What’s the Difference Between a Double-bend Waveguide and a Single Bend Waveguide?

When designing compact microwave and millimeter-wave systems, engineers face a critical challenge: tight spaces demand sharp directional changes, yet signal integrity cannot be compromised. A Double-bend Waveguide solves this dilemma by employing two consecutive bends to achieve compact 90-degree routing while minimizing reflection losses that plague simpler configurations, making it indispensable for satellite communications, radar systems, and aerospace applications where both space efficiency and signal quality are non-negotiable.

Understanding Single Bend Waveguide Fundamentals

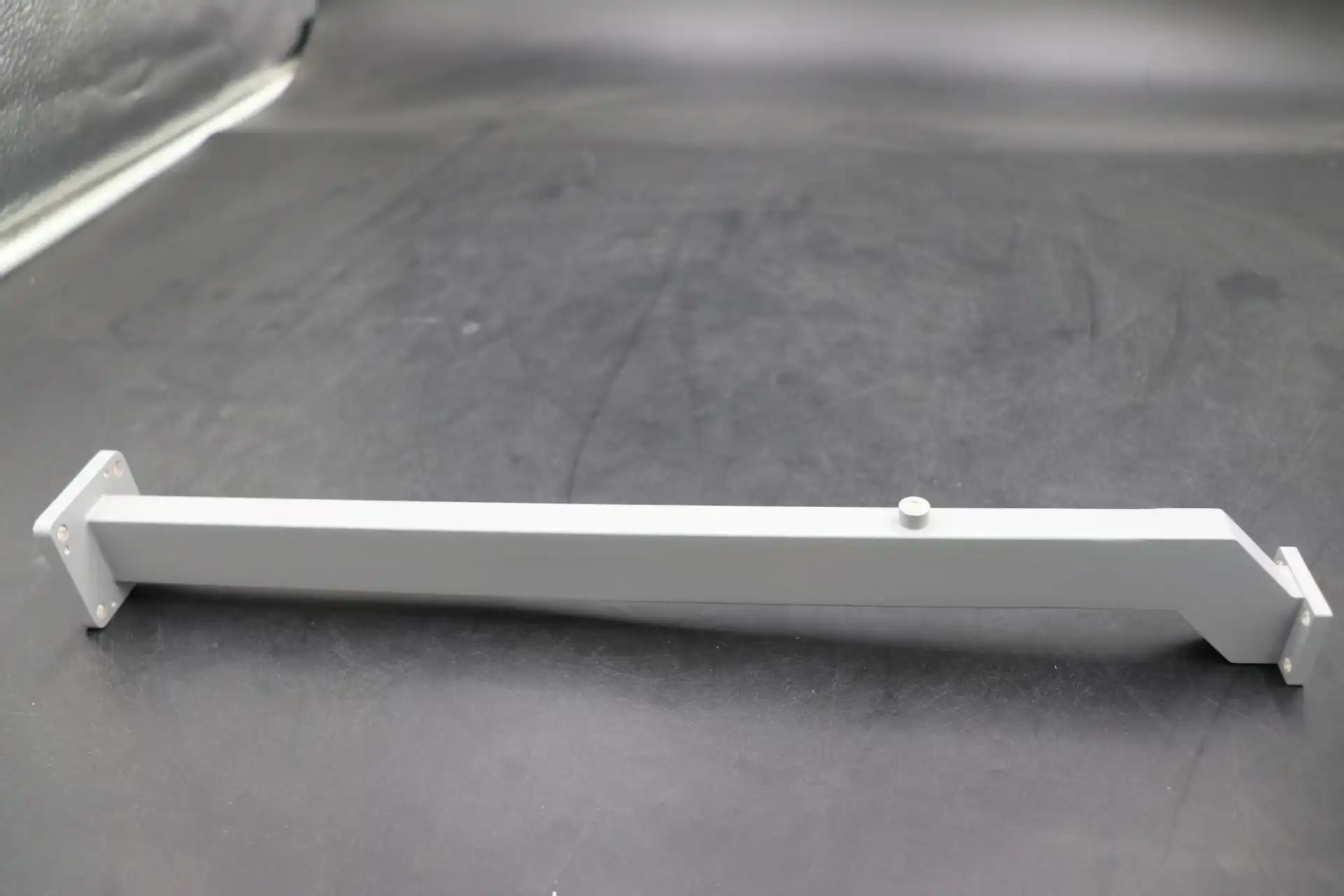

Single bend waveguides represent the most straightforward approach to redirecting electromagnetic waves within confined transmission systems. These components utilize a single curved section to alter signal direction, typically achieving 45-degree or 90-degree turns depending on application requirements. The fundamental principle behind single bend operation relies on maintaining proper field distribution throughout the curved section to prevent mode conversion and signal degradation. The primary advantage of single bend waveguides lies in their simplicity of design and manufacturing. Engineers can implement either gradual radius bends or sharp mitered corners depending on space constraints and performance requirements. For gradual bends, the radius must typically exceed two to three times the waveguide width to minimize reflections and maintain acceptable voltage standing wave ratio (VSWR) performance. This design consideration becomes particularly critical at higher frequencies where wavelength reduction makes dimensional tolerances more stringent. However, single bend configurations face inherent limitations when sharp directional changes are required within minimal footprints. Sharp single bends, even when properly designed with 45-degree mitered surfaces, can generate significant reflection losses that accumulate in systems requiring multiple directional changes. The electromagnetic field distribution experiences abrupt changes at the bend interface, potentially exciting higher-order modes that contribute to insertion loss and signal distortion. These challenges become especially pronounced in millimeter-wave applications operating above 30 GHz where the Double-bend Waveguide architecture offers superior performance characteristics.

Single Bend Design Considerations

Material selection plays a crucial role in single bend waveguide performance optimization. High-conductivity metals like oxygen-free copper or aluminum with appropriate surface finishes minimize resistive losses along the bent section. Surface roughness must be carefully controlled, typically maintaining values below 0.4 micrometers for high-frequency applications to prevent excessive attenuation. The internal surface quality directly impacts the skin effect losses that become increasingly dominant at millimeter-wave frequencies. Thermal considerations also influence single bend waveguide design decisions. Temperature variations cause dimensional changes through thermal expansion, potentially shifting the cutoff frequency and degrading impedance matching. Coefficient of thermal expansion (CTE) matching between different waveguide sections and mounting structures prevents mechanical stress accumulation that could lead to performance degradation or structural failure in demanding aerospace and satellite environments.

Double-bend Waveguide Architecture and Advantages

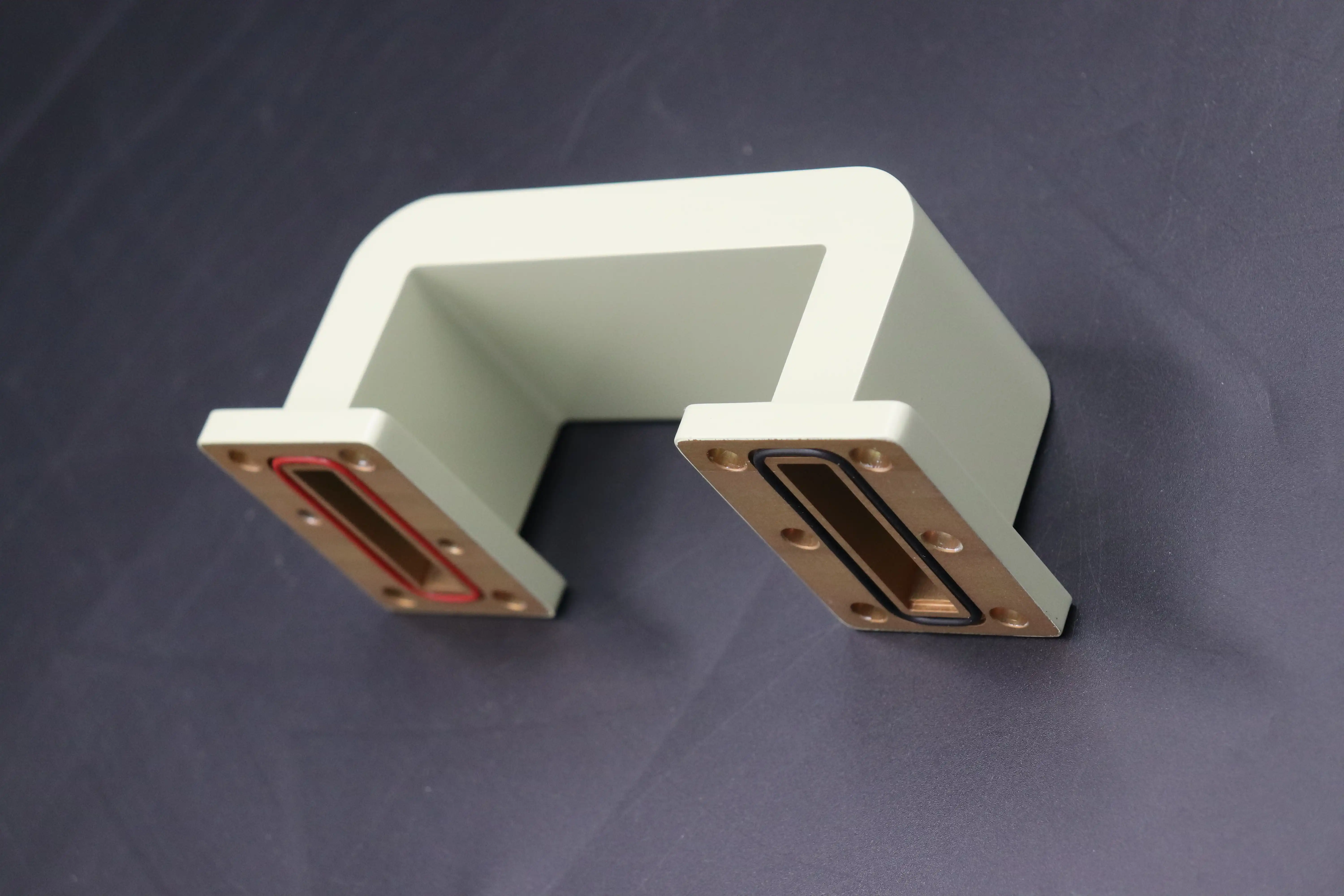

Double-bend waveguide configurations employ two consecutive bends strategically positioned to achieve compact directional changes while optimizing electromagnetic field transitions. This dual-bend approach, often referred to as a double miter configuration, leverages interference effects between reflections generated at each bend interface to achieve superior performance compared to single bend alternatives. The key innovation lies in precise spacing between the two bends, typically set at odd multiples of quarter wavelengths to enable destructive interference of reflected signals. Advanced Microwave's Double-bend Waveguide exemplifies high-performance design optimized for modern microwave and millimeter-wave applications. The carefully engineered layout maximizes reduction of signal reflection and loss through precise geometric control of both bend angles and spacing. Constructed from oxygen-free copper and other high-conductivity metals with polished internal surfaces, these components minimize insertion loss and signal attenuation across the operational frequency range. The dual-bend structure efficiently transmits signals along specified paths while controlling direction with minimal distortion, making it particularly advantageous in compact or enclosed spaces where traditional straight waveguides prove impractical. The Double-bend Waveguide offers several critical performance advantages over single bend configurations. First, the dual-bend architecture achieves lower VSWR across broader bandwidth by canceling reflections through quarter-wave spacing optimization. Second, compact footprint enables efficient space utilization in densely packed RF systems where every millimeter counts. Third, the configuration provides superior signal direction control with enhanced routing flexibility for complex system layouts. Fourth, well-designed double bends reduce signal attenuation more effectively than equivalent single sharp bends, ensuring efficient low-loss transmission critical for maintaining system sensitivity and dynamic range.

Technical Specifications and Performance Characteristics

Advanced Microwave's Double-bend Waveguide product demonstrates exceptional performance characteristics aligned with demanding industry requirements. The model ADM-HT180WEEB12.34X49.58X6.12T1 operates across the frequency range of 19.2 to 21.2 GHz, covering critical K-band applications in satellite communications and radar systems. With maximum VSWR specification of 1.1 and insertion loss limited to just 0.1 dB maximum, this component maintains signal integrity through the dual-bend transition. The aluminum construction with gold plating inside finish provides excellent conductivity while maintaining corrosion resistance essential for long-term reliability. The compact design philosophy inherent to Double-bend Waveguide architecture enables efficient space utilization through the two-bend structure, making it suitable for areas with severely limited room. Signal direction control capabilities allow the bends to direct signals along specific paths, offering exceptional routing flexibility for complex system geometries. Minimized signal loss characteristics result from carefully optimized bend geometry that reduces signal attenuation, ensuring efficient transmission with minimal power penalty. Reduced interference performance stems from the bending configuration that confines electromagnetic energy within the waveguide structure, limiting susceptibility to external interference sources. Flexible application scope makes Double-bend Waveguide components ideal for optical, microwave, and other electromagnetic wave systems, especially in confined setups where conventional routing proves impossible. Low reflection characteristics achieved through careful impedance matching design minimize standing waves, maintaining superior signal integrity throughout the transmission path. Enhanced performance in tight spaces makes these components perfect for applications requiring navigation around obstacles or fitting into constrained equipment volumes common in aerospace, defense, and satellite communication platforms.

Comparative Analysis: Performance Metrics

When comparing double-bend and single bend waveguide configurations, several critical performance metrics differentiate these architectures. Insertion loss represents the primary figure of merit, quantifying signal attenuation through the bend structure. Double-bend Waveguide configurations typically achieve 0.1 dB or lower insertion loss through optimized dual-bend geometry, whereas single sharp bends may exhibit 0.5 dB or higher losses depending on design constraints and operating frequency. This performance advantage becomes increasingly significant in systems employing multiple bends where losses accumulate. VSWR performance provides another crucial comparison metric, indicating impedance matching quality and reflection characteristics. Double-bend architectures leverage destructive interference between consecutive bend reflections to achieve VSWR values of 1.1 or better across operational bandwidth. Single bend configurations, particularly sharp mitered corners, may struggle to achieve comparable VSWR performance without increasing bend radius beyond space constraints. The superior VSWR performance of Double-bend Waveguide designs directly translates to improved system efficiency and reduced standing wave effects that could degrade adjacent component performance. Bandwidth characteristics also favor double-bend configurations when properly designed. The dual-bend architecture with quarter-wave spacing optimization provides broader frequency response compared to single bends optimized for narrow-band operation. This broadband capability proves essential for modern communication systems supporting multiple channels or frequency-agile radar applications requiring wide instantaneous bandwidth. Temperature stability represents another important consideration, with double-bend designs offering more predictable performance across operating temperature ranges through balanced thermal expansion effects.

Application-Specific Considerations

Microwave communications systems represent primary application domains where Double-bend Waveguide components prove crucial. In radar systems, satellite communications, and wireless infrastructure, these components enable compact signal routing while maintaining the low insertion loss essential for maximizing system sensitivity and range performance. The ability to achieve sharp directional changes within minimal footprints allows system designers to optimize equipment packaging density without compromising RF performance specifications. Optical communications applications leverage Double-bend Waveguide principles adapted to photonic waveguide structures for directing light signals through fiber-optic systems navigating tight spatial constraints. Integrated circuits incorporating photonic and MEMS technologies benefit from dual-bend architectures enabling low-loss signal routing within chip-scale dimensions. Sensor systems requiring space-saving layouts with precise signal guidance utilize double-bend configurations to achieve compact sensor head designs without sacrificing measurement accuracy. Medical device applications employ Double-bend Waveguide concepts for delivering light or RF signals through endoscopic instruments navigating complex anatomical pathways. The compact dual-bend architecture enables flexible instrument designs reaching deep anatomical locations while maintaining adequate signal transmission for imaging or therapeutic procedures. Laser systems benefit from double-bend routing capabilities for shaping and directing laser beams through optical trains, enhancing overall system performance and efficiency. Antenna systems redirect signals using dual-bend configurations to improve radiation efficiency and coverage patterns while accommodating mechanical constraints. Quantum computing applications leverage low-loss double-bend designs for guiding quantum information with minimal decoherence and error accumulation critical for maintaining quantum state fidelity.

Manufacturing and Quality Control Considerations

Manufacturing precision represents a critical factor differentiating high-performance Double-bend Waveguide components from marginal designs. Advanced Microwave Technologies Co., Ltd. employs precision machining techniques maintaining dimensional tolerances within micrometers to ensure consistent electromagnetic performance across production quantities. Computer numerical control (CNC) machining enables complex dual-bend geometries with repeatability essential for volume manufacturing while maintaining the tight tolerances required for millimeter-wave operation. Material selection and preparation significantly impact final component performance characteristics. Oxygen-free copper provides optimal electrical conductivity while minimizing dielectric losses that could accumulate through the dual-bend structure. Aluminum alternatives offer weight advantages for aerospace applications where mass reduction drives design decisions, though requiring careful surface treatment to achieve comparable conductivity. The internal surface finish undergoes polishing processes achieving sub-micrometer roughness values that minimize skin effect losses at high frequencies where electromagnetic fields concentrate near conductor surfaces. Quality control procedures ensure each Double-bend Waveguide component meets stringent performance specifications before customer delivery. Vector network analyzer testing across the full operational frequency range verifies insertion loss, return loss, and VSWR compliance with datasheet specifications. Near-field and far-field antenna measurement systems validate radiation pattern characteristics for integrated antenna assemblies incorporating double-bend routing. Environmental testing including temperature cycling, vibration, and humidity exposure confirms reliability under operational conditions encountered in aerospace, defense, and satellite communication environments.

ISO Certification and Standards Compliance

Advanced Microwave Technologies Co., Ltd. maintains ISO 9001:2015 certification demonstrating commitment to quality management across all manufacturing operations. This international standard ensures consistent product quality through documented procedures covering design, development, production, testing, and delivery processes. The comprehensive quality management system encompasses every aspect from raw material procurement through final product acceptance testing and customer delivery. ISO 14001:2015 certification reflects Advanced Microwave's environmental stewardship commitment, implementing comprehensive environmental management systems minimizing ecological footprint throughout operations. Waste management, energy conservation, and emissions reduction programs ensure technological advancement proceeds without environmental compromise. ISO 45001:2018 standard certification showcases concern for employee well-being through occupational health and safety prioritization, providing proper training, protective equipment, and safety protocols for technicians and engineers operating within the challenging microwave technology realm. RoHS compliance ensures all Double-bend Waveguide products meet restrictions on hazardous substances, eliminating lead, mercury, cadmium, and other toxic materials from manufacturing processes. This compliance proves essential for global market access, particularly in European and Asian markets with stringent environmental regulations. The combination of ISO certifications and RoHS compliance demonstrates Advanced Microwave's comprehensive approach to quality, environmental responsibility, and workplace safety integral to corporate operations.

System Integration and OEM Services

System integration challenges often drive requirements for customized Double-bend Waveguide solutions tailored to specific application constraints. Advanced Microwave Technologies Co., Ltd. offers comprehensive OEM services enabling customers to obtain optimized solutions perfectly fitting unique requirements. Whether serving large multinational corporations or small R&D-driven companies, Advanced Microwave provides high-quality products and technical support tailored to diverse business needs across global markets. OEM service capabilities encompass custom design based on detailed client application requirements, including frequency range, power handling, environmental conditions, and mechanical interface specifications. Prototype development with rapid turnaround enables testing and evaluation before committing to full-scale production tooling investments. Expert material selection leverages decades of microwave engineering experience to optimize performance, cost, and reliability trade-offs specific to each application. Precision manufacturing utilizing advanced CNC machining, metal plating, and surface finishing technologies ensures components meet exacting specifications. Comprehensive testing validates electrical performance, mechanical integrity, and environmental durability before production release. Integration support assists customers incorporating Double-bend Waveguide components into larger systems, providing mechanical interface drawings, electromagnetic simulation models, and installation guidance. Mass production capabilities scale from prototype quantities through high-volume manufacturing runs after prototype approval, maintaining consistent quality across production quantities. Post-production support includes technical assistance, troubleshooting guidance, and field failure analysis ensuring long-term customer success.

Technical Support and Engineering Collaboration

Advanced Microwave's expert engineering team provides in-depth technical assistance throughout the product lifecycle from initial concept through field deployment. Installation guidance helps customers properly integrate Double-bend Waveguide components into complex RF systems, avoiding common pitfalls that could degrade performance or cause installation delays. Troubleshooting support diagnoses field issues rapidly, minimizing downtime for critical communication and radar systems where availability directly impacts operational effectiveness. Collaborative development programs partner with customers developing next-generation systems pushing microwave technology boundaries. Advanced Microwave's 24-meter microwave darkroom and measurement facilities up to 110 GHz enable comprehensive antenna characterization and system-level performance validation. The Antenna Plane Near and Far Field Measuring Recombination Chamber allows fluid transition between measurement modes, extracting granular details about radiation patterns, gain, and impedance characteristics essential for optimizing integrated designs incorporating custom Double-bend Waveguide routing.

Conclusion

Double-bend Waveguide architecture delivers superior performance over single bend alternatives through optimized dual-bend geometry minimizing reflections while enabling compact routing essential for modern microwave systems across satellite communications, aerospace, and defense applications.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands as your trusted China Double-bend Waveguide manufacturer, China Double-bend Waveguide supplier, and China Double-bend Waveguide factory offering High Quality Double-bend Waveguide with competitive Double-bend Waveguide price. Our China Double-bend Waveguide wholesale capabilities and Double-bend Waveguide for sale inventory serve global markets with over 20 years microwave expertise, ISO-certified quality, and cutting-edge 24m measurement facilities testing up to 110 GHz. Partner with us for customized solutions, rapid prototyping, and exceptional technical support. Contact craig@admicrowave.com today to discuss your requirements and experience the Advanced Microwave advantage in precision RF components.

References

1. Pozar, David M. "Microwave Engineering, Fourth Edition." John Wiley & Sons, 2012. Chapter 3: Transmission Lines and Waveguides.

2. Saad, Theodor S. "Microwave Engineers' Handbook, Volume 1." Artech House Publishers, 1971. Section on Waveguide Components and Bends.

3. Balanis, Constantine A. "Advanced Engineering Electromagnetics, Second Edition." John Wiley & Sons, 2012. Chapter 9: Rectangular Waveguides and Cavities.

4. Collin, Robert E. "Foundations for Microwave Engineering, Second Edition." IEEE Press, 2001. Chapter 4: Waveguides and Resonators.