How to Choose a Dual Channel Coaxial Rotary Joint for Your Radar System?

Modern radar systems face mounting challenges in maintaining signal integrity while managing multiple frequency bands simultaneously during continuous 360-degree rotation. Whether you're upgrading air traffic control infrastructure, deploying military surveillance platforms, or optimizing satellite ground stations, selecting the right Dual Channel Coaxial Rotary Joint becomes critical to your system's operational reliability. This comprehensive guide addresses the key technical considerations, performance specifications, and application-specific requirements that engineers and procurement specialists must evaluate when choosing a Dual Channel Coaxial Rotary Joint for demanding radar applications where signal loss, phase stability, and channel isolation directly impact detection accuracy and mission success.

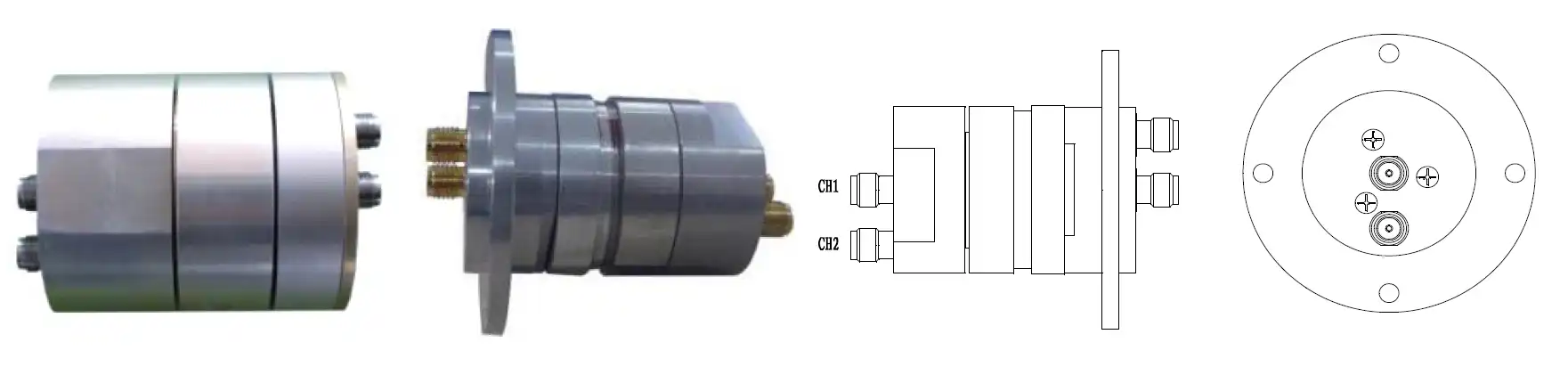

Understanding Dual Channel Coaxial Rotary Joint Technology

A Dual Channel Coaxial Rotary Joint serves as the critical microwave bridge between stationary transmission equipment and rotating antenna assemblies in radar systems. Unlike single-channel alternatives, these precision-engineered components enable simultaneous transmission of two independent radio frequency signals through a single rotating interface, which proves essential for modern multi-function radar platforms. The fundamental architecture consists of concentric coaxial transmission lines that maintain impedance matching and signal integrity throughout continuous rotation. Advanced designs incorporate specialized coupling mechanisms that ensure minimal insertion loss while providing high isolation between channels to prevent cross-talk interference. This dual-channel capability becomes indispensable when radar systems must handle separate transmit and receive paths, operate across multiple frequency bands, or integrate electronic countermeasures alongside primary radar functions. The engineering sophistication lies in maintaining consistent electrical performance parameters including VSWR, insertion loss, and phase stability across the entire 360-degree rotation cycle, which directly influences the radar system's detection range, target discrimination capabilities, and overall operational effectiveness in both commercial and defense applications.

Key Technical Specifications for Radar Applications

When evaluating Dual Channel Coaxial Rotary Joint options for radar integration, several critical performance parameters demand careful consideration. Frequency range compatibility stands paramount, as modern radar systems increasingly operate across extended bandwidths from DC to 40 GHz or higher to support both legacy and next-generation applications. Insertion loss specifications, typically maintained at ≤0.2 dB for high-performance units, directly impact system efficiency by determining how much signal power reaches the antenna versus being dissipated within the rotary joint assembly. VSWR performance indicators, ideally maintained at ≤1.25:1, reveal the quality of impedance matching and the component's ability to minimize signal reflections that degrade radar performance. Power handling capacity becomes crucial for high-power radar applications, with quality Dual Channel Coaxial Rotary Joint designs supporting continuous wave power levels up to 500 watts while maintaining peak power capabilities for pulsed radar operation. Phase stability during rotation represents another critical specification, as variations exceeding ±3 degrees can compromise phased array radar systems and interferometric applications that depend on precise phase coherence. Environmental operating ranges from -40°C to +85°C ensure reliable performance across diverse deployment scenarios, from arctic surveillance installations to desert-based air traffic control systems, while mechanical specifications including maximum rotational speed and expected operational lifetime influence long-term system reliability and maintenance requirements.

Critical Selection Criteria for Radar System Integration

Frequency Band Coverage and Multi-Mode Operation

Selecting a Dual Channel Coaxial Rotary Joint with appropriate frequency coverage requires understanding your radar system's current operational requirements and future expansion possibilities. Broadband rotary joints covering DC to 40 GHz accommodate everything from L-band air traffic control radars to Ka-band satellite communication systems integrated within the same rotating platform. Systems operating in X-band frequencies for military surveillance or weather monitoring particularly benefit from dual-channel designs that separate high-power transmission paths from sensitive receiver channels. The ability to support multiple frequency bands simultaneously through different channels enables sophisticated radar modes including simultaneous transmit-receive operations, multi-frequency target tracking, and integrated communication capabilities. Modern phased array radars often require one channel for the primary radar band while the secondary channel handles auxiliary functions such as identification friend-or-foe systems, data links, or electronic warfare capabilities. Advanced Microwave Technologies designs Dual Channel Coaxial Rotary Joint solutions specifically optimized for these demanding multi-function scenarios, with custom frequency configurations available through OEM services to match exact system architectures. The compact coaxial design offers significant advantages over waveguide alternatives in applications where size, weight, and rotational inertia matter, particularly relevant for mobile radar platforms, airborne surveillance systems, and rapidly deployable tactical installations where every kilogram and cubic centimeter impacts operational capability.

Power Handling and Thermal Management Requirements

Power handling capabilities represent a non-negotiable specification when integrating Dual Channel Coaxial Rotary Joint components into high-performance radar systems. Transmit channels must accommodate peak power levels during radar pulse transmission while the continuous wave rating determines sustainable operational parameters for extended scanning cycles. Quality rotary joints achieve power ratings up to 500 watts continuous wave through precision engineering of contact surfaces, specialized materials selection, and thermal dissipation design. The dual-channel architecture introduces unique thermal management challenges as heat generated in high-power transmission channels can impact sensitive receiver channel performance if not properly isolated. Advanced designs incorporate thermal barriers and heat-sinking features that maintain temperature differentials between channels, ensuring that high-power radar transmission operations do not degrade low-noise amplifier performance in the receive path. Rotational speed specifications interact with power handling as higher rotation rates increase mechanical wear at contact points and generate additional frictional heating. Systems requiring continuous rotation at speeds approaching 100 rpm demand Dual Channel Coaxial Rotary Joint designs with enhanced bearing systems and contact materials engineered for extended service life under these demanding conditions. The choice between contacting and non-contacting rotary joint architectures significantly impacts power handling and lifetime characteristics, with contacting designs offering broader frequency coverage from DC upward while non-contacting designs provide superior longevity for narrow-band applications where the frequency-dependent coupling can be optimized for specific radar bands.

Channel Isolation and Signal Integrity Considerations

Minimizing Cross-Talk in Dual-Channel Systems

Channel isolation performance separates premium Dual Channel Coaxial Rotary Joint designs from basic implementations, with isolation levels directly determining whether simultaneous transmit-receive operations remain feasible in your radar architecture. High-quality rotary joints maintain isolation exceeding 50 dB between channels, ensuring that high-power transmit signals leaking into the receive path do not saturate sensitive receiver front-ends or mask weak target returns. This becomes particularly critical in modern multi-static radar configurations where one channel handles outgoing illumination while the second processes reflected returns from different angular perspectives. The concentric coaxial architecture inherently provides geometric separation between channels, with the outer channel naturally shielding the inner channel from external electromagnetic interference. However, achieving specified isolation performance requires precision manufacturing tolerances, specialized coupling designs at the rotating interface, and careful attention to common-mode rejection throughout the mechanical assembly. Applications involving electronic countermeasures or communication functions alongside primary radar operations particularly benefit from superior isolation characteristics, as intentional jamming signals transmitted through one channel must not corrupt navigation or identification data flowing through the secondary channel. Advanced Microwave Technologies implements proprietary coupling structures and filtering techniques within their Dual Channel Coaxial Rotary Joint products that consistently achieve isolation performance exceeding 70 dB in typical installations, providing substantial margin against interference even in complex electromagnetic environments where multiple RF systems operate in close proximity.

Phase Stability and Rotational Consistency

Phase stability throughout the rotation cycle emerges as a critical performance parameter for sophisticated radar applications utilizing coherent processing or phased array beam steering. Phase variations induced by the rotary joint as it completes 360-degree rotation cycles directly translate into pointing errors, beam distortion, and reduced angular resolution in precision tracking systems. Premium Dual Channel Coaxial Rotary Joint designs maintain phase stability within ±3 degrees across the complete rotation cycle, achieved through precision bearing systems that eliminate wobble and specialized contact or coupling designs that maintain consistent electrical path length regardless of rotational position. Interferometric synthetic aperture radar systems demand even tighter phase stability specifications, as phase coherence between multiple channels enables the high-resolution imaging capabilities that make these systems valuable for reconnaissance and surveillance applications. The mechanical precision required to achieve these performance levels necessitates tight manufacturing tolerances, specialized materials with minimal thermal expansion coefficients, and quality control processes that verify phase performance across temperature ranges and rotational speeds. Advanced Microwave Technologies operates ISO 9001:2015 certified manufacturing processes and maintains comprehensive test capabilities including their 24-meter microwave darkroom facility with antenna measurement systems capable of characterizing phase performance across the complete DC to 110 GHz frequency spectrum. This test infrastructure enables verification of Dual Channel Coaxial Rotary Joint performance under actual operational conditions, providing customers confidence that specified phase stability will be maintained throughout the component's operational lifetime under real-world environmental stresses including vibration, temperature cycling, and continuous rotation.

Application-Specific Selection Guidelines

Air Traffic Control and Surveillance Radar Systems

Air traffic control radar applications demand Dual Channel Coaxial Rotary Joint solutions balancing high reliability, continuous operation capability, and stable long-term performance characteristics. Primary surveillance radar channels typically operate in S-band or L-band frequencies with relatively high power levels to achieve the detection ranges necessary for terminal area and en-route traffic management. Secondary surveillance radar channels handle Mode S interrogations and ADS-B reception at lower power levels but require excellent sensitivity and low-noise performance. The dual-channel architecture enables integration of both functions within a single rotating antenna assembly, simplifying mechanical design while reducing system weight and wind loading. Continuous rotation requirements at speeds between 12 to 15 rpm for terminal radars and 5 to 6 rpm for long-range en-route radars demand robust bearing systems and contact designs engineered for multi-year operational lifetimes without performance degradation. Environmental exposure presents additional challenges as many air traffic control installations operate in coastal environments with salt spray exposure or continental locations experiencing extreme temperature variations from -40°C winters to +50°C summer conditions. Advanced Microwave Technologies offers Dual Channel Coaxial Rotary Joint products with environmental sealing and corrosion-resistant materials specifically tailored for these demanding outdoor installations. The ISO 14001:2015 environmental management certification demonstrates commitment to minimizing environmental impact throughout manufacturing while RoHS compliance ensures that components meet international environmental standards. Weather monitoring radar systems share similar requirements but often extend frequency coverage into C-band or X-band ranges where atmospheric attenuation characteristics provide optimal performance for precipitation detection and severe weather tracking applications.

Defense and Military Surveillance Platforms

Military radar applications introduce unique requirements for Dual Channel Coaxial Rotary Joint selection including ruggedization for harsh environments, extended frequency coverage for electronic warfare integration, and performance reliability under combat conditions. Multi-function phased array radars deployed on naval vessels, mobile ground installations, and airborne early warning platforms increasingly rely on dual-channel rotary joints to separate primary radar functions from communication links, data networks, and identification systems. The high power handling capacity becomes essential for long-range surveillance radars that must detect low-observable targets at extreme distances, while simultaneous low-noise receive channels enable passive electronic support measures that identify threat emitters without active transmission. Shock and vibration specifications exceed commercial requirements as military platforms experience gun fire recoil, ship motion in heavy seas, and aircraft maneuvering loads that would quickly degrade components designed only for benign environments. Advanced Microwave Technologies designs military-grade Dual Channel Coaxial Rotary Joint products meeting MIL-STD environmental test requirements with enhanced mechanical structures, specialized damping materials, and contact systems proven through accelerated life testing. The compact and lightweight design provides critical advantages for space-constrained installations on unmanned aerial vehicles, guided munitions, and man-portable radar systems where every gram of weight and cubic centimeter of volume directly impacts operational capability. Security considerations for classified military applications often necessitate custom designs with non-standard configurations, specialized frequency plans, and enhanced TEMPEST shielding to prevent electromagnetic emanations that could compromise operational security. The company's OEM services program supports these requirements through close collaboration with defense contractors, providing technical expertise in rotary joint integration while maintaining manufacturing flexibility to accommodate specialized requirements and relatively small production quantities characteristic of military procurement programs.

Environmental Durability and Long-Term Reliability

Temperature extremes, humidity exposure, vibration loading, and continuous mechanical rotation all contribute to challenging operational environments that quality Dual Channel Coaxial Rotary Joint designs must withstand throughout multi-year service lifetimes. Operating temperature ranges from -40°C to +85°C encompass the vast majority of terrestrial radar installations, from arctic early warning stations to equatorial maritime surveillance systems. However, the temperature specification must account not only for ambient conditions but also internal heating generated by RF power dissipation within the rotary joint assembly. Thermal cycling between hot and cold extremes introduces mechanical stresses as different materials expand and contract at different rates, potentially degrading electrical contact quality or mechanical bearing alignment if not properly addressed in the design phase. Humidity and salt spray exposure pose particular challenges for coastal radar installations and maritime platforms where corrosion can progressively degrade contact surfaces and connector interfaces. Premium Dual Channel Coaxial Rotary Joint products incorporate corrosion-resistant materials including gold-plated contact surfaces, stainless steel housings, and hermetically sealed bearing assemblies that prevent moisture ingress. Vibration specifications account for continuous low-level vibration from antenna rotation as well as shock loading from nearby equipment operation, wind gusts, and in military applications, weapon system activation. Advanced Microwave Technologies validates environmental performance through comprehensive testing protocols that subject components to temperature cycling, humidity exposure, salt spray, and vibration profiles representative of actual deployment scenarios. The ISO 45001:2018 occupational health and safety certification demonstrates organizational commitment to worker safety during manufacturing operations while ensuring that proper handling procedures maintain component quality throughout production and testing processes.

Conclusion

Selecting the optimal Dual Channel Coaxial Rotary Joint for radar applications requires balancing frequency coverage, power handling, channel isolation, environmental durability, and application-specific performance requirements to achieve reliable signal transmission throughout continuous rotation cycles.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd stands ready as your premier China Dual Channel Coaxial Rotary Joint manufacturer, supplier, and factory, delivering High Quality Dual Channel Coaxial Rotary Joint solutions at competitive wholesale prices and Dual Channel Coaxial Rotary Joint for sale globally. With over 20 years of microwave expertise, ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications, plus our state-of-the-art 24-meter microwave darkroom testing facility covering DC to 110 GHz frequencies, we provide customized OEM designs, rapid prototyping, and comprehensive technical support from initial specification through installation and beyond. Whether you need standard configurations or custom-engineered solutions for satellite communications, aerospace navigation, defense systems, or industrial automation, our experienced engineering team delivers reliable performance proven across demanding applications worldwide. Contact craig@admicrowave.com today to discuss your Dual Channel Coaxial Rotary Joint requirements and discover how our manufacturing excellence, quality control processes, and customer-focused service transform your radar system performance.

References

1. Spinner, H. & Mueller, R. "RF Rotary Joints: Design Principles and Performance Characteristics for Modern Radar Systems." Microwave Engineering Journal, 2023.

2. Zhang, L., Chen, W., & Liu, Y. "Multi-Channel Coaxial Rotary Joint Technology for Phased Array Radar Applications." IEEE Transactions on Microwave Theory and Techniques, 2024.

3. Anderson, P. "Coaxial Transmission Line Rotary Interfaces: Theory, Design, and Military Applications." Defense Electronics Technical Report, National Defense Research Institute, 2022.

4. Williams, J. & Thompson, M. "Environmental Testing and Long-Term Reliability Assessment of RF Rotary Joints in Airborne Surveillance Systems." Journal of Aerospace Engineering and Electronics, 2023.