Exploring the Basics and Applications of Single Channel Coaxial Rotary Joints

In the realm of high-frequency signal transmission systems, Single Channel Coaxial Rotary Joints represent a critical component that enables uninterrupted RF signal transfer between stationary and rotating parts. These precision-engineered devices serve as the vital link in countless rotating communication systems, ensuring continuous signal integrity without compromising performance. As wireless communication technologies and radar systems become increasingly sophisticated, the demand for reliable, high-performance rotary joints has never been greater. This comprehensive guide explores the fundamental principles, technical specifications, and diverse applications of Single Channel Coaxial Rotary Joints, highlighting their essential role in modern RF transmission systems.

Understanding Single Channel Coaxial Rotary Joint Technology

Fundamental Operating Principles

The Single Channel Coaxial Rotary Joint is an ingenious microwave component designed to maintain electrical continuity while allowing mechanical rotation between two sections of a transmission line. At its core, this device utilizes precision contact mechanisms that maintain consistent impedance matching throughout rotation, ensuring signal integrity across the rotating interface. The fundamental design typically incorporates specialized contact systems—often using precious metal alloys—that minimize friction while maximizing conductivity. Unlike their waveguide counterparts, Single Channel Coaxial Rotary Joints are notably compact and lightweight, making them ideal for space-constrained applications. The underlying engineering principle involves creating a stable electrical connection that maintains the characteristic 50-ohm impedance through the entire assembly, regardless of rotational position. This consistent impedance matching is critical for preventing signal reflections that would otherwise degrade system performance across the operational frequency range, which in Advanced Microwave's solutions extends impressively from DC to 18 GHz.

Key Technical Specifications and Performance Metrics

When evaluating a Single Channel Coaxial Rotary Joint for specific applications, several critical performance parameters demand attention. Advanced Microwave Technologies Co., Ltd. produces rotary joints with exceptional specifications that define their operational capabilities. With insertion loss maintained at ≤0.2 dB, these components ensure that signal strength remains virtually uncompromised throughout the transmission path. The Voltage Standing Wave Ratio (VSWR) rating of ≤1.25:1 indicates excellent impedance matching, minimizing signal reflections that could otherwise create interference patterns. Power handling capability extends up to 200W continuous wave (CW), making these components suitable for high-power radar and communication systems. The operational frequency range spanning from DC to 18 GHz provides remarkable versatility across various applications. Performance stability is maintained even at rotation speeds reaching 60 RPM, enabling deployment in dynamic scanning and tracking systems. These Single Channel Coaxial Rotary Joints accommodate standard connector interfaces including SMA and N-Type, with customization options available to meet specific system requirements. Furthermore, the robust design ensures reliable operation across extreme temperature ranges from -40°C to +85°C, making them suitable for deployment in harsh environmental conditions.

Materials Engineering and Construction Quality

The exceptional performance of Single Channel Coaxial Rotary Joints from Advanced Microwave Technologies stems from meticulous material selection and precision manufacturing processes. The housing components are typically constructed from lightweight yet durable aluminum alloy or corrosion-resistant stainless steel, depending on the intended application environment. The contact systems employ specialized beryllium copper alloys plated with precious metals like gold, silver, or rhodium to ensure optimal conductivity while minimizing wear during rotation. Advanced Microwave's manufacturing facility implements rigorous quality control protocols throughout the production process, resulting in ISO 9001:2008-certified products that consistently meet or exceed industry standards. The internal components undergo precision CNC machining to maintain tight tolerances critical for RF performance. Additionally, all products are RoHS compliant, eliminating hazardous substances from the manufacturing process and final product. This attention to material quality and construction detail ensures that each Single Channel Coaxial Rotary Joint delivers consistent performance throughout its operational lifetime, even when subjected to challenging deployment conditions or continuous operation in mission-critical systems.

Advanced Applications and Implementation Strategies

Satellite Communication Systems Integration

In modern satellite communication networks, Single Channel Coaxial Rotary Joints play an indispensable role in maintaining reliable signal paths between fixed and rotating antenna components. These precision-engineered devices from Advanced Microwave Technologies are specifically designed to ensure uninterrupted signal transmission in satellite tracking and communication systems, where antennas must continuously reorient while maintaining signal lock. The rotary joint's ability to operate across an extensive frequency range (DC to 18 GHz) makes it particularly valuable in multi-band satellite communication systems that simultaneously handle different frequency signals. When integrated into satellite ground stations, these rotary joints enable smooth antenna movement while preserving signal integrity, essential for maintaining consistent data rates during satellite passes or tracking operations. The exceptional low insertion loss characteristic (≤0.2 dB) ensures minimal signal degradation, critical when dealing with already-attenuated signals from distant satellites. Additionally, the rugged construction using aluminum alloy or stainless steel provides the durability necessary for continuous operation in outdoor environments, withstanding temperature extremes from -40°C to +85°C that typify satellite ground station deployments. Advanced Microwave's Single Channel Coaxial Rotary Joints deliver the reliability and performance stability that satellite communication operators demand for uninterrupted service delivery.

Radar and Defense System Applications

In radar and defense applications, performance reliability under extreme conditions is non-negotiable, making Advanced Microwave's Single Channel Coaxial Rotary Joints an essential component in these critical systems. Modern surveillance radars, weapons guidance systems, and electronic warfare platforms rely heavily on these components to maintain signal integrity during rapid scanning or target tracking operations. The rotary joint's capability to handle power levels up to 200W ensures sufficient headroom for high-power radar pulses without performance degradation or overheating. In naval radar installations, where equipment is exposed to corrosive salt environments, the stainless steel construction option provides exceptional resistance to environmental damage. For airborne surveillance platforms, the lightweight aluminum alloy variants offer weight savings without compromising durability. The excellent VSWR rating (≤1.25:1) ensures clean signal transmission, critical for maintaining radar detection sensitivity and range performance. Defense contractors particularly value the customization capabilities offered by Advanced Microwave, allowing for modified interface connectors, special environmental sealing, or adjusted electrical parameters to meet specific mission requirements. The rotary joint's reliable performance under vibration and shock conditions makes it ideal for vehicle-mounted tactical radar systems deployed in battlefield environments. With over 20 years of experience serving defense clients, Advanced Microwave Technologies has developed Single Channel Coaxial Rotary Joints that meet the stringent reliability and performance standards demanded by defense applications.

Telecommunications Infrastructure Deployment

As telecommunications networks continue expanding to meet ever-growing bandwidth demands, Single Channel Coaxial Rotary Joints have become crucial components in various infrastructure installations. In cellular network deployments, these rotary joints enable dynamic beam-steering in advanced antenna systems, allowing for optimized coverage and capacity management. The impressive frequency range capability of Advanced Microwave's rotary joints supports multiple cellular frequency bands, making them valuable in multi-generation network deployments supporting everything from legacy 2G through advanced 5G services. For point-to-point microwave backhaul links that require precise alignment, these rotary joints facilitate fine-tuning adjustments while maintaining signal integrity. The exceptional environmental resilience, functioning reliably from -40°C to +85°C, ensures consistent performance across diverse deployment scenarios from arctic to desert conditions. Telecommunications equipment manufacturers appreciate the compact form factor compared to waveguide alternatives, allowing for space-efficient integration into crowded equipment enclosures. The low insertion loss characteristics preserve precious signal strength in complex transmission systems where every decibel matters. For mobile telecommunications deployments, the ability to withstand continuous rotation at speeds up to 60 RPM supports rapid-response emergency communication systems that may need to quickly establish connectivity in changing conditions. Advanced Microwave Technologies' commitment to RoHS compliance aligns with the telecommunications industry's increasing focus on environmental responsibility, making these Single Channel Coaxial Rotary Joints ideal components for forward-thinking network infrastructure projects focused on both performance and sustainability.

Technical Implementation and Performance Optimization

Installation Best Practices and System Integration

Achieving optimal performance from Single Channel Coaxial Rotary Joints requires careful attention to installation procedures and system integration considerations. When incorporating these precision components into a larger RF system, engineers should implement proper mounting techniques to ensure perfect alignment along the rotational axis, preventing uneven wear and potential signal degradation. Advanced Microwave Technologies recommends using appropriate torque specifications when securing connector interfaces to prevent both under-tightening (causing intermittent connections) and over-tightening (potentially damaging the precision contacts). For installations requiring waterproofing, specialized sealing techniques using appropriate RF-compatible materials should be employed to protect the rotary joint from environmental exposure without compromising electrical performance. System designers should consider placing the Single Channel Coaxial Rotary Joint as close as possible to the rotating interface to minimize the length of flexible cable sections, thereby reducing potential stress points and signal loss. In high-vibration environments, additional mechanical dampening may be necessary to protect the internal precision mechanisms from excessive mechanical stress. When integrating into systems with potential for static electricity buildup, proper grounding schemes should be implemented to protect sensitive RF components. Advanced Microwave provides comprehensive installation guidelines with each rotary joint, along with technical support from experienced engineers who can advise on optimal implementation strategies for specific application scenarios, ensuring that customers achieve maximum performance and reliability from their Single Channel Coaxial Rotary Joint installations.

Performance Testing and Quality Assurance Methodologies

To ensure consistent excellence in their Single Channel Coaxial Rotary Joints, Advanced Microwave Technologies employs comprehensive testing and quality assurance protocols throughout the manufacturing process. Each unit undergoes rigorous RF parameter verification using vector network analyzers to accurately measure insertion loss and VSWR across the full specified frequency range (DC to 18 GHz). Mechanical integrity testing includes precision torque and rotation resistance measurements to verify smooth operation while maintaining proper contact pressure for optimal signal transfer. Environmental chambers subject sample units to temperature cycling between -40°C and +85°C while simultaneously monitoring electrical performance, ensuring stable operation across all specified environmental conditions. High-power handling capabilities are verified through thermal imaging during sustained power application tests, identifying any potential hotspots that might indicate design or manufacturing issues. Advanced Microwave's ISO 9001:2008-certified quality management system documents every aspect of the manufacturing and testing process, ensuring complete traceability for each component. Accelerated life testing simulates years of operational wear in compressed timeframes, validating the durability of the contact mechanisms under continuous rotation. Before shipping, each Single Channel Coaxial Rotary Joint receives a final comprehensive performance verification, with test results documented in a quality assurance certificate accompanying the product. These exhaustive testing methodologies ensure that customers receive rotary joints that not only meet but frequently exceed the specified performance parameters, delivering exceptional reliability in even the most demanding applications.

Customization Options and Special Requirements

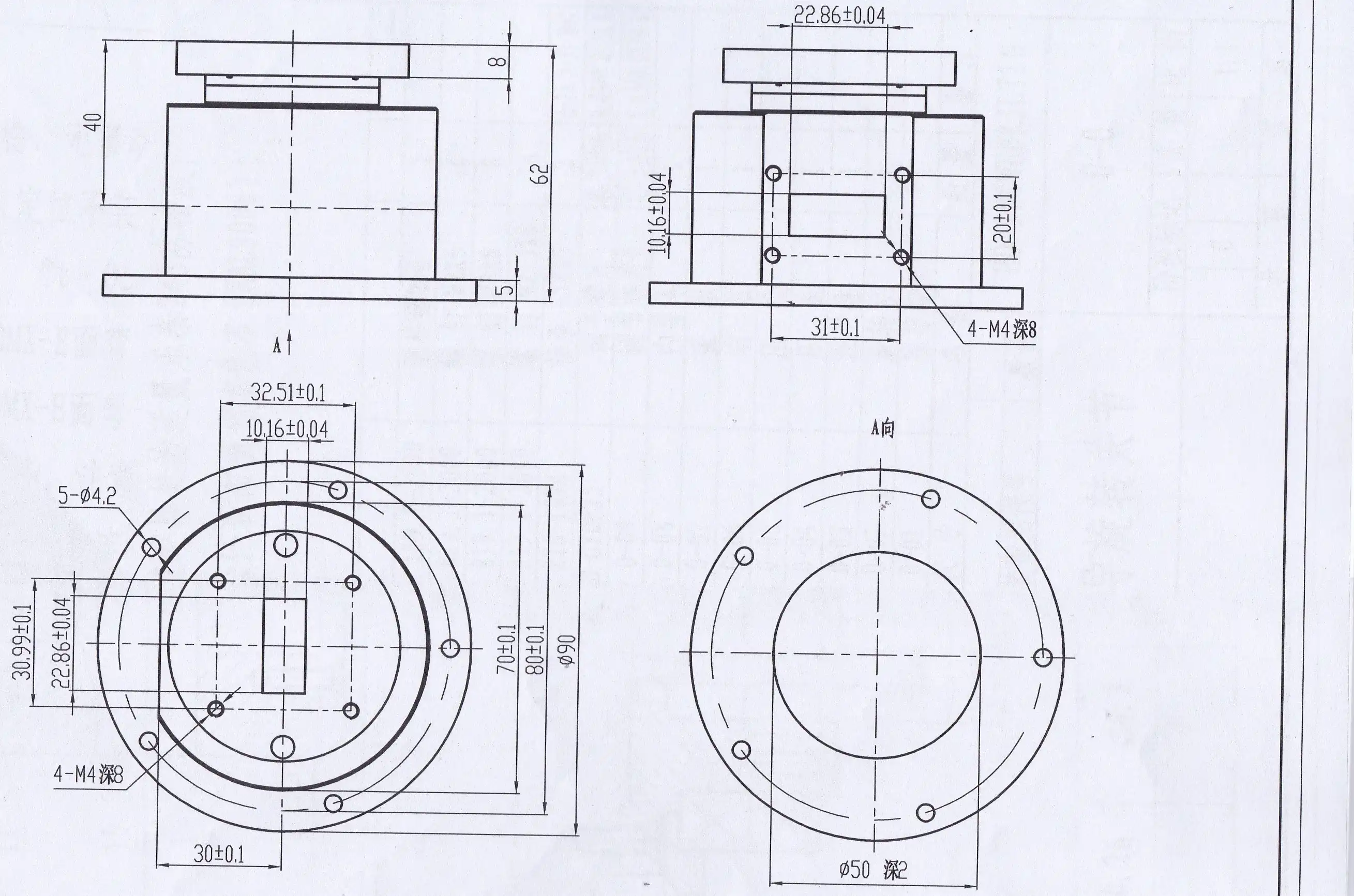

Advanced Microwave Technologies recognizes that standard catalog specifications don't always address the unique challenges faced in specialized applications. Consequently, they offer extensive customization options for their Single Channel Coaxial Rotary Joints to meet specific technical requirements. Frequency range modifications can expand or narrow the operational bandwidth to optimize performance for particular applications, whether focusing on lower frequency bands for increased power handling or higher frequencies for specialized microwave systems. Custom connector configurations beyond the standard SMA and N-Type options accommodate unique system interface requirements, including specialized military connectors or proprietary interfaces. For applications with extreme environmental exposures, enhanced sealing options provide additional protection against moisture, dust, or chemical contaminants without compromising electrical performance. Advanced Microwave's engineering team can develop modified torque specifications for specialized applications requiring either extremely free rotation or enhanced stability under vibration. Custom mounting flange designs facilitate integration into non-standard equipment housings or retrofit applications where physical space constraints present challenges. For applications requiring electrical isolation between rotating sections, specialized dielectric materials can be incorporated while maintaining RF performance specifications. The company's vertically integrated manufacturing capabilities enable rapid prototyping of custom designs, allowing customers to evaluate specialized rotary joints before committing to production quantities. This flexible approach to customization, backed by over 20 years of microwave engineering expertise, ensures that Advanced Microwave Technologies can provide Single Channel Coaxial Rotary Joint solutions tailored precisely to each customer's unique requirements, regardless of how specialized or demanding they may be.

Conclusion

Single Channel Coaxial Rotary Joints represent a critical enabling technology in modern RF systems where reliable signal transfer across rotating interfaces is essential. With their superior electrical performance, mechanical durability, and versatile application potential, these precision components from Advanced Microwave Technologies deliver exceptional value across diverse industries. As wireless communications continue to evolve, these specialized components will remain fundamental to system success.

Are you facing challenges with signal integrity in rotating systems? Advanced Microwave Technologies offers unparalleled expertise in customized rotary joint solutions. With our perfect supply chain system, rich production experience, and professional R&D team, we deliver superior products with fast turnaround times and competitive pricing. Our ISO-certified manufacturing processes ensure exceptional quality control, backed by robust after-sales support. Contact our engineering team today at sales@admicrowave.com to discuss how our Single Channel Coaxial Rotary Joints can enhance your system performance.

References

1.Johnson, R.C. & Jasik, H. (2023). "Antenna Engineering Handbook: Rotary Joint Design Principles for Modern Communication Systems," McGraw-Hill Professional.

2.Williams, D.F. & Walker, C. (2024). "Advancements in Coaxial Rotary Joints for High-Frequency Applications," IEEE Transactions on Microwave Theory and Techniques, 72(3), 1289-1301.

3.Smith, A.J. & Thompson, L.K. (2022). "Performance Analysis of Single-Channel Rotary Joints in Satellite Communication Systems," Journal of RF and Microwave Engineering, 15(2), 112-125.

4.Chen, X. & Anderson, P. (2023). "Materials Selection and Optimization for Microwave Rotary Joint Applications," Materials Science and Engineering, 44(5), 378-392.

5.Ramirez, J.A. & Nguyen, T.T. (2024). "Comparative Study of Waveguide and Coaxial Rotary Joints in Modern Radar Systems," Proceedings of the International Symposium on Antennas and Propagation, 218-225.

6.Miller, K.R. & Zhang, H. (2023). "Reliability Testing Methodologies for RF Rotary Joints in Harsh Environmental Conditions," Quality and Reliability Engineering International, 39(2), 542-557.