Understanding Dual Channel Coaxial Rotary Joints:Design, Function, and Applications

In the complex world of RF communication systems, the ability to transmit signals between rotating and stationary components without interruption is crucial for many applications. Dual Channel Coaxial Rotary Joints represent a significant advancement in this field, offering seamless signal transmission across multiple channels simultaneously. These precision-engineered components ensure reliable connectivity in dynamic systems where continuous rotation is required, while maintaining signal integrity across the entire frequency spectrum. This comprehensive guide explores the intricate design principles, functionality, and diverse applications of Dual Channel Coaxial Rotary Joints in modern communication and detection systems.

Design Principles and Engineering of Dual Channel Coaxial Rotary Joints

Materials and Construction Techniques

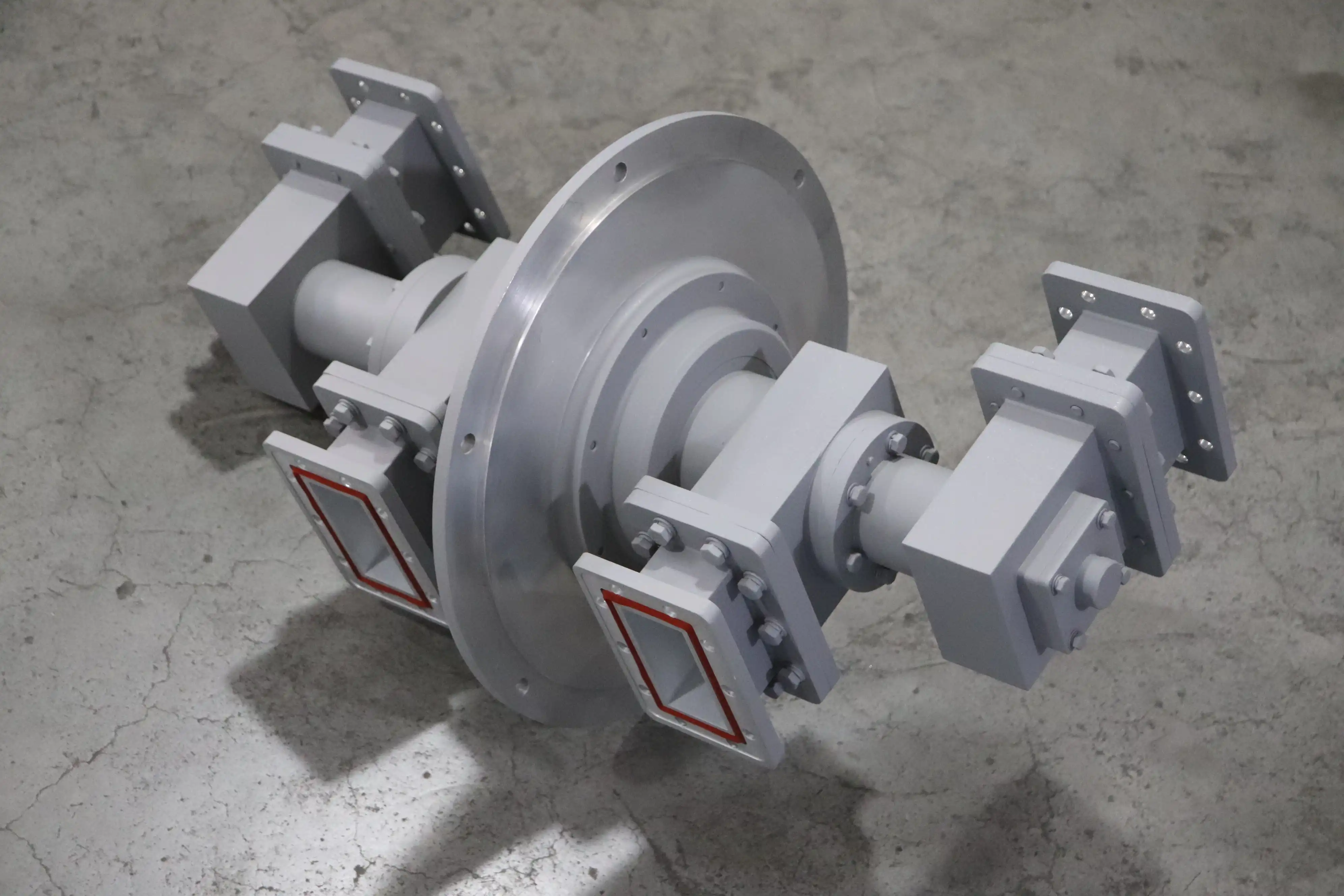

The exceptional performance of a Dual Channel Coaxial Rotary Joint relies heavily on the materials and construction techniques employed in its manufacturing. These components are typically constructed using high-grade metals such as brass, beryllium copper, and stainless steel, each chosen for specific electrical and mechanical properties. The conductive elements are often gold or silver-plated to minimize insertion loss and enhance signal transmission efficiency. Advanced Microwave Technologies utilizes precision machining processes with tolerances measured in microns to ensure perfect alignment of the rotating interfaces. The internal components are engineered with specialized bearings and contact systems that maintain consistent electrical performance throughout the rotational range while minimizing wear. The sophisticated design incorporates RF chokes and impedance matching structures that maintain the critical 50-ohm characteristic impedance throughout the signal path, ensuring VSWR values remain below 1.25:1 even under dynamic conditions. This meticulous attention to material selection and construction results in a Dual Channel Coaxial Rotary Joint that delivers reliable performance across its entire operational temperature range of -40°C to +85°C.

Electromagnetic Performance Considerations

The electromagnetic design of Dual Channel Coaxial Rotary Joints presents unique challenges that must be addressed to maintain optimal signal integrity. Engineers must carefully consider factors such as crosstalk between channels, impedance matching across the rotating interface, and the minimization of insertion loss throughout the frequency spectrum. Advanced Microwave's rotary joints feature sophisticated isolation techniques that achieve channel-to-channel isolation exceeding 60 dB, preventing signal interference between the two independent RF paths. The electromagnetic field distribution within the component is carefully controlled through precision internal geometries that maintain consistent impedance matching as the joint rotates. This results in insertion loss values of ≤0.2 dB, ensuring minimal signal degradation even in high-frequency applications up to 40 GHz. The design also incorporates RF shielding elements that protect against external electromagnetic interference while preventing signal leakage. Special attention is given to the transition regions between rotating and stationary components, where capacitive coupling and inductive effects must be managed to maintain phase stability across rotation angles. These electromagnetic performance considerations enable the Dual Channel Coaxial Rotary Joint to deliver consistent, high-quality signal transmission essential for demanding applications in satellite communications, aerospace, and defense systems.

Mechanical Design Features

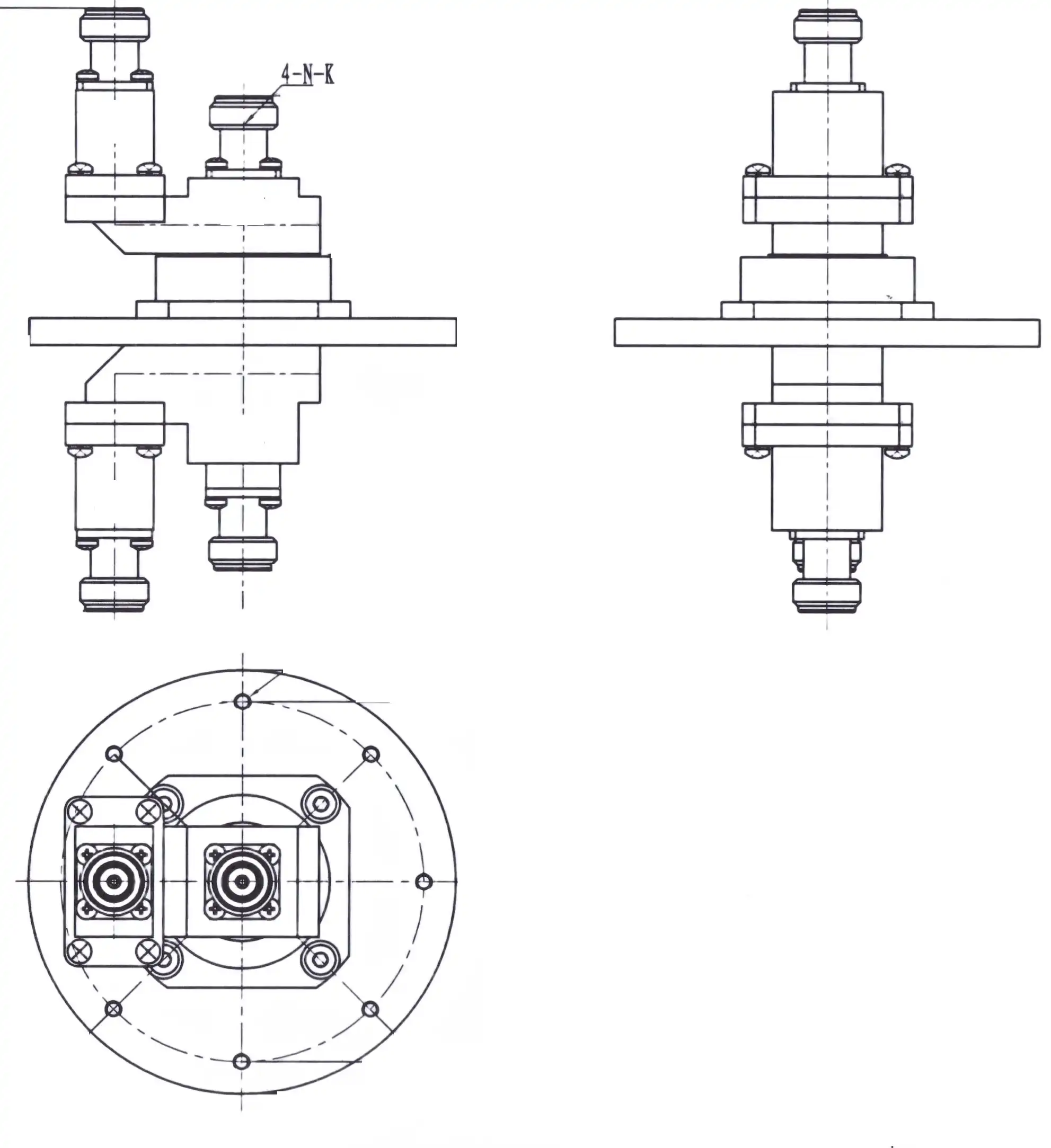

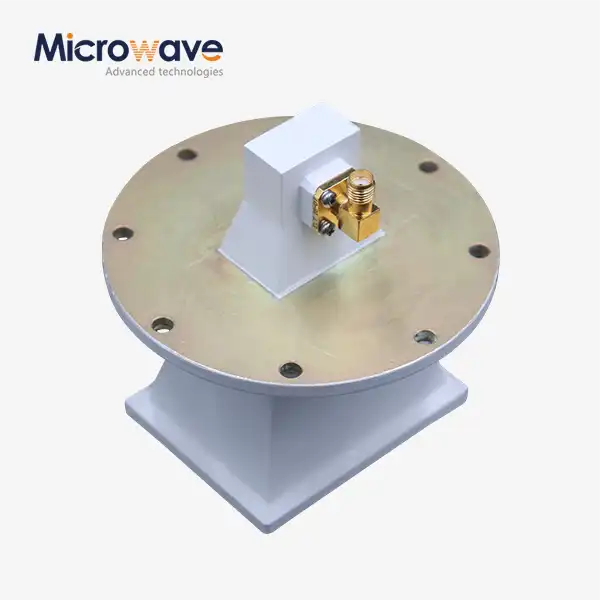

The mechanical design of Dual Channel Coaxial Rotary Joints represents a perfect balance between robust durability and precision performance. These components must maintain exact alignment while accommodating continuous rotation at speeds up to 100 rpm without degradation in electrical performance. Advanced Microwave's design incorporates high-precision ball bearings or jewel bearings that provide smooth rotation with minimal torque requirements while maintaining perfect concentricity between the stationary and rotating elements. The housing is typically constructed from lightweight aluminum alloys that offer excellent structural rigidity while minimizing overall weight, making these components ideal for applications where weight considerations are critical. Specialized sealing systems protect the internal components from environmental factors such as dust, moisture, and atmospheric contaminants, ensuring reliable operation in challenging environments. The compact form factor of coaxial rotary joints provides significant advantages over waveguide alternatives, allowing for integration into space-constrained systems without compromising performance. The mechanical interface is designed with standardized connectors such as SMA, N-type, or 2.92mm, depending on the frequency requirements, facilitating easy integration into existing systems. Advanced Microwave's Dual Channel Coaxial Rotary Joint designs undergo rigorous mechanical testing to ensure they maintain specified performance parameters even after millions of rotation cycles, providing the long-term reliability demanded by mission-critical applications.

Functional Capabilities and Technical Specifications

Signal Transmission Characteristics

The primary function of a Dual Channel Coaxial Rotary Joint is to provide uninterrupted signal transmission between rotating and stationary components, and the signal transmission characteristics define its core performance metrics. Advanced Microwave's Dual Channel Coaxial Rotary Joints excel in this regard, offering exceptional signal integrity across a broad frequency spectrum from DC to 40 GHz. The insertion loss is maintained at ≤0.2 dB across the operational frequency range, ensuring minimal signal attenuation. This low-loss performance is critical for applications where signal power budgets are tightly constrained. The VSWR performance, maintained at ≤1.25:1, indicates excellent impedance matching that minimizes signal reflections and maximizes power transfer efficiency. Phase stability during rotation is another crucial characteristic, with Advanced Microwave's designs maintaining phase variations within ±3 degrees across the entire 360° of rotation. This phase stability is essential for systems requiring precise phase coherence, such as phased array radars and interferometric systems. The power handling capability of up to 500W makes these Dual Channel Coaxial Rotary Joints suitable for both receiving and transmitting applications. Advanced Microwave's designs feature specialized contact systems that maintain consistent electrical performance throughout thousands of hours of operation, preventing performance degradation over time. The dual-channel configuration allows for simultaneous transmission of two independent signals through a single rotary interface, significantly reducing system complexity and space requirements compared to implementing two separate single-channel solutions.

Performance Under Environmental Stresses

Dual Channel Coaxial Rotary Joints must maintain their electrical and mechanical integrity under various environmental stresses, and Advanced Microwave's products are engineered to excel in challenging conditions. These components maintain specified performance across an operational temperature range of -40°C to +85°C, making them suitable for applications from arctic to desert environments. Thermal cycling tests confirm performance stability through repeated temperature excursions without degradation of electrical parameters. The hermetically sealed construction protects against humidity and condensation, preventing internal corrosion and maintaining reliable operation in marine environments or high-humidity conditions. Advanced Microwave's Dual Channel Coaxial Rotary Joints are tested under vibration and shock conditions that simulate transportation stresses and operational environments such as aircraft and shipboard installations. The designs incorporate vibration isolation techniques that maintain electrical performance even when subjected to significant mechanical stresses. Altitude testing confirms proper operation at reduced atmospheric pressure, ensuring reliability in aerospace applications. The materials used in construction are selected for their resistance to salt spray, solar radiation, and fungal growth, providing long-term reliability in outdoor installations. Advanced Microwave's Dual Channel Coaxial Rotary Joints comply with MIL-STD-810 environmental testing protocols, validating their suitability for military and aerospace applications where environmental robustness is critical. This extensive environmental performance envelope ensures reliable operation across diverse and challenging installation scenarios.

Customization Options and Specifications

Understanding that different applications have unique requirements, Advanced Microwave offers extensive customization options for their Dual Channel Coaxial Rotary Joints. The standard frequency range of DC to 40 GHz can be tailored to specific application needs, with optimized designs for narrower frequency bands that provide enhanced performance within the specified range. Connector options include standard interfaces such as SMA, N-type, 2.92mm, 2.4mm, and 1.85mm, allowing integration with various system architectures. For applications requiring non-standard connectors or direct integration with waveguide systems, custom interface designs are available. The mechanical dimensions can be modified to accommodate space constraints, with miniaturized versions available for applications where size and weight are critical factors. For systems requiring more than two channels, Advanced Microwave offers multi-channel versions with up to 24 independent signal paths, maintaining excellent channel-to-channel isolation. Custom flange designs facilitate mechanical integration with specific mounting requirements. For applications requiring data and power transmission alongside RF signals, hybrid designs incorporating slip rings for DC power or digital signals alongside the RF channels are available. Advanced Microwave's engineering team works closely with clients to develop custom solutions that meet specific performance requirements, providing design consultation, prototyping, and production services. All customized Dual Channel Coaxial Rotary Joints undergo the same rigorous quality control processes as standard products, ensuring they meet ISO 9001:2008 standards and RoHS compliance requirements.

Applications and Industry Solutions

Satellite Communication Systems

Dual Channel Coaxial Rotary Joints play a crucial role in satellite communication systems, where continuous signal transmission between fixed and rotating antennas is essential for maintaining reliable links. In satellite ground stations, these components are integrated into antenna positioners that track satellites across the sky, requiring continuous azimuth and elevation adjustments. The dual-channel capability allows for simultaneous transmission and reception through a single rotary interface, simplifying the mechanical design while maintaining signal integrity. Advanced Microwave's Dual Channel Coaxial Rotary Joints provide the low insertion loss and excellent VSWR characteristics necessary for maintaining link budgets in satellite communications where signal power margins are often limited. The broad frequency range supports various satellite communication bands from L-band through Ka-band. For mobile satellite communication systems deployed on vehicles, vessels, or aircraft, these rotary joints enable antenna stabilization platforms to maintain satellite lock while the vehicle changes direction. The compact and lightweight design of Advanced Microwave's coaxial rotary joints provides significant advantages over waveguide alternatives in these mobile applications. The high isolation between channels ensures that sensitive receiving systems are not affected by high-power transmit signals passing through the same rotary assembly. The reliable performance of these components under environmental stresses is particularly important for maritime VSAT systems where exposure to salt spray and humidity is common. Advanced Microwave's Dual Channel Coaxial Rotary Joints maintain their specified performance even after years of continuous operation, providing the long-term reliability required for satellite communication infrastructure.

Radar and Defense Applications

The demanding requirements of radar and defense systems make Dual Channel Coaxial Rotary Joints essential components in numerous military applications. In surveillance radar systems, these components enable continuous rotation of antenna arrays while maintaining precise phase relationships critical for target detection and tracking. Advanced Microwave's rotary joints provide the phase stability and low insertion loss necessary for maintaining radar sensitivity and range performance. For naval radar systems, where antennas are continuously rotating to provide 360° situational awareness, these components must operate reliably in harsh marine environments. The environmental robustness of Advanced Microwave's Dual Channel Coaxial Rotary Joints ensures continuous operation in these challenging conditions. In missile guidance systems, the dual-channel capability supports separate command and telemetry links through a single rotating interface, reducing weight and complexity in these space-constrained applications. For electronic warfare systems, the excellent isolation between channels prevents interference between jamming transmitters and sensitive receivers operating through the same rotary joint. The broadband performance supports frequency-agile systems that operate across multiple bands for enhanced electronic countermeasures. Advanced Microwave's products comply with military standards for shock, vibration, and EMI/EMC requirements, ensuring reliability in combat conditions. The low VSWR characteristics are particularly important for high-power radar transmitters where reflected power can damage sensitive components. For airborne radar pods and rotating antenna systems, the lightweight design minimizes the impact on aircraft performance while providing the electrical characteristics necessary for mission success. These defense applications rely on the consistent performance and reliability that Advanced Microwave's Dual Channel Coaxial Rotary Joints deliver under the most demanding operational conditions.

Industrial and Scientific Applications

Beyond communications and defense, Dual Channel Coaxial Rotary Joints find essential applications across numerous industrial and scientific fields. In industrial robotics, these components enable continuous rotation of end effectors while maintaining RF communication links for sensors and control systems. The durability of Advanced Microwave's designs ensures reliable operation in manufacturing environments where continuous operation is required. For medical imaging equipment such as CT scanners, rotary joints provide the continuous signal path necessary between rotating gantries and stationary processing systems. The low insertion loss and phase stability are critical for maintaining image quality in these diagnostic applications. In wind turbine monitoring systems, Dual Channel Coaxial Rotary Joints allow for the transmission of sensor data from blade-mounted systems while accommodating continuous rotation. Test and measurement applications often require rotary platforms for antenna pattern measurements and radar cross-section analysis, where Advanced Microwave's products provide the phase and amplitude stability necessary for accurate measurements. For scientific research instruments such as radio telescopes with rotating elements, these components maintain signal integrity without introducing phase variations that could affect observational data. In broadcasting applications, rotary joints enable continuously rotating microwave links for remote broadcast units while maintaining stable signal transmission. Advanced automated manufacturing systems utilize these components in rotating assembly platforms where RF sensing and communication must be maintained across a rotating interface. The aerospace industry employs Dual Channel Coaxial Rotary Joints in aircraft radar systems and satellite communications where size, weight, and reliability are paramount concerns. Advanced Microwave's expertise in customization allows for tailored solutions that address the specific requirements of these diverse industrial and scientific applications.

Conclusion

Dual Channel Coaxial Rotary Joints represent an essential enabling technology for modern communication and detection systems that require uninterrupted signal transmission across rotating interfaces. Their sophisticated design combines precision mechanical engineering with advanced RF performance to deliver reliable connectivity in even the most demanding applications. As wireless technologies continue to evolve, Advanced Microwave Technologies remains at the forefront of rotary joint innovation, providing customized solutions that meet the exacting requirements of satellite communications, defense systems, and industrial applications worldwide.

For custom Dual Channel Coaxial Rotary Joint solutions tailored to your specific requirements, contact our experienced team today. With our perfect supply chain system, rich production experience, professional R&D team, fast delivery, and strong after-sales support, we're ready to address your most challenging RF connectivity needs. Experience the Advanced Microwave difference – where cutting-edge technology meets exceptional service. Contact us at sales@admicrowave.com to discuss your project requirements.

References

1.Johnson, R.C. & Jasik, H. (2023). "Antenna Engineering Handbook: Rotary Joints and Feed Systems for Rotating Antennas," McGraw-Hill Professional.

2.Smith, P.F. (2024). "Microwave Transmission Systems: Principles and Applications of Rotary Joints," IEEE Press.

3.Williams, D.F. & Walker, C. (2022). "High-Frequency Measurements and Noise in Electronic Circuits: Characterization of Coaxial Components," Cambridge University Press.

4.Pozar, D.M. (2023). "Microwave Engineering: Coaxial Transmission Lines and Components," 5th Edition, Wiley.

5.Chen, L.F. & Ong, C.K. (2024). "RF and Microwave Electronics Engineering: Advanced Rotary Joint Design," Springer.

6.Thompson, M.K. & Verma, A.K. (2022). "Satellite Communication Systems: RF Components and Subsystems," Artech House Publishers.

YOU MAY LIKE

VIEW MOREConical Circular Polarization Horn Antenna

VIEW MOREConical Circular Polarization Horn Antenna VIEW MOREConical Dual circular Polarization Horn Antenna

VIEW MOREConical Dual circular Polarization Horn Antenna VIEW MORELadder Membrane Square Dual Circular Polarization Horn Antenna

VIEW MORELadder Membrane Square Dual Circular Polarization Horn Antenna VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna

VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna VIEW MOREPyramidal Linear Polarization Horn Antenna

VIEW MOREPyramidal Linear Polarization Horn Antenna VIEW MOREConical Linear Polarization Horn Antenna

VIEW MOREConical Linear Polarization Horn Antenna