Waveguide Fixed Attenuator Suppliers & Factory - Wholesale

When your satellite communication system experiences signal distortion or your radar equipment delivers inconsistent readings due to uncontrolled power levels, the root cause often traces back to inadequate signal attenuation solutions. Finding reliable Waveguide Fixed Attenuator suppliers who can deliver precision-engineered components at wholesale prices becomes critical for maintaining system integrity and avoiding costly downtime. This comprehensive guide explores everything you need to know about sourcing high-quality waveguide fixed attenuators from trusted manufacturers and factories, ensuring your high-frequency applications perform at optimal levels while controlling costs effectively.

Understanding Waveguide Fixed Attenuator Technology and Applications

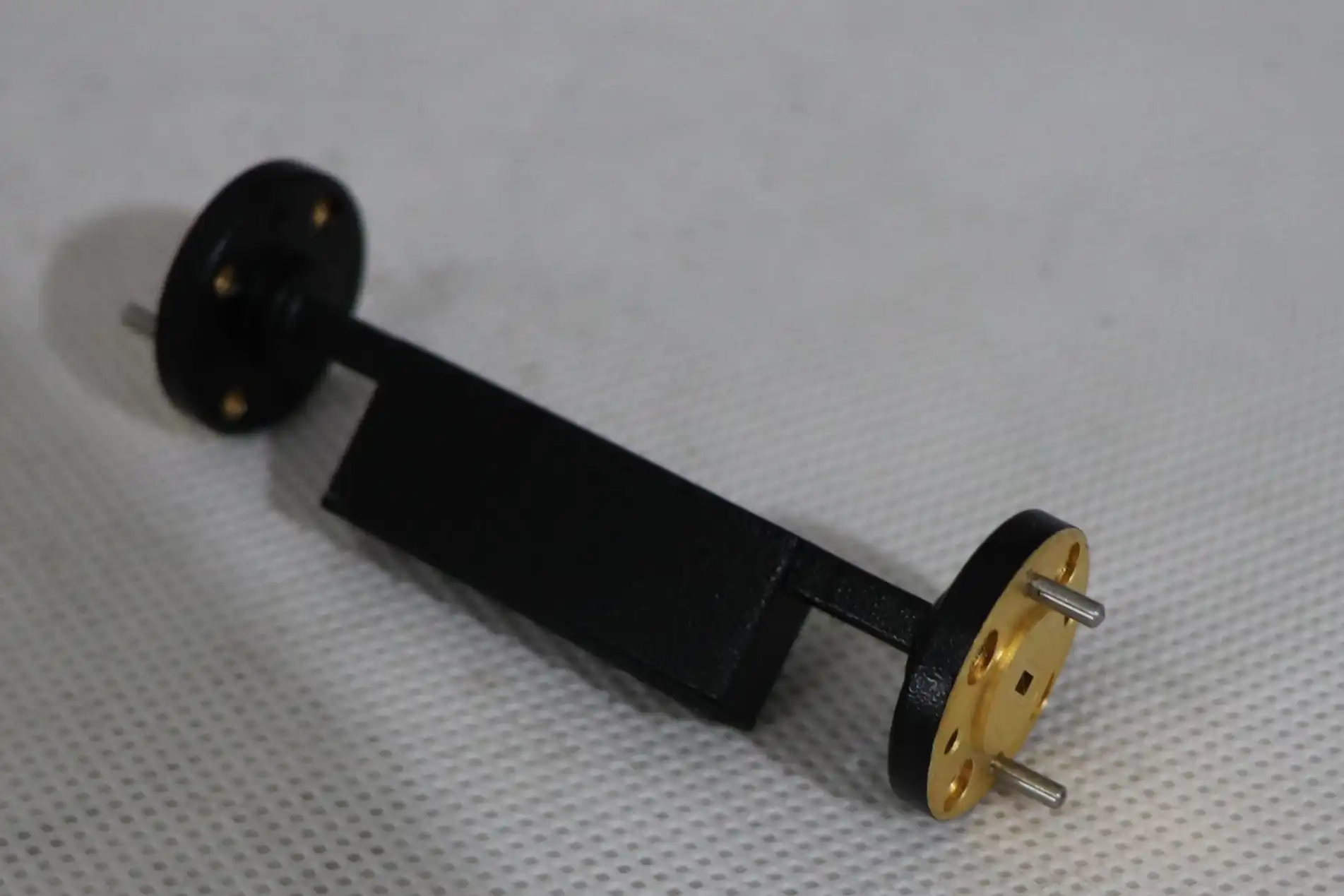

The Waveguide Fixed Attenuator serves as an essential passive component in microwave and millimeter-wave systems, designed to reduce signal strength by a predetermined amount without introducing significant distortion or reflection. Unlike variable attenuators that allow adjustment, fixed attenuators provide consistent, reliable attenuation values throughout their operational lifespan. In high-frequency applications ranging from satellite communications to aerospace radar systems, these components play a crucial role in signal strength control, preventing receiver overload, matching power levels between different system components, and improving overall measurement accuracy in testing environments.

Key Technical Specifications for Waveguide Fixed Attenuators

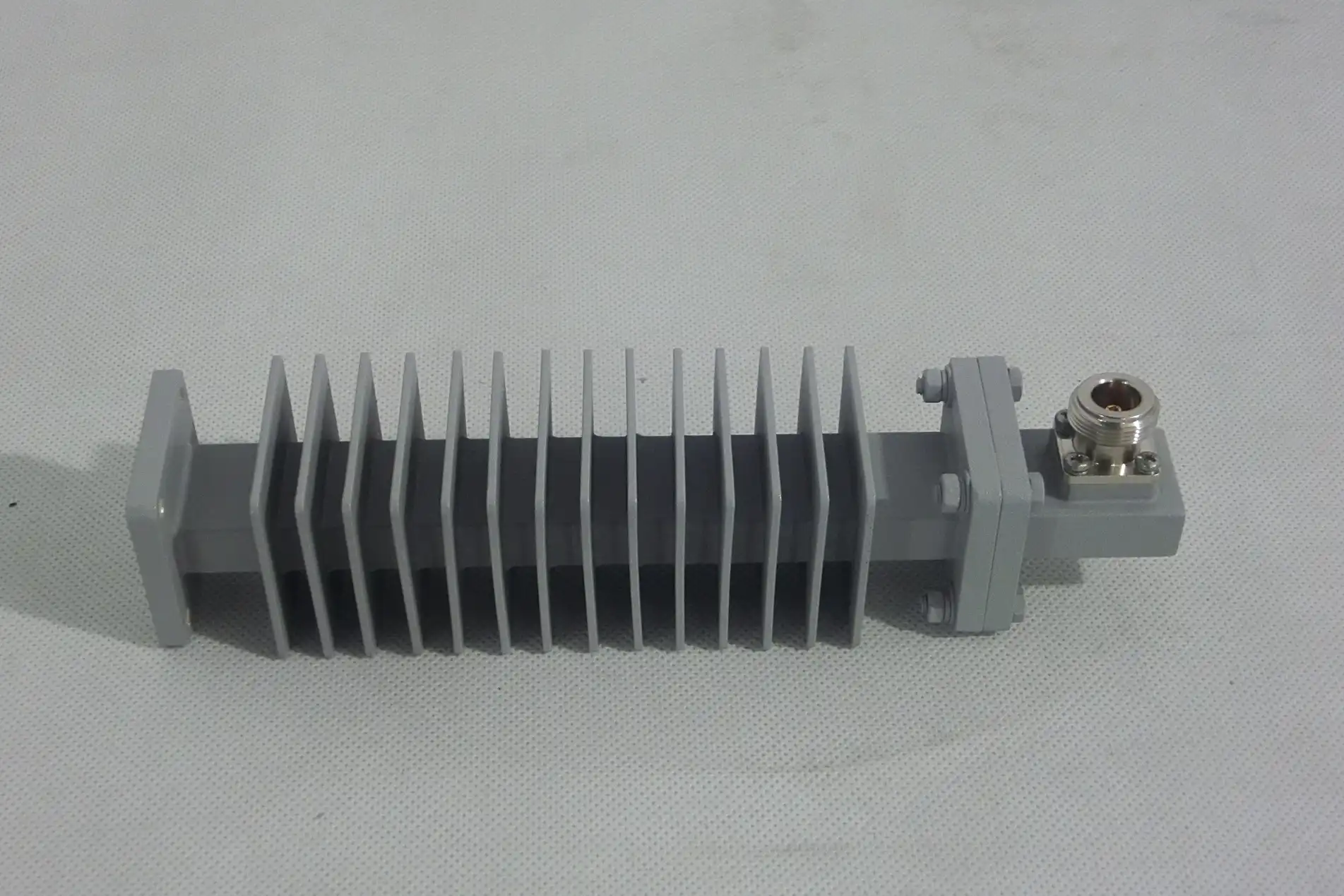

Professional-grade waveguide fixed attenuators are manufactured with exacting tolerances to ensure reliable operation across demanding applications. The most common attenuation values available from reputable suppliers include 3dB, 6dB, 10dB, 20dB, and 30dB configurations, though custom values can be engineered for specialized requirements. The assembled construction incorporates precision resistive elements carefully positioned within the waveguide structure to achieve optimum electrical performance. Advanced manufacturers offer both normal power units suitable for typical laboratory and communication applications, as well as high-power variants capable of handling elevated power levels without performance degradation. The frequency coverage is equally impressive, with state-of-the-art Waveguide Fixed Attenuator designs supporting operations from lower microwave frequencies up to 110 GHz, encompassing everything from legacy communication systems to cutting-edge 5G and emerging 6G technologies.

Critical Performance Parameters

When evaluating Waveguide Fixed Attenuator suppliers, several performance parameters demand careful consideration. Low Voltage Standing Wave Ratio (VSWR) ensures minimal signal loss and reflection, which is particularly crucial in high-precision measurement applications where even minor reflections can compromise accuracy. Attenuation accuracy typically falls within ±0.5dB of the nominal value, with frequency sensitivity maintained at approximately ±0.7dB across the specified operating range. Heat resistance capabilities allow these components to sustain elevated power levels without experiencing thermal degradation, making them suitable for continuous operation in demanding environments. The compact design philosophy employed by leading manufacturers ensures these components can be easily incorporated into various system architectures without consuming excessive space or adding unnecessary weight to the overall assembly.

Industrial Applications Driving Waveguide Fixed Attenuator Demand

Several critical industries rely extensively on the versatile Waveguide Fixed Attenuator to maintain signal integrity and system performance. In satellite communication systems, both uplink and downlink configurations require precise signal control to maintain optimal transmission quality across vast distances. The aerospace and defense sectors utilize these components as essential elements in advanced weapon systems, navigation equipment, and sophisticated radar installations where reliability and precision are non-negotiable requirements. Telecommunications infrastructure, including base station testing and signal management systems, depends on high-quality attenuators to ensure network performance meets stringent quality standards. Research and development laboratories conducting cutting-edge microwave testing and experimental work require attenuators that deliver consistent, repeatable results across wide frequency ranges.

Aviation and Aerospace Integration

The aviation and aerospace industry presents particularly demanding requirements for Waveguide Fixed Attenuator components. Aircraft navigation systems, satellite communication terminals, and weather radar installations all require attenuators that can withstand extreme environmental conditions while maintaining precise performance characteristics. Shipboard systems face similar challenges, with the added complexity of operating in corrosive maritime environments where component reliability becomes even more critical. Weather monitoring installations depend on accurate signal processing to deliver reliable meteorological data, making precision attenuation essential for maintaining measurement accuracy. Security check systems employed at airports and critical infrastructure facilities utilize microwave technology that requires carefully controlled signal levels to function effectively.

Defense and UAV Applications

Unmanned Aerial Vehicle (UAV) systems represent a rapidly growing application area for compact, lightweight Waveguide Fixed Attenuator solutions. These platforms require components that deliver exceptional performance while minimizing size and weight constraints. Direction finding systems used for electronic warfare and surveillance applications demand attenuators with exceptional frequency stability and minimal insertion loss variation. Military communication systems operating across multiple frequency bands benefit from attenuators that provide consistent performance across wide bandwidths, ensuring reliable operation in contested electromagnetic environments.

Selecting the Right Waveguide Fixed Attenuator Supplier and Factory

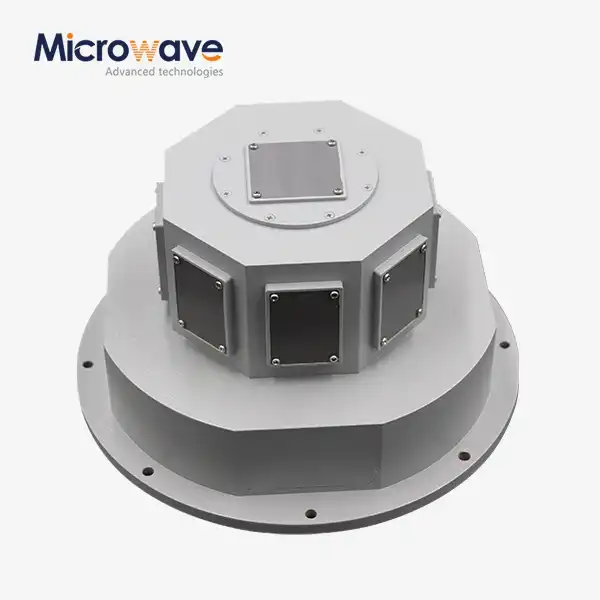

Choosing between various Waveguide Fixed Attenuator suppliers requires careful evaluation of multiple factors beyond simple price comparison. Manufacturing capability and quality control processes directly impact component reliability and long-term performance. Suppliers with advanced testing facilities, such as state-of-the-art microwave darkrooms equipped with antenna plane near and far field measuring recombination chambers, can validate performance across the entire specified frequency range, ensuring every component meets stringent specifications before shipment. ISO certification, including ISO 9001:2015 for quality management, ISO 14001:2015 for environmental management, and ISO 45001:2018 for occupational health and safety, demonstrates a supplier's commitment to systematic quality control and continuous improvement.

Manufacturing Excellence and Customization Capabilities

Leading China Waveguide Fixed Attenuator factory operations combine extensive experience with modern manufacturing techniques to deliver components that meet or exceed international standards. Over two decades of specialized microwave product development and manufacturing experience translates into deep understanding of design challenges and practical solutions for complex applications. The ability to provide customized designs that modify size, material composition, and frequency ranges according to specific requirements sets premium suppliers apart from commodity vendors. Rapid prototyping capabilities enable quick turnaround for special project needs, allowing engineers to test and validate designs before committing to full-scale production runs. Comprehensive support from design through installation ensures smooth integration into existing systems, minimizing deployment time and reducing the risk of compatibility issues.

Quality Assurance and Testing Infrastructure

China Waveguide Fixed Attenuator manufacturer facilities equipped with advanced measurement equipment up to 110 GHz can thoroughly characterize component performance across intended operating frequencies. The precision engineering involved in producing Waveguide Fixed Attenuator components with exacting tolerances requires sophisticated manufacturing processes and rigorous quality control at every production stage. RoHS compliance ensures components meet environmental standards for hazardous substance restrictions, which is increasingly important for products destined for European and other regulated markets. Long-term reliability testing under various environmental conditions validates component durability, providing confidence that attenuators will maintain performance specifications throughout their operational lifetime.

Wholesale Procurement Advantages and Bulk Ordering Benefits

Establishing relationships with reliable China Waveguide Fixed Attenuator wholesale suppliers delivers significant advantages beyond unit cost reduction. Volume purchasing enables better inventory management and ensures component availability for ongoing production or maintenance requirements. Consistent sourcing from established suppliers maintains quality standards across multiple procurement cycles, eliminating the variability that can arise when switching between different manufacturers. Technical support and application engineering assistance become more accessible when working with suppliers who understand your specific requirements and application environments. For organizations managing multiple projects or product lines, wholesale relationships with China Waveguide Fixed Attenuator supplier networks provide flexibility to address diverse requirements while maintaining procurement efficiency.

Price Competitiveness and Value Proposition

While Waveguide Fixed Attenuator price comparison remains an important consideration, total cost of ownership encompasses factors beyond initial purchase price. Components from established manufacturers with proven reliability reduce long-term maintenance costs and minimize system downtime. The price advantage offered by experienced suppliers often stems from manufacturing efficiency and economies of scale rather than compromised quality or performance. High Quality Waveguide Fixed Attenuator components may command premium pricing, but the investment pays dividends through extended service life, consistent performance, and reduced failure rates. Organizations seeking Waveguide Fixed Attenuator for sale should evaluate suppliers based on comprehensive value propositions that consider technical support, customization capabilities, delivery reliability, and after-sales service alongside pricing.

Supply Chain Reliability and Delivery Performance

Perfect supply chain systems ensure components arrive when needed, supporting project schedules and production timelines. Fast delivery capabilities separate leading suppliers from competitors, particularly for time-sensitive projects where delays can cascade through entire program schedules. Strong after-sales capability provides confidence that issues will be addressed promptly should they arise, minimizing operational disruption. Professional technical R&D teams continuously improve product designs and develop new solutions to address emerging application requirements, ensuring suppliers remain relevant as technology evolves.

Product Benefits and Technical Features of Premium Waveguide Fixed Attenuators

Improved signal control stands as the primary benefit delivered by precision Waveguide Fixed Attenuator components, enabling clearer signals with reduced noise through accurate attenuation across specified frequency ranges. The broad frequency support extending up to 110 GHz makes these components suitable for high-frequency applications spanning current and next-generation communication technologies. Durability achieved through robust material selection and careful manufacturing ensures long-term performance even in challenging environmental conditions including temperature extremes, vibration, and humidity exposure. Customizable options allow solutions tailored to specific needs, whether that involves unusual frequency ranges, non-standard attenuation values, or specialized flange configurations to match existing system interfaces.

Engineering Excellence and Performance Optimization

Precision engineering applied throughout the manufacturing process produces components with exacting tolerances that ensure reliable operation across temperature variations and extended operating periods. Minimal signal loss and reflection ensured by low VSWR characteristics preserve signal integrity throughout the transmission path. Heat resistance capabilities enable sustained operation at elevated power levels without experiencing performance degradation or physical damage to internal components. The compact design philosophy employed by experienced manufacturers facilitates easy integration into various system architectures without requiring extensive modifications to existing layouts or consuming valuable real estate in space-constrained applications.

Conclusion

Selecting the right Waveguide Fixed Attenuator supplier requires balancing technical performance, quality assurance, customization capabilities, and cost-effectiveness to ensure optimal system performance and long-term reliability.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands ready as your trusted China Waveguide Fixed Attenuator factory, China Waveguide Fixed Attenuator supplier, and China Waveguide Fixed Attenuator manufacturer offering competitive China Waveguide Fixed Attenuator wholesale pricing. With over 20 years of microwave manufacturing excellence, our High Quality Waveguide Fixed Attenuator components deliver proven performance across satellite communications, defense, aerospace, and navigation applications. Our Waveguide Fixed Attenuator for sale portfolio features competitive Waveguide Fixed Attenuator price structures backed by ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications. Our state-of-the-art 24m Microwave Darkroom with testing capabilities up to 110 GHz ensures every component meets stringent specifications. Whether you need rapid prototyping, customized designs, or comprehensive technical support, our expert team delivers solutions from concept to installation. Contact craig@admicrowave.com today to discuss your requirements and receive a detailed quotation. Bookmark this page for quick reference whenever you need reliable waveguide solutions.

References

1. Pozar, David M. "Microwave Engineering, Fourth Edition." John Wiley & Sons, 2012.

2. Saad, Theodore S. "Microwave Engineers' Handbook, Volume 1." Artech House Publishers, 1971.

3. Bahl, I. J. and Bhartia, Prakash. "Microwave Solid State Circuit Design, Second Edition." John Wiley & Sons, 2003.

4. Collin, Robert E. "Foundations for Microwave Engineering, Second Edition." IEEE Press, 2001.

YOU MAY LIKE

VIEW MORELog Periodic Antenna

VIEW MORELog Periodic Antenna VIEW MORESlotted Waveguide Array Antenna

VIEW MORESlotted Waveguide Array Antenna VIEW MOREOpen Boundary Dual Linear Polarization Four Ridged Horn Antenna

VIEW MOREOpen Boundary Dual Linear Polarization Four Ridged Horn Antenna VIEW MOREConical Dual circular Polarization Horn Antenna

VIEW MOREConical Dual circular Polarization Horn Antenna VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna

VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna VIEW MOREConical Linear Polarization Horn Antenna

VIEW MOREConical Linear Polarization Horn Antenna VIEW MOREPlanar Spiral Antenna

VIEW MOREPlanar Spiral Antenna