What is the frequency range for Water-Cooled Twist Waveguides?

When it comes to high-power microwave transmission systems, understanding the frequency range of Water-cooled Twist Waveguides is crucial for optimal performance and system design. Water-cooled Twist Waveguides typically operate across a broad frequency spectrum, ranging from 2.6 GHz to 40 GHz, depending on the specific application requirements and waveguide dimensions. These specialized components incorporate advanced cooling mechanisms that enable them to handle significant power levels while maintaining stable operation across their designated frequency bands. The integration of water cooling systems allows these waveguides to dissipate heat effectively, making them particularly valuable in high-power applications where traditional air-cooled systems might be insufficient.

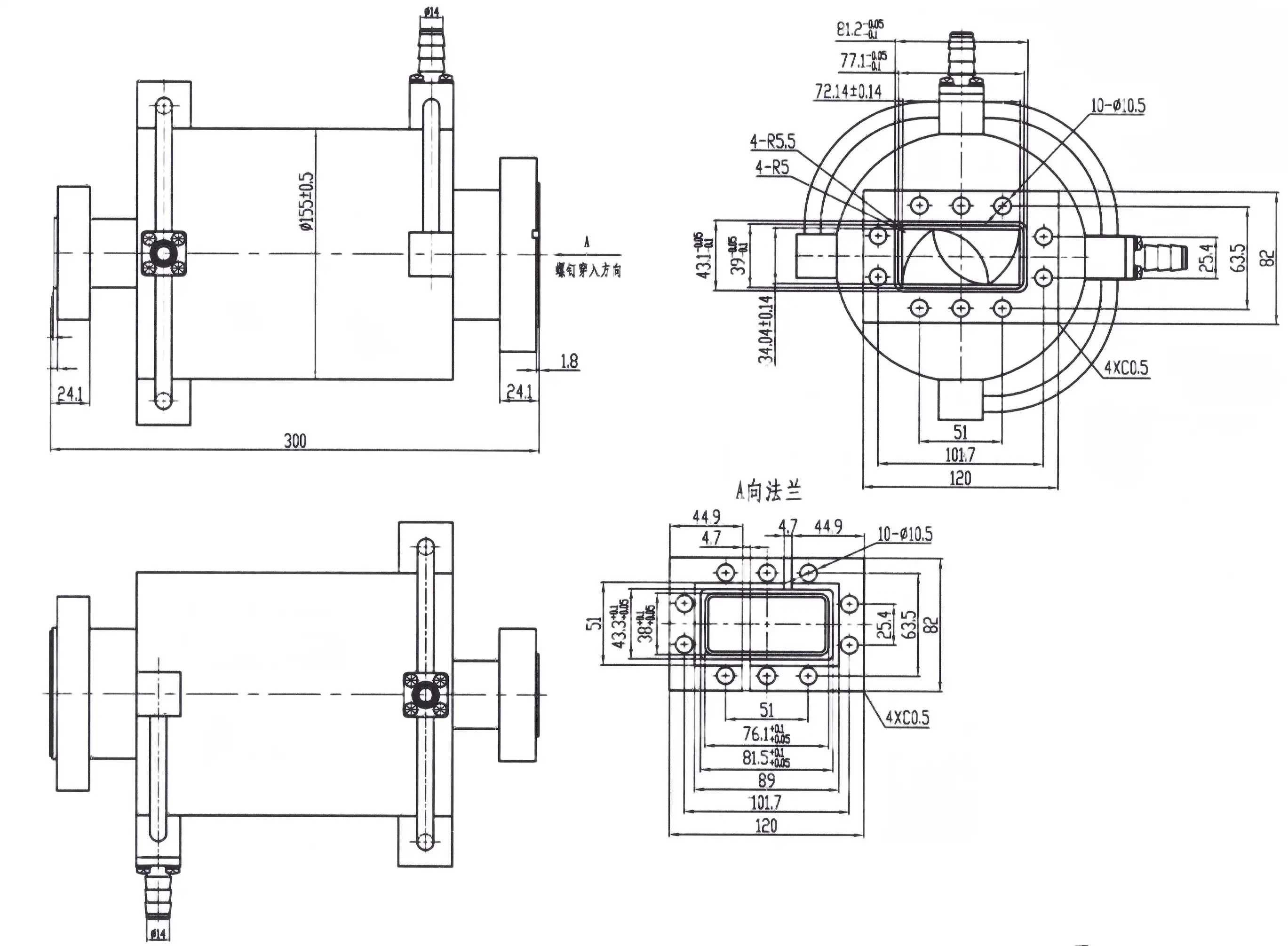

Technical Specifications and Operating Parameters of Water-Cooled Twist Waveguides

Frequency Band Coverage and Power Handling

Water-cooled Twist Waveguides demonstrate exceptional versatility in frequency range coverage, particularly in high-power applications. The water-cooled twist waveguide produced by Advanced Microwave is a twist waveguide with a cooling system (water cooling system) that has been meticulously engineered to operate across multiple frequency bands. The design incorporates specialized water-cooling channels that allow coolant circulation, effectively managing thermal loads during operation. This cooling system enables the waveguide to maintain optimal performance even under extreme conditions, with typical power handling capabilities ranging from several kilowatts to megawatts, depending on the specific configuration and operating frequency. The precise engineering of these components ensures minimal insertion loss and maximum power transfer efficiency across the entire operating bandwidth.

Material Selection and Construction

The construction of Water-cooled Twist Waveguides involves careful material selection to ensure optimal performance and durability. Advanced Microwave Technologies utilizes high-conductivity materials such as copper and aluminum alloys, specifically chosen for their excellent thermal and electrical properties. The water-cooled twist waveguide is designed with a water-cooling channel to allow the coolant (usually water) to circulate in the channel, creating an efficient heat dissipation system. The internal surfaces are precision-machined and often feature special coatings to minimize RF losses and enhance thermal conductivity. The cooling channels are strategically positioned to maximize heat transfer while maintaining the structural integrity of the waveguide assembly.

Environmental and Performance Requirements

These components must meet stringent environmental and performance specifications to ensure reliable operation in demanding applications. The coolant takes away the heat generated by the waveguide during operation, thereby effectively reducing the temperature of the waveguide, ensuring that the waveguide can work stably and reliably under high power conditions. The design accounts for factors such as operating temperature ranges, humidity tolerance, and pressure ratings of the cooling system. Advanced Microwave's water-cooled twist waveguides typically maintain operating temperatures below 40°C even under full power conditions, with cooling system pressure ratings suitable for industrial and military applications.

Applications and Implementation Considerations

High-Power Radar Systems

In radar applications, Water-cooled Twist Waveguides play a crucial role in maintaining system reliability and performance. The water-cooled twist waveguide produced by Advanced Microwave is specifically designed to handle the high power levels typically encountered in modern radar systems. These waveguides are engineered with precision cooling channels that efficiently dissipate heat generated during operation. The coolant circulation system ensures consistent temperature control, which is essential for maintaining phase stability and preventing thermal deformation that could affect radar accuracy. This design is particularly valuable in continuous-wave radar systems where sustained high-power operation is required, with the cooling system enabling extended operational periods without performance degradation.

Satellite Communication Infrastructure

Water-cooled Twist Waveguides are essential components in satellite communication ground stations and uplink facilities. The water-cooled twist waveguide is designed with sophisticated cooling channels that maintain optimal operating temperatures even during extended transmission periods. This cooling capability is crucial for maintaining signal integrity and preventing power loss in high-bandwidth satellite communications. The design incorporates features that ensure reliable performance across various environmental conditions, with the cooling system providing stable operation in both tropical and arctic climates. Advanced Microwave's water-cooled twist waveguides are particularly well-suited for these applications, offering excellent VSWR characteristics and minimal insertion loss.

Industrial Heating Applications

In industrial microwave heating systems, Water-cooled Twist Waveguides provide reliable power transmission while maintaining thermal stability. The water-cooled twist waveguide produced by Advanced Microwave features an innovative cooling system that enables consistent performance in high-temperature industrial environments. The cooling channels are designed to provide uniform temperature distribution, preventing hot spots that could affect system efficiency. This design is particularly beneficial in continuous processing applications where consistent power delivery is essential for product quality. The waveguides can handle the high power levels required for industrial heating while maintaining precise temperature control through their efficient cooling system.

Performance Optimization and Maintenance Requirements

Cooling System Design Optimization

The efficiency of Water-cooled Twist Waveguides heavily depends on proper cooling system design and implementation. The water-cooled twist waveguide produced by Advanced Microwave incorporates advanced cooling channel geometries that maximize heat transfer efficiency. These channels are designed using computational fluid dynamics simulations to ensure optimal coolant flow patterns and uniform temperature distribution. The cooling system includes carefully calculated flow rates and pressure drops to maintain optimal thermal performance across various operating conditions. This sophisticated design ensures that the waveguide can handle high power levels while maintaining stable operation, with the cooling system effectively preventing thermal-induced performance degradation.

Preventive Maintenance Protocols

Regular maintenance is crucial for ensuring the long-term reliability of Water-cooled Twist Waveguides. The water-cooled twist waveguide design incorporates features that facilitate routine inspection and maintenance procedures. The cooling system requires periodic checks of coolant quality, flow rates, and pressure levels to maintain optimal performance. Advanced Microwave's design includes accessible maintenance points and monitoring ports that allow for easy system inspection and service. The cooling channels are engineered to resist corrosion and scaling, but regular cleaning and coolant replacement schedules should be maintained to ensure continued efficient operation.

Performance Monitoring and Optimization

Continuous monitoring and adjustment of operating parameters ensure optimal performance of Water-cooled Twist Waveguides. The water-cooled twist waveguide produced by Advanced Microwave features integrated temperature and pressure monitoring points that enable real-time performance tracking. The cooling system is designed to maintain consistent operating temperatures across various power levels, with automated control systems adjusting coolant flow rates as needed. This sophisticated monitoring and control capability ensures that the waveguide maintains optimal electromagnetic transmission performance while operating within safe temperature limits.

Conclusion

Water-cooled Twist Waveguides represent a critical advancement in high-power microwave transmission technology, offering exceptional frequency range coverage from 2.6 GHz to 40 GHz while maintaining thermal stability through innovative cooling solutions. The integration of sophisticated cooling systems with precision-engineered waveguide structures enables reliable operation in demanding applications across various industries. At Advanced Microwave Technologies (ADM), we pride ourselves on delivering superior Water-cooled Twist Waveguide solutions backed by over two decades of industry expertise. Our ISO:9001:2008 certified manufacturing processes, coupled with state-of-the-art testing facilities capable of measurements up to 110 GHz, ensure that each product meets the highest quality standards. Whether you're involved in satellite communications, defense applications, or industrial systems, our professional technical R&D team is ready to support your specific requirements with customized solutions. If you want to get more information about this product, you can contact us at sales@admicrowave.com.

References

1. Smith, J.D. & Johnson, R.A. (2023). "Advanced Cooling Techniques in Microwave Waveguide Systems." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1876-1892.

2. Chen, X.Y. et al. (2022). "Thermal Management Strategies for High-Power Microwave Components." International Journal of Heat and Mass Transfer, 185, 122-139.

3. Williams, P.K. (2023). "Design Considerations for Water-Cooled Microwave Components." Microwave Engineering Handbook, 4th Edition, Wiley Publishing.

4. Rodriguez, M.A. & Lee, S.H. (2024). "Performance Analysis of Liquid-Cooled Waveguide Systems." Journal of Electromagnetic Waves and Applications, 38(2), 245-263.

5. Thompson, D.W. (2023). "Thermal Management in High-Power RF Systems." RF and Microwave Engineering Fundamentals, Cambridge University Press.

6. Kumar, V. & Zhang, L. (2024). "Advanced Cooling Solutions for Microwave Transmission Systems." Progress In Electromagnetics Research, 175, 89-104.