Achieve Optimal RF Alignment with Custom Double-bend Waveguide Solutions

In modern microwave and RF systems, engineers frequently encounter a critical challenge: how to route electromagnetic signals through complex, space-constrained environments without compromising signal integrity or system performance. When traditional straight waveguides simply cannot accommodate the physical layout requirements of satellite ground stations, radar installations, or telecommunications infrastructure, signal degradation, increased reflection losses, and misalignment issues become inevitable obstacles. The Double-bend Waveguide emerges as the engineered solution to these persistent problems, offering a sophisticated approach to achieving optimal RF alignment while maintaining minimal insertion loss and superior signal quality. This article explores how custom Double-bend Waveguide solutions address real-world routing challenges and enable engineers to design more efficient, reliable microwave systems.

Understanding Double-bend Waveguide Technology and Its Critical Role in RF Systems

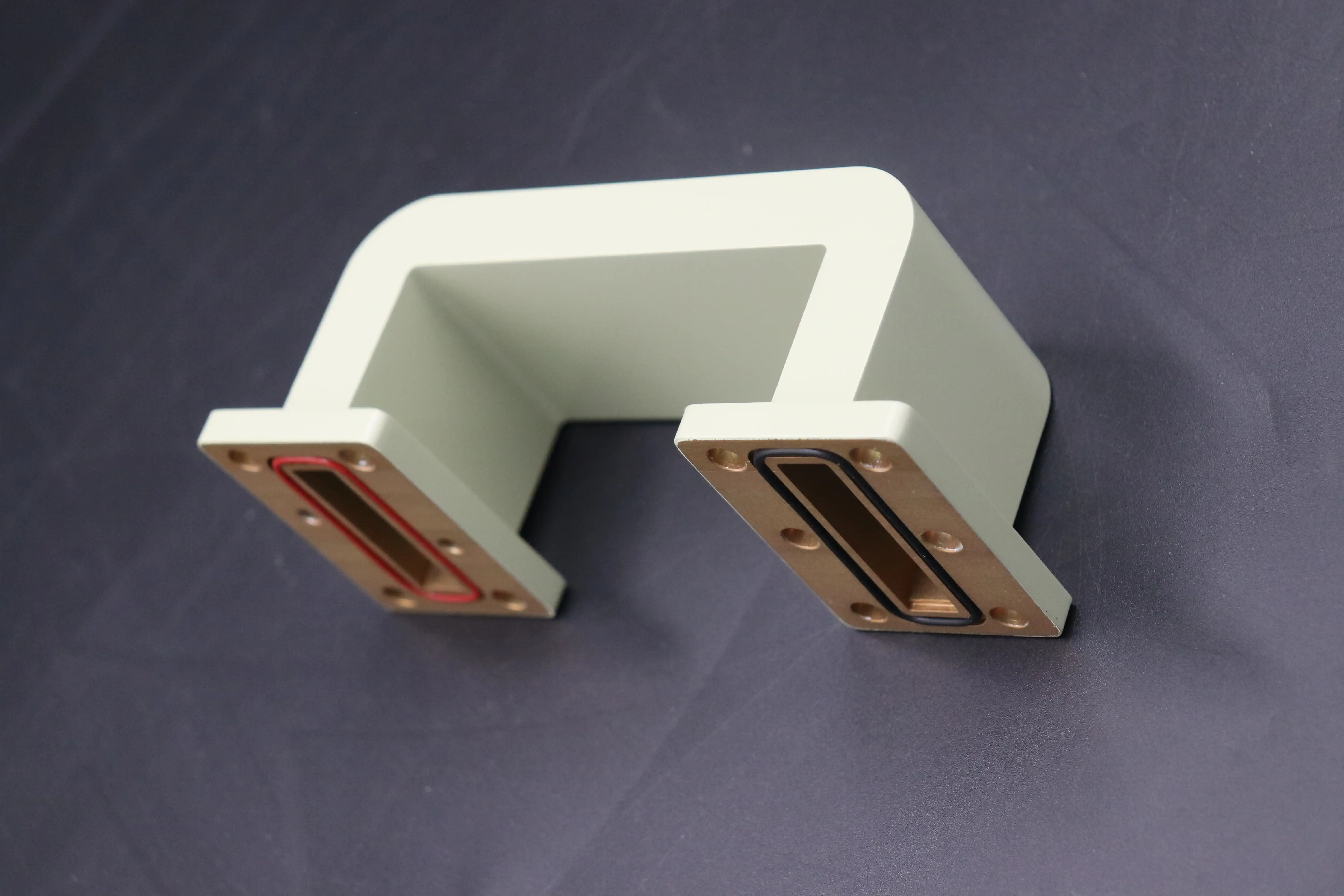

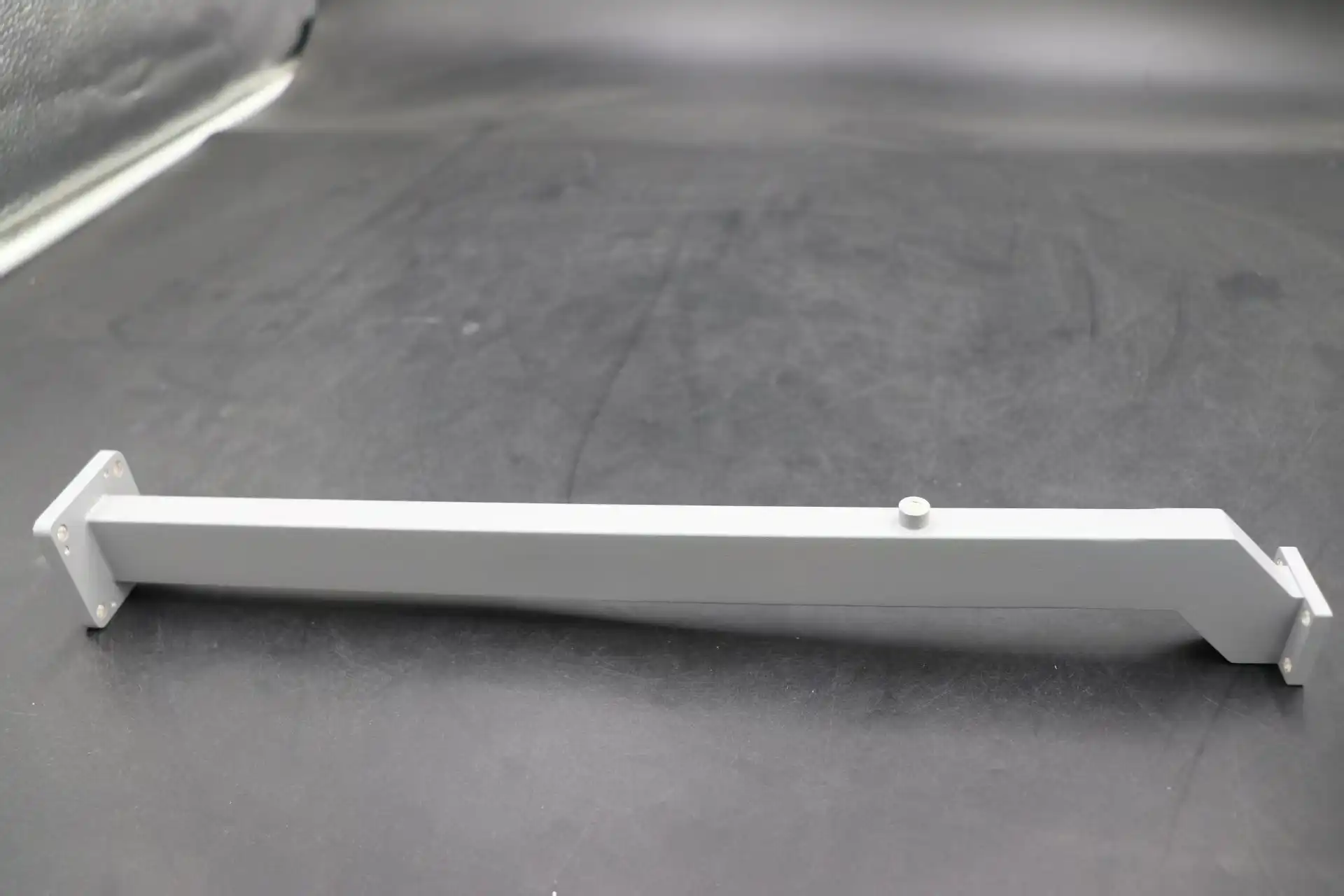

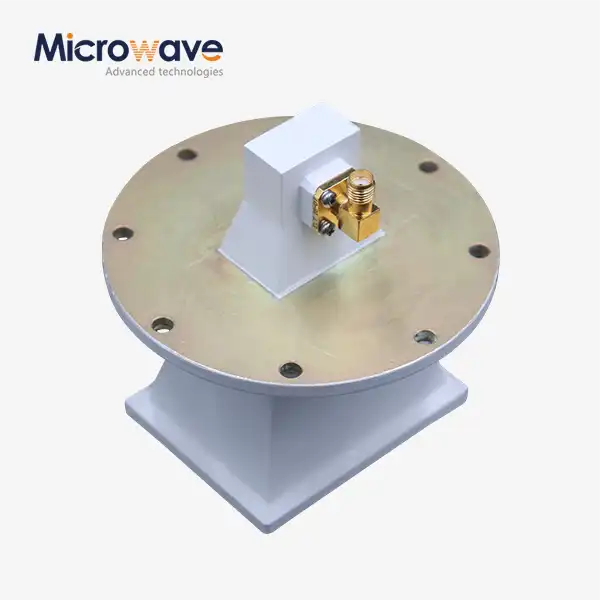

The Double-bend Waveguide represents a specialized microwave transmission component engineered with two precisely calculated bends that enable signal routing through complex spatial configurations. Unlike conventional straight waveguides that demand direct line-of-sight paths between components, the Double-bend Waveguide architecture provides engineers with the flexibility to navigate around physical obstacles, accommodate tight installation spaces, and maintain proper RF alignment in challenging environments. This technology proves indispensable in applications ranging from shipboard communication systems where space is at a premium, to large-scale satellite ground stations requiring precise antenna feed networks. Advanced Microwave's Double-bend Waveguide represents a high-performance component specifically designed to meet the demanding requirements of modern microwave and millimeter-wave applications. The fundamental design principle centers on minimizing signal reflection and transmission loss through carefully optimized bend geometry. Each bend angle, radius, and transition point undergoes rigorous electromagnetic simulation and testing to ensure that the waveguide maintains consistent impedance characteristics throughout the entire signal path. The layout design maximizes the reduction of signal reflection through precise mathematical modeling of the electromagnetic field distribution within the bent sections. Material selection plays an equally critical role in Double-bend Waveguide performance. Advanced Microwave manufactures these components using oxygen-free copper and other high-conductivity metals that provide superior electrical characteristics compared to standard materials. The interior surfaces undergo specialized polishing processes that minimize surface roughness to exceptionally low levels, directly reducing conductor losses and signal attenuation. This meticulous attention to material properties and surface finishing ensures that signals propagating through the Double-bend Waveguide experience minimal degradation, even across extended frequency ranges and demanding operational conditions.

Key Design Features That Differentiate High-Performance Double-bend Waveguides

The compact design architecture of the Double-bend Waveguide enables efficient space utilization that proves essential in modern system integration scenarios. The two-bend structure provides engineers with unprecedented flexibility in routing RF signals through areas with severe spatial constraints, such as equipment racks, antenna assemblies, or enclosed system housings. This space-saving capability becomes particularly valuable in aerospace applications, military communications systems, and commercial telecommunications infrastructure where every cubic centimeter of available space carries significant cost implications. Signal direction control represents another fundamental advantage of properly engineered Double-bend Waveguide systems. The bends direct electromagnetic waves along precisely defined paths, offering routing flexibility that straight waveguides simply cannot provide. Engineers can position system components based on optimal thermal management, maintenance accessibility, or mechanical mounting requirements rather than being constrained by rigid transmission line geometries. This flexibility accelerates system design cycles, reduces integration complexity, and enables more efficient use of available installation volume. Beyond spatial considerations, well-designed Double-bend Waveguides achieve remarkably low signal attenuation through the careful optimization of bend radius, wall thickness, and transition geometry. Advanced electromagnetic modeling techniques allow engineers to predict and minimize losses before physical fabrication, resulting in components that maintain excellent transmission efficiency. The reduction of external electromagnetic interference constitutes an additional benefit, as the bending structure naturally confines the propagating fields within the waveguide boundaries, minimizing unwanted coupling to adjacent components or external radiation that could compromise system performance or regulatory compliance.

Technical Specifications and Performance Characteristics of Advanced Double-bend Waveguide Solutions

Advanced Microwave's product line demonstrates the level of precision achievable in modern Double-bend Waveguide manufacturing. The model ADM-HT180WEEB12.34X49.58X6.12T1 exemplifies the company's engineering capabilities, operating across the frequency range of 19.2 to 21.2 GHz with exceptional performance metrics. This frequency band encompasses critical applications in satellite communications, radar systems, and wireless infrastructure, making the component valuable across multiple industries and deployment scenarios. The voltage standing wave ratio specification of 1.1 maximum represents an outstanding achievement in impedance matching and reflection control. This low VSWR ensures that minimal signal power reflects back toward the source, maximizing forward power transfer and system efficiency. In high-power transmission applications, excellent VSWR performance becomes critical for preventing thermal damage to transmitter components and maintaining stable operation under varying load conditions. The specification demonstrates Advanced Microwave's capability to design and manufacture Double-bend Waveguide components that maintain consistent impedance characteristics through complex bend geometries. Insertion loss performance of 0.1 dB maximum further underscores the quality of these precision components. Such minimal loss figures indicate exceptionally low conductor losses and negligible reflection effects across the entire operating bandwidth. For system designers, this translates to longer transmission distances, reduced amplifier requirements, and improved overall link budgets. The combination of low VSWR and minimal insertion loss enables engineers to confidently incorporate these Double-bend Waveguide components into demanding applications without compromising system performance margins.

Material Selection and Manufacturing Excellence in Double-bend Waveguide Production

The choice of aluminum as the primary structural material for many Double-bend Waveguide products reflects careful consideration of electrical performance, mechanical properties, weight constraints, and cost effectiveness. Aluminum alloys provide excellent electrical conductivity when properly processed, while offering significant weight advantages compared to copper or brass alternatives. This becomes particularly important in aerospace applications, satellite systems, and portable equipment where mass budgets impose strict limitations. The gold plating finish applied to interior waveguide surfaces represents a premium treatment that delivers multiple performance benefits. Gold's exceptional electrical conductivity surpasses that of aluminum, reducing conductor losses to absolute minimum levels. The noble metal properties of gold provide superior oxidation resistance, ensuring stable long-term performance even in harsh environmental conditions involving temperature extremes, humidity, or corrosive atmospheres. This surface treatment proves especially valuable in defense applications, marine systems, and outdoor installations where environmental exposure could otherwise degrade component performance over operational lifetimes spanning decades. Manufacturing precision determines the ultimate performance achievable from Double-bend Waveguide designs. Advanced Microwave employs computer-numerical-control machining centers with exceptional dimensional tolerances to fabricate waveguide components that precisely match electromagnetic design specifications. The company's quality control processes include comprehensive dimensional verification, surface finish measurement, and electrical performance testing to ensure every component meets or exceeds published specifications before shipment to customers.

Comprehensive Applications Across Critical Industries and Technology Sectors

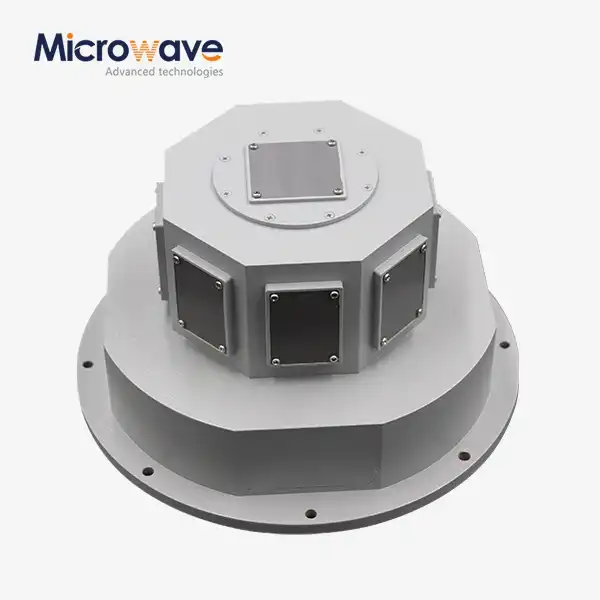

Microwave communication systems represent the primary application domain for Double-bend Waveguide technology. In radar installations, these components enable flexible antenna feed configurations that optimize coverage patterns and detection performance. Satellite ground stations utilize Double-bend Waveguides to route signals between precision tracking antennas and receiver systems while accommodating the mechanical constraints of antenna pedestals and equipment shelters. Wireless communication infrastructure increasingly depends on millimeter-wave frequencies where waveguide transmission offers superior performance compared to coaxial cables, and the routing flexibility of Double-bend Waveguide components facilitates efficient base station and backhaul network designs. Optical communication applications leverage Double-bend Waveguide principles in fiber-optic systems and integrated photonic circuits. Although fabricated using different materials and processes than microwave waveguides, the fundamental physics of guided wave propagation through bent structures remains analogous. Photonic integrated circuits employ waveguide bends to route optical signals through complex chip-level architectures, enabling advanced signal processing functions in compact form factors. The design methodologies developed for microwave Double-bend Waveguides inform optical waveguide engineering, creating cross-domain knowledge transfer that accelerates innovation in both fields. Integrated circuit applications extend Double-bend Waveguide concepts into the realm of photonic and microelectromechanical systems where on-chip signal routing demands extreme miniaturization. These advanced implementations enable sophisticated functionality in telecommunications equipment, sensing platforms, and quantum computing systems. The ability to efficiently guide electromagnetic or optical energy through multiple bends on a chip-scale substrate opens possibilities for highly integrated system architectures that would be impossible using straight-line routing approaches.

Specialized Applications in Medical Technology and Scientific Instrumentation

Medical device manufacturers incorporate Double-bend Waveguide technology into endoscopic systems and therapeutic equipment where flexible signal delivery through tortuous anatomical pathways becomes necessary. Fiber-optic endoscopes use optical waveguide bundles with multiple bends to illuminate internal body cavities and capture diagnostic images. Laser-based surgical systems employ similar waveguide routing techniques to deliver therapeutic energy precisely to target tissues while navigating the complex three-dimensional spaces within the human body. Laser system applications benefit from Double-bend Waveguide components that shape and route high-power coherent beams through processing stations, measurement equipment, or target delivery systems. Industrial laser cutting and welding installations use waveguide-based beam delivery systems that provide superior power handling and beam quality compared to alternative approaches. Scientific research facilities employ precision waveguide components in spectroscopy systems, materials characterization equipment, and fundamental physics experiments where signal integrity and measurement accuracy represent paramount concerns. Antenna system implementations utilize Double-bend Waveguide components to create efficient feed networks that distribute transmitted power or combine received signals from multiple radiating elements. Phased array antennas in radar and communications applications require complex feed networks with precise amplitude and phase characteristics across all elements. Double-bend Waveguides enable designers to implement these feed networks in physically compact configurations while maintaining the electrical performance necessary for proper array operation. The resulting systems achieve improved radiation patterns, enhanced directional coverage, and superior interference rejection compared to designs using less sophisticated feed architectures.

OEM Customization Services and Engineering Support from Advanced Microwave Technologies

Advanced Microwave Technologies Co., Ltd. provides comprehensive OEM services that enable customers to obtain Double-bend Waveguide solutions precisely tailored to their specific application requirements. The customization process begins with detailed consultation to understand the customer's technical specifications, operating environment, physical constraints, and performance objectives. Advanced Microwave's engineering team analyzes these requirements and develops preliminary designs that balance electrical performance, mechanical feasibility, and cost effectiveness to deliver optimal value. Custom design capabilities encompass all aspects of Double-bend Waveguide engineering, including frequency band selection, power handling requirements, physical dimensions, mounting interfaces, and environmental protection specifications. The company's advanced electromagnetic simulation tools enable accurate prediction of component performance before physical fabrication, reducing development risk and accelerating time to market. Engineers can explore multiple design alternatives, optimize critical parameters, and validate performance against customer specifications through virtual prototyping before committing to expensive tooling and production processes. Prototype development services provide customers with functional samples for evaluation, testing, and system integration validation. Advanced Microwave's rapid prototyping capabilities enable quick turnaround on initial units, allowing customers to verify fit, form, and function early in the development cycle. This iterative approach identifies potential issues before volume production, reducing the risk of costly design changes or performance shortfalls discovered late in the project timeline.

Material Selection Expertise and Manufacturing Precision for Custom Applications

Expert material selection represents a critical component of successful Double-bend Waveguide customization. Advanced Microwave's materials engineers possess deep knowledge of conductor properties, surface finish treatments, environmental resistance characteristics, and cost-performance tradeoffs across a wide range of metals and alloys. They guide customers toward optimal material choices that meet technical requirements while respecting budget constraints and production schedules. Whether the application demands lightweight aluminum for aerospace use, high-conductivity copper for maximum electrical performance, or exotic alloys for extreme temperature environments, the company can accommodate diverse material specifications. Precision manufacturing capabilities enable Advanced Microwave to fabricate Double-bend Waveguide components with the tight dimensional tolerances necessary for proper electromagnetic performance. The company's production facilities employ advanced CNC machining centers, specialized waveguide forming equipment, and automated measurement systems that ensure consistent quality across production quantities. Rigorous process controls and in-process inspection procedures catch potential defects early, minimizing scrap rates and ensuring that delivered components meet all specified requirements. Comprehensive testing protocols validate both mechanical and electrical characteristics of custom Double-bend Waveguide products. Dimensional verification confirms that physical parameters match design specifications within required tolerances. Electrical testing using vector network analyzers characterizes insertion loss, return loss, and phase response across the full operating frequency range. Environmental testing subjects components to temperature cycling, humidity exposure, vibration, and other conditions representative of actual operating environments. This thorough validation provides customers with confidence that components will perform reliably throughout their intended service life.

Integration Support and Production Scalability for Volume Applications

Integration into larger system assemblies often requires coordination between waveguide components and adjacent equipment, mounting structures, or transmission line networks. Advanced Microwave's applications engineering team provides technical support to ensure seamless integration of Double-bend Waveguide components into customer systems. This assistance may include interface compatibility verification, installation procedure development, thermal analysis, or troubleshooting of unexpected performance issues discovered during system-level testing. Mass production capabilities enable Advanced Microwave to scale from prototype quantities to high-volume manufacturing as customer programs mature from development through full-rate production. The company's production planning systems coordinate material procurement, manufacturing operations, quality assurance activities, and logistics to deliver components on schedule at competitive pricing. Customers benefit from consistent quality and performance across production lots, supported by comprehensive documentation and traceability systems that facilitate configuration management and quality audits. Post-production support ensures customer success throughout the product lifecycle. Advanced Microwave provides technical assistance for installation questions, performance optimization, or troubleshooting of field issues that may arise during equipment deployment or operation. The company maintains detailed production records that enable root cause analysis if quality concerns emerge, and can provide replacement components or engineering changes to address identified issues. This commitment to customer support extends beyond the initial sale to create lasting partnerships that support ongoing business success.

Conclusion

Custom Double-bend Waveguide solutions from Advanced Microwave Technologies deliver the performance, flexibility, and reliability that modern RF systems demand, enabling engineers to overcome spatial constraints while maintaining exceptional signal integrity.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands as your trusted China Double-bend Waveguide factory, China Double-bend Waveguide supplier, and China Double-bend Waveguide manufacturer, offering competitive Double-bend Waveguide wholesale pricing and premium Double-bend Waveguide for sale. Our High Quality Double-bend Waveguide products, supported by ISO certifications and over 20 years of manufacturing excellence, deliver the Double-bend Waveguide price advantages you need without compromising performance. With our state-of-the-art 24m Microwave Darkroom testing facility, experienced engineering team, and commitment to rapid prototyping and volume production, we provide end-to-end OEM services from initial design through post-production support. Whether you're developing next-generation satellite communications, defense systems, or telecommunications infrastructure, our technical expertise and quality assurance ensure your Double-bend Waveguide components exceed expectations. Contact craig@admicrowave.com today to discuss your specific requirements and discover how our customized solutions can optimize your RF system performance and accelerate your project timeline.

References

1. Pozar, David M. "Microwave Engineering, Fourth Edition." John Wiley & Sons, 2012. This comprehensive textbook covers fundamental waveguide theory, bend design principles, and electromagnetic propagation in complex geometries.

2. Balanis, Constantine A. "Advanced Engineering Electromagnetics, Second Edition." John Wiley & Sons, 2012. Detailed treatment of electromagnetic field analysis in waveguiding structures including bent and curved configurations.

3. Collin, Robert E. "Foundations for Microwave Engineering, Second Edition." IEEE Press, 2001. Authoritative reference on transmission line theory, impedance matching, and waveguide component design.

4. Saad, Theodore S. "Microwave Engineers' Handbook, Volumes 1 and 2." Artech House, 1971. Classic industry reference containing practical design data for waveguide bends, transitions, and custom assemblies.

YOU MAY LIKE

VIEW MORESlotted Waveguide Array Antenna

VIEW MORESlotted Waveguide Array Antenna VIEW MOREConical Circular Polarization Horn Antenna

VIEW MOREConical Circular Polarization Horn Antenna VIEW MORELadder Membrane Square Dual Circular Polarization Horn Antenna

VIEW MORELadder Membrane Square Dual Circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Circular Polarization Horn Antenna VIEW MOREPyramidal Linear Polarization Horn Antenna

VIEW MOREPyramidal Linear Polarization Horn Antenna VIEW MORELow Side Lobe Diagonal Linear Polarization Horn Antenna

VIEW MORELow Side Lobe Diagonal Linear Polarization Horn Antenna VIEW MOREQuadrifilar Helix Antenna

VIEW MOREQuadrifilar Helix Antenna VIEW MORECassegrain Antenna

VIEW MORECassegrain Antenna