Waveguide High Power Fixed Attenuator Suppliers & Factory

When your high-frequency communication system experiences signal overload, unpredictable power fluctuations, or equipment damage from excessive signal strength, finding reliable Waveguide Fixed Attenuator solutions becomes critical. Whether you're managing satellite ground stations, military radar installations, or advanced telecommunications infrastructure, the right supplier can mean the difference between system failure and flawless performance. This comprehensive guide explores how to identify trustworthy Waveguide High Power Fixed Attenuator suppliers and factories, what technical specifications matter most, and how to ensure you're partnering with manufacturers who deliver precision-engineered components that protect your mission-critical systems.

Understanding Waveguide Fixed Attenuator Technology

The Critical Role of Signal Control in High-Power Applications

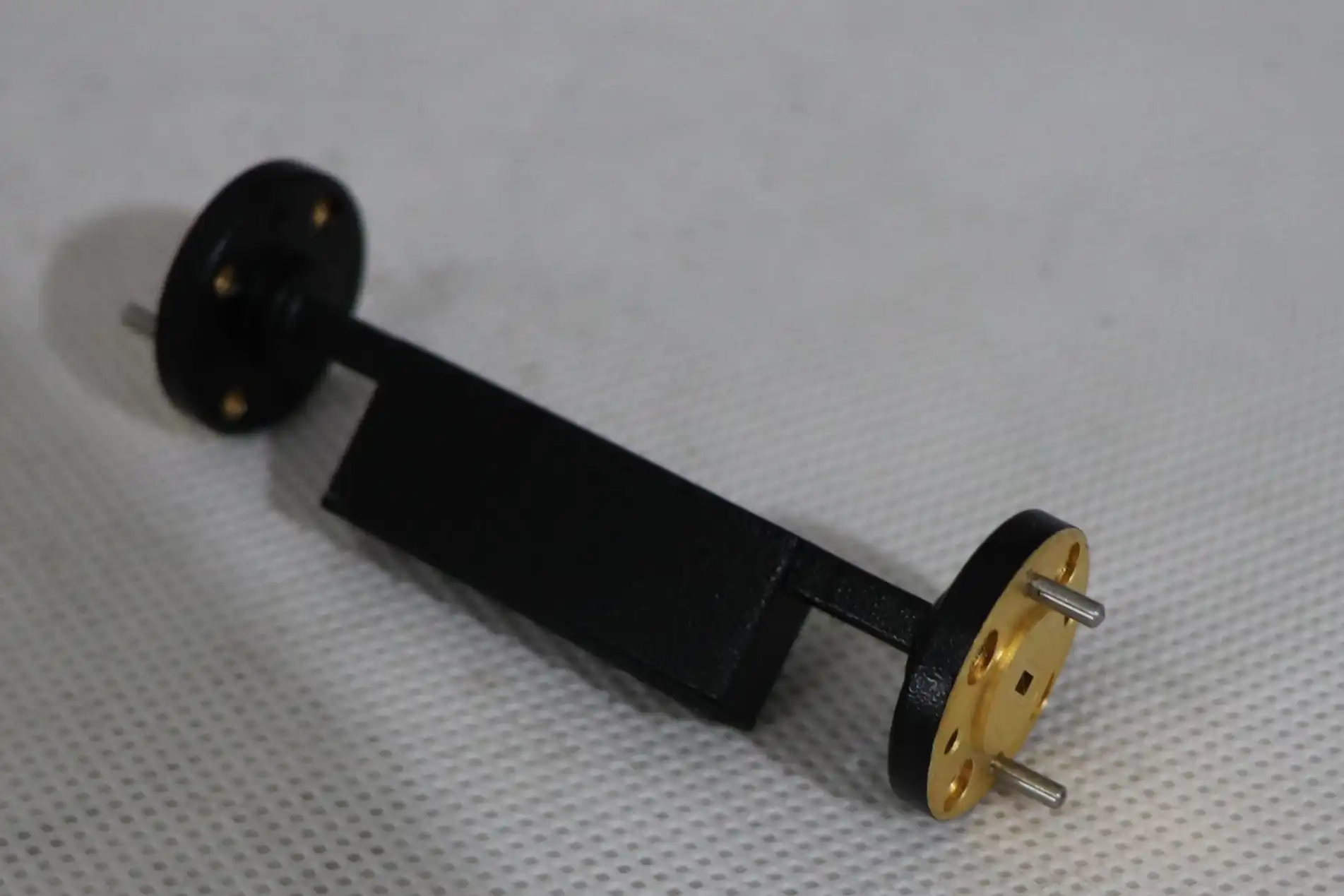

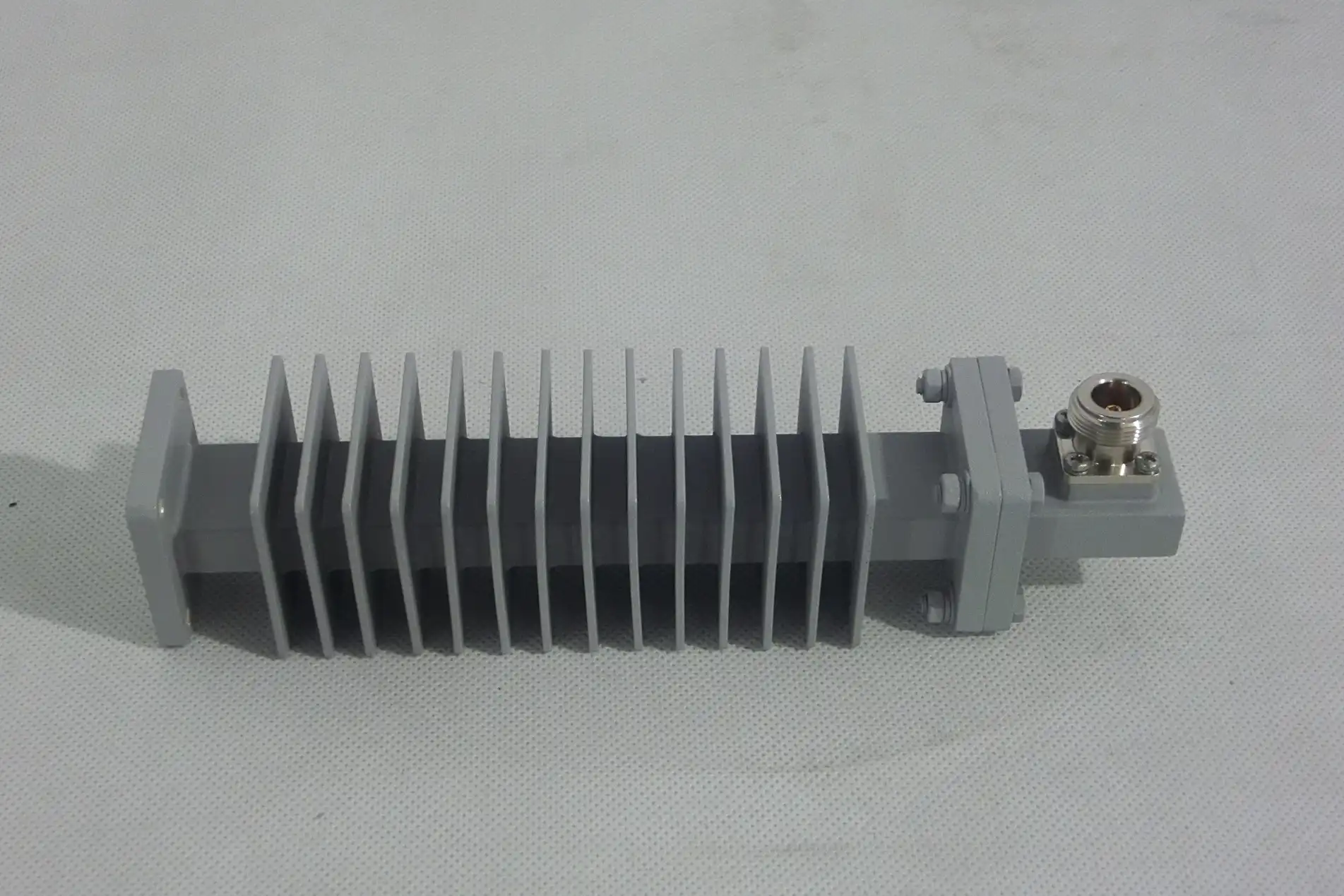

In modern microwave and millimeter-wave systems, managing signal power levels is not merely a technical preference but an operational necessity. Waveguide Fixed Attenuator components serve as the gatekeepers of signal integrity, precisely reducing power levels to prevent receiver saturation, equipment damage, and signal distortion. Unlike variable attenuators that offer adjustable settings, fixed attenuators provide consistent, predictable attenuation values that remain stable across varying environmental conditions and frequency ranges. This reliability makes them indispensable in applications where signal consistency directly impacts safety and performance, such as aircraft navigation systems, missile guidance radar, and satellite communication uplinks. The engineering principles behind waveguide fixed attenuators involve carefully designed resistive elements positioned within the waveguide structure to absorb electromagnetic energy. High-power units must dissipate substantial thermal energy without degrading performance, requiring advanced materials and thermal management designs. Quality manufacturers employ precision-machined housings with excellent thermal conductivity, specialized resistive films with stable temperature coefficients, and rigorous testing protocols to ensure each unit meets specified attenuation values across the entire operating frequency range. When evaluating suppliers, understanding these technical fundamentals helps distinguish between basic commercial-grade components and professional-grade solutions suitable for demanding applications.

Key Technical Specifications That Define Quality

When sourcing Waveguide Fixed Attenuator products from suppliers and factories, several technical parameters separate exceptional performers from mediocre alternatives. Attenuation accuracy typically ranges from ±0.5dB to ±1.0dB depending on the attenuation value and frequency band, with tighter tolerances commanding premium prices but delivering superior system performance. Frequency sensitivity, which measures how attenuation varies across the operating bandwidth, should remain within ±0.7dB for most precision applications. Voltage Standing Wave Ratio (VSWR) serves as a critical indicator of impedance matching quality, with values below 1.15:1 considered excellent and minimizing signal reflections that could compromise system efficiency. Power handling capability distinguishes standard Waveguide Fixed Attenuator units from high-power variants. While conventional models typically handle 1-5 watts of continuous wave power, high-power attenuators designed for broadcast transmitters, radar systems, and industrial heating applications can safely dissipate 40 watts or more without performance degradation. This capability depends on the physical size of the attenuator, the thermal conductivity of housing materials (brass versus aluminum), surface treatments like silver plating, and the design of the resistive element itself. Operating temperature range, insertion loss beyond the specified attenuation, and long-term stability under continuous operation further differentiate professional-grade components from consumer alternatives.

Evaluating Waveguide Fixed Attenuator Suppliers and Manufacturers

Manufacturing Capabilities and Quality Assurance

Identifying reliable China Waveguide Fixed Attenuator factory operations or established global manufacturers requires careful evaluation of their production capabilities and quality management systems. ISO 9001:2015 certification provides baseline assurance that quality management procedures govern all aspects of production, from incoming material inspection through final testing and packaging. However, truly exceptional manufacturers go beyond basic certification, implementing advanced quality control measures including statistical process control, automated optical inspection, and 100% electrical testing of finished units. Look for suppliers equipped with vector network analyzers, spectrum analyzers, and calibrated power meters traceable to national standards, enabling them to provide detailed test reports documenting each unit's performance characteristics. Manufacturing infrastructure directly impacts product consistency and customization capability. State-of-the-art facilities feature computer numerical control (CNC) machining centers capable of maintaining tolerances within microns, essential for waveguide components where dimensional accuracy directly affects electrical performance. Advanced surface finishing capabilities including electroless nickel plating, gold plating, and passivation ensure corrosion resistance and long-term reliability in harsh environmental conditions. Suppliers with in-house engineering teams can provide custom Waveguide Fixed Attenuator designs tailored to unique frequency bands, power levels, or mechanical configurations, while those merely reselling off-the-shelf components offer limited flexibility for specialized applications.

Global Supply Chain and Delivery Performance

In today's interconnected marketplace, evaluating China Waveguide Fixed Attenuator supplier credentials extends beyond manufacturing quality to encompass supply chain reliability and international logistics capabilities. Established suppliers maintain relationships with multiple raw material sources, ensuring component availability even during global supply chain disruptions. They invest in inventory management systems that balance stock levels against demand forecasts, enabling rapid fulfillment of standard configurations while maintaining flexibility for custom orders. Lead times for standard Waveguide Fixed Attenuator products typically range from two to four weeks, while custom designs may require six to eight weeks depending on complexity and testing requirements. Export documentation expertise proves critical when sourcing from international manufacturers. Competent China Waveguide Fixed Attenuator wholesale suppliers navigate customs regulations, provide proper certificates of origin, handle export licenses for items with potential defense applications, and ensure products comply with destination country regulations including RoHS, REACH, and conflict minerals declarations. They offer multiple shipping options balancing cost against urgency, from economical sea freight for large volume orders to express air courier for prototype deliveries and urgent replacements. Responsive communication across time zones, multilingual technical support, and willingness to accommodate special packaging or labeling requirements further distinguish professional international suppliers from opportunistic trading companies.

Product Applications and Industry-Specific Solutions

Aerospace and Defense Applications

Military and aerospace systems impose the most stringent requirements on Waveguide Fixed Attenuator performance, where component failure can jeopardize missions and endanger personnel. Air traffic control radar systems utilize fixed attenuators to protect sensitive receiver components from the intense pulses generated by high-power magnetron transmitters, while enabling precise calibration of receiver gain for accurate target detection. These applications demand attenuators capable of handling peak power levels exceeding kilowatts in microsecond pulses, requiring robust construction with excellent thermal management and minimal passive intermodulation distortion that could generate false targets. Satellite communication systems, both military and commercial, depend on Waveguide Fixed Attenuator components throughout ground station infrastructure. In transmit chains, attenuators enable precise power level adjustment to prevent uplink signal saturation during atmospheric attenuation variations. On receive paths, they protect low-noise amplifiers from damage during maintenance activities or antenna testing procedures. The extreme temperature ranges encountered in outdoor installations, from Arctic cold to desert heat, demand attenuators with stable performance across -40°C to +85°C operating temperatures. Suppliers serving aerospace and defense markets typically maintain additional certifications such as AS9100D, participate in trusted supplier programs, and implement rigorous configuration management to ensure traceability and quality throughout product lifecycles.

Telecommunications and Research Applications

Modern 5G telecommunications infrastructure relies heavily on millimeter-wave frequencies where Waveguide Fixed Attenuator technology provides advantages over coaxial alternatives in terms of power handling and insertion loss. Base station testing facilities employ fixed attenuators to simulate various signal conditions during equipment validation, while network operators use them for calibrating measurement equipment and characterizing antenna performance. The push toward even higher frequencies for 6G research, potentially extending to 110 GHz and beyond, creates demand for precision attenuators operating in these challenging frequency bands where dimensional tolerances become increasingly critical and even minor manufacturing variations can significantly impact electrical performance. Research laboratories conducting fundamental microwave and millimeter-wave investigations require Waveguide Fixed Attenuator components with exceptional accuracy and repeatability. Physics experiments exploring atmospheric propagation, radio astronomy observations, and materials characterization studies all benefit from attenuators that introduce known, stable signal reductions without adding noise or distortion. Academic and commercial research institutions value suppliers who understand experimental requirements, provide detailed technical documentation including scattering parameters across frequency, and support custom configurations for specialized measurement setups. The ability to calibrate attenuators at precise frequencies of interest, rather than just across broad bands, proves especially valuable for applications requiring maximum measurement accuracy.

Selecting the Right Manufacturing Partner

OEM Services and Customization Capabilities

Forward-thinking organizations recognize that standard catalog Waveguide Fixed Attenuator products cannot address every application requirement. Partnering with China Waveguide Fixed Attenuator manufacturer operations offering comprehensive OEM services enables development of optimized solutions tailored to specific system architectures. Customization options span mechanical dimensions to accommodate space-constrained installations, alternative flange types for compatibility with existing waveguide infrastructure, non-standard attenuation values addressing unique signal level requirements, and specialized environmental sealing for harsh outdoor or marine applications. The best manufacturing partners engage collaboratively during the design phase, offering engineering expertise to optimize performance while managing cost and schedule constraints. Rapid prototyping capabilities accelerate development cycles for systems incorporating custom Waveguide Fixed Attenuator designs. Manufacturers equipped with additive manufacturing technologies can produce prototype housings within days, enabling early-stage testing and design validation before committing to production tooling. They provide engineering samples with preliminary testing to verify electrical performance meets specifications, supporting iterative refinement until optimal results are achieved. Once designs are finalized, efficient manufacturing processes enable production scaling from pilot quantities through full-rate manufacturing, maintaining consistent quality throughout. Technical support extends beyond delivery, with experienced application engineers available to assist with installation, provide troubleshooting guidance, and recommend complementary components for complete system integration.

Price Considerations and Total Cost of Ownership

While Waveguide Fixed Attenuator price represents an obvious procurement consideration, sophisticated buyers evaluate total cost of ownership rather than focusing solely on unit cost. High-quality components from established China Waveguide Fixed Attenuator supplier operations may command premium initial pricing but deliver superior long-term value through extended operational lifetimes, reduced failure rates, and minimal performance drift requiring recalibration or replacement. Conversely, bargain-priced units from questionable sources often exhibit poor quality control, leading to high failure rates, system downtime, and expensive emergency replacements. When budget permits, specifying High Quality Waveguide Fixed Attenuator products from reputable manufacturers proves economically advantageous over multi-year ownership periods. Volume pricing structures vary significantly among suppliers, with some offering aggressive discounts for large quantity orders while others maintain relatively flat pricing regardless of volume. For projects requiring substantial quantities, requesting formal quotations detailing price breaks at various volume tiers enables accurate budgeting and identification of optimal order quantities balancing inventory carrying costs against per-unit savings. Beyond unit pricing, consider the total landed cost including international shipping, customs duties, and any special handling requirements. Suppliers offering consolidated shipping across product lines, managing export documentation, and providing flexible payment terms deliver additional value beyond the baseline component pricing.

Conclusion

Selecting the optimal Waveguide High Power Fixed Attenuator suppliers and factory partners requires balancing technical performance, quality assurance, customization capabilities, and commercial terms. By thoroughly evaluating manufacturing capabilities, supply chain reliability, and industry-specific expertise, procurement teams can identify partners capable of delivering precision-engineered components that ensure system performance and reliability.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands as a premier China Waveguide Fixed Attenuator supplier with over 20 years of proven expertise serving global aerospace, defense, telecommunications, and research markets. As a certified China Waveguide Fixed Attenuator manufacturer, we maintain ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications while operating advanced production facilities equipped with measurement capabilities extending to 110 GHz. Our comprehensive product portfolio includes standard catalog items available as Waveguide Fixed Attenuator for sale alongside fully customized OEM solutions tailored to your exact specifications. Whether you require High Quality Waveguide Fixed Attenuator components for satellite ground stations, radar systems, or research applications, our experienced engineering team delivers optimized designs manufactured to exacting tolerances. We offer competitive Waveguide Fixed Attenuator price structures for both prototype quantities and volume production, supported by efficient China Waveguide Fixed Attenuator wholesale programs and reliable global delivery. Contact us at craig@admicrowave.com today to discuss your requirements, request technical specifications, or receive a detailed quotation. Partner with Advanced Microwave Technologies Co., Ltd. where precision engineering meets responsive service for all your waveguide component needs.

References

1. Pozar, David M. "Microwave Engineering (Fourth Edition)." John Wiley & Sons, 2012.

2. Collin, Robert E. "Foundations for Microwave Engineering (Second Edition)." IEEE Press, 2001.

3. Saad, Theodore S. "Microwave Engineers' Handbook (Volumes 1 & 2)." Artech House, 1971.

4. Montgomery, C. George; Dicke, Robert H.; Purcell, Edward M. "Principles of Microwave Circuits." McGraw-Hill Book Company, 1948.

YOU MAY LIKE

VIEW MOREAc Power Amplifier

VIEW MOREAc Power Amplifier VIEW MOREVoltage Controlled Phase Shifter

VIEW MOREVoltage Controlled Phase Shifter VIEW MOREStandard Horn Antenna

VIEW MOREStandard Horn Antenna VIEW MOREConical Horn Lens Antenna

VIEW MOREConical Horn Lens Antenna VIEW MOREPoint Focusing Horn Lens Antenna

VIEW MOREPoint Focusing Horn Lens Antenna VIEW MORECorrugated Horn and Multimode Horn Antenna

VIEW MORECorrugated Horn and Multimode Horn Antenna VIEW MOREWideband Double-ridged Horn Antenna

VIEW MOREWideband Double-ridged Horn Antenna VIEW MOREMini Wideband Double-ridged Horn Antenna

VIEW MOREMini Wideband Double-ridged Horn Antenna