Double-bend Waveguide vs. Flexible Waveguide: Which Is Better for Your Application?

Picture this: your satellite ground station has just a few centimeters of clearance between equipment racks, yet you need to route high-frequency signals with zero degradation. The wrong waveguide choice here means signal loss, system failure, and costly redesigns. Engineers in aerospace, radar, and telecommunications face this dilemma daily when selecting between double-bend waveguide and flexible waveguide solutions. Understanding which technology suits your specific constraints—whether space limitations, signal integrity requirements, or installation flexibility—can mean the difference between optimal system performance and compromised results.

Understanding Double-bend Waveguide Technology

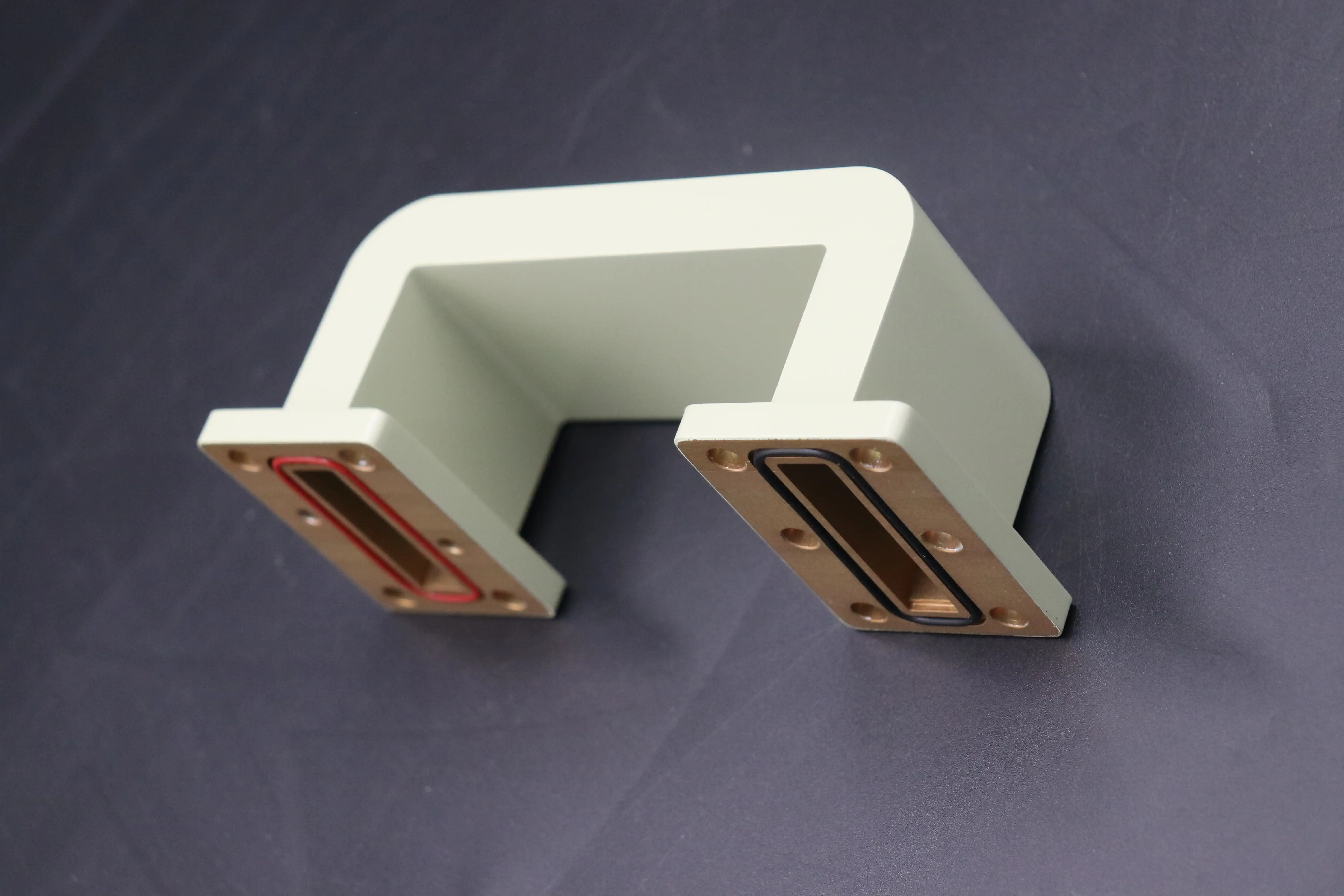

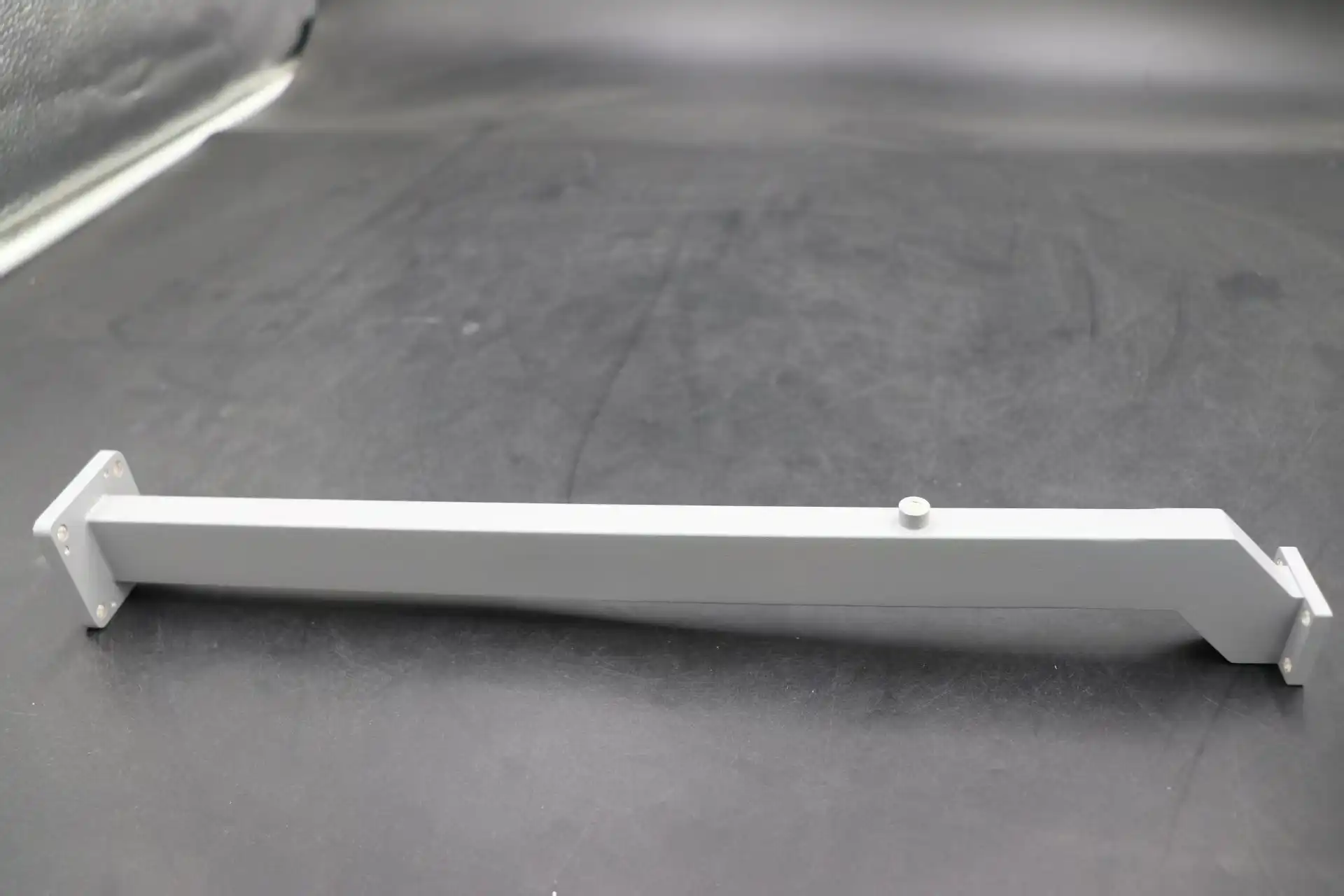

Double-bend waveguide represents a precision-engineered solution designed specifically for applications demanding sharp directional changes within confined spaces while maintaining exceptional signal integrity. Unlike gradual bends that require extensive physical space, the double-bend waveguide utilizes two consecutive angled sections, typically at forty-five degrees each, to achieve a ninety-degree turn in minimal real estate. This innovative design leverages the principle of controlled reflection cancellation, where the first bend generates reflections that are precisely offset by the second bend when properly spaced. Advanced Microwave's double-bend waveguide is a high-performance component designed to meet the complex demands of modern microwave and millimeter-wave applications. The layout design of the double-bend waveguide maximizes the reduction of signal reflection and loss through meticulous geometric optimization.

Constructed from oxygen-free copper and other high-conductivity metals, these components are polished to minimize loss and signal attenuation, ensuring that critical frequency signals remain intact throughout transmission. The fundamental advantage of double-bend waveguide technology lies in its ability to maintain rigid construction while accommodating tight spatial constraints. When engineers need to navigate around obstacles or fit waveguide runs into densely packed equipment bays, the double-bend configuration provides a deterministic, predictable solution. The distance between the two forty-five-degree bends is engineered to be an odd multiple of quarter wavelengths, creating destructive interference for unwanted reflections while allowing the primary signal to pass through with minimal distortion. In satellite communication ground stations, radar installations, and aerospace systems where every fraction of a decibel matters, the double-bend waveguide delivers consistent performance across its operating frequency range. Unlike flexible alternatives that may exhibit variable characteristics depending on installation conditions, the rigid double-bend structure provides repeatable electrical performance that can be precisely characterized during system design. This predictability becomes crucial in applications where system budgets are tight and performance margins cannot accommodate unexpected losses or reflections.

Exploring Flexible Waveguide Characteristics

Flexible waveguide technology addresses a completely different set of engineering challenges, prioritizing mechanical adaptability over the rigid precision of double-bend solutions. Manufactured through helical winding of silver-coated brass strips or corrugated metal forming processes, flexible waveguides can accommodate complex routing paths, absorb thermal expansion and contraction, and compensate for mechanical vibrations that would stress rigid waveguide installations. This mechanical versatility comes at the cost of increased insertion loss and potentially higher passive intermodulation distortion compared to rigid counterparts. The construction of flexible waveguide typically involves interlocking metal segments that maintain a rectangular cross-section while allowing bending in multiple planes. Some designs incorporate friction joints between segments to enable twisting capabilities, essential for matching polarization requirements in antenna installations. The conductive surfaces in flexible waveguide, while functional, cannot match the smoothness and uniformity achieved in precision-machined rigid waveguide, resulting in measurably higher attenuation per unit length. This performance tradeoff becomes acceptable in applications where mechanical flexibility is paramount.

Flexible waveguide excels in scenarios involving antenna positioning systems, mobile communications platforms, and installations where exact alignment between fixed connection points cannot be guaranteed during assembly. The ability to bend, twist, and conform to existing infrastructure without requiring custom-fabricated rigid components significantly reduces installation time and complexity. However, engineers must carefully observe minimum bend radius specifications to prevent permanent deformation or performance degradation. Exceeding these mechanical limits can introduce unacceptable levels of signal loss and reflection that compromise system operation. The economic considerations surrounding flexible waveguide often favor its use in field installations, system retrofits, and applications where labor costs for custom rigid waveguide fabrication would exceed the material cost premium of flexible solutions. Additionally, flexible waveguide simplifies shipping and handling, as it can be coiled for transport rather than requiring careful packaging of rigid sections. For temporary installations, test setups, or applications anticipating future reconfiguration, the reusability and adaptability of flexible waveguide provides distinct advantages over permanent rigid installations.

Performance Comparison: Double-bend Waveguide vs. Flexible Waveguide

Electrical Performance Metrics

When evaluating waveguide solutions purely on electrical performance parameters, double-bend waveguide demonstrates clear superiority in insertion loss, voltage standing wave ratio, and power handling capability. Typical insertion loss for precision double-bend waveguide ranges from zero point zero five to zero point two decibels per bend, depending on frequency and manufacturing quality. In contrast, flexible waveguide exhibits insertion loss between zero point three to one point two decibels per meter, with additional losses introduced at each bend point. For systems operating at high frequencies where accumulated loss directly impacts link budgets, this difference becomes critically important. The VSWR characteristics of double-bend waveguide can be optimized through precise manufacturing to achieve values below one point one across the operating band, as demonstrated by Advanced Microwave's product specifications featuring a maximum VSWR of one point one for their double-bend waveguide operating in the nineteen point two to twenty-one point two gigahertz range. Flexible waveguide, by contrast, typically exhibits higher VSWR values due to the inherent irregularities in the interlocking segments and the difficulty in maintaining perfect internal geometry throughout bends and twists. These reflections, while manageable in many applications, can accumulate in complex systems to create standing wave patterns that degrade performance. Power handling capacity represents another area where double-bend waveguide technology excels. The smooth internal surfaces and rigid construction allow these components to handle kilowatt-level power densities without risk of arc discharge or thermal damage. Flexible waveguide, with its jointed construction and potentially less robust dielectric barriers, generally exhibits lower power handling thresholds. In high-power radar transmitters, satellite uplink stations, and industrial heating applications, this limitation may preclude the use of flexible waveguide entirely, necessitating rigid solutions despite increased installation complexity.

Mechanical and Installation Considerations

The mechanical advantages of flexible waveguide become apparent during installation planning and execution. Where double-bend waveguide requires precise pre-installation measurement, custom fabrication to exact dimensions, and careful alignment during assembly, flexible waveguide can be formed on-site to accommodate actual as-built conditions. This adaptability dramatically reduces the risk of fit-up problems that can plague rigid waveguide installations, particularly in retrofit scenarios where original design documentation may be incomplete or inaccurate. Double-bend waveguide installations demand skilled technicians capable of proper flange alignment, torque specifications, and gasket installation to ensure optimal electrical and mechanical performance. The rigid nature of these components means that any misalignment between connection points must be accommodated through custom fabrication or the strategic insertion of flexible sections at specific locations. However, once properly installed, double-bend waveguide requires minimal maintenance and delivers consistent performance over decades of operation, unaffected by vibration, thermal cycling, or mechanical stress within design limits. The ability of flexible waveguide to absorb mechanical vibration and thermal expansion represents a significant advantage in mobile platforms, shipboard installations, and equipment subject to environmental extremes. Rigid waveguide systems in these environments require expansion joints or flexible sections to prevent mechanical failure due to stress accumulation. By incorporating flexibility throughout the waveguide run, designers can eliminate discrete expansion joints and their associated complexity. This becomes particularly valuable in applications like airborne radar systems, vehicle-mounted communications equipment, and industrial machinery where vibration is continuous and unpredictable.

Cost-Benefit Analysis Across Application Types

Economic evaluation of double-bend waveguide versus flexible waveguide solutions must extend beyond simple component pricing to encompass total installation costs, lifecycle maintenance expenses, and system performance value. Double-bend waveguide components command premium pricing due to precision machining requirements and high-conductivity materials like oxygen-free copper. However, their superior electrical performance and durability often justify the initial investment in fixed installations where system optimization directly impacts operational value. The elimination of signal loss translates to reduced transmitter power requirements, improved receiver sensitivity, and extended system range. Flexible waveguide, while potentially more expensive per unit length than straight rigid sections, can reduce total installation costs through labor savings and elimination of custom fabrication requirements. The ability to accommodate installation tolerances without field modifications accelerates deployment schedules and reduces the need for specialized machining capabilities at installation sites. For telecommunications infrastructure, broadcast facilities, and other applications involving numerous installations, these labor efficiencies can substantially impact project economics despite higher material costs. Long-term ownership costs favor double-bend waveguide in permanent installations due to lower maintenance requirements and immunity to gradual performance degradation. Flexible waveguide joints may develop corrosion over time, particularly in outdoor or marine environments, leading to increased insertion loss and passive intermodulation products that interfere with system operation. The smooth, sealed construction of double-bend waveguide minimizes these environmental degradation mechanisms, reducing lifecycle costs through extended service intervals and decreased probability of failure requiring emergency repair.

Application-Specific Selection Guidelines for Double-bend Waveguide

Satellite Communication Ground Stations

Satellite communication ground stations represent ideal applications for double-bend waveguide technology, where signal integrity requirements are exceptionally stringent and installations are essentially permanent. The high-frequency signals employed in these systems, often extending into Ka-band frequencies above twenty gigahertz, suffer dramatically from even minor insertion losses. Advanced Microwave's double-bend waveguide, optimized for the nineteen point two to twenty-one point two gigahertz frequency range, exemplifies the precision engineering required for these demanding applications. The compact design enables efficient signal routing within equipment shelters while maintaining the low insertion loss—maximum zero point one decibel—critical for preserving link margin. In satellite ground station applications, the ability to precisely control signal paths through double-bend waveguide configurations ensures optimal antenna feed network performance. The signal direction control inherent in the two-bend structure allows designers to route signals around structural obstacles, cable trays, and other equipment without resorting to lossy flexible sections. The low reflection characteristics, achieved through careful geometric optimization, prevent standing waves that could interfere with sensitive receiver front-ends or increase transmitter reflected power, potentially damaging high-power amplifiers. The material selection for double-bend waveguide in satellite applications directly impacts long-term reliability. Aluminum construction with gold plating internal finishes, as specified in Advanced Microwave's product line, provides excellent corrosion resistance for installations in coastal or humid environments while maintaining superior conductivity. This attention to material science ensures that the waveguide performance remains stable over decades of continuous operation, critical for commercial satellite operators where downtime directly impacts revenue and service-level agreements.

Aerospace and Defense Radar Systems

Military surveillance radar and airborne early warning systems demand the absolute minimum signal loss and maximum power handling capability that double-bend waveguide delivers. These applications often involve transmitter power levels in the multi-kilowatt range, where even small amounts of resistive heating in waveguide components can lead to thermal management challenges. The smooth internal surfaces of precision-machined double-bend waveguide minimize ohmic losses, ensuring that maximum transmitted power reaches the antenna while preventing hotspot formation that could compromise structural integrity. The predictable, repeatable electrical characteristics of double-bend waveguide simplify system integration and testing in aerospace platforms where weight and volume constraints are severe. Unlike flexible waveguide that may exhibit performance variations depending on installation configuration and bending stress, double-bend waveguide provides deterministic performance that can be precisely modeled during system design. This predictability allows radar engineers to optimize detection range and resolution with confidence that field performance will match analytical predictions, critical for defense systems where operational effectiveness directly impacts mission success. Advanced air traffic control radar systems benefit from the ultra-sharp beamforming capabilities enabled by low-loss waveguide distribution networks incorporating double-bend components. The ability to maintain phase coherence across complex antenna feed structures ensures accurate aircraft tracking even in challenging weather conditions. The compact design of double-bend waveguide facilitates integration into rotating antenna assemblies where space is at an absolute premium, while the low VSWR characteristics minimize pattern distortion that could compromise target discrimination capabilities.

Industrial and Medical Applications

High-power industrial microwave systems for materials processing, plasma generation, and semiconductor manufacturing require the robust construction and high power handling of double-bend waveguide technology. These applications subject waveguide components to continuous high-power operation at duty cycles that would quickly degrade flexible alternatives. The ability to handle kilowatt power levels without arcing or thermal damage makes double-bend waveguide the only viable solution for feeding industrial microwave applicators and plasma chambers. Medical linear accelerators used in radiation oncology depend on precise microwave energy delivery to generate the therapeutic x-ray beams that destroy cancer cells. The compact design of double-bend waveguide enables efficient routing within the confined space of linear accelerator treatment heads, where traditional gradual bends would be impossible to accommodate. The enhanced performance in tight spaces makes double-bend waveguide perfect for applications where the waveguide must navigate obstacles or fit into tight spots while maintaining the signal integrity required for consistent dose delivery to patients undergoing cancer treatment. Quantum computing systems represent an emerging application where the low reflection and minimal signal loss of double-bend waveguide become critical for guiding quantum information with minimal decoherence and error introduction. The cryogenic operating temperatures of quantum processors demand waveguide materials and construction techniques that maintain performance under thermal stress while minimizing heat leak into the quantum computing core. The precision-engineered geometry of double-bend waveguide meets these challenging requirements, supporting the development of practical quantum computing platforms.

When Flexible Waveguide Remains the Better Choice?

Despite the electrical performance advantages of double-bend waveguide, specific application scenarios continue to favor flexible waveguide solutions. Antenna installations requiring continuous rotation or scanning movements necessitate the mechanical compliance that only flexible waveguide can provide. The ability to twist and bend in multiple planes while maintaining a reasonable level of signal transmission makes flexible waveguide irreplaceable in rotating radar antennas, satellite tracking systems, and mobile communications platforms where mechanical motion is inherent to operation. Retrofit installations in existing facilities often encounter spatial constraints and alignment challenges that make rigid waveguide installation prohibitively expensive or technically infeasible. The ability of flexible waveguide to absorb tolerance stackup and accommodate as-built conditions without custom fabrication dramatically accelerates deployment schedules. Broadcast television transmitter installations, distributed antenna systems in commercial buildings, and telecommunications infrastructure upgrades frequently leverage flexible waveguide to minimize installation disruption and reduce project costs despite the electrical performance compromises. Test and measurement applications benefit from the reconfigurability of flexible waveguide, allowing laboratory setups to be modified quickly without requiring permanent waveguide fabrication. The ability to form flexible waveguide into temporary configurations, evaluate system performance, and then reconfigure for different test scenarios provides experimental flexibility that rigid components cannot match. Research institutions, academic laboratories, and development engineering teams routinely employ flexible waveguide for prototyping and proof-of-concept work before committing to optimized rigid waveguide designs for production systems.

Conclusion

Selecting between double-bend waveguide and flexible waveguide demands careful evaluation of electrical performance requirements, mechanical constraints, installation conditions, and lifecycle economics. Double-bend waveguide excels where signal integrity, power handling, and long-term reliability justify premium investment in precision-engineered components.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands as a premier China double-bend waveguide manufacturer with over twenty years of proven excellence in microwave component design and production. As a leading China double-bend waveguide supplier, we maintain ISO nine thousand one, ISO fourteen thousand one, and ISO forty-five thousand one certifications ensuring quality, environmental responsibility, and workplace safety across all operations. Our state-of-the-art twenty-four meter microwave darkroom and comprehensive test capabilities spanning zero point five to one hundred ten gigahertz position us as the trusted China double-bend waveguide factory for aerospace, defense, satellite communications, and industrial applications worldwide.

Whether you require high-quality double-bend waveguide for demanding radar systems, China double-bend waveguide wholesale volumes for telecommunications infrastructure, or custom double-bend waveguide for sale tailored to unique application requirements, our expert engineering team delivers optimized solutions backed by rigorous testing and validation. Our competitive double-bend waveguide price structure, combined with rapid prototyping capabilities and comprehensive technical support, makes Advanced Microwave your ideal partner for mission-critical waveguide components. Contact our team at craig@admicrowave.com today to discuss your specific requirements and discover how our OEM services can accelerate your project from concept through production deployment with confidence.

References

1. Pozar, David M. "Microwave Engineering, 4th Edition." John Wiley & Sons, focused on waveguide bend design and performance optimization.

2. Collin, Robert E. "Foundations for Microwave Engineering, 2nd Edition." IEEE Press, covering fundamental waveguide theory and practical implementation considerations.

3. Marcuvitz, Nathan. "Waveguide Handbook." Dover Publications, providing comprehensive reference data for waveguide components including bend configurations and electrical characteristics.

4. Rao, S. "Microwave Engineering." Universities Press, addressing practical aspects of waveguide system design, installation methodologies, and application-specific selection criteria for communication and radar systems.