How Does a Double Ridge Waveguide Load Achieve VSWR Below 1.05?

In critical microwave applications where signal integrity determines mission success or failure, engineers face a persistent challenge: achieving ultra-low VSWR performance that prevents costly signal reflections and system failures. The Double Ridge Waveguide Load emerges as the definitive solution, utilizing precision conical load elements and advanced geometrical designs to achieve remarkable VSWR performance below 1.05 across the full waveguide bandwidth. This exceptional performance level represents a breakthrough in microwave termination technology, addressing the fundamental pain point of reflection-induced system degradation that has plagued high-frequency applications in satellite communications, aerospace defense systems, and precision measurement equipment.

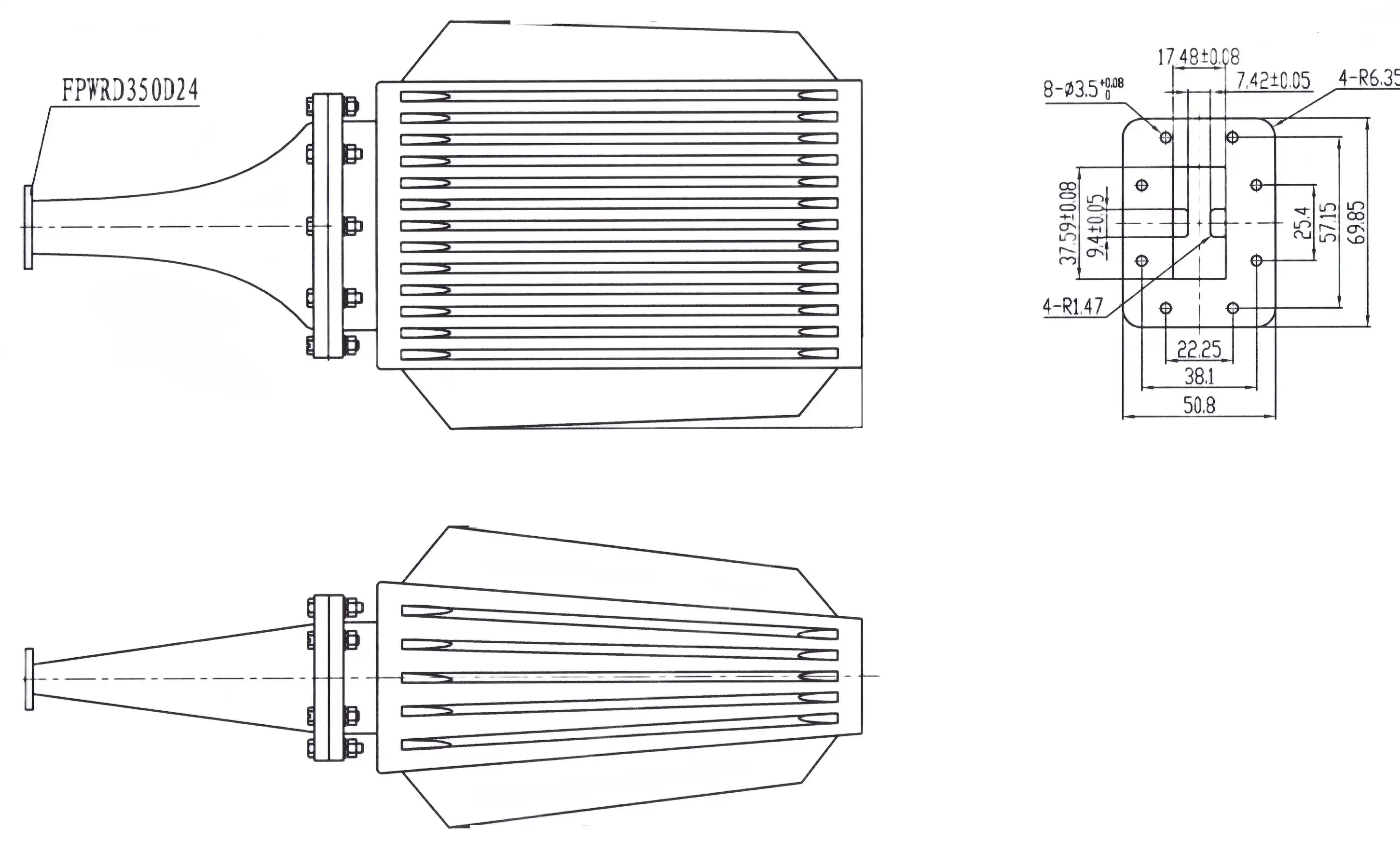

Understanding Double Ridge Waveguide Load Architecture

The foundation of achieving VSWR below 1.05 lies in the sophisticated architectural design of the Double Ridge Waveguide Load. Unlike conventional waveguide terminations that rely on simple absorptive materials, these advanced components incorporate precision-engineered conical load elements that create a gradual impedance transition from the characteristic impedance of the waveguide to the resistive load impedance. This gradual transition is critical for minimizing reflections, as abrupt impedance changes are the primary source of unwanted reflections in microwave systems. The double ridge geometry itself plays a fundamental role in achieving superior VSWR performance. The ridges create a controlled electric field distribution that enables better impedance matching across a broader frequency range. Advanced Microwave Technologies' standard product line utilizes this principle, with precision conical load elements specifically designed for optimum electrical performance. The geometric parameters of these ridges, including their height, width, and taper angles, are carefully optimized through electromagnetic simulation and validated in advanced measurement facilities to ensure consistent VSWR performance below 1.05.

Material Engineering for Optimal Absorption

The material composition of the Double Ridge Waveguide Load directly impacts its ability to achieve ultra-low VSWR performance. High-quality metals form the waveguide structure, providing excellent conductivity and thermal stability, while specialized absorptive materials are strategically positioned to dissipate microwave energy without creating significant impedance discontinuities. The selection and placement of these materials undergo rigorous testing to ensure they maintain their electrical properties across the entire operating frequency range of 2.6 GHz to 110 GHz. Advanced manufacturing techniques enable the creation of load elements with precisely controlled surface roughness and dimensional tolerances. These factors are crucial because even minor variations in geometry can create impedance mismatches that degrade VSWR performance. The manufacturing process involves multiple quality control checkpoints, ensuring that each Double Ridge Waveguide Load meets the stringent specifications required for VSWR performance below 1.05.

Precision Conical Load Element Design

The heart of achieving VSWR below 1.05 lies in the precision conical load element design that forms the core of high-performance Double Ridge Waveguide Loads. These elements utilize a carefully engineered taper geometry that creates a smooth impedance transformation from the waveguide's characteristic impedance to the terminating load resistance. The conical shape provides a gradual transition that minimizes reflection coefficients across the entire operational bandwidth, ensuring consistent VSWR performance that remains well below the 1.05 threshold. The geometric parameters of the conical load element are determined through advanced electromagnetic modeling and optimization algorithms. Engineers analyze the electric and magnetic field distributions within the waveguide structure, adjusting the cone angle, length, and material properties to achieve optimal impedance matching. This process requires sophisticated simulation tools and extensive validation testing to ensure that the theoretical performance translates into real-world applications where environmental factors and manufacturing tolerances can impact performance.

Advanced Manufacturing Techniques

Manufacturing precision conical load elements requires specialized machining capabilities and quality control processes. Advanced CNC machining centers equipped with high-precision tooling create the complex geometries with tolerances measured in micrometers. Surface finish quality becomes critical, as rough surfaces can create scattering centers that degrade VSWR performance. Advanced Microwave Technologies employs state-of-the-art manufacturing facilities with environmental controls that maintain stable temperatures and humidity levels during the machining process. Quality assurance protocols include dimensional verification using coordinate measuring machines, surface roughness analysis, and electrical performance testing. Each precision conical load element undergoes comprehensive testing in controlled laboratory environments before assembly into the final Double Ridge Waveguide Load configuration. This rigorous approach ensures that every component meets the exacting standards required for VSWR performance below 1.05.

Frequency Range Optimization and Performance Characteristics

Achieving VSWR below 1.05 across the broad frequency range from 2.6 GHz to 110 GHz presents unique engineering challenges that require innovative design approaches. The Double Ridge Waveguide Load must maintain consistent impedance characteristics across this extensive bandwidth while accommodating the varying propagation modes and field distributions that occur at different frequencies. Advanced design techniques utilize multi-section impedance transformers and carefully shaped absorptive elements to create a frequency-independent termination that performs reliably across the entire operational spectrum. The wide frequency range operation of the Double Ridge Waveguide Load demonstrates its versatility in supporting diverse applications from legacy communication systems operating at lower frequencies to cutting-edge 5G and future 6G technologies that utilize higher frequency bands. This broad compatibility makes it an essential component for system designers who need reliable performance across multiple frequency allocations without compromising VSWR specifications. The ability to maintain VSWR below 1.05 across such an extensive range represents a significant technological achievement that enables more efficient and reliable microwave systems.

Electromagnetic Field Management

Effective electromagnetic field management within the Double Ridge Waveguide Load structure is essential for achieving ultra-low VSWR performance. The double ridge geometry creates a controlled field distribution that enables better coupling between the propagating modes and the absorptive load elements. Advanced electromagnetic simulation tools analyze the field patterns and identify potential areas where reflections might occur, allowing engineers to optimize the geometry and material placement for minimal reflection characteristics. The field management strategy incorporates gradient matching techniques where the electromagnetic impedance gradually transitions from the waveguide characteristic impedance to the load impedance. This gradual transition prevents the formation of standing wave patterns that would increase VSWR values. The implementation of these techniques requires precise control over manufacturing tolerances and material properties to ensure that the theoretical performance predictions are realized in the final product.

Manufacturing Excellence and Quality Control

The achievement of VSWR below 1.05 in Double Ridge Waveguide Loads demands exceptional manufacturing precision and comprehensive quality control processes. Advanced Microwave Technologies employs ISO 9001:2015 certified manufacturing procedures that ensure consistent product quality and performance reliability. The manufacturing process begins with precise material selection, where high-quality metals and specialized absorptive materials undergo rigorous incoming inspection to verify their electrical and mechanical properties meet specification requirements. Computer-controlled machining centers equipped with advanced tooling systems create the complex geometries required for optimal VSWR performance. The manufacturing process incorporates real-time monitoring systems that track dimensional accuracy and surface finish quality throughout production. Environmental controls maintain stable temperature and humidity conditions that prevent thermal expansion and material property variations that could impact final performance. This comprehensive approach to manufacturing excellence ensures that each Double Ridge Waveguide Load achieves the specified VSWR performance below 1.05.

Advanced Testing and Validation

Comprehensive testing protocols validate the VSWR performance of every Double Ridge Waveguide Load before shipment to customers. Advanced Microwave Technologies operates a sophisticated 24-meter microwave darkroom facility equipped with precision measurement equipment capable of characterizing performance up to 110 GHz. This state-of-the-art facility enables accurate far-field antenna measurements and comprehensive electromagnetic characterization that validates theoretical performance predictions. The testing process incorporates both near-field and far-field measurement techniques using the Antenna Plane Near and Far Field Measuring Recombination Chamber. This advanced measurement capability allows engineers to extract detailed information about radiation patterns, gain characteristics, and impedance parameters across the entire frequency range. The measurement data undergoes rigorous analysis to ensure that VSWR specifications are met with appropriate margins for manufacturing variations and environmental conditions.

Applications and Performance Benefits

Double Ridge Waveguide Loads achieving VSWR below 1.05 provide critical performance benefits in demanding applications across satellite communications, aerospace defense, radar systems, and precision measurement equipment. In satellite communication systems, the ultra-low VSWR performance ensures efficient power transfer and minimal signal degradation in both uplink and downlink configurations. The reliable termination characteristics prevent reflected power from damaging sensitive amplifier components and eliminate measurement uncertainties that could compromise system performance. Aerospace and defense applications particularly benefit from the exceptional VSWR performance, as mission-critical radar and navigation systems require the highest levels of signal integrity and measurement accuracy. The Double Ridge Waveguide Load's ability to maintain consistent performance across extreme environmental conditions makes it ideal for airborne and space-based applications where reliability cannot be compromised. Military surveillance radars utilize these components to achieve the detection sensitivity and target discrimination capabilities required for modern defense applications.

Telecommunications and Research Applications

The telecommunications industry relies on Double Ridge Waveguide Loads with VSWR below 1.05 for network testing, base station calibration, and communication system optimization. The exceptional performance characteristics enable accurate power measurements and system characterization that are essential for deploying reliable communication networks. Research institutions utilize these components in advanced measurement systems where precise calibration and minimal measurement uncertainty are required for breakthrough scientific investigations. Industrial applications including microwave testing laboratories benefit from the stable, repeatable performance characteristics that enable accurate device characterization and quality assurance testing. The ability to maintain VSWR specifications below 1.05 across extended temperature ranges and varying environmental conditions makes these components essential for production testing environments where consistent results are required for product certification and compliance verification.

Conclusion

The achievement of VSWR below 1.05 in Double Ridge Waveguide Loads represents a pinnacle of microwave engineering excellence, combining precision conical load element design, advanced manufacturing techniques, and comprehensive quality control processes. This exceptional performance level enables reliable operation in the most demanding applications across satellite communications, aerospace defense, and precision measurement systems, providing the signal integrity and measurement accuracy required for mission-critical applications.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a leading China Double Ridge Waveguide Load factory with over 20 years of experience, Advanced Microwave Technologies Co., Ltd. stands ready to support your most challenging microwave applications. Our ISO-certified facilities and advanced 24m Microwave Darkroom enable us to deliver High Quality Double Ridge Waveguide Load solutions that exceed industry standards. Whether you need standard configurations or custom OEM services, our expert engineering team provides comprehensive technical support from prototyping through production. As your trusted China Double Ridge Waveguide Load supplier and China Double Ridge Waveguide Load manufacturer, we offer competitive Double Ridge Waveguide Load price options and China Double Ridge Waveguide Load wholesale programs. Our Double Ridge Waveguide Load for sale includes comprehensive technical documentation and after-sales support. Contact craig@admicrowave.com today to discuss your specific requirements and experience why leading organizations worldwide choose Advanced Microwave Technologies for their critical microwave components.

FAQ

Q: What specific design features enable VSWR below 1.05 in double ridge waveguide loads?

A: Precision conical load elements create gradual impedance transitions from waveguide to load impedance, minimizing reflections through controlled electromagnetic field distribution and optimized ridge geometry.

Q: How does the frequency range of 2.6-110 GHz affect VSWR performance?

A: Multi-section impedance transformers and frequency-independent absorptive elements maintain consistent VSWR below 1.05 across the entire bandwidth through advanced electromagnetic modeling and optimization techniques.

Q: What manufacturing tolerances are required to achieve VSWR below 1.05?

A: Micrometer-level dimensional accuracy and controlled surface finish quality are essential, achieved through precision CNC machining and comprehensive quality control processes in environmentally controlled facilities.

Q: How do environmental conditions impact VSWR performance below 1.05?

A: High-quality metal construction and thermal stability design ensure consistent VSWR performance across temperature variations, while rigorous testing validates performance under extreme environmental conditions.

References

1. "Microwave Engineering Principles and Applications" by David M. Pozar, focusing on waveguide termination design and VSWR optimization techniques

2. "Advanced Waveguide Components for Microwave Systems" by IEEE Microwave Theory and Techniques Society, covering precision load element engineering

3. "High-Performance Microwave Terminations: Design and Manufacturing" by Robert E. Collin, detailing conical load element optimization strategies

4. "Electromagnetic Field Theory and Waveguide Applications" by Samuel Y. Liao, examining impedance matching techniques for ultra-low VSWR achievement

YOU MAY LIKE

VIEW MOREWaveguide Fixed Attenuator

VIEW MOREWaveguide Fixed Attenuator VIEW MOREWaveguide Probe Coupler

VIEW MOREWaveguide Probe Coupler VIEW MOREHigh Power Waveguide Circulator

VIEW MOREHigh Power Waveguide Circulator VIEW MOREHigh Power Waveguide Differential Phase Shift Circulator

VIEW MOREHigh Power Waveguide Differential Phase Shift Circulator VIEW MOREWaveguide Variable Attenuator

VIEW MOREWaveguide Variable Attenuator VIEW MOREHigh Power Waveguide Isolator

VIEW MOREHigh Power Waveguide Isolator VIEW MOREWG Bandpass Filter

VIEW MOREWG Bandpass Filter VIEW MOREWG Harmonic Filter

VIEW MOREWG Harmonic Filter