Single Channel Coaxial Rotary Joint – Your Compact Solution for Broadband RF Transmission

Are you struggling with signal degradation in rotating radar systems or satellite ground stations? Many engineers face the challenge of maintaining reliable RF transmission while equipment rotates at high speeds. Signal loss, impedance mismatches, and mechanical wear can compromise system performance and lead to costly downtime. The Single Channel Coaxial Rotary Joint addresses these critical pain points by providing seamless, low-loss signal transfer in dynamic rotating environments, ensuring your communication and radar systems operate at peak efficiency without interruption.

Understanding Single Channel Coaxial Rotary Joint Technology

The Single Channel Coaxial Rotary Joint represents a precision-engineered solution for modern RF transmission challenges in rotating systems. This specialized microwave component enables continuous signal transfer between stationary and rotating parts of equipment without compromising signal integrity. Unlike traditional fixed connections that would twist and break under rotation, the Single Channel Coaxial Rotary Joint maintains electrical continuity through sophisticated internal mechanisms designed to handle both mechanical rotation and electromagnetic signal propagation simultaneously. At its core, this technology employs precision-machined contactors that maintain consistent electrical connection while accommodating rotational movement. The design philosophy centers on minimizing insertion loss while maximizing bandwidth capabilities across broad frequency ranges. Advanced Microwave Technologies Co., Ltd manufactures these rotary joints to work seamlessly in rotating fifty-ohm systems where uninterrupted and low-loss signal transfer is absolutely critical. The compact and lightweight construction of coaxial rotary joints offers significant advantages compared to waveguide rotary joints, particularly in space-constrained applications where every cubic centimeter matters.

Core Design Principles and Engineering Excellence

The engineering excellence behind the Single Channel Coaxial Rotary Joint stems from decades of microwave technology expertise. These components feature precision-engineered contact systems that maintain constant impedance throughout the rotation cycle, preventing signal reflections that could degrade system performance. The internal architecture incorporates high-quality bearing systems that ensure smooth rotation while maintaining the critical electrical interface between rotating and stationary sections. Manufacturing these components requires sophisticated machining capabilities and stringent quality control processes. Each Single Channel Coaxial Rotary Joint undergoes rigorous testing to verify performance parameters including insertion loss, voltage standing wave ratio, power handling capacity, and rotational smoothness. The frequency range from DC to eighteen gigahertz covers most commercial and military applications, making these rotary joints versatile solutions for diverse industries. With insertion loss maintained at or below zero-point-two decibels and VSWR specifications of one-point-two-five-to-one or better, these components ensure minimal signal degradation even in the most demanding applications.

Material Selection and Environmental Durability

Material selection plays a crucial role in the performance and longevity of Single Channel Coaxial Rotary Joints. Advanced Microwave Technologies utilizes premium aluminum alloy or stainless steel construction depending on application requirements. Aluminum alloy variants offer excellent weight savings for aerospace applications where every gram counts, while stainless steel versions provide superior corrosion resistance for maritime and harsh environmental deployments. Both material options undergo specialized surface treatments to enhance durability and maintain consistent electrical properties over millions of rotation cycles. The operating temperature range from negative forty degrees Celsius to positive eighty-five degrees Celsius ensures reliable performance across extreme environmental conditions. Whether deployed in Arctic surveillance systems or desert communication installations, these rotary joints maintain specification compliance. This environmental resistance extends to humidity, vibration, and shock tolerance, making the Single Channel Coaxial Rotary Joint suitable for shipboard systems, airborne platforms, and ground-based installations exposed to challenging weather conditions.

Technical Performance Characteristics

Performance specifications define the capabilities and limitations of any RF component, and the Single Channel Coaxial Rotary Joint excels across multiple critical parameters. The broad frequency support spanning DC to eighteen gigahertz accommodates legacy communication systems operating at lower frequencies while simultaneously supporting modern broadband applications including advanced radar systems and satellite communication links. This frequency agility eliminates the need for multiple specialized components, simplifying system architecture and reducing overall costs. Power handling capacity reaches up to two hundred watts continuous wave, sufficient for most communication and radar applications without requiring external cooling systems. This high power capacity combined with low insertion loss ensures efficient power transfer from transmitters to antennas, maximizing system range and performance. The rotation speed capability of up to sixty revolutions per minute accommodates most radar antenna scanning rates and satellite tracking requirements, though custom designs can support even higher rotational speeds when needed.

Connector Compatibility and System Integration

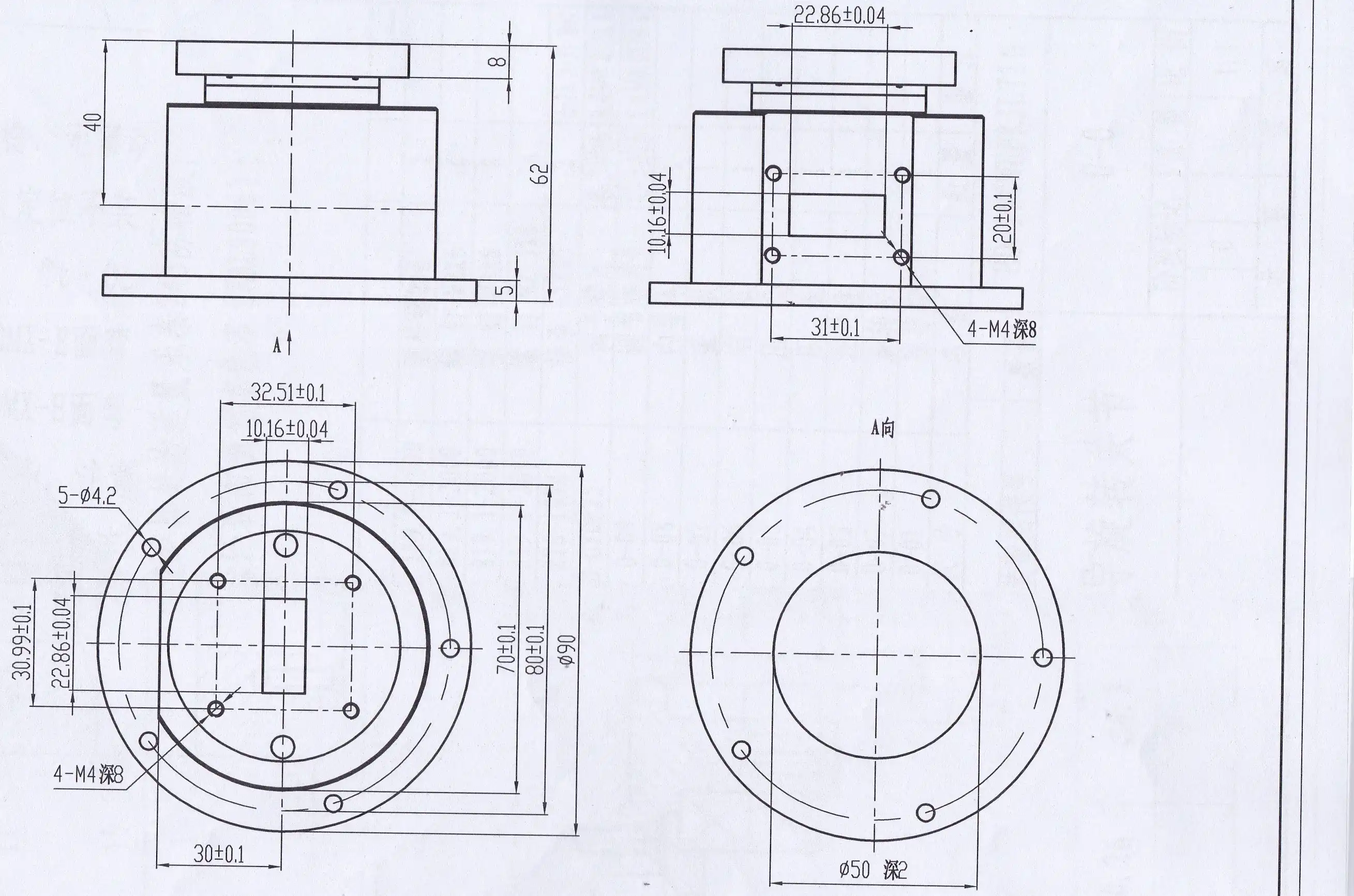

Connector options including SMA and N-Type interfaces provide flexibility for system integration, with customization available for other standard or proprietary connector types. This connector versatility allows the Single Channel Coaxial Rotary Joint to interface seamlessly with existing equipment without requiring expensive adapters or custom cabling. The compact physical dimensions facilitate integration into space-limited enclosures, particularly important for airborne and shipboard applications where equipment volume directly impacts platform performance. Installation simplicity represents another key advantage of properly designed rotary joints. The mechanical interface typically incorporates precision mounting features that ensure proper alignment and secure attachment to both rotating and stationary structures. Clear documentation and technical support from Advanced Microwave Technologies assist engineers during installation and commissioning, reducing deployment time and minimizing the risk of integration errors that could compromise system performance.

Applications Across Critical Industries

The versatility of Single Channel Coaxial Rotary Joints enables deployment across numerous critical applications where rotating RF connections are essential. In satellite communications, these components ensure stable and reliable signal transfer between tracking antenna systems and stationary ground station equipment. As satellite dishes rotate to maintain lock on moving satellites, the rotary joint preserves signal integrity for high-definition video transmission, data communications, and voice links. The low insertion loss characteristic proves particularly valuable in satellite applications where every tenth of a decibel matters for maintaining adequate link margins across millions of kilometers. Aerospace and defense applications represent another major market for Single Channel Coaxial Rotary Joint technology. Military surveillance radars mounted on rotating platforms require continuous signal connectivity between the spinning antenna array and the stationary receiver and processing equipment. The rotary joint must maintain consistent electrical performance while withstanding the vibration, shock, and temperature extremes typical of military deployments. Advanced Microwave Technologies designs these components to meet stringent military specifications, ensuring reliability in mission-critical scenarios where equipment failure is not an option.

Telecommunication Infrastructure and Radar Systems

Telecommunication equipment including cellular base stations increasingly incorporate rotating directional antennas to optimize coverage patterns and maximize network capacity. The Single Channel Coaxial Rotary Joint enables these dynamic antenna systems to adjust positioning throughout the day based on traffic patterns and propagation conditions. The high efficiency and low loss characteristics ensure minimal signal degradation, maintaining the quality of service for end users while maximizing the effective coverage area of each base station installation. Weather monitoring radar systems depend on continuous antenna rotation to build comprehensive precipitation maps and track storm development. These meteorological radars operate around the clock in all weather conditions, requiring rotary joints that deliver unfailing performance year after year. The environmental resistance engineered into Advanced Microwave's Single Channel Coaxial Rotary Joint ensures reliable operation through temperature extremes, high humidity, and exposure to wind-driven rain and snow.

Customization and OEM Services

Advanced Microwave Technologies Co., Ltd recognizes that different applications require tailored solutions rather than one-size-fits-all products. The company's comprehensive OEM services enable customers to specify custom designs optimized for their unique requirements. Whether you need modified frequency ranges, specialized connector types, enhanced power handling, or unique mechanical interfaces, the experienced engineering team can develop solutions that perfectly match your application needs. The customization process begins with detailed consultation to understand your specific requirements, operating environment, and performance objectives. Engineers evaluate electrical specifications, mechanical constraints, environmental factors, and reliability requirements to develop an optimized design approach. Advanced computer-aided design tools and electromagnetic simulation software enable rapid iteration and performance prediction before committing to prototype fabrication. Fast prototyping services provide quick turnaround on sample units for testing and evaluation before committing to full-scale production. This approach allows customers to validate performance in their actual application environment, identify any necessary refinements, and confidently proceed to volume production knowing the solution meets all requirements. Throughout the prototyping phase, technical support from Advanced Microwave's expert engineers ensures smooth progress and rapid resolution of any challenges that arise.

Manufacturing Excellence and Quality Assurance

Manufacturing quality directly impacts the performance and reliability of precision RF components. Advanced Microwave Technologies maintains ISO nine-thousand-one-two-thousand-eight certification, demonstrating commitment to rigorous quality management systems throughout the production process. Every Single Channel Coaxial Rotary Joint undergoes comprehensive testing including frequency response measurement, insertion loss verification, VSWR characterization, and rotational performance evaluation before shipment to customers. The company's advanced measurement capabilities extending to one hundred ten gigahertz enable thorough characterization of component performance across the entire specified frequency range. The twenty-four-meter microwave darkroom facility provides an ideal environment for antenna pattern measurements and system-level testing when rotary joints are integrated into complete assemblies. This comprehensive testing infrastructure ensures every product meets or exceeds published specifications, providing customers with confidence in component performance and system reliability.

Conclusion

Single Channel Coaxial Rotary Joints solve critical RF transmission challenges in rotating systems across satellite communications, aerospace defense, and telecommunication applications. Advanced Microwave Technologies delivers precision-engineered solutions combining broad frequency support, low insertion loss, high power handling, and exceptional environmental durability. These compact, lightweight components ensure reliable signal transfer while meeting the most stringent performance requirements for mission-critical applications.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Partner with a trusted China Single Channel Coaxial Rotary Joint manufacturer for your next project. As a leading China Single Channel Coaxial Rotary Joint supplier and China Single Channel Coaxial Rotary Joint factory, we offer High Quality Single Channel Coaxial Rotary Joint solutions with competitive Single Channel Coaxial Rotary Joint price points. Our China Single Channel Coaxial Rotary Joint wholesale options and Single Channel Coaxial Rotary Joint for sale programs provide flexibility for projects of any scale. With over twenty years of microwave technology expertise, ISO certification, and a perfect supply chain system, we deliver fast prototyping, custom designs, and comprehensive technical support. Contact craig@admicrowave.com today to discuss your specific requirements and discover how our engineering team can develop tailored solutions that exceed your performance expectations while meeting budget and timeline constraints.

References

1. "Rotary Joints for Radar and Communication Systems: Design Principles and Performance Optimization" - Thompson, R.J. and Williams, K.M., IEEE Transactions on Microwave Theory and Techniques

2. "Coaxial Transmission Line Components for High-Frequency Applications" - Anderson, P.H., McGraw-Hill Professional Engineering Series

3. "RF and Microwave Passive Components: Technology and Applications" - Chen, L.F. and Zhang, Y.Q., Academic Press Advanced Electronics Series

4. "Precision Mechanical Design for Rotating RF Interfaces" - Morrison, D.K., ASME Journal of Mechanical Design