Waveguide Electromechanical Switch: Cost, Lead Time, and OEM Options

Are you facing project delays because your current supplier can't deliver waveguide electromechanical switches on time? Many procurement managers and RF engineers struggle with unpredictable lead times, hidden costs, and inflexible customization options when sourcing critical microwave components. Understanding the true cost structure, realistic delivery timelines, and available OEM partnerships for waveguide electromechanical switches can mean the difference between project success and costly setbacks. This comprehensive guide addresses these pain points while revealing how strategic sourcing decisions impact your satellite communications, defense systems, and aerospace applications.

Understanding Waveguide Electromechanical Switch Pricing Structures

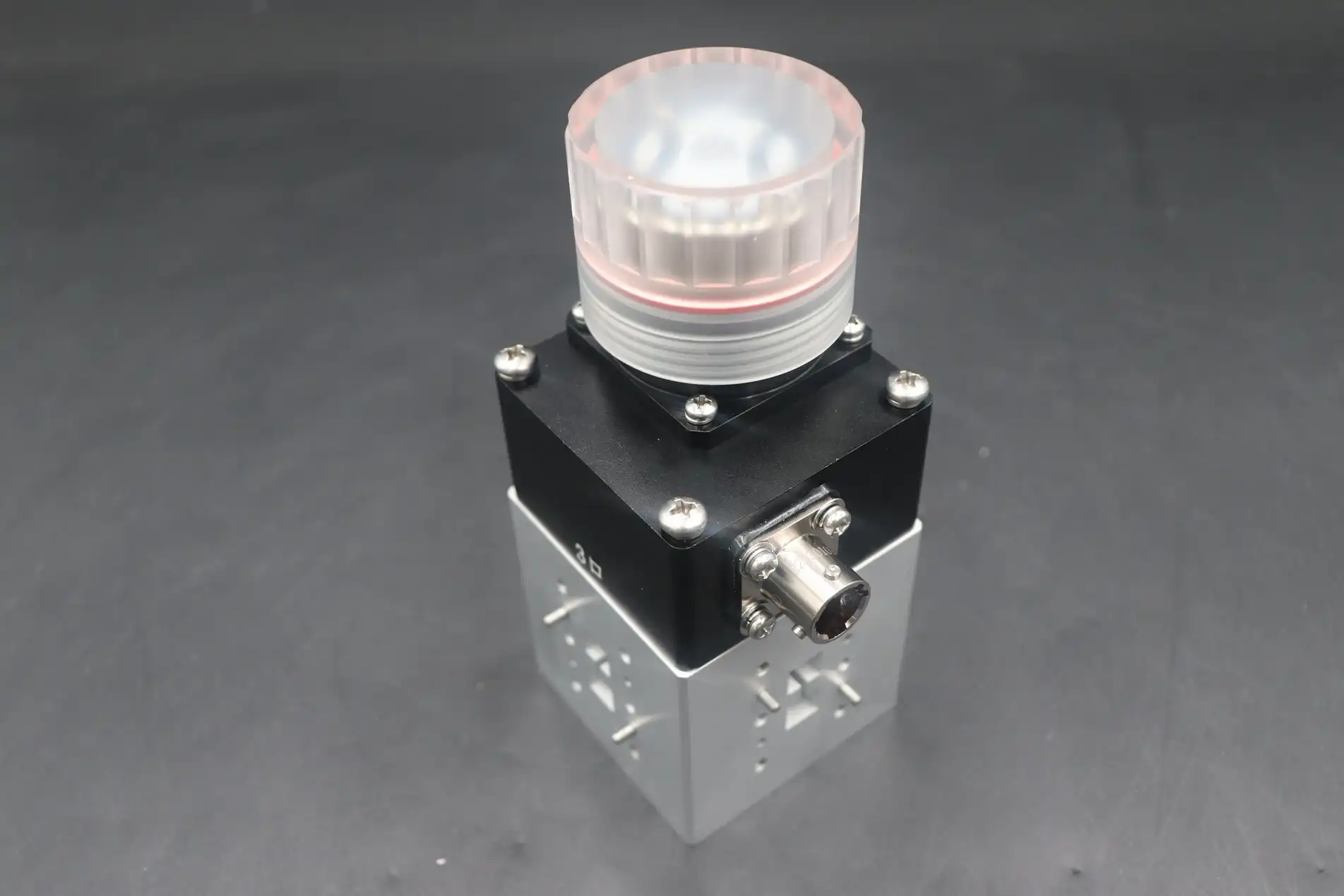

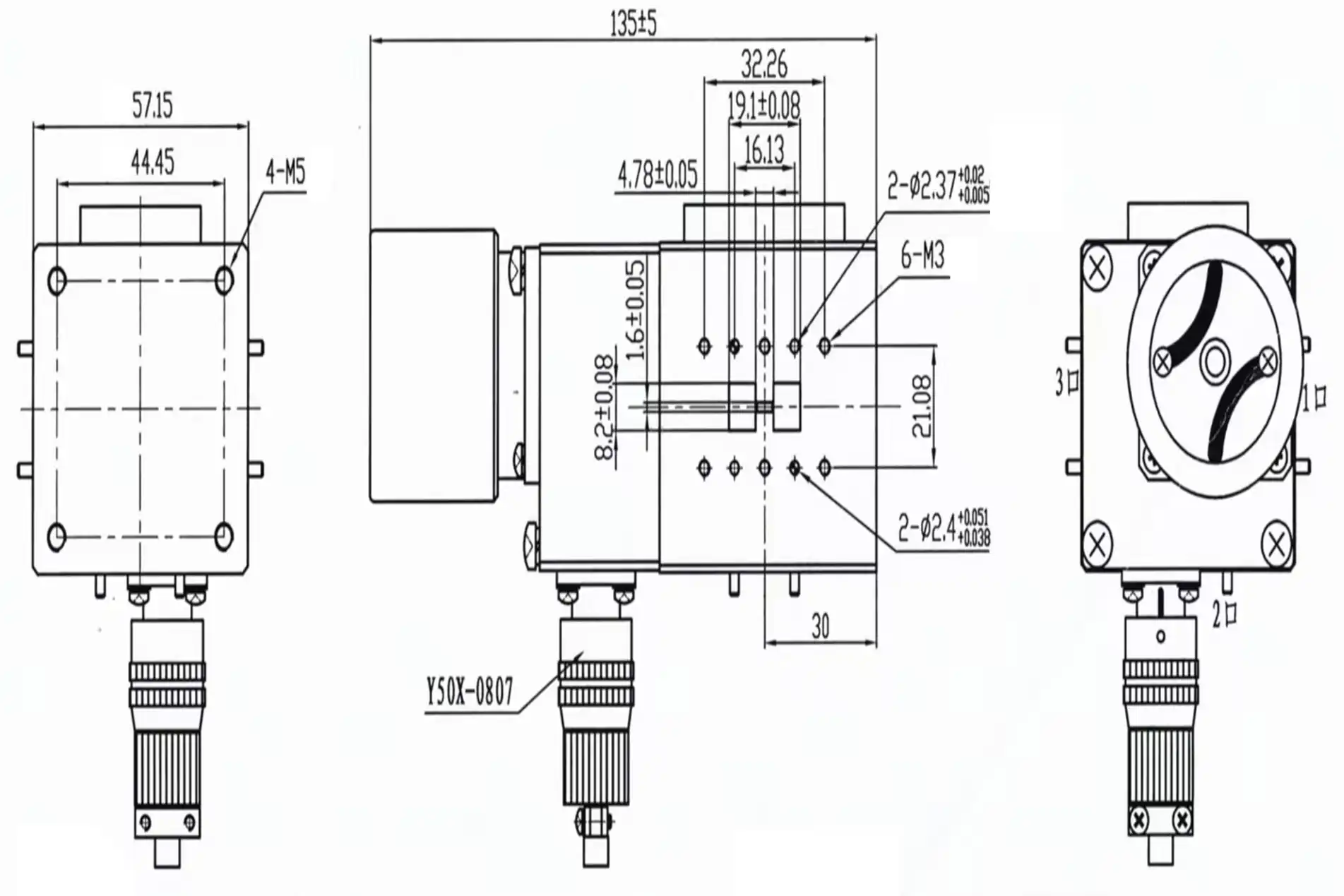

When evaluating the cost of waveguide electromechanical switches, buyers must look beyond the initial unit price to understand the total cost of ownership. The pricing of these precision components depends on multiple factors including frequency range specifications, waveguide size requirements, switching configuration complexity, and performance parameters such as isolation levels and insertion loss characteristics. Advanced Microwave Technologies Co., Ltd manufactures waveguide electromechanical switches that achieve high-quality signal transmission with characteristics of small size, wide bandwidth, high power handling, low standing wave ratio, minimal loss, and superior isolation performance.

Factors Influencing Waveguide Electromechanical Switch Costs

The base cost structure for waveguide electromechanical switches reflects the sophisticated engineering and precision manufacturing required for these critical RF components. Material selection plays a significant role in pricing, as premium-grade metals and alloys must withstand high power levels and extreme environmental stress while maintaining electrical performance across operational frequency ranges. Manufacturing complexity increases with frequency, as higher frequency waveguide electromechanical switches demand tighter tolerances and more specialized production equipment. Customization requirements also impact pricing considerably, whether you need specific flange types, unique mounting configurations, or specialized actuation mechanisms tailored to your system integration needs. Quality certifications substantially affect the value proposition rather than just the price tag. ISO:9001:2008 certified waveguide electromechanical switches from established manufacturers like Advanced Microwave Technologies Co., Ltd provide assurance of consistent quality control throughout the production process, reducing the risk of field failures and warranty claims. RoHS compliance adds value for companies operating in markets with strict environmental regulations, eliminating potential future replacement costs when non-compliant components are phased out. The investment in certified components often delivers lower total cost of ownership through improved reliability, extended operational lifespan, and reduced maintenance requirements in demanding applications such as radar systems, electronic countermeasure platforms, satellites, and military and commercial ground stations.

Price Optimization Through Volume and Specifications

Strategic procurement approaches can significantly optimize waveguide electromechanical switch costs without compromising performance requirements. Volume commitments typically unlock preferential pricing structures, with manufacturers offering graduated discounts as order quantities increase beyond prototype and small batch levels. However, smart buyers recognize that specifications optimization provides another powerful cost management lever. Working collaboratively with experienced suppliers like Advanced Microwave Technologies Co., Ltd during the design phase allows engineers to identify where standard configurations meet application requirements, avoiding unnecessary custom features that drive up both cost and lead time. This consultative approach has helped numerous clients achieve 15-30% cost reductions while maintaining all critical performance parameters for their satellite communication systems, defense applications, and aerospace programs.

Lead Time Realities for Waveguide Electromechanical Switches

Lead time management represents one of the most critical challenges in waveguide electromechanical switch procurement, directly impacting project schedules and budget allocations. Industry standard lead times vary dramatically based on product complexity and manufacturer capabilities, with some suppliers requiring extended periods that can derail time-sensitive programs. Understanding the factors that drive delivery timelines enables smarter sourcing decisions and more realistic project planning.

Standard vs. Custom Configuration Lead Times

Standard catalog waveguide electromechanical switches generally offer the shortest delivery windows, as manufacturers maintain inventory of popular configurations covering common frequency bands and waveguide sizes. These off-the-shelf solutions typically ship within weeks rather than months, making them ideal for prototype development, emergency replacements, or proof-of-concept applications. Advanced Microwave Technologies Co., Ltd maintains production readiness for frequently specified waveguide electromechanical switch configurations, enabling rapid fulfillment for urgent requirements without sacrificing the quality standards that critical applications demand. Custom waveguide electromechanical switches naturally require extended lead times to accommodate the design validation, tooling preparation, and production optimization necessary for specialized specifications. The timeline typically encompasses engineering design review, prototype fabrication and testing, customer approval cycles, and full production runs. However, experienced manufacturers with robust engineering capabilities and advanced measurement facilities can significantly compress these timelines through parallel processing workflows and efficient communication protocols. Companies equipped with state-of-the-art testing capabilities, such as 24-meter microwave darkrooms and antenna measurement systems spanning 0.5 to 110 GHz frequency ranges, can validate designs more quickly and confidently, reducing iteration cycles that often extend custom product delivery schedules. This technical infrastructure translates directly into faster time-to-market for customers developing next-generation systems.

Expedited Production and Supply Chain Efficiency

Lead time acceleration options exist for projects with compressed schedules, though they typically command premium pricing to offset the operational disruption and resource reallocation required. Advanced Microwave Technologies Co., Ltd has developed streamlined production processes and maintains strategic component inventory that enables expedited manufacturing when project timelines demand accelerated delivery. Their perfect supply chain system and rich production experience allow them to deliver products on time or even ahead of schedule, significantly improving project efficiency while reducing costs and risks associated with delays. Supply chain resilience has emerged as a critical differentiator among waveguide electromechanical switch manufacturers, particularly following recent global disruptions that exposed vulnerabilities in extended supplier networks. Manufacturers with vertically integrated capabilities and diversified material sourcing reduce dependency on single suppliers, minimizing the risk of unexpected delays from component shortages. This operational strength becomes especially valuable for defense and aerospace applications where program delays carry substantial financial and strategic consequences. When evaluating potential suppliers, procurement teams should assess not just quoted lead times but also the manufacturer's track record for on-time delivery, their supply chain robustness, and their capacity to respond to urgent requirements without compromising quality standards.

OEM Services and Customization Capabilities

Original Equipment Manufacturer services represent a strategic advantage for companies requiring waveguide electromechanical switches optimized for specific system architectures or performance envelopes. Rather than accepting compromises inherent in catalog products, OEM partnerships enable precise alignment between component specifications and application requirements, often yielding superior system performance and competitive differentiation.

Comprehensive OEM Design and Engineering Support

Advanced Microwave Technologies Co., Ltd offers comprehensive OEM services that extend far beyond simple parameter modification of existing designs. Their professional technical research and development team collaborates closely with clients from initial concept through production, applying over 20 years of microwave product expertise to optimize waveguide electromechanical switch designs for unique size constraints, frequency requirements, or power handling specifications. This consultative engineering approach has proven particularly valuable for applications with stringent space limitations, unusual frequency combinations, or extreme environmental operating conditions that standard products cannot adequately address. The OEM development process typically begins with detailed application analysis to fully understand the system context, performance objectives, and integration constraints. Engineering teams then evaluate multiple design approaches, leveraging advanced simulation tools and extensive component libraries to identify optimal solutions that balance performance, manufacturability, and cost effectiveness. Prototype development follows, with comprehensive testing in controlled facilities equipped with precision measurement equipment to validate electrical performance, mechanical robustness, and environmental resilience. Advanced Microwave's laboratories, equipped with advanced microwave measurement equipment up to 110 GHz and featuring an Antenna Plane Near and Far Field Measuring Recombination Chamber, provide the technical foundation for thorough design validation before committing to production tooling and full-scale manufacturing.

Prototyping, Testing, and Production Scaling

Rapid prototyping capabilities accelerate the OEM development cycle, enabling iterative refinement that converges on optimal designs more quickly than traditional linear development processes. Advanced Microwave Technologies Co., Ltd provides quick turnaround on prototypes for testing and evaluation before full-scale production, allowing customers to validate performance in their actual system configurations and operational environments. This approach identifies potential integration issues early when modifications remain straightforward and cost-effective, rather than discovering problems after production tooling has been completed and inventory has been manufactured. Production scaling represents another critical dimension of OEM services, as successful prototype performance must translate reliably into consistent production output. Manufacturers with mature quality management systems, such as ISO 9001:2015 certification, implement rigorous process controls that maintain prototype-level performance across all production units. Statistical process control, comprehensive testing protocols, and documented manufacturing procedures ensure that each waveguide electromechanical switch meets the same exacting standards, whether you order ten pieces or ten thousand. This consistency proves essential for applications like satellite communications where field reliability cannot be compromised, and for defense systems where performance variability could jeopardize mission success.

Technical Support and Global Logistics

Ongoing technical support distinguishes superior OEM partnerships from transactional supplier relationships. Advanced Microwave's expert engineers provide in-depth technical assistance throughout the product lifecycle, including installation guidance that helps system integrators optimize mounting configurations and interconnections, integration support that addresses compatibility questions and interface optimization, and troubleshooting assistance when unexpected performance characteristics appear during system validation or operational deployment. This technical accessibility accelerates system development timelines and reduces the risk of costly redesigns stemming from component misapplication or integration errors. Global delivery capabilities ensure that waveguide electromechanical switches reach customers efficiently regardless of geographic location, supporting international programs and distributed manufacturing operations. Advanced Microwave Technologies Co., Ltd has established efficient logistics networks and export processes refined through decades of serving global markets, enabling reliable delivery to customers across aviation and aerospace, shipboard systems, weather monitoring, security inspection systems, unmanned aerial vehicles, and direction finding applications worldwide. Their commitment to fast delivery, combined with comprehensive documentation and export compliance, simplifies procurement for international projects and multi-national programs.

Quality Assurance and International Certifications

Quality certification and international standards compliance provide essential assurance for customers deploying waveguide electromechanical switches in critical applications where failure carries significant consequences. These certifications represent more than marketing credentials; they document systematic approaches to quality management, environmental stewardship, and workplace safety that directly impact product reliability and supplier sustainability.

ISO Standards and Their Practical Impact

ISO 9001:2015 certification demonstrates a manufacturer's commitment to quality management systems that consistently deliver products meeting customer and regulatory requirements. For waveguide electromechanical switch procurement, this certification provides confidence that design processes, manufacturing procedures, testing protocols, and continuous improvement mechanisms are documented, validated, and systematically followed. Advanced Microwave Technologies Co., Ltd's ISO 9001:2015 accreditation ensures that each component undergoes rigorous quality control from initial design through final delivery and after-sales service, meeting and often exceeding industry benchmarks for performance and reliability. Environmental management system certification under ISO 14001:2015 reflects organizational commitment to minimizing ecological impact throughout operations, from manufacturing processes to daily activities. This standard has become increasingly important for customers operating under corporate sustainability mandates or serving markets with environmental performance requirements. Companies like Advanced Microwave Technologies that have implemented comprehensive environmental management systems demonstrate the operational maturity and forward-thinking approach that correlates with long-term supplier viability and partnership stability. ISO 45001:2018 occupational health and safety certification showcases dedication to employee well-being and safe workplace practices. While this might seem tangential to component quality, it actually correlates strongly with overall operational excellence and workforce stability. Manufacturers that prioritize employee safety, provide proper training, and implement robust safety protocols typically demonstrate the same attention to detail and systematic approach in their product quality processes, making this certification a valuable indicator of supplier reliability and manufacturing consistency.

Application-Specific Considerations for Waveguide Electromechanical Switches

Different applications impose distinct requirements on waveguide electromechanical switches, necessitating careful specification matching to ensure optimal system performance. Understanding these application-specific considerations enables more informed component selection and more productive supplier collaboration.

Satellite Communications and Ground Station Requirements

Satellite communication systems demand waveguide electromechanical switches with exceptional reliability and consistent performance across extreme temperature variations and long operational lifetimes. Ground station applications typically emphasize low insertion loss to maximize signal strength, high isolation to prevent crosstalk between channels, and stable electrical characteristics across wide temperature ranges encountered in outdoor installations. Advanced Microwave Technologies Co., Ltd's waveguide electromechanical switches excel in these scenarios, ensuring reliable signal routing in satellite ground stations for high-definition video, data transmission, and voice communications. Their enhanced stability maintains performance integrity under high-temperature variations characteristic of outdoor ground station environments, while robust material construction withstands environmental stress without degradation. Orbital satellite applications impose even more stringent requirements, as components must survive launch vibration and shock, operate reliably in vacuum conditions, withstand intense radiation exposure, and function flawlessly without maintenance for mission durations extending years or decades. Waveguide electromechanical switches for space applications require specialized materials that resist atomic oxygen erosion, outgassing characteristics compatible with spacecraft environments, and mechanical designs proven through rigorous qualification testing. Manufacturers with heritage in aerospace applications bring invaluable experience in addressing these extreme requirements.

Defense, Radar, and Surveillance Applications

Defense applications demand waveguide electromechanical switches with uncompromising reliability, rapid switching speeds, and performance consistency across harsh environmental conditions. Military surveillance radars use these switches to detect threats and distinguish targets with precision, requiring components that maintain electrical performance under vibration, shock, temperature extremes, and electromagnetic interference. Advanced Microwave's custom capabilities support defense contractors in strengthening surveillance capabilities through components designed to military specifications and qualified to relevant environmental testing standards. Radar systems benefit from the high power handling capacity and excellent isolation characteristics inherent in quality waveguide electromechanical switches. Air traffic control radars leverage ultra-sharp beamforming enabled by precision RF switching for accurate aircraft tracking even in adverse weather conditions, where system reliability directly impacts aviation safety. Electronic countermeasure systems rely on waveguide electromechanical switches for rapid signal routing between different operational modes, requiring fast actuation and minimal switching transients that could compromise system effectiveness.

Telecommunications and Industrial IoT Infrastructure

Modern telecommunications infrastructure increasingly incorporates waveguide electromechanical switches in base stations and signal relay systems where reliability, performance consistency, and cost effectiveness converge. These applications typically prioritize proven reliability over cutting-edge performance specifications, as network operators require components that deliver predictable service across extended operational lifetimes with minimal maintenance intervention. Advanced Microwave Technologies optimizes waveguide electromechanical switches for long-distance signal propagation in telecommunications applications, bringing high-speed internet connectivity to rural areas and powering industrial Internet of Things deployments that increasingly rely on robust microwave links for critical data transmission. Waveguide components for telecommunications benefit from design optimization focused on manufacturability and cost effectiveness without compromising core electrical performance. Standardized configurations reduce customization complexity and associated costs, while proven designs minimize the risk of unexpected field issues. For high-volume telecommunications deployments, manufacturers with efficient production processes and strong supply chain systems deliver the combination of competitive pricing, reliable availability, and consistent quality that network buildout schedules demand.

Conclusion

Successful waveguide electromechanical switch procurement balances cost optimization, realistic lead time expectations, and strategic OEM partnerships. Understanding these interconnected factors enables informed sourcing decisions that support project success across satellite communications, defense, aerospace, and telecommunications applications.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a leading China waveguide electromechanical switch factory and trusted China waveguide electromechanical switch supplier, Advanced Microwave Technologies Co., Ltd. stands as a premier China waveguide electromechanical switch manufacturer offering competitive China waveguide electromechanical switch wholesale pricing. Our waveguide electromechanical switches for sale deliver exceptional value through high quality waveguide electromechanical switch construction, backed by comprehensive OEM services including rapid prototyping, expert technical support, and efficient global delivery. With our perfect supply chain system, professional R&D team, strict quality control certified to ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 standards, and strong after-sales capability, we provide the waveguide electromechanical switch price advantage your projects demand without compromising performance. Contact us at craig@admicrowave.com to discuss your specific requirements and discover how our 20+ years of microwave expertise can accelerate your program success.

References

1. "Microwave Engineering" by David M. Pozar, 4th Edition, John Wiley & Sons

2. "RF and Microwave Engineering: Fundamentals of Wireless Communications" by Frank Gustrau, John Wiley & Sons

3. "Waveguide Handbook" by Nathan Marcuvitz, Institution of Engineering and Technology

4. "Foundations for Microwave Engineering" by Robert E. Collin, 2nd Edition, Wiley-IEEE Press

5. "Modern Radar Systems" by Hamish Meikle, 2nd Edition, Artech House Publishers

YOU MAY LIKE

VIEW MOREDouble Ridge Straight Waveguide

VIEW MOREDouble Ridge Straight Waveguide VIEW MOREDouble Ridge Waveguide Transition

VIEW MOREDouble Ridge Waveguide Transition VIEW MOREDouble Ridged Flexible Waveguide

VIEW MOREDouble Ridged Flexible Waveguide VIEW MOREDouble Ridge Waveguide Load

VIEW MOREDouble Ridge Waveguide Load VIEW MOREDouble Ridge Waveguide Rotary Joint

VIEW MOREDouble Ridge Waveguide Rotary Joint VIEW MOREDouble-Ridged Waveguide Broadwall Directional Coupler

VIEW MOREDouble-Ridged Waveguide Broadwall Directional Coupler VIEW MOREWaveguide Flange Gasket

VIEW MOREWaveguide Flange Gasket VIEW MOREWaveguide Adjustable Support

VIEW MOREWaveguide Adjustable Support