How does a waveguide power divider work?

In the realm of microwave engineering, understanding the functionality of critical components is essential for designing efficient systems. A Waveguide Power Divider represents one of these vital elements, serving as the cornerstone for signal distribution in high-frequency applications. These sophisticated devices effectively split an input microwave signal into multiple output signals with minimal loss and precise power distribution. By utilizing electromagnetic wave principles within carefully engineered hollow structures, Waveguide Power Dividers maintain signal integrity while providing the flexibility needed for complex microwave systems. Their operation relies on carefully controlled impedance matching and strategic coupling mechanisms to ensure optimal performance across demanding applications.

Fundamental Operating Principles of Waveguide Power Dividers

Electromagnetic Wave Propagation in Waveguides

Waveguide Power Dividers function based on the fundamental principles of electromagnetic wave propagation within confined structures. Unlike traditional transmission lines, waveguides utilize the entire cross-sectional area to propagate electromagnetic energy, which significantly reduces power losses at high frequencies. When electromagnetic waves enter a waveguide, they establish specific field patterns known as modes, with the dominant mode typically being TE10 (Transverse Electric). The geometry of the waveguide strictly controls these modes, ensuring predictable wave behavior. Advanced Microwave Technologies' Waveguide Power Dividers are precisely engineered to maintain these ideal propagation conditions while dividing power. Our dividers support a frequency range from 2 GHz to an impressive 110 GHz, accommodating various waveguide sizes including WR-90, WR-51, WR-34, WR-28, and WR-22. This wide operational bandwidth makes them suitable for cutting-edge communication systems where reliable performance is non-negotiable. The insertion loss in these dividers is remarkably low—less than 0.5 dB—ensuring that virtually all input power is efficiently distributed to the output ports without significant signal degradation.

Power Division Techniques and Structures

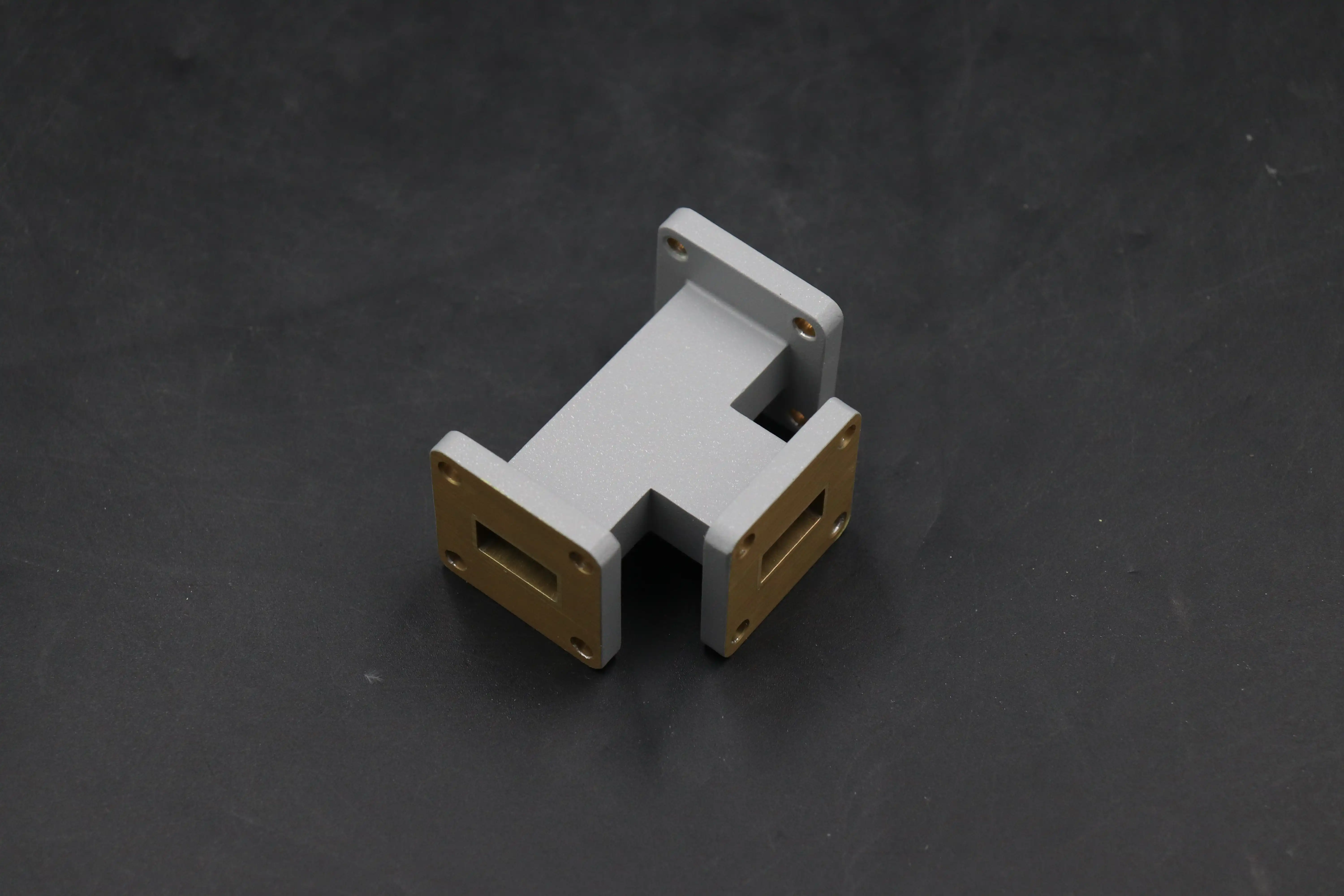

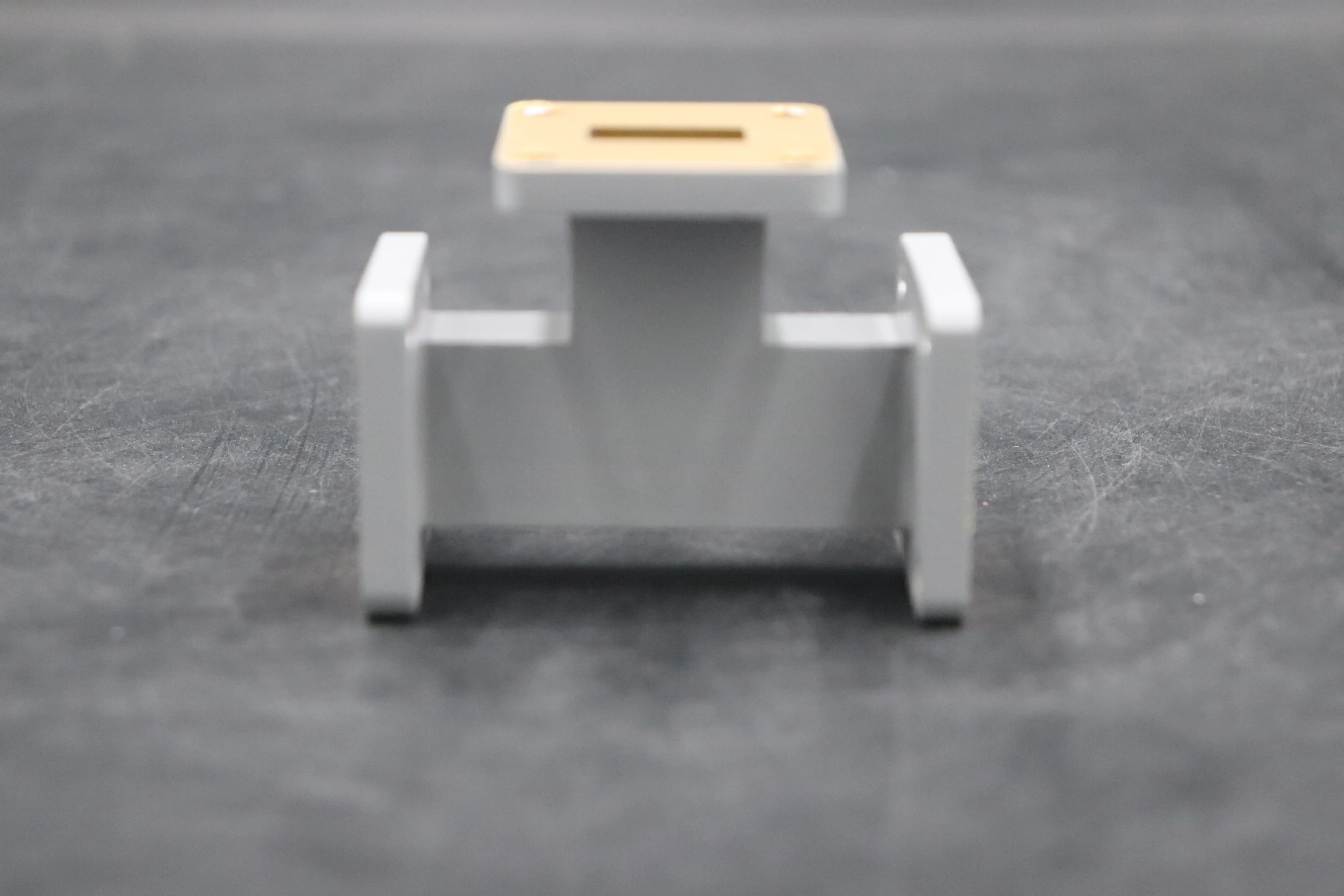

The internal structure of a Waveguide Power Divider determines its performance characteristics and power division capabilities. Two primary architectures dominate the industry: T-junction dividers and corporate power divider networks. T-junction dividers use a simple branching structure where the main waveguide branches into two or more output waveguides. Meanwhile, corporate networks employ multiple division stages to create numerous output ports with equal power distribution. Advanced Microwave Technologies engineers our Waveguide Power Dividers with precision-machined components made from high-quality materials such as aluminum, brass, and copper, offering superior electrical conductivity and thermal stability. This construction ensures outstanding power handling capabilities—up to 100W—without performance degradation. The isolation between output ports exceeds 20 dB, preventing unwanted interactions between divided signals. This isolation is critical in complex systems where multiple components might otherwise interfere with each other. Our manufacturing process incorporates meticulous quality control measures to maintain a VSWR (Voltage Standing Wave Ratio) below 1.5, minimizing reflections and ensuring maximum power transfer to the intended destinations.

Impedance Matching and Phase Relationships

One of the most critical aspects of Waveguide Power Divider design is maintaining proper impedance matching throughout the division network. Without proper matching, reflections occur at junction points, leading to power loss and system inefficiency. Advanced Microwave Technologies' power dividers implement sophisticated impedance matching techniques, including quarter-wave transformers and strategic discontinuities, to ensure smooth power flow. Additionally, phase relationships between output ports are carefully controlled to maintain coherence in multi-channel systems. This phase balance is especially important in phased array applications where precise timing between signals is essential. Our Waveguide Power Dividers maintain consistent phase relationships across their entire operational bandwidth, from 2 GHz to 110 GHz. They remain stable across the entire operating temperature range of -40°C to +85°C, making them suitable for deployment in extreme environments. The flanges (available in CPR, UG, or custom configurations) are precision-machined to industry standards, ensuring compatibility with existing systems while providing a secure, low-loss connection that maintains the integrity of these carefully engineered impedance and phase characteristics.

Applications and Performance Optimization

Satellite Communication Systems Integration

Waveguide Power Dividers serve as critical components in satellite communication infrastructure, where signal integrity and reliability are paramount. In ground station applications, these dividers distribute incoming signals from satellite dishes to multiple receivers or combine signals from various sources for transmission. Advanced Microwave Technologies' Waveguide Power Dividers excel in these demanding environments due to their exceptional durability and performance characteristics. The low insertion loss (< 0.5 dB) ensures that valuable signal strength isn't wasted during the division process, maximizing the effective range and data throughput of communication systems. Their broad frequency coverage supports everything from traditional C-band applications to cutting-edge Ka-band and beyond. The high isolation between ports (> 20 dB) prevents cross-talk and interference, which is particularly important in satellite communication systems where signals from multiple sources must be processed simultaneously without degradation. Additionally, our power dividers' robust construction withstands the rigorous demands of continuous operation, with materials selected specifically for their resistance to environmental factors. The ability to handle up to 100W of power makes these dividers suitable for both receiving and transmitting applications in satellite networks, providing the versatility needed for comprehensive communication solutions.

Radar System Performance Enhancement

In radar systems, Waveguide Power Dividers play a dual role: distributing the high-power transmit signal to multiple antenna elements and combining the weak return signals for processing. This dual functionality demands exceptional performance across varying power levels, which is precisely what Advanced Microwave Technologies' products deliver. Our power dividers maintain consistent characteristics when handling both high-power transmission pulses and low-power received signals, ensuring accurate target detection and tracking. The extremely low VSWR (< 1.5) minimizes reflections that could potentially damage sensitive radar transmitters or create false targets through system-generated noise. These dividers support the precise phase relationships required for beam steering in modern phased array radar systems, where timing differences between elements must be controlled to fractions of a wavelength. Their wide frequency range capabilities allow for frequency-agile radar operations, enhancing resistance to jamming and interference. Advanced Microwave Technologies manufactures these components using high-quality materials such as aluminum, brass, and copper, ensuring they withstand the mechanical stresses typical in mobile or airborne radar platforms. Their reliable performance across the full temperature range of -40°C to +85°C makes them suitable for deployment in diverse operational environments, from arctic reconnaissance to desert surveillance systems, without compromising detection capabilities or range accuracy.

Telecommunications Network Infrastructure

Modern telecommunications networks rely on microwave and millimeter-wave frequencies to handle ever-increasing data demands, with Waveguide Power Dividers serving as essential building blocks in these systems. Advanced Microwave Technologies' dividers provide the signal distribution backbone needed for network infrastructure, supporting frequencies up to 110 GHz that accommodate next-generation 5G and beyond. Their compact design makes them ideal for installation in space-constrained environments typical of urban telecommunications equipment rooms. Despite their small footprint, these dividers handle substantial power requirements—up to 100W—supporting multiple high-bandwidth channels simultaneously. The exceptional isolation between ports (> 20 dB) prevents cross-channel interference, maintaining data integrity across complex network architectures. This becomes increasingly important as network densification continues, with more transmitters operating in closer proximity. Advanced Microwave's Waveguide Power Dividers support the precise power distribution needed for sector antennas in cellular networks, ensuring balanced coverage and preventing dead zones or oversaturated areas. Their low insertion loss preserves signal strength throughout the distribution network, maximizing effective range and data rates while minimizing power consumption and operational costs. Additionally, their robust construction ensures reliable performance over extended deployment periods, reducing maintenance requirements and network downtime while supporting the continuous evolution of telecommunications standards and technologies.

Custom Engineering and Manufacturing Excellence

Tailored Solutions for Specific Applications

Understanding that standard configurations don't always address unique requirements, Advanced Microwave Technologies specializes in creating customized Waveguide Power Divider solutions. Our engineering team works closely with clients to develop dividers optimized for specific frequency bands, power levels, and physical constraints. This customization capability is particularly valuable in specialized fields such as quantum computing, medical imaging, and cutting-edge research applications where off-the-shelf components may not suffice. We can modify critical parameters including waveguide dimensions, material selection, flange types, and power handling capabilities to meet exact project specifications. For instance, while our standard dividers operate within 2 GHz to 110 GHz, we can fine-tune designs for enhanced performance within narrower bands when applications demand maximum efficiency in specific frequency ranges. Our manufacturing facilities are equipped with precision machining capabilities that allow for creating custom waveguide sizes beyond the standard WR-90, WR-51, WR-34, WR-28, and WR-22 offerings. Additionally, we can engineer unique power division ratios beyond equal splits when applications require asymmetric power distribution. These customized Waveguide Power Dividers undergo the same rigorous testing as our standard products, ensuring they meet or exceed specified performance metrics including insertion loss, VSWR, isolation, and power handling. Whether you need components for extreme environmental conditions or with specialized coating treatments for corrosion resistance, our team delivers solutions that precisely match your operational requirements while maintaining the highest standards of quality and reliability.

Quality Control and Performance Testing

Every Waveguide Power Divider from Advanced Microwave Technologies undergoes comprehensive quality control and rigorous testing to ensure exceptional performance in real-world applications. Our ISO 9001:2008 certified manufacturing processes include multiple inspection points throughout production, from raw material verification to final assembly validation. Each divider is tested for insertion loss across its full operational bandwidth, with our stringent requirements ensuring losses remain below 0.5 dB, significantly outperforming industry averages. VSWR measurements confirm reflection coefficients remain under 1.5:1, preventing signal degradation from impedance mismatches. Isolation testing verifies that cross-coupling between output ports stays below -20 dB, ensuring signals remain separate and uncontaminated. Our laboratories feature advanced microwave measurement equipment capable of characterizing components up to 110 GHz with exceptional precision. This testing infrastructure allows us to verify performance under various environmental conditions, including the full temperature range from -40°C to +85°C. Power handling capabilities are confirmed through both continuous wave and peak power tests, verifying that our Waveguide Power Dividers can reliably handle up to 100W without degradation. Additionally, mechanical inspections ensure dimensional accuracy and proper finishing of all surfaces, particularly at flange interfaces where precision is critical for minimizing connection losses. We maintain detailed test reports for each production batch, providing customers with comprehensive documentation of performance parameters. This exhaustive testing regimen ensures that when you incorporate Advanced Microwave's Waveguide Power Dividers into your system, you can do so with complete confidence in their reliability and specified performance characteristics.

Prototyping and Production Scalability

Advanced Microwave Technologies offers exceptional flexibility in the development and production of Waveguide Power Dividers, supporting customers from initial concept through full-scale deployment. Our rapid prototyping capabilities enable quick iterations of design concepts, allowing engineers to evaluate performance and integration aspects before committing to final specifications. This accelerated development cycle significantly reduces time-to-market for new systems incorporating our Waveguide Power Dividers. Our manufacturing infrastructure scales seamlessly from small prototype runs to high-volume production orders without compromising quality or consistency. Using advanced CNC machining centers and specialized production equipment, we maintain precise tolerances regardless of production quantity. This scalability makes us an ideal partner for growing projects, from research initiatives to large-scale commercial deployments. Our material selection process ensures optimal performance characteristics while considering factors such as weight, corrosion resistance, and cost efficiency. While aluminum offers excellent performance in standard applications, we can produce dividers in brass or copper when electrical performance requirements are particularly demanding. Each Waveguide Power Divider is manufactured to the exact specifications determined during the design phase, with our RoHS-compliant processes ensuring environmental responsibility. Our engineering team provides comprehensive documentation including detailed specifications, performance data, and integration guidelines, facilitating smooth incorporation into your systems. Throughout the production process, from prototype to mass manufacturing, our quality control systems maintain consistent performance characteristics, ensuring that the hundredth or thousandth unit performs identically to the first. This reliability in manufacturing makes Advanced Microwave Technologies' Waveguide Power Dividers the trusted choice for critical applications where consistent performance is essential to system functionality.

Conclusion

Waveguide Power Dividers represent crucial components in modern microwave systems, enabling efficient signal distribution while maintaining signal integrity. Advanced Microwave Technologies' solutions deliver exceptional performance across frequencies from 2 GHz to 110 GHz with minimal insertion loss and superior isolation. Whether for satellite communications, radar systems, or telecommunications infrastructure, our precision-engineered dividers provide reliable operation in demanding environments. With our perfect supply chain system, rich production experience, and professional R&D team, we deliver customized solutions with price advantages and strict quality control. Looking to optimize your microwave system with high-performance Waveguide Power Dividers? Contact our expert team today at sales@admicrowave.com to discuss your specific requirements and discover how our 20+ years of industry experience can enhance your next project.

References

1. Johnson, R.C. & Jasik, H. (2023). "Antenna Engineering Handbook: Waveguide Components and Systems." McGraw-Hill Professional.

2. Zhang, L. & Wu, K. (2024). "Microwave Power Dividers and Couplers: Theory and Design." IEEE Press.

3. Smith, D.R. & Liu, Y. (2022). "Advanced Waveguide Technology for Modern Communication Systems." Cambridge University Press.

4. Williams, A.E. & Okamura, H. (2023). "Waveguide Power Dividers: Design Principles and Applications." Artech House.

5. Chen, X. & Pozar, D.M. (2024). "Microwave Engineering: Components and Systems." Wiley-IEEE Press.

6. Bhartia, P. & Bahl, I.J. (2023). "Millimeter Wave Engineering and Applications: Waveguide Components." Springer Publishing.

YOU MAY LIKE

VIEW MOREDouble Ridge Straight Waveguide

VIEW MOREDouble Ridge Straight Waveguide VIEW MOREDouble Ridge Waveguide Bend

VIEW MOREDouble Ridge Waveguide Bend VIEW MOREDouble Ridge Waveguide Transition

VIEW MOREDouble Ridge Waveguide Transition VIEW MOREDouble Ridge Twist Waveguide

VIEW MOREDouble Ridge Twist Waveguide VIEW MOREDouble Ridged Flexible Waveguide

VIEW MOREDouble Ridged Flexible Waveguide VIEW MOREDouble Ridged WG To Coaxial Adapter

VIEW MOREDouble Ridged WG To Coaxial Adapter VIEW MOREDouble Ridge Waveguide Load

VIEW MOREDouble Ridge Waveguide Load VIEW MOREDouble-Ridged Waveguide Magic Tee

VIEW MOREDouble-Ridged Waveguide Magic Tee