What is the principle of RF rotary joint?

In modern radar systems, satellite tracking stations, and defense applications, a critical challenge emerges: how do you maintain pristine signal transmission between components that are constantly rotating and those that remain stationary? Signal degradation, cable twisting, and mechanical failures can compromise mission-critical operations. The principle of RF rotary joint technology, particularly through advanced solutions like the Dual Channel Coaxial Rotary Joint, addresses this fundamental challenge by enabling seamless radio frequency signal transmission across rotating interfaces without distortion or loss. Understanding this principle is essential for engineers and procurement specialists working in aerospace, telecommunications, and defense sectors where uninterrupted signal integrity determines operational success.

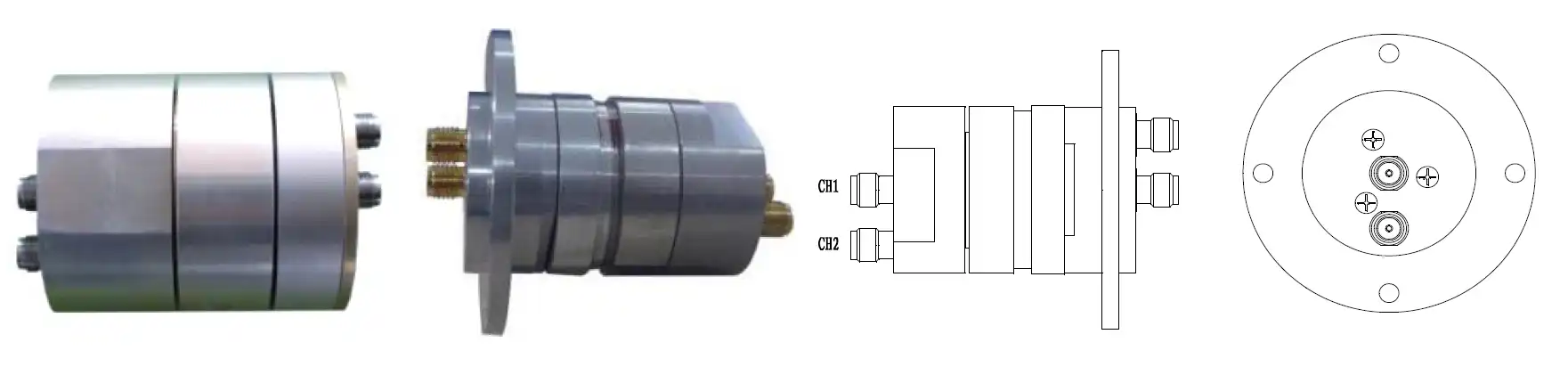

Understanding the Fundamental Principle of RF Rotary Joints

At its core, the RF rotary joint operates on the fundamental principles of electromagnetics combined with precision mechanical engineering. These electromechanical devices are designed to transmit radio frequency signals between stationary and rotating sections of a system while maintaining signal integrity throughout continuous rotation. The operating principle centers on creating a transmission path that preserves the electromagnetic characteristics of RF signals despite mechanical movement. This is achieved through specialized coupling mechanisms that allow energy transfer across the rotational interface without physical contact in advanced designs, or through carefully engineered contact points in traditional configurations. The electromagnetic principle underlying RF rotary joints involves maintaining impedance continuity across the rotating interface. When RF signals propagate through transmission lines, any discontinuity in characteristic impedance causes reflections and signal loss. The Dual Channel Coaxial Rotary Joint addresses this challenge through precision-engineered coaxial structures that maintain a consistent fifty-ohm impedance throughout the signal path, even as components rotate relative to each other. This design ensures minimal reflection and maximum power transfer, which is critical for applications ranging from satellite ground stations to airborne radar systems.

Electromagnetic Wave Propagation in Rotating Systems

The transmission of electromagnetic waves through rotating interfaces requires careful consideration of field distributions and mode structures. In coaxial rotary joints, the fundamental TEM mode propagates through the coaxial structure, where electric and magnetic fields are transverse to the direction of propagation. The Dual Channel Coaxial Rotary Joint maintains this field configuration across the rotational boundary through precisely machined inner and outer conductors that preserve the coaxial geometry. The circular symmetry of coaxial structures is particularly advantageous for rotary applications because the electromagnetic field distribution remains constant regardless of rotational position, eliminating variations that could cause signal distortion. Advanced designs incorporate sophisticated coupling mechanisms that facilitate energy transfer across the air gap between rotating and stationary sections. Non-contacting rotary joints utilize capacitive or inductive coupling principles, where electromagnetic energy bridges the physical gap through near-field interactions. These designs employ resonant structures such as quarter-wave transformers or choke flanges that create electromagnetic boundaries, containing the microwave energy within the desired transmission path while preventing radiation losses. The frequency-dependent nature of these resonant structures means they are optimized for specific frequency bands, with the Dual Channel Coaxial Rotary Joint typically designed to cover broad ranges from DC to forty gigahertz.

Mechanical Design Principles and Signal Integrity

The mechanical construction of RF rotary joints is equally critical to their electromagnetic performance. Precision bearings enable smooth rotation while maintaining exact alignment between rotating and stationary sections. Any misalignment or wobble introduces variations in the coupling gap, which manifests as amplitude and phase variations in the transmitted signal. High-quality Dual Channel Coaxial Rotary Joint designs employ ceramic ball bearings or precision roller bearings that minimize friction and ensure consistent rotational characteristics over millions of cycles. These bearings must support both radial and axial loads while maintaining micron-level tolerances that are essential for RF performance at higher frequencies. The materials used in rotary joint construction directly impact both mechanical durability and electrical performance. Copper and aluminum alloys provide excellent electrical conductivity while offering good mechanical properties. The inner and outer conductors are often gold or silver-plated to enhance conductivity and reduce insertion loss, particularly important in high-frequency applications where skin effect concentrates current flow at conductor surfaces. The Dual Channel Coaxial Rotary Joint benefits from these precision manufacturing techniques, delivering insertion losses below zero point two decibels across its operational frequency range. Dielectric materials separating the inner and outer conductors must exhibit low loss tangent and stable dielectric constants across temperature variations to maintain consistent electrical performance.

Types of Coupling Mechanisms in Dual Channel Coaxial Rotary Joints

RF rotary joints can be categorized based on their coupling mechanism: contacting and non-contacting designs. Each approach offers distinct advantages depending on application requirements. Contacting rotary joints employ physical connections between rotating and stationary conductors through sliding contacts or spring-loaded interfaces. These designs typically use silver-graphite composite materials that provide good electrical conductivity while minimizing wear during rotation. The primary advantage of contacting designs is their broadband capability, enabling signal transmission from DC to extremely high frequencies limited only by the coaxial line dimensions. The Dual Channel Coaxial Rotary Joint in contacting configuration can support continuous rotation while maintaining electrical continuity through carefully engineered contact pressure and surface treatments. However, contacting designs face challenges related to wear and electrical noise generation at the sliding interface. Friction between moving contacts produces particles that can degrade performance over time, and micro-arcing at the contact points introduces noise that may be problematic in sensitive receiving applications. Despite these limitations, contacting rotary joints remain popular for applications requiring ultra-broadband performance or transmission of high-power signals where non-contacting designs would face breakdown limitations. Modern Dual Channel Coaxial Rotary Joint designs mitigate wear issues through advanced materials and sealed construction that protects contact surfaces from environmental contamination.

Non-Contacting Rotary Joint Technology

Non-contacting RF rotary joints represent an advanced approach that eliminates physical sliding contacts through electromagnetic coupling across an air gap. These designs employ resonant coupling structures such as choke flanges or impedance-matching sections that facilitate energy transfer without direct conductor-to-conductor contact. The absence of physical contact eliminates wear mechanisms, dramatically extending operational lifetime and reducing maintenance requirements. Non-contacting Dual Channel Coaxial Rotary Joint designs are particularly valuable in applications requiring millions of rotation cycles or operation in harsh environments where contamination could degrade contact surfaces. The operational principle of non-contacting rotary joints relies on creating resonant cavities or coupling structures tuned to the operating frequency band. Choke flanges employ quarter-wave sections that create high impedance at the desired frequency, effectively trapping electromagnetic energy within the transmission path while preventing leakage. These structures must be precisely dimensioned relative to the operating wavelength, which limits their bandwidth compared to contacting designs. Typical non-contacting rotary joints achieve bandwidth of approximately twenty percent of the center frequency. The Dual Channel Coaxial Rotary Joint balances these trade-offs by offering optimized designs for specific frequency bands common in radar, satellite communications, and aerospace applications. Advanced non-contacting designs can support multiple frequency bands through sophisticated coupling structures that resonate at different frequencies. This enables a single Dual Channel Coaxial Rotary Joint to handle both transmit and receive channels operating at different frequency bands, such as X-band and L-band combinations common in satellite ground stations. The engineering challenge involves designing coupling structures that maintain low insertion loss and good return loss across both frequency bands while preserving isolation between channels to prevent crosstalk. Modern electromagnetic simulation tools enable optimization of these complex structures before manufacturing, reducing development time and ensuring first-pass design success.

Dual Channel Architecture and Multi-Signal Transmission

The dual-channel architecture of advanced coaxial rotary joints enables simultaneous transmission of two independent RF signals through a single mechanical assembly. This capability is essential in modern communication and radar systems that require separate transmit and receive paths or simultaneous operation at different frequencies. The Dual Channel Coaxial Rotary Joint achieves this through concentric coaxial structures where an inner coaxial line is nested within the outer conductor of a larger coaxial line. This nested configuration allows both channels to share common mechanical components while maintaining electrical isolation between signal paths. The electrical isolation between channels in a Dual Channel Coaxial Rotary Joint is critical to preventing crosstalk that would degrade system performance. Isolation specifications typically exceed sixty decibels, meaning that less than one-millionth of the power in one channel couples into the adjacent channel. This high isolation is achieved through careful attention to electromagnetic shielding and ground plane continuity. The outer conductor of the inner coaxial line serves as both the return path for the inner signal and the shield separating it from the outer channel. Manufacturing precision is paramount because any discontinuities or gaps in the shield create coupling paths that degrade isolation.

Power Handling and Thermal Management

The power handling capability of RF rotary joints depends on multiple factors including conductor dimensions, dielectric materials, and thermal dissipation mechanisms. At lower frequencies, power handling is primarily limited by ohmic heating in conductors and dielectric losses in insulating materials. The Dual Channel Coaxial Rotary Joint can handle power levels up to five hundred watts in continuous operation, with peak power capabilities extending higher for pulsed radar applications. Thermal management becomes increasingly critical at higher power levels, where heat generation can cause dimensional changes that affect electrical performance or potentially damage dielectric materials. Advanced thermal design incorporates heat sinks, forced air cooling, or liquid cooling systems for high-power applications. The rotational nature of these devices complicates thermal management because heat must be conducted from rotating sections to stationary heat sinks across the mechanical interface. Some Dual Channel Coaxial Rotary Joint designs incorporate rotating fluid couplings that enable coolant flow through rotating sections, dramatically increasing power handling capability. Material selection plays a crucial role in thermal performance, with copper offering superior thermal conductivity compared to aluminum, though at the cost of increased weight and cost. At microwave and millimeter-wave frequencies, power handling limitations increasingly relate to voltage breakdown phenomena. The peak electric field strength within the coaxial structure must remain below the breakdown threshold of the dielectric material and air gaps in non-contacting designs. The Dual Channel Coaxial Rotary Joint employs careful dimensioning of conductor spacing and dielectric material selection to maximize power handling while maintaining compact dimensions. For ultra-high-power applications such as weather radar transmitters, specialized pressurized designs may employ dry nitrogen or sulfur hexafluoride gas to increase breakdown thresholds substantially beyond atmospheric air capabilities.

Applications of Dual Channel Coaxial Rotary Joint Technology

Satellite communication ground stations represent one of the most demanding applications for Dual Channel Coaxial Rotary Joint technology. These systems require antenna systems that track satellites across the sky while maintaining simultaneous transmit and receive capabilities. The rotary joint must handle both the uplink signal transmitted to the satellite and the downlink signal received from it, often operating at different frequency bands such as C-band or Ku-band. The dual-channel architecture enables these separate signal paths through a single mechanical assembly, simplifying installation and reducing system complexity. Signal integrity requirements are stringent because any degradation directly impacts data throughput and communication reliability. In satellite ground stations, the Dual Channel Coaxial Rotary Joint must maintain stable electrical performance across elevation and azimuth rotations as the antenna tracks satellite motion. Environmental protection is critical because outdoor installations expose the rotary joint to temperature extremes, precipitation, and solar radiation. Advanced designs incorporate sealed housings with environmental gaskets and corrosion-resistant materials to ensure long-term reliability. The frequency ranges supported by satellite communication rotary joints span from L-band at one to two gigahertz through Ka-band extending beyond thirty gigahertz, requiring broadband designs or band-specific optimizations depending on application requirements.

Aerospace and Defense Radar Systems

Military and commercial radar systems rely extensively on RF rotary joint technology to enable continuous azimuth scanning while maintaining signal connections to stationary transmitter and receiver equipment. Air traffic control radar exemplifies this application, where the antenna must continuously rotate to provide comprehensive coverage of surrounding airspace. The Dual Channel Coaxial Rotary Joint enables separate paths for transmitted radar pulses and received echo signals, with isolation between channels preventing transmitter leakage from saturating sensitive receivers. The power handling requirements can be substantial, with some radar transmitters generating peak powers exceeding one megawatt in pulsed operation. Airborne radar systems present additional challenges due to weight and size constraints combined with exposure to vibration and acceleration forces during aircraft maneuvers. The Dual Channel Coaxial Rotary Joint for these applications must be extremely compact and lightweight while maintaining electrical performance under severe mechanical stress. Military specifications often require operation across temperature ranges from minus fifty-five to plus one hundred twenty-five degrees Celsius, along with resistance to shock, vibration, and electromagnetic interference. Advanced designs employ specialized materials and manufacturing processes to meet these demanding requirements while providing the multi-channel capabilities essential for modern electronically scanned array radar systems. Shipboard radar installations must additionally address corrosion concerns from saltwater exposure and moisture ingress. The Dual Channel Coaxial Rotary Joint designs for naval applications incorporate extensive environmental sealing and may utilize materials such as titanium or specialized corrosion-resistant alloys. The mechanical design must also accommodate the ship motion that induces additional loads on the rotary joint structure. Some naval applications require continuous operation for months or years without maintenance opportunity, demanding exceptional reliability and durability from the Dual Channel Coaxial Rotary Joint assembly.

Performance Specifications and Quality Standards

The electrical performance of RF rotary joints is characterized by several key parameters that determine suitability for specific applications. Insertion loss quantifies the signal attenuation through the device, with high-performance Dual Channel Coaxial Rotary Joint designs achieving values below zero point two decibels across their operating frequency range. This low insertion loss is critical because it directly impacts system performance metrics such as radar range or communication link margin. Every decibel of insertion loss reduces transmitted power or received signal strength, potentially degrading overall system capability. Advanced manufacturing techniques and material selection minimize conductor losses and dielectric losses to achieve these exceptional performance levels. Voltage Standing Wave Ratio measures the impedance match between the rotary joint and connected transmission lines. Poor impedance matching causes signal reflections that reduce power transfer efficiency and can cause interference patterns within the system. The Dual Channel Coaxial Rotary Joint typically achieves VSWR values of one point two-five to one or better, corresponding to return loss exceeding approximately twenty decibels. This excellent matching is achieved through precision manufacturing that maintains consistent characteristic impedance throughout the device, including transitions between different mechanical sections. Electromagnetic simulation during design phase enables optimization of transition geometries to minimize discontinuities that would degrade impedance match.

Manufacturing Quality and Certification

Quality manufacturing processes are essential to achieving the stringent performance requirements of RF rotary joints. Advanced Microwave Technologies Co., Ltd. maintains ISO nine thousand one certification demonstrating commitment to comprehensive quality management systems throughout design, manufacturing, and testing processes. Each Dual Channel Coaxial Rotary Joint undergoes rigorous testing including swept frequency measurements of insertion loss, return loss, and isolation across the full operating frequency range. Time-domain reflectometry identifies any impedance discontinuities that could affect performance, while high-power testing validates power handling capabilities under realistic operating conditions. Environmental testing ensures the Dual Channel Coaxial Rotary Joint maintains performance across temperature extremes, humidity exposure, and mechanical stress conditions representative of field deployment. Thermal cycling between minus forty and plus eighty-five degrees Celsius verifies that dimensional changes due to thermal expansion do not degrade electrical performance. Vibration and shock testing validate mechanical integrity under transportation and operational loads. These comprehensive test procedures ensure that each rotary joint meets published specifications and will provide reliable service throughout its operational lifetime. RoHS compliance certification demonstrates that the Dual Channel Coaxial Rotary Joint manufacturing process avoids hazardous materials including lead, mercury, cadmium, and other restricted substances. This environmental responsibility is increasingly important for international equipment sales and ensures compatibility with modern electronic assembly processes. The combination of ISO quality certification, comprehensive performance testing, and environmental compliance makes Advanced Microwave Technologies' Dual Channel Coaxial Rotary Joint suitable for the most demanding aerospace, defense, and commercial applications.

Conclusion

The principle of RF rotary joint technology enables seamless signal transmission across rotating interfaces through sophisticated electromagnetic and mechanical design. The Dual Channel Coaxial Rotary Joint exemplifies these principles, delivering exceptional performance for satellite communications, aerospace navigation, defense systems, and industrial applications through precision engineering and quality manufacturing.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands as your premier China Dual Channel Coaxial Rotary Joint manufacturer, factory, supplier, and wholesale provider. With over thirty years of expertise and ISO fourteen thousand one, nine thousand one, and forty-five thousand one certifications, we deliver High Quality Dual Channel Coaxial Rotary Joint solutions at competitive Dual Channel Coaxial Rotary Joint prices. Our twenty-four-meter microwave darkroom and measurement capabilities up to one hundred ten gigahertz ensure every Dual Channel Coaxial Rotary Joint for sale meets exacting standards. Contact craig@admicrowave.com today for customized solutions tailored to your specifications. Bookmark this resource for future reference whenever rotary joint challenges arise.

References

1. Levy, R. & Cohn, S. B. "A History of Microwave Filter Research, Design, and Development" IEEE Transactions on Microwave Theory and Techniques, Institute of Electrical and Electronics Engineers

2. Pozar, D. M. "Microwave Engineering" Fourth Edition, John Wiley and Sons Publishing

3. Collin, R. E. "Foundations for Microwave Engineering" Second Edition, IEEE Press Series on Electromagnetic Wave Theory

4. Balanis, C. A. "Advanced Engineering Electromagnetics" Second Edition, John Wiley and Sons Incorporated

YOU MAY LIKE

VIEW MORERight Angle Double Ridged WG To Coaxial Adapter

VIEW MORERight Angle Double Ridged WG To Coaxial Adapter VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter

VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter VIEW MORERight Angle Waveguide to Microstrip Adapter

VIEW MORERight Angle Waveguide to Microstrip Adapter VIEW MOREWG Termination

VIEW MOREWG Termination VIEW MOREDouble Ridge Waveguide Termination

VIEW MOREDouble Ridge Waveguide Termination VIEW MOREWaveguide Power Divider

VIEW MOREWaveguide Power Divider VIEW MOREE-Plane Tee

VIEW MOREE-Plane Tee VIEW MORECrossguide Directional Coupler

VIEW MORECrossguide Directional Coupler