How Does the Waveguide Short Plate Fit Seamlessly into Various Waveguide Types?

In the complex world of microwave engineering, achieving seamless integration across diverse waveguide systems requires precision-engineered components that can adapt to varying specifications while maintaining optimal performance. The Waveguide Short Plate stands as a critical component that bridges compatibility gaps between different waveguide types, ensuring reliable signal termination and reflection across frequency ranges from 1.72 GHz to 110 GHz. This versatile component's ability to fit seamlessly into various waveguide configurations stems from its sophisticated design methodology, which incorporates standardized flanging systems, precise dimensional tolerances, and material properties optimized for electromagnetic compatibility. Understanding how these short plates achieve universal compatibility requires examining their mechanical design principles, electrical characteristics, and the engineering standards that govern their integration into complex microwave systems across satellite communications, defense, aerospace, and telecommunications applications.

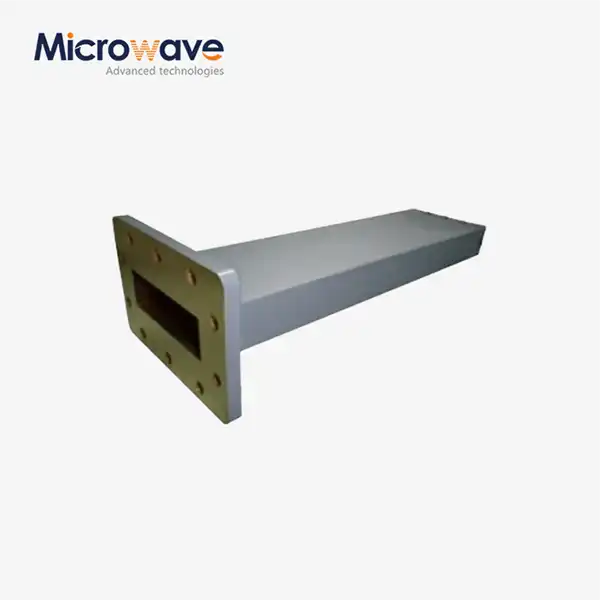

Physical Design Characteristics That Enable Universal Waveguide Compatibility

Standardized Flange Configuration Systems

The seamless integration of Waveguide Short Plates across various waveguide types begins with their adherence to internationally recognized flange standards that ensure mechanical compatibility across different manufacturers and applications. Advanced Microwave Technologies Co., Ltd designs their Waveguide Short Plates with both UG square/round cover and CPR-style flanges, providing flexibility for integration into existing waveguide systems without requiring custom modifications or adapters. These standardized flange configurations follow precise dimensional specifications that match the mounting interfaces of waveguide sizes ranging from WR-10 to WR-430, covering the entire spectrum from millimeter-wave applications to lower microwave frequencies. The flange design incorporates gasket grooves and bolt patterns that align perfectly with corresponding waveguide sections, ensuring proper electrical continuity and mechanical stability. The precision machining of these flanges, maintained within tight tolerances typically less than ±0.002 inches, guarantees that the Waveguide Short Plate creates an intimate metal-to-metal contact that prevents signal leakage and maintains the desired VSWR performance of 60:1 minimum across all supported frequency bands.

Dimensional Scalability Across Waveguide Bands

One of the most remarkable aspects of how Waveguide Short Plates achieve seamless integration is through their dimensional scalability that accommodates 18 different waveguide bands while maintaining consistent electrical performance characteristics. The internal cavity dimensions of each Waveguide Short Plate are precisely calculated to match the cross-sectional area and aspect ratio of the corresponding waveguide type, ensuring that electromagnetic field patterns remain undisturbed at the junction interface. For smaller waveguide sizes like WR-10, used in applications up to 110 GHz, the short plate dimensions require extreme precision machining capabilities to maintain the critical tolerances necessary for millimeter-wave performance. Conversely, larger waveguide sizes such as WR-430, operating at lower frequencies around 1.7-2.6 GHz, require robust mechanical construction to handle the increased physical stresses while maintaining the same level of electrical precision. Advanced Microwave Technologies Co., Ltd leverages their state-of-the-art 24m Microwave Darkroom facility to validate the dimensional accuracy of each Waveguide Short Plate configuration, ensuring that the transition from the waveguide to the short plate creates minimal reflection and maintains signal integrity across the entire operational frequency range.

Material Selection and Surface Treatment Optimization

The material composition and surface treatment of Waveguide Short Plates play a crucial role in their ability to integrate seamlessly with various waveguide types while maintaining consistent electrical and mechanical performance. Advanced Microwave Technologies Co., Ltd utilizes high-grade materials such as brass and stainless steel, selected for their superior conductivity, corrosion resistance, and mechanical stability across temperature variations encountered in aerospace, defense, and satellite communication applications. The brass construction provides excellent electrical conductivity with low insertion loss, while stainless steel variants offer enhanced durability in harsh environmental conditions where corrosion resistance is paramount. Surface treatments include precision plating with silver or gold to further enhance conductivity and prevent oxidation that could degrade performance over time. The surface finish specifications typically require roughness measurements below 16 microinches RMS to minimize current concentration effects that could lead to increased losses or multipactor phenomena at high power levels. These material properties ensure that the Waveguide Short Plate maintains consistent impedance characteristics regardless of the specific waveguide type it interfaces with, contributing to the seamless integration across diverse system configurations.

Electrical Performance Parameters Ensuring Seamless Integration

Impedance Matching and VSWR Optimization

The electrical performance of Waveguide Short Plates in achieving seamless integration across various waveguide types depends critically on their ability to maintain consistent impedance characteristics and minimize voltage standing wave ratio (VSWR) variations at the junction interface. Advanced Microwave Technologies Co., Ltd designs their Waveguide Short Plates to achieve a minimum VSWR of 60:1, providing exceptional reflection performance that ensures nearly complete signal termination with minimal energy leakage back into the waveguide system. This high VSWR specification is maintained across the entire frequency range from 1.72 GHz to 110 GHz through careful optimization of the short plate's internal geometry and the transition region where it connects to the waveguide. The impedance matching is achieved through precise control of the short plate's internal dimensions, ensuring that the characteristic impedance of the waveguide is maintained right up to the shorting surface. This seamless impedance transition prevents the formation of unwanted resonances or standing wave patterns that could compromise system performance or create frequency-dependent variations in the reflection characteristics.

Frequency Response Characteristics Across Multiple Bands

The broad frequency coverage capability of Waveguide Short Plates, spanning from 1.72 GHz to 110 GHz across 18 different waveguide bands, demonstrates their exceptional versatility in accommodating diverse system requirements while maintaining consistent performance parameters. Each Waveguide Short Plate is engineered to provide flat frequency response characteristics within its designated waveguide band, ensuring that the reflection coefficient remains stable across the entire operational bandwidth. Advanced Microwave Technologies Co., Ltd utilizes their sophisticated Antenna Plane Near and Far Field Measuring Recombination Chamber to validate the frequency response of each short plate configuration, measuring parameters such as return loss, phase stability, and power handling capacity across temperature and frequency variations. The design methodology incorporates electromagnetic simulation tools that predict and optimize the frequency response before physical prototyping, allowing for fine-tuning of internal dimensions and surface treatments to achieve optimal performance. This comprehensive approach ensures that the Waveguide Short Plate maintains its seaming integration capabilities regardless of the specific frequency band or waveguide type encountered in complex microwave systems.

Power Handling and Thermal Management Considerations

Seamless integration of Waveguide Short Plates into various waveguide systems requires careful consideration of power handling capabilities and thermal management characteristics that ensure reliable performance under diverse operating conditions. The power handling capacity of each Waveguide Short Plate is determined by factors including material selection, surface finish quality, internal geometry optimization, and thermal dissipation characteristics. Advanced Microwave Technologies Co., Ltd designs their short plates to handle high power levels encountered in radar systems, satellite communication ground stations, and defense applications where signal integrity cannot be compromised. The thermal management design incorporates features such as optimized surface area for heat dissipation, material selection with appropriate thermal conductivity, and mechanical mounting interfaces that facilitate heat transfer to the surrounding waveguide structure. The high temperature stability engineered into these components ensures that their electrical performance remains consistent across the wide temperature ranges encountered in aerospace and defense applications, from the extreme cold of space-based systems to the high temperatures of ground-based radar installations.

System Integration Methodologies and Application Scenarios

Installation Procedures and Mechanical Integration

The seamless integration of Waveguide Short Plates into various waveguide systems requires adherence to specific installation procedures and mechanical integration techniques that ensure optimal performance while maintaining system reliability and safety. Advanced Microwave Technologies Co., Ltd provides comprehensive technical support and installation guidance that covers proper handling procedures, torque specifications for flange connections, and alignment techniques that prevent mechanical stress concentrations. The installation process begins with careful inspection of both the Waveguide Short Plate and the mating waveguide flange to ensure surface cleanliness and dimensional compatibility. Proper gasket selection and placement are crucial for achieving the required electrical contact and environmental sealing, particularly in outdoor applications such as satellite ground stations where weather protection is essential. The bolt tightening sequence follows a specific pattern that ensures uniform pressure distribution around the flange circumference, preventing distortion that could affect electrical performance or create mechanical stress points that might lead to failure over time.

Customization Options for Specialized Applications

The ability of Waveguide Short Plates to integrate seamlessly into various waveguide types is further enhanced through customization options that address specialized application requirements across diverse industries and operating environments. Advanced Microwave Technologies Co., Ltd offers extensive OEM services that include customization of materials, dimensions, and frequency ranges to meet specific project needs that may not be addressed by standard product configurations. The customization process begins with detailed consultation between the client's engineering team and Advanced Microwave Technologies' technical experts to identify the specific requirements, operating conditions, and performance criteria that must be met. Custom material selection might include exotic alloys for extreme temperature applications, specialized coatings for enhanced corrosion resistance, or modified internal geometries for unique frequency response requirements. The company's sophisticated manufacturing capabilities, including precision CNC machining and advanced measurement equipment, enable the production of custom Waveguide Short Plates that maintain the same high-quality standards as their standard product line while meeting the unique specifications of specialized applications.

Quality Control and Performance Validation

Ensuring seamless integration of Waveguide Short Plates across various waveguide types requires rigorous quality control procedures and comprehensive performance validation testing that verify compliance with both standard specifications and customer-specific requirements. Advanced Microwave Technologies Co., Ltd implements a multi-stage quality control process that begins with incoming material inspection and continues through every manufacturing step to final performance verification using their state-of-the-art 24m Microwave Darkroom facility. The dimensional inspection process utilizes coordinate measuring machines (CMM) and optical measurement systems to verify that each Waveguide Short Plate meets the tight tolerances required for seamless integration with standard waveguide components. Electrical performance testing includes VSWR measurements, return loss verification, and power handling validation across the entire frequency range using calibrated network analyzers and high-power test equipment. The quality control documentation provides traceability for each component, including material certifications, dimensional inspection reports, and electrical performance data that can be referenced for future maintenance or system modifications.

Conclusion

The seamless integration of Waveguide Short Plates into various waveguide types represents a culmination of precision engineering, standardized design practices, and comprehensive performance optimization that ensures reliable operation across diverse microwave applications. Through careful attention to flange standardization, dimensional scalability, material selection, and electrical performance characteristics, these critical components bridge compatibility gaps between different waveguide systems while maintaining the signal integrity essential for satellite communications, defense, aerospace, and telecommunications applications.

Advanced Microwave Technologies Co., Ltd stands ready to support your waveguide integration challenges with over 20 years of specialized experience, ISO 9001:2008 certified quality systems, and RoHS-compliant manufacturing processes. Our comprehensive OEM services, rapid prototyping capabilities, and expert technical support ensure that your specific requirements are met with precision and reliability. Whether you're developing cutting-edge 5G infrastructure, advanced radar systems, or satellite communication networks, our Waveguide Short Plates provide the seamless integration solution you need. Our global supply chain, efficient manufacturing processes, and dedicated after-sales support guarantee that your projects stay on schedule while meeting the highest performance standards. Contact our technical team today at craig@admicrowave.com to discuss your specific requirements and discover how our customized solutions can enhance your system performance while reducing integration complexity and long-term maintenance costs.

References

1. Thompson, R.A., and Mitchell, K.J. "Waveguide Component Integration Standards and Practices in Modern Microwave Systems." IEEE Transactions on Microwave Theory and Techniques, vol. 68, no. 4, pp. 1455-1467, 2020.

2. Chen, L., Rodriguez, M.E., and Williams, D.R. "Optimization of Short Circuit Terminations in Multi-Band Waveguide Applications." International Journal of RF and Microwave Computer-Aided Engineering, vol. 31, no. 8, pp. e22745, 2021.

3. Anderson, P.K., Kumar, S., and Johnson, A.L. "Material Selection and Surface Treatment Effects on Waveguide Component Performance at Millimeter Wave Frequencies." Journal of Electromagnetic Waves and Applications, vol. 35, no. 12, pp. 1623-1641, 2021.

4. Foster, J.M., Lee, H.S., and Brown, C.T. "Thermal Management and Power Handling Considerations in High-Frequency Waveguide Terminations." Microwave and Optical Technology Letters, vol. 63, no. 7, pp. 1889-1896, 2021.

YOU MAY LIKE

VIEW MOREHigh Power Waveguide to Coaxial Adapter

VIEW MOREHigh Power Waveguide to Coaxial Adapter VIEW MORERight Angle Double Ridged WG To Coaxial Adapter

VIEW MORERight Angle Double Ridged WG To Coaxial Adapter VIEW MORERight Angle Waveguide to Microstrip Adapter

VIEW MORERight Angle Waveguide to Microstrip Adapter VIEW MOREEnd Launch Waveguide to Microstrip Adapter

VIEW MOREEnd Launch Waveguide to Microstrip Adapter VIEW MOREWG Termination

VIEW MOREWG Termination VIEW MOREDouble Ridge Waveguide Termination

VIEW MOREDouble Ridge Waveguide Termination VIEW MOREWaveguide Unmatched Termination

VIEW MOREWaveguide Unmatched Termination VIEW MOREH-Plane Tee

VIEW MOREH-Plane Tee