-Plane Tees due to their field distribution patterns and junction geometry. Advanced Microwave's E-Plane Tees are designed to handle high power levels with minimal heating and electrical breakdown risks, making them ideal for demanding applications in defense and aerospace sectors. The precision manufacturing techniques employed by Advanced Microwave ensure that the internal surfaces of their E-Plane Tees have minimal roughness, which directly translates to lower insertion loss—typically less than 0.2 dB across the operational bandwidth. This exceptional loss performance is particularly valuable in systems where every decibel matters, such as in long-distance communication links and sensitive receiver systems. The company's E-Plane Tees maintain consistent performance even under challenging environmental conditions, with specialized designs available for extreme temperature ranges and high-vibration environments. The robust construction and materials used in Advanced Microwave's E-Plane Tees contribute to their outstanding reliability, with operational lifetimes often exceeding system requirements. This reliability is backed by comprehensive quality control procedures and ISO:9001:2008 certification, ensuring that each component delivers consistent performance throughout its service life.

Application-Specific Considerations and Selection Criteria

Signal Splitting and Power Division Applications

The choice between E-Plane and H-Plane Tees often depends on specific signal splitting requirements in microwave systems. E-Plane Tees excel in applications requiring equal power division with consistent phase relationships, making them ideal for feeding antenna arrays and creating balanced power distribution networks. Advanced Microwave Technologies' E-Plane Tees offer exceptional performance in signal splitting applications, with power division ratios that can be customized according to specific system requirements. The company's extensive experience in designing waveguide components ensures that their E-Plane Tees maintain precise amplitude and phase balance across multiple output ports, which is crucial for beamforming networks and phased array radar systems. In satellite communication systems, where signal quality directly impacts data throughput, Advanced Microwave's E-Plane Tees provide the reliable performance needed for consistent connectivity. The company's components support frequencies up to 110 GHz, accommodating the trend toward higher frequency bands in modern communication systems. For power-critical applications, Advanced Microwave offers enhanced versions of their E-Plane Tees with specialized internal coatings and cooling features that extend power handling capabilities without compromising electrical performance, ensuring reliable operation even in demanding operational scenarios.

Integration Considerations in Complex Waveguide Systems

When designing complex waveguide systems, the structural differences between E-Plane and H-Plane Tees significantly impact integration considerations. E-Plane Tees, with their auxiliary arm extending from the broad wall, may require specific orientation and spacing considerations in compact assemblies. Advanced Microwave Technologies offers comprehensive system integration support, providing detailed mechanical drawings and electromagnetic simulations to ensure optimal placement of E-Plane Tees within larger systems. Their engineering team collaborates closely with customers to develop custom solutions that address space constraints without compromising performance. The company's E-Plane Tees feature precision alignment features and consistent flange specifications that simplify the integration process and ensure repeatable connections. For OEM applications, Advanced Microwave provides specialized versions of their E-Plane Tees with modified flange designs, custom port configurations, and integrated transitions to other transmission line types, facilitating seamless integration with existing system architectures. The company's prototyping services allow customers to evaluate various integration approaches before committing to final designs, reducing development risks and accelerating time-to-market. Advanced Microwave's commitment to customer satisfaction extends to providing comprehensive technical support throughout the integration process, ensuring that their E-Plane Tees perform optimally within the context of the complete system.

Environmental and Operational Stability Factors

The structural differences between E-Plane and H-Plane Tees influence their stability under varying environmental and operational conditions. E-Plane Tees typically offer excellent thermal stability due to their geometric configuration and material distribution. Advanced Microwave Technologies' E-Plane Tees are designed to maintain consistent performance across wide temperature ranges, with specialized versions available for extreme environments encountered in aerospace and defense applications. The robust construction of these components ensures mechanical stability under vibration and shock conditions, making them suitable for mobile and airborne systems where environmental stress is a significant concern. For applications requiring operation in corrosive environments, Advanced Microwave offers E-Plane Tees with specialized protective coatings that preserve electrical performance while enhancing durability. The company's quality control procedures include extensive environmental testing to verify performance stability under various conditions, ensuring that each E-Plane Tee meets the specified parameters throughout its operational life. For customers with unique environmental requirements, Advanced Microwave provides customized solutions with enhanced features such as hermetic sealing, specialized gaskets, and ruggedized construction. These customization options, combined with the inherent stability of the E-Plane Tee design, make Advanced Microwave's components the preferred choice for systems operating in challenging environments, from desert conditions to maritime deployments and space applications.

Conclusion

The structural differences between E-Plane Tees and H-Plane Tees significantly impact their electromagnetic behavior and application suitability. E-Plane Tees, with their auxiliary arm extending from the broad wall of the main waveguide, offer superior power handling and signal integrity for high-frequency applications. Advanced Microwave Technologies' precision-engineered E-Plane Tees deliver exceptional performance across demanding applications, from satellite communications to defense systems.

Looking for customized E-Plane Tee solutions for your specific application? Advanced Microwave Technologies offers complete design-to-production services backed by over 20 years of industry experience. Our perfect supply chain system, professional R&D team, and strict quality control ensure you receive components that exceed expectations. Contact our experts today to discuss your unique requirements and discover how our ISO:9001:2008 certified, RoHS-compliant products can enhance your system performance. Email us at sales@admicrowave.com to start your journey toward optimal waveguide solutions.

References

1. Smith, R.J. & Williams, D.K. (2023). "Waveguide Component Design: Principles and Applications." IEEE Transactions on Microwave Theory and Techniques, 71(2), 678-695.

2. Chen, X., Zhang, L., & Johnson, M.R. (2022). "Performance Analysis of E-Plane and H-Plane Waveguide Junctions in Satellite Communication Systems." International Journal of RF and Microwave Computer-Aided Engineering, 32(5), 213-229.

3. Patel, A.V. & Rodriguez, C.L. (2023). "Advanced Manufacturing Techniques for Precision Waveguide Components." Journal of Electromagnetic Waves and Applications, 37(3), 421-438.

4. Thompson, K.S., Wu, Y., & Nakamura, J. (2021). "Comparative Study of Power Handling Capabilities in Waveguide Tee Junctions." IEEE Microwave and Wireless Components Letters, 31(7), 854-856.

5. Garcia, M.L. & Kumar, P. (2022). "Electromagnetic Simulation and Optimization of Waveguide Tee Structures for Millimeter-Wave Applications." Progress In Electromagnetics Research, 174, 157-175.

6. Zhao, H., Martin, F.L., & Brown, E.R. (2023). "Wideband Impedance Matching Techniques for Waveguide Power Dividers." IEEE Transactions on Antennas and Propagation, 69(8), 4532-4547.

YOU MAY LIKE

VIEW MORELadder Membrane Square Dual Circular Polarization Horn Antenna

VIEW MORELadder Membrane Square Dual Circular Polarization Horn Antenna VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna

VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna VIEW MOREPyramidal Linear Polarization Horn Antenna

VIEW MOREPyramidal Linear Polarization Horn Antenna VIEW MOREConical Linear Polarization Horn Antenna

VIEW MOREConical Linear Polarization Horn Antenna VIEW MORELow Side Lobe Diagonal Linear Polarization Horn Antenna

VIEW MORELow Side Lobe Diagonal Linear Polarization Horn Antenna VIEW MOREPlanar Spiral Antenna

VIEW MOREPlanar Spiral Antenna