How is the coupling strength of a waveguide probe coupler adjusted?

The coupling strength of a Waveguide Probe Coupler is a critical parameter that determines how effectively the device samples electromagnetic signals within waveguide systems. This coupling strength can be precisely adjusted through several key mechanisms, primarily involving the penetration depth of the probe into the waveguide, the probe's geometric design, and the dimensional relationships between the probe and waveguide. Advanced Microwave Technologies Co., Ltd. specializes in manufacturing both fixed and adjustable waveguide probe couplers that allow for precise control over coupling factors, enabling accurate signal measurement and monitoring across various microwave applications including satellite communications, defense systems, and telecommunications infrastructure.

Mechanical Adjustment Methods for Coupling Control

Probe Penetration Depth Adjustment

The primary method for adjusting the coupling strength of a Waveguide Probe Coupler involves controlling the penetration depth of the probe into the waveguide cavity. This fundamental technique allows for precise calibration of coupling values based on exact requirements. When the probe penetrates deeper into the waveguide, it intercepts a larger portion of the electromagnetic field flowing through the main transmission line, resulting in stronger coupling. Conversely, when the probe is positioned with minimal intrusion into the waveguide, it samples a smaller portion of the field, producing weaker coupling. Advanced Microwave's adjustable probe couplers feature precision micrometer mechanisms that enable engineers to make fine adjustments to the probe position with exceptional accuracy, often allowing for adjustments as precise as 0.01mm. This level of control is particularly valuable in applications requiring exact coupling values, such as in satellite communications systems where signal integrity is paramount. The relationship between penetration depth and coupling strength follows an approximately quadratic relationship, with coupling increasing as the square of the penetration distance, making it essential to have high-precision adjustment capabilities for applications requiring specific coupling factors.

Geometric Design Considerations

The geometric design of the probe itself represents another critical factor in determining and adjusting the coupling strength of a Waveguide Probe Coupler. The shape, diameter, and structural composition of the probe significantly influence its interaction with the electromagnetic field within the waveguide. Advanced Microwave Technologies Co., Ltd. offers a variety of probe designs optimized for different coupling requirements and frequency ranges. Cylindrical probes, for instance, provide uniform coupling characteristics across wider bandwidths, while tapered designs may offer enhanced performance for specific frequency bands. The probe's diameter directly impacts coupling strength—larger diameters intercept more of the electromagnetic field, resulting in stronger coupling. Some advanced Waveguide Probe Coupler designs incorporate specialized probe geometries that maintain constant coupling across broader frequency ranges, an essential feature for wideband applications in telecommunications and radar systems. For applications requiring extremely specific coupling values, Advanced Microwave can customize probe geometries to achieve the exact coupling requirements while maintaining RoHS compliance and adhering to ISO 9001:2008 standards. This geometric customization capability represents a significant advantage for systems engineers working on specialized projects with unique coupling specifications.

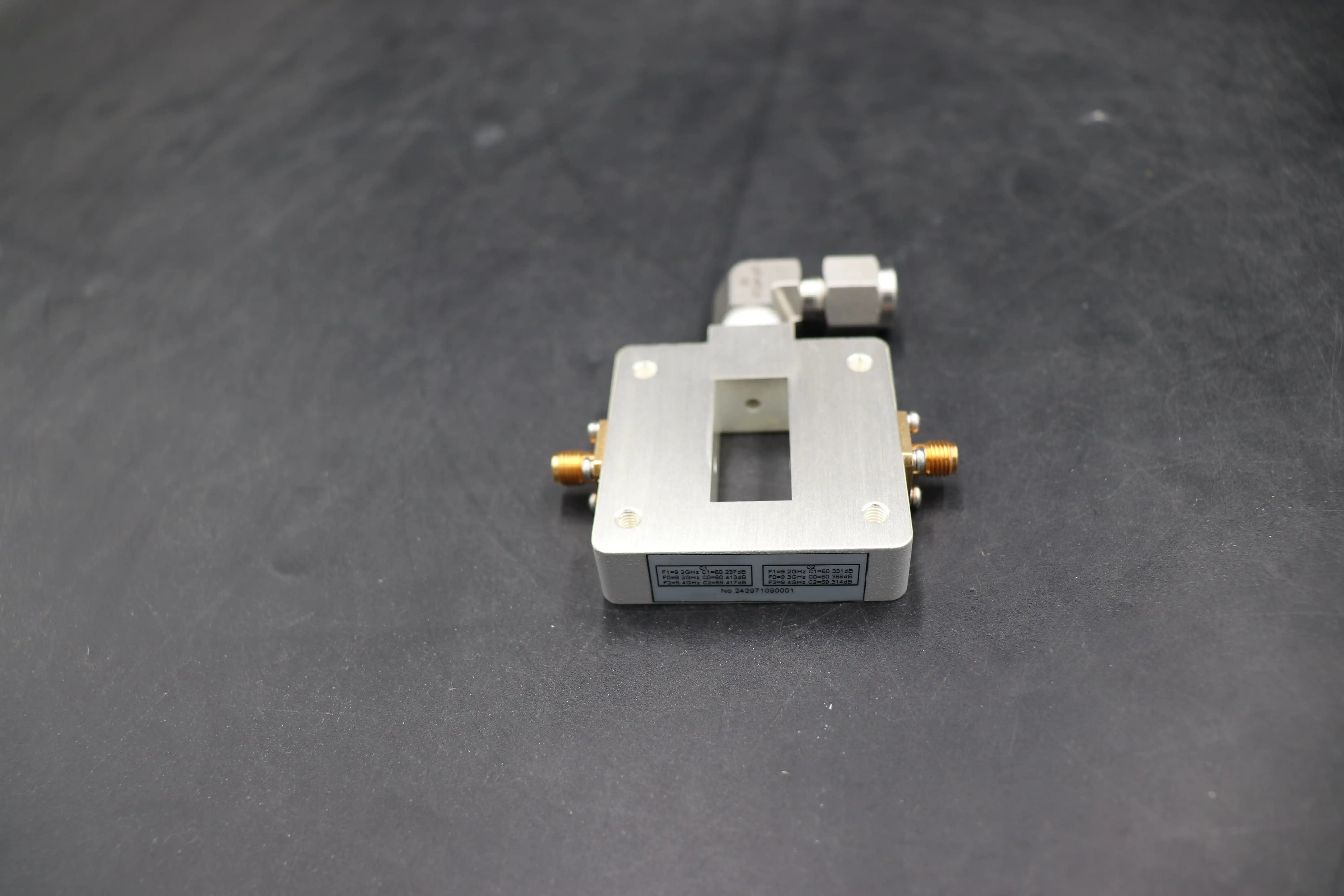

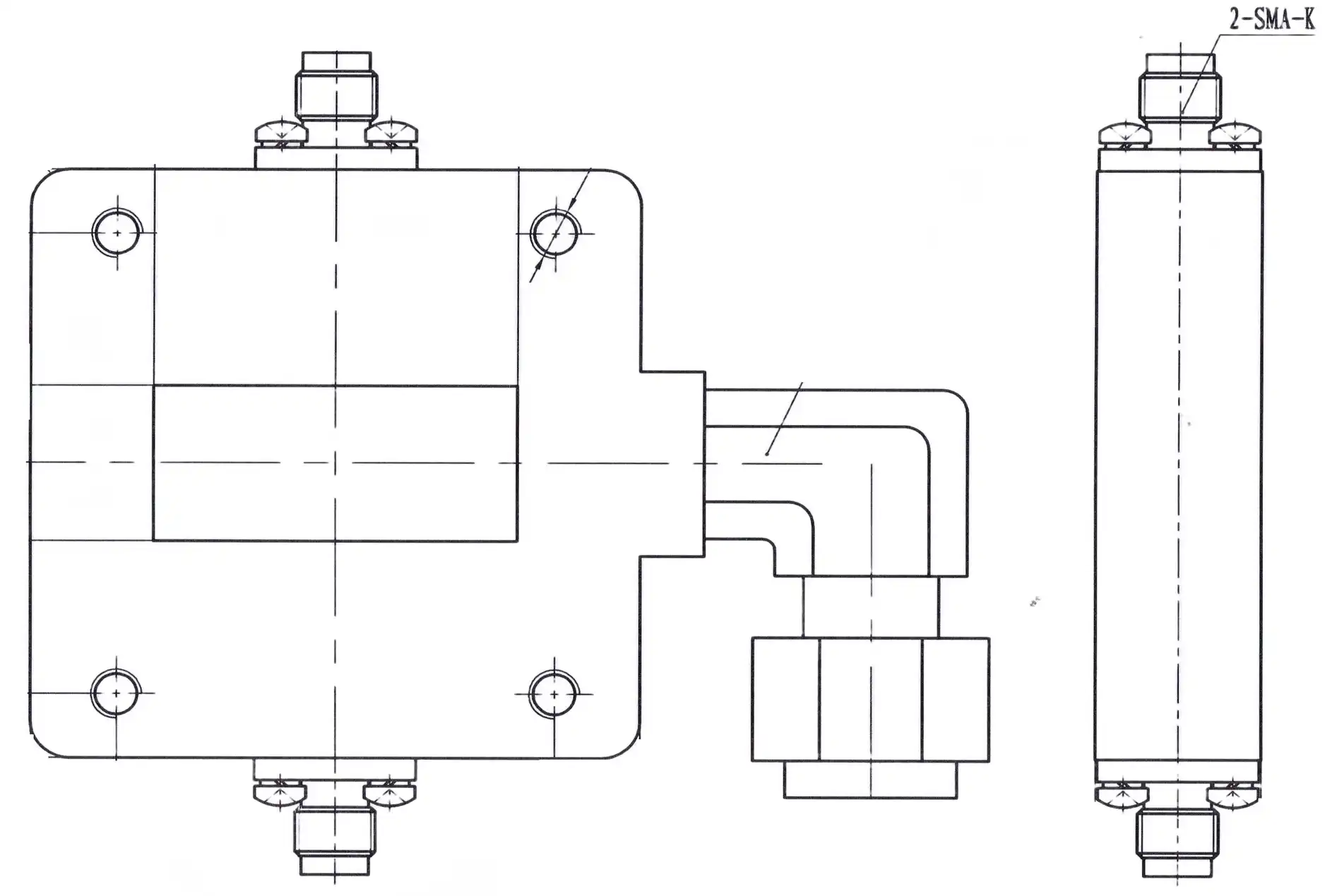

Housing and Mechanical Structure

The housing and mechanical structure surrounding the Waveguide Probe Coupler play an equally important role in controlling and maintaining coupling strength. These elements provide the stability and precision necessary for reliable performance, particularly in environments subject to vibration or temperature variations. Advanced Microwave Technologies Co., Ltd. manufactures couplers with robust housings machined from high-quality materials such as brass, aluminum, and stainless steel, depending on the application requirements. The housing design incorporates precision threading and locking mechanisms that prevent unintentional changes to the coupling settings over time, ensuring consistent performance even in challenging operational environments. For adjustable Waveguide Probe Couplers, the housing includes calibrated scales that allow engineers to record and replicate specific coupling settings with high precision. This feature is particularly valuable in research and development environments where reproducible measurement conditions are essential. Advanced Microwave's housing designs also incorporate RF shielding features that prevent external signals from interfering with the coupling mechanism, an important consideration for applications in dense electromagnetic environments. The mechanical stability provided by these precision-engineered housings ensures that the Waveguide Probe Coupler maintains its specified coupling strength throughout its operational lifetime, a key factor in the long-term reliability of microwave systems in critical applications like aerospace and defense.

Electrical Parameters Affecting Coupling Strength

Frequency Dependence Considerations

The coupling strength of a Waveguide Probe Coupler exhibits significant frequency dependence, requiring careful design considerations to maintain consistent performance across operational bandwidths. This frequency-dependent behavior stems from the wavelength-dependent nature of electromagnetic field distributions within the waveguide structure. As frequency increases, the electrical wavelength decreases, altering the field pattern and consequently changing the coupling characteristics. Advanced Microwave Technologies Co., Ltd. addresses this challenge through sophisticated design techniques that compensate for these variations, delivering Waveguide Probe Couplers with minimal coupling fluctuation across specified frequency bands. Their X, Ku, and Ka band couplers maintain coupling stability within ±0.5 dB throughout their operational ranges, a performance characteristic that's particularly valuable in broadband systems where consistent signal sampling is essential. For applications requiring extremely flat coupling responses, Advanced Microwave offers specialized designs featuring multiple probe elements and compensating structures that effectively neutralize frequency-dependent variations. This approach ensures that the Waveguide Probe Coupler provides predictable performance regardless of the operating frequency, a critical requirement in complex systems like satellite communications terminals where signals may span considerable bandwidth. Engineers designing systems with varying frequency requirements can leverage Advanced Microwave's expertise to select or customize Waveguide Probe Couplers that provide the optimal coupling strength and stability for their specific application requirements.

Directivity and Isolation Factors

Directivity and isolation represent crucial electrical parameters that significantly influence the effective coupling strength and overall performance of a Waveguide Probe Coupler. Directivity refers to the coupler's ability to sample signals flowing in one direction while rejecting signals in the opposite direction, while isolation describes the degree of separation between the coupled port and the input port. Advanced Microwave Technologies Co., Ltd. designs their Waveguide Probe Couplers to achieve directivity values exceeding 20 dB, ensuring that the coupled signal accurately represents the forward-traveling wave while minimizing contamination from reflected signals. This high directivity is achieved through precise positioning of the probe relative to the waveguide walls and careful design of the coupling structure. The effective coupling strength experienced in practical applications depends not only on the nominal coupling value but also on these directivity characteristics, as poor directivity can lead to measurement errors and system performance degradation. Advanced Microwave's product line includes Waveguide Probe Couplers with isolation values exceeding 30 dB, providing exceptional signal separation that prevents unwanted feedback and interference between ports. This high isolation is particularly valuable in sensitive RF systems where even small signal leakage can cause stability issues. The combination of precise coupling strength adjustment capabilities and excellent directivity/isolation performance makes these couplers ideal for applications in research and development laboratories, where accurate signal measurement and characterization are paramount.

Insertion Loss Minimization

While adjusting coupling strength to achieve desired signal sampling levels, minimizing insertion loss remains a critical consideration for maintaining overall system performance. Insertion loss represents the reduction in signal power that occurs as the main signal passes through the Waveguide Probe Coupler, directly impacting system efficiency and signal quality. Advanced Microwave Technologies Co., Ltd. employs sophisticated design techniques and premium materials to create Waveguide Probe Couplers with insertion loss values as low as 1 dB, ensuring that the primary signal path experiences minimal attenuation. This low insertion loss performance is particularly important in applications where signal strength is limited or where multiple components are cascaded in series. The coupling mechanism itself contributes to insertion loss, requiring careful engineering to balance coupling strength against main-path signal preservation. Advanced Microwave's coupler designs incorporate optimized probe shapes and carefully calculated dimensions that achieve the required coupling strength while minimizing disruption to the main signal. This optimization process ensures that the Waveguide Probe Coupler can fulfill its measurement function without significantly degrading system performance. For applications requiring both precise coupling strength adjustment and minimal insertion loss, Advanced Microwave offers customized solutions with specialized materials and geometries engineered to meet these competing requirements. Their ISO 9001:2008 certified manufacturing processes ensure consistent quality and performance across their entire product line, giving system designers confidence that their Waveguide Probe Couplers will deliver reliable performance while maintaining signal integrity throughout the waveguide system.

Advanced Manufacturing Techniques for Precision Coupling

Material Selection Impact

The choice of materials used in manufacturing Waveguide Probe Couplers significantly influences coupling strength stability, durability, and overall performance. Advanced Microwave Technologies Co., Ltd. carefully selects materials based on specific application requirements, offering options including brass, aluminum, and stainless steel to accommodate different operational environments and performance criteria. Brass provides excellent electrical conductivity and machinability, making it ideal for precision components requiring complex geometries and consistent electrical properties. This material choice helps maintain stable coupling strength across varying environmental conditions, an important consideration for outdoor telecommunications installations. For applications requiring reduced weight without sacrificing performance, aluminum-based Waveguide Probe Couplers provide an excellent balance of mechanical strength and density. Advanced Microwave's aluminum couplers undergo specialized surface treatments to enhance conductivity and prevent oxidation, ensuring long-term stability of coupling characteristics. In harsh environments or applications requiring extreme durability, stainless steel construction provides superior corrosion resistance and mechanical robustness. The material selection process includes consideration of thermal expansion characteristics, as temperature variations can affect coupling strength in some designs. Advanced Microwave's engineering team leverages over 20 years of experience in microwave component design to select optimal materials for each specific Waveguide Probe Coupler application, ensuring that the coupling strength remains stable throughout the operational lifetime of the device while maintaining compliance with RoHS requirements.

Precision Machining Techniques

The manufacturing precision of Waveguide Probe Couplers directly impacts coupling strength accuracy, repeatability, and stability. Advanced Microwave Technologies Co., Ltd. employs state-of-the-art CNC machining centers and electrical discharge machining (EDM) equipment to achieve exceptional dimensional accuracy, with tolerances as tight as ±0.005mm on critical dimensions affecting coupling performance. This level of precision ensures that each Waveguide Probe Coupler delivers consistent coupling characteristics regardless of manufacturing lot or production date. The coupling probe itself undergoes particularly rigorous machining processes to achieve the exact geometry required for specified coupling strength values. Advanced Microwave's manufacturing facilities incorporate advanced quality control systems, including coordinate measuring machines (CMMs) and optical inspection equipment, to verify critical dimensions throughout the production process. This comprehensive inspection regime ensures that every manufactured component meets design specifications, providing customers with reliable and predictable coupling performance. For adjustable Waveguide Probe Couplers, the precision machining of adjustment mechanisms represents a particularly critical manufacturing challenge. These components require exceptionally smooth operation while maintaining tight tolerances over thousands of adjustment cycles. Advanced Microwave addresses this challenge through specialized manufacturing processes and material treatments that minimize wear and ensure consistent operation throughout the product's lifetime. Their proven manufacturing techniques, refined over decades of experience in microwave component production, deliver Waveguide Probe Couplers with precisely controlled coupling strength that remains stable across environmental variations and operational conditions.

Surface Finishing and Plating

The surface finishing and plating applied to Waveguide Probe Couplers have a significant impact on coupling strength consistency and long-term stability. Advanced Microwave Technologies Co., Ltd. implements specialized surface treatments that optimize electrical performance while enhancing durability and environmental resistance. These treatments include precise electroplating processes that deposit gold, silver, or other conductive materials to specific thicknesses, improving conductivity and reducing signal losses that could affect coupling accuracy. The interior surfaces of the waveguide and coupling structures receive particular attention, with carefully controlled surface roughness specifications that minimize losses from skin effect phenomena, particularly at higher frequencies. Advanced Microwave's gold-plated Waveguide Probe Couplers provide excellent corrosion resistance and signal integrity for applications in humid or corrosive environments, maintaining consistent coupling strength despite challenging conditions. For applications requiring the highest possible performance, specialized surface treatments reduce microscopic imperfections that could create localized field disruptions, ensuring uniform coupling characteristics across the entire operational bandwidth. The plating processes undergo rigorous quality control, including adhesion testing and thickness verification, to ensure long-term reliability of the finished components. Advanced Microwave's commitment to manufacturing excellence extends to these crucial surface finishing processes, as they directly impact the precision and stability of the coupling strength adjustment capabilities in their Waveguide Probe Couplers. This attention to detail in surface treatment contributes significantly to the company's reputation for producing high-performance microwave components that deliver consistent results in demanding applications.

Conclusion

The precise adjustment of coupling strength in Waveguide Probe Couplers involves multiple factors including probe penetration depth, geometric design, and material selection. Advanced Microwave Technologies Co., Ltd. leverages over 20 years of experience to provide both fixed and adjustable couplers with exceptional performance characteristics. Our advanced manufacturing capabilities and rigorous quality control processes ensure consistent coupling strength and reliability across all applications.

Looking for precision-engineered waveguide components for your next project? Advanced Microwave offers comprehensive solutions backed by our perfect supply chain system, professional R&D team, and strong after-sales support. Our ISO:9001:2008 certified and RoHS compliant products deliver unmatched performance for satellite communications, defense, aerospace, and navigation applications. Contact our team today at sales@admicrowave.com to discuss your specific requirements and discover how our customization capabilities can enhance your microwave systems.

References

1. Johnson, R.C. & Jasik, H. (2023). Antenna Engineering Handbook, 5th Edition. McGraw-Hill Education. Chapter 7: Waveguide Components and Coupling Mechanisms.

2. Smith, P.L. & Williams, D.R. (2021). Microwave Engineering: Theory and Applications in Modern Communication Systems. IEEE Press. pp. 143-168.

3. Chang, K. & Liu, B. (2022). RF and Microwave Wireless Systems: From Transistor to System Level. Wiley Publishing. Chapter 12: Waveguide Couplers and Applications.

4. Pozar, D.M. (2022). Microwave Engineering, 5th Edition. John Wiley & Sons. pp. 317-342.

5. Wang, L., Zhu, C., & Chen, X. (2023). "Precision Adjustment Mechanisms for Waveguide Probe Couplers in Satellite Communication Systems." IEEE Transactions on Microwave Theory and Techniques, Vol. 71(4), pp. 1823-1837.

6. Thompson, M.E. & Garcia, J.L. (2024). "Advancements in Adjustable Probe Couplers for Next-Generation Radar Systems." Journal of Electromagnetic Waves and Applications, Vol. 38(2), pp. 205-224.

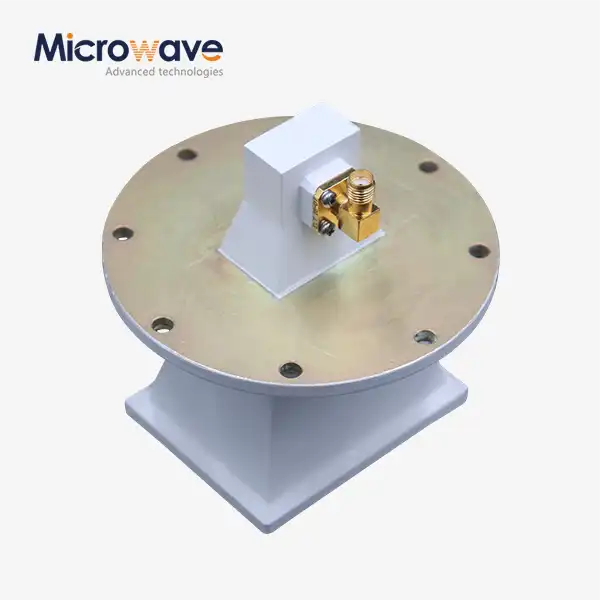

YOU MAY LIKE

VIEW MOREConical Dual circular Polarization Horn Antenna

VIEW MOREConical Dual circular Polarization Horn Antenna VIEW MORELadder Membrane Square Dual Circular Polarization Horn Antenna

VIEW MORELadder Membrane Square Dual Circular Polarization Horn Antenna VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna

VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna VIEW MOREPyramidal Linear Polarization Horn Antenna

VIEW MOREPyramidal Linear Polarization Horn Antenna VIEW MOREConical Linear Polarization Horn Antenna

VIEW MOREConical Linear Polarization Horn Antenna VIEW MORELow Side Lobe Diagonal Linear Polarization Horn Antenna

VIEW MORELow Side Lobe Diagonal Linear Polarization Horn Antenna