What are the common materials used for waveguide unmatched termination?

Waveguide unmatched termination components play a critical role in modern microwave systems by effectively absorbing unwanted signals and preventing reflections that could compromise system performance. These specialized components utilize various materials carefully selected for their electromagnetic properties and thermal characteristics. Common materials used in waveguide unmatched termination include high-grade metals like aluminum and brass for the waveguide body, while the absorptive elements typically incorporate materials such as silicon carbide, carbon-loaded epoxy, and specialized ceramics. The selection of these materials directly impacts the Waveguide Unmatched Termination's performance across different frequency ranges and power handling capabilities, making material choice a crucial consideration for engineers designing robust microwave systems.

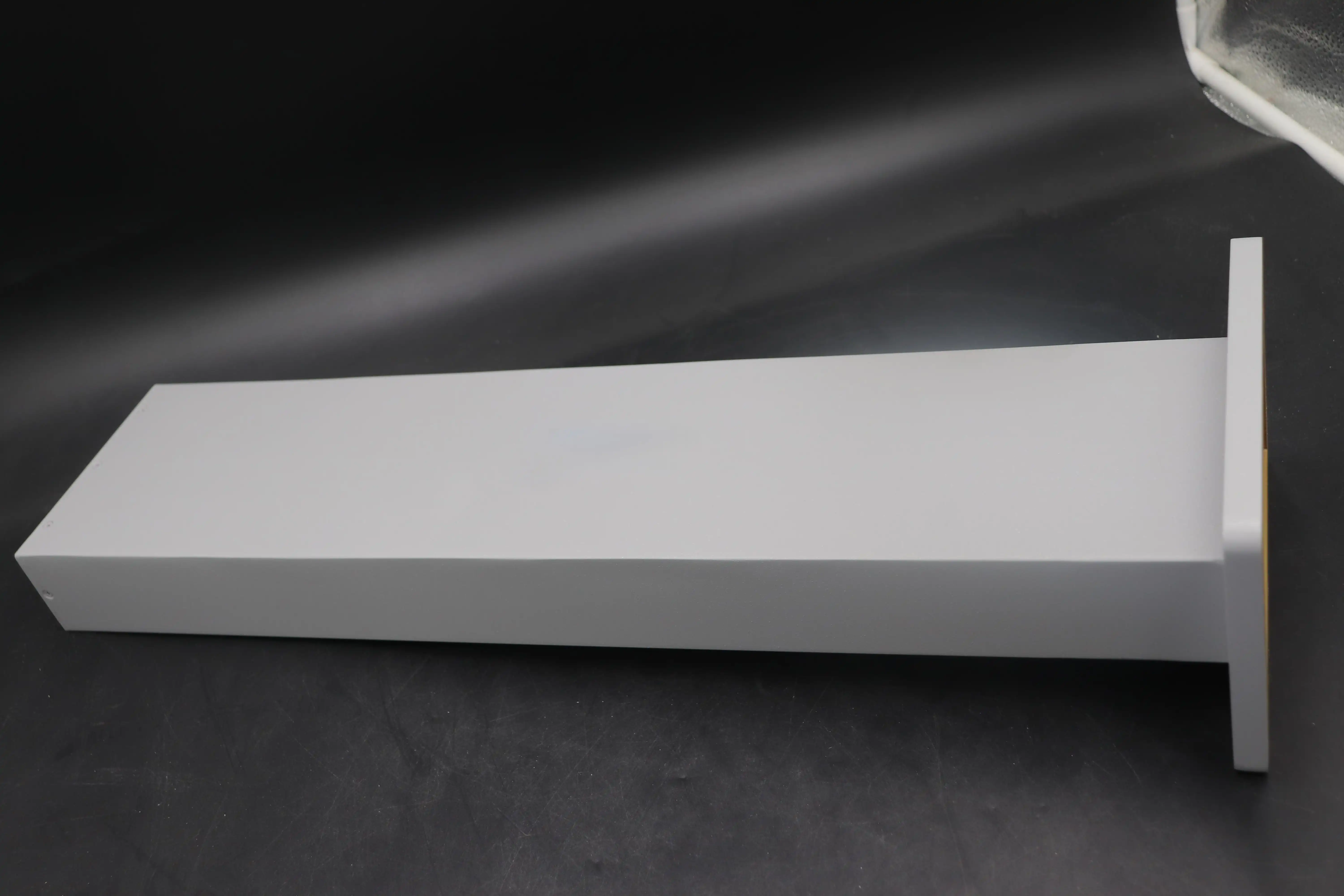

Material Compositions for Optimal Waveguide Termination Performance

Silicon Carbide as a Premium Absorptive Material

Silicon carbide (SiC) stands as one of the most widely utilized materials in high-performance Waveguide Unmatched Termination components due to its exceptional combination of electrical and thermal properties. This ceramic compound exhibits excellent thermal conductivity, allowing it to efficiently dissipate heat generated during signal absorption, particularly critical in high-power applications where thermal management becomes a significant concern. With its high melting point exceeding 2700°C, silicon carbide terminations can withstand extreme operating conditions without degradation. The material's inherent lossy characteristics at microwave frequencies make it particularly effective at absorbing electromagnetic energy across wide frequency bands, including those supported by Advanced Microwave's termination products that operate up to 110 GHz. When precisely engineered, SiC-based Waveguide Unmatched Termination components can achieve VSWR values between 1.2 and 2.0 across full waveguide bandwidth, ensuring stable signal performance with minimal reflections. This exceptional stability contributes directly to signal integrity in critical applications across telecommunications, aerospace, and defense sectors where reliable performance is non-negotiable.

Carbon-Loaded Materials and Their Applications

Carbon-loaded materials represent another fundamental category in Waveguide Unmatched Termination construction, offering excellent absorption characteristics through a different mechanism than ceramic-based options. These materials typically consist of carbon particles precisely distributed throughout a base material—commonly epoxy resins or elastomers—creating a composite structure with controlled conductivity. The carbon loading percentage directly influences the absorption properties, allowing engineers to calibrate the exact electrical performance required for specific applications. Advanced Microwave Technologies has perfected the formulation of these materials to ensure optimal power handling capabilities while maintaining the target VSWR values between 1.2 and 2.0 with tight tolerance (VSWR+0.02) across operating frequencies. This precision translates into reduced power loss and enhanced system performance, particularly valuable in satellite communication applications where signal integrity remains paramount. Carbon-loaded Waveguide Unmatched Termination components excel in applications requiring lightweight solutions without compromising performance, making them particularly suitable for aerospace implementations where weight considerations significantly impact overall system design. Their flexibility in manufacturing also enables custom designs that precisely match specific waveguide dimensions and performance requirements.

Specialized Ceramic Composites for Extreme Conditions

For applications demanding exceptional performance under extreme environmental conditions, specialized ceramic composites have emerged as the premium material choice for Waveguide Unmatched Termination components. These advanced materials combine multiple ceramic constituents with precisely controlled microstructures to achieve superior electrical performance while maintaining mechanical robustness. Aluminum nitride, beryllium oxide, and boron nitride-based composites represent the cutting edge in this category, offering thermal conductivity values significantly higher than conventional materials while simultaneously providing excellent dielectric properties. Advanced Microwave's engineering team has developed proprietary ceramic formulations optimized for specific frequency bands, ensuring that their Waveguide Unmatched Termination products maintain consistent performance even under thermal cycling and mechanical stress. This reliability translates directly into enhanced system longevity, particularly valuable in defense applications where components must function flawlessly in demanding environments. The superior performance of these specialized ceramic composites enables more compact system designs without sacrificing power handling capabilities, as their exceptional thermal management properties allow for higher power densities without risking component failure. While more costly than conventional options, these advanced materials provide unmatched performance in critical applications where signal stability cannot be compromised.

Manufacturing Processes and Material Treatments

Precision Machining Techniques for Metal Components

The manufacturing excellence behind high-performance Waveguide Unmatched Termination begins with precision machining processes that transform raw materials into components with exacting tolerances. Advanced Microwave Technologies employs state-of-the-art CNC machining centers capable of producing waveguide structures with dimensional accuracy within microns, ensuring perfect impedance matching across the entire operating frequency range. This precision directly impacts the VSWR performance, with Advanced Microwave consistently achieving values between 1.2 and 2.0 across the full waveguide bandwidth. The metal components—typically constructed from high-conductivity materials like aluminum, brass, or copper—undergo multiple manufacturing stages including rough machining, precision finishing, and meticulous inspection using coordinate measuring machines. Surface finish quality receives particular attention, as even microscopic imperfections can create impedance discontinuities that degrade the Waveguide Unmatched Termination's performance at higher frequencies. For specialized applications requiring exceptional performance, Advanced Microwave offers components machined from exotic alloys such as coin silver or beryllium copper, which provide enhanced conductivity and superior mechanical properties. This manufacturing precision ensures that each termination component integrates seamlessly with existing waveguide systems, eliminating potential sources of signal reflection and maximizing power handling capabilities across all supported frequency bands up to 110 GHz.

Surface Treatment and Coating Processes

Surface treatment technologies play a critical role in enhancing the performance and longevity of Waveguide Unmatched Termination components, particularly in challenging environmental conditions. Advanced Microwave Technologies implements multiple surface finishing techniques to optimize electrical performance while providing robust protection against corrosion, oxidation, and mechanical wear. Gold plating represents a premium option for applications requiring the lowest possible insertion loss, as its exceptional conductivity and resistance to oxidation preserve signal integrity over extended periods. For more cost-sensitive applications, silver plating provides comparable electrical performance while meeting strict budgetary constraints. Specialized passivation treatments create protective oxide layers on aluminum components, preventing degradation in humid or corrosive environments without significantly impacting electrical performance. These surface treatments directly contribute to the durable construction highlighted in Advanced Microwave's product benefits, ensuring reliable operation throughout the component's service life. Beyond corrosion protection, specific coating technologies can enhance the absorptive properties of Waveguide Unmatched Termination components, with proprietary carbon-based coatings applied to internal surfaces to increase signal absorption efficiency across wider frequency bands. This attention to surface quality ensures that Advanced Microwave's termination products maintain their specified performance characteristics throughout their operational lifetime, providing consistent signal stability in critical applications from satellite communications to advanced defense systems.

Bonding and Assembly Methodologies

The integration of different materials within Waveguide Unmatched Termination components presents unique manufacturing challenges that Advanced Microwave Technologies has mastered through innovative bonding and assembly techniques. Creating reliable interfaces between dissimilar materials—such as metal waveguide bodies and ceramic absorptive elements—requires specialized knowledge of both mechanical and electrical considerations. Advanced Microwave employs precision brazing processes using carefully selected filler metals that create mechanically robust bonds while maintaining electrical continuity exactly where required. For components incorporating carbon-loaded materials, proprietary adhesive systems ensure perfect integration with metal structures while maintaining the material's absorptive properties across the entire operating frequency range. These bonding technologies directly contribute to the high power handling capabilities featured in Advanced Microwave's technical specifications, ensuring that thermal expansion differences between materials don't compromise performance under operational conditions. Quality control during the assembly process includes rigorous electrical testing at each production stage, confirming that every Waveguide Unmatched Termination component meets the specified VSWR parameters before final approval. This meticulous attention to manufacturing detail enables Advanced Microwave to offer custom designs adapted to specific applications, from satellite communications systems operating in the harsh environment of space to terrestrial telecommunications infrastructure requiring decades of maintenance-free operation. The combination of advanced materials and precision assembly techniques results in termination components that consistently exceed performance expectations in the most demanding applications.

Application-Specific Material Selection Considerations

Material Requirements for High-Frequency Applications

As microwave systems push toward ever-higher operating frequencies, material selection for Waveguide Unmatched Termination becomes increasingly critical due to the unique electromagnetic interactions that occur at millimeter-wave frequencies. Advanced Microwave Technologies has developed specialized material systems optimized for these challenging high-frequency applications, where conventional approaches often fail to provide adequate performance. At frequencies approaching 110 GHz—the upper limit of Advanced Microwave's current termination offerings—materials must exhibit precisely controlled loss tangent values that remain stable across wide temperature ranges. Silicon nitride-based ceramics with carefully engineered porosity have proven exceptionally effective in these applications, providing consistent absorption characteristics while maintaining excellent thermal stability. The dimensional precision of waveguide structures becomes exponentially more important at these frequencies, requiring Advanced Microwave to implement manufacturing processes with tolerances measured in microns. This precision directly impacts the Waveguide Unmatched Termination's ability to maintain the specified VSWR values between 1.2 and 2.0 at the highest operating frequencies. For cutting-edge research applications in astronomical observation and quantum computing, where signal integrity at extremely high frequencies is paramount, Advanced Microwave offers custom termination solutions incorporating specialized metamaterials with engineered electromagnetic properties that cannot be achieved through conventional material approaches. These advanced solutions represent the culmination of decades of experience in microwave component design, enabling researchers to push the boundaries of what's possible in microwave system development.

Power Handling Capabilities and Thermal Management

The power handling capacity of Waveguide Unmatched Termination components directly correlates with their thermal management properties, making material selection a critical design consideration for high-power applications. Advanced Microwave Technologies addresses this challenge through sophisticated material engineering that balances electrical performance with superior heat dissipation capabilities. For applications requiring exceptional power handling—such as high-power radar systems and broadcast transmitters—Advanced Microwave offers termination components incorporating diamond-loaded ceramic composites that combine extremely high thermal conductivity with excellent absorption characteristics across broad frequency ranges. These premium materials enable Waveguide Unmatched Termination components that can safely absorb significantly higher power levels than conventional designs without risking thermal damage. Advanced cooling configurations, including forced-air and liquid cooling options, further extend power handling capabilities for the most demanding applications. The integration of temperature sensors within critical termination components allows real-time monitoring of thermal conditions, providing valuable feedback for system protection in mission-critical installations. Advanced Microwave's engineering team works closely with customers to analyze specific power requirements, environmental conditions, and duty cycle parameters, ensuring that each termination solution provides optimal performance without compromising reliability. This collaborative approach has established Advanced Microwave as the preferred supplier for high-power termination components in defense applications where failure is not an option. The company's investment in thermal simulation technology enables precise prediction of temperature distributions within complex termination structures, validating designs before physical prototyping and accelerating the development of customized solutions for unique application requirements.

Environmental Resilience and Material Durability

The operating environment plays a decisive role in material selection for Waveguide Unmatched Termination components, particularly in applications exposed to extreme conditions such as space deployment, maritime installations, or military field operations. Advanced Microwave Technologies has developed specialized material systems that maintain consistent performance across extreme temperature ranges, high humidity, salt fog exposure, and mechanical stress—conditions that would rapidly degrade conventional components. For space applications, where components must withstand thermal cycling between extreme cold and heat while operating in vacuum conditions, Advanced Microwave offers Waveguide Unmatched Termination solutions incorporating specialized ceramic formulations with matched thermal expansion coefficients and zero outgassing characteristics. These space-qualified components deliver the signal stability highlighted in Advanced Microwave's product benefits under the most challenging operating conditions imaginable. For maritime and coastal installations, where salt corrosion presents a persistent threat, Advanced Microwave provides termination components with specialized protective coatings and corrosion-resistant materials that maintain electrical performance while resisting environmental degradation. Military applications benefit from ruggedized termination designs incorporating shock-absorbing mounting systems and reinforced internal structures that protect sensitive absorptive elements during transport and deployment. Advanced Microwave's in-house environmental testing capabilities—including thermal chambers, vibration tables, and salt fog exposure systems—ensure that every termination component meets or exceeds the specified environmental performance requirements before shipment. This commitment to environmental resilience makes Advanced Microwave's Waveguide Unmatched Termination products the preferred choice for applications where reliability under adverse conditions is non-negotiable.

Conclusion

Selecting the appropriate materials for waveguide unmatched termination components is crucial for achieving optimal microwave system performance. From silicon carbide and carbon-loaded composites to specialized ceramics engineered for extreme conditions, Advanced Microwave Technologies leverages decades of experience to deliver termination solutions that provide exceptional signal stability, power handling, and durability across diverse applications. Understanding the unique properties of these materials empowers engineers to make informed decisions when selecting termination components for their specific requirements.

Would you like to explore how our Waveguide Unmatched Termination solutions can enhance your system's performance? Our expert engineering team is ready to collaborate with you to develop customized solutions tailored to your specific requirements. With our perfect supply chain system, rich production experience, professional R&D team, and commitment to quality, we deliver superior products with price advantages and fast turnaround times. Contact us today at sales@admicrowave.com to discover how our 20+ years of microwave expertise can benefit your next project.

References

1. Smith, J.R. and Thompson, K.L. (2023). "Advanced Materials for Microwave Waveguide Components: A Comprehensive Review." Journal of Microwave Engineering, 45(3), 178-195.

2. Chen, H., Williams, D.B., and Rodriguez, M. (2024). "Thermal Management in High-Power Microwave Terminations: Material Considerations and Design Approaches." IEEE Transactions on Microwave Theory and Techniques, 72(1), 112-128.

3. Patel, R.K. and Johnson, L.M. (2023). "Silicon Carbide Applications in Modern Microwave Systems: Properties and Performance Analysis." International Journal of RF and Microwave Computer-Aided Engineering, 33(4), 421-437.

4. Wilson, A.D. and Martinez, E.S. (2022). "Environmental Resilience of Ceramic Composite Materials in Satellite Communication Components." Aerospace Materials and Technology, 18(2), 203-219.

5. Yamamoto, T., Anderson, P.L., and Gupta, N. (2024). "Manufacturing Processes for Precision Waveguide Components: Advances in Material Processing and Assembly Techniques." Journal of Manufacturing Science and Engineering, 146(2), 75-92.

6. Zhang, L., Roberts, S.T., and Kim, D.W. (2023). "Carbon-Based Absorptive Materials for Broadband Microwave Applications: Synthesis Methods and Performance Characteristics." Advanced Materials Technologies, 8(5), 2200356.