Elliptical Waveguide vs Rectangular: Which Is Better?

When designing high-frequency microwave systems for satellite communications, radar installations, or defense applications, engineers face a critical decision that can impact system performance, installation costs, and long-term reliability. Choosing between an Elliptical Waveguide and rectangular waveguide isn't just about technical specifications—it's about finding the optimal solution that balances efficiency, flexibility, installation complexity, and budget constraints. This comprehensive analysis examines both waveguide types from multiple perspectives to help you make an informed decision for your specific application requirements.

Understanding the Fundamental Differences Between Elliptical Waveguide and Rectangular Designs

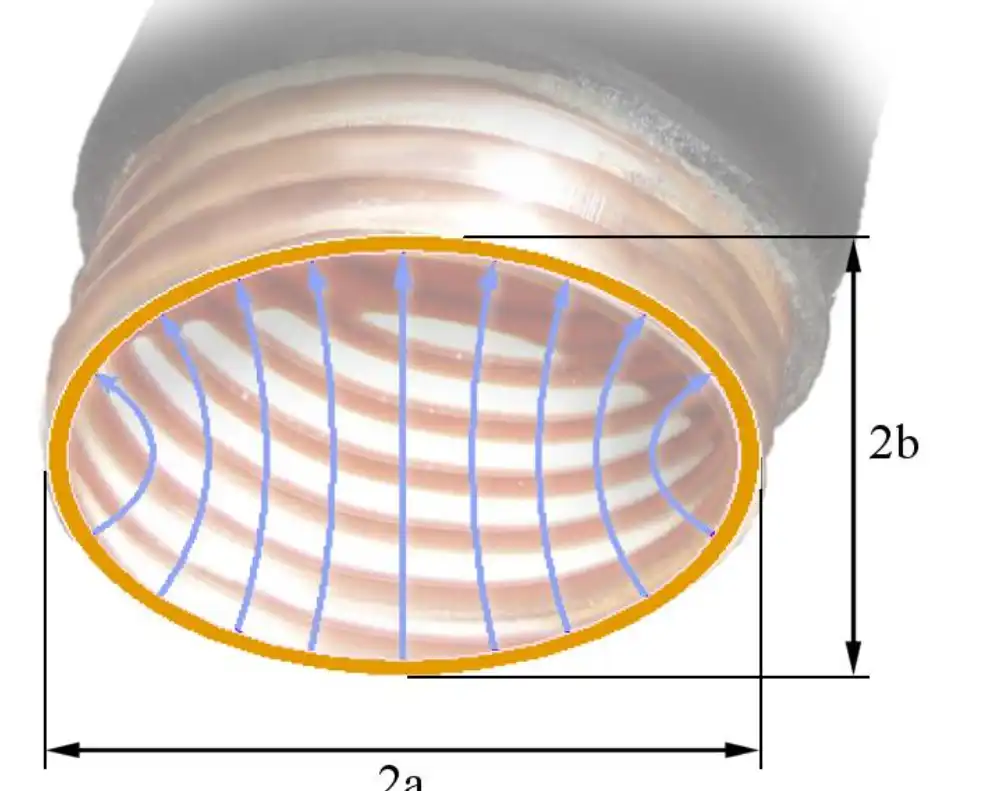

Waveguide geometry fundamentally determines how electromagnetic energy propagates through the transmission system. Rectangular waveguides have been the traditional choice for microwave applications, featuring a cross-section where the broad dimension is typically twice the narrow dimension. This standardized design has dominated the industry for decades, particularly in short-run applications and laboratory settings where rigid installations are feasible. The rectangular geometry provides predictable mode propagation characteristics, with the fundamental TE10 mode being the primary transmission mode. The walls of rectangular waveguides are precisely manufactured to maintain consistent dimensions, which is essential for preventing unwanted mode conversions and ensuring stable signal transmission across the operational frequency range. Elliptical Waveguide technology emerged as an innovative alternative to address specific limitations of rectangular designs. The elliptical cross-section offers a unique combination of mechanical flexibility and electrical performance that rectangular waveguides cannot match. Advanced Microwave offers an Elliptical Waveguide made with an Elliptical Corrugated Copper tube and UV resistant, Black Polyethylene Jacket, providing superior durability in challenging environmental conditions. The corrugated structure allows the waveguide to bend with minimal signal degradation, a critical advantage in complex installations where routing around obstacles is necessary. The fundamental mode in elliptical waveguides is designated as HC11, with field distribution patterns that differ from rectangular configurations but offer comparable or superior performance in many applications.

Electrical Performance Comparison: Loss Characteristics and Frequency Response

When evaluating transmission efficiency, loss characteristics become paramount in system design. Rectangular waveguides exhibit excellent performance in controlled environments with straight runs, offering low insertion loss when properly installed and maintained. However, the rigid nature of rectangular waveguide means that any installation requiring directional changes necessitates precision-manufactured elbows, each introducing additional insertion loss and potential reflection points. The cumulative effect of multiple elbows in a complex routing scenario can significantly degrade overall system performance, particularly at higher frequencies where tolerance requirements become increasingly stringent. Elliptical Waveguide systems demonstrate remarkable efficiency in both straight runs and bent configurations. The flexible nature of the elliptical design allows for smooth bending radii that maintain signal integrity without the discrete reflection points created by rigid elbows. Advanced Microwave Technologies Co., Ltd manufactures Elliptical Waveguide products designed to reduce signal attenuation, ensuring stable transfer of high-frequency signals over long distances. The elliptical shape provides optimal impedance matching and minimizes losses for frequencies up to 110 GHz, making these waveguides versatile for a variety of applications from legacy communication systems to cutting-edge 5G and future 6G technologies. The low insertion loss characteristic is particularly valuable in satellite ground stations, where maintaining signal strength over extended transmission paths directly impacts data throughput and communication reliability.

Mechanical Flexibility and Installation Advantages

Installation complexity and labor costs represent significant factors in total system economics. Rectangular waveguide installations require meticulous planning, precise measurements, and specialized components for every directional change. Each straight section must be custom-ordered to exact specifications, and elbows must be positioned precisely to maintain alignment and minimize reflection. The installation process typically demands experienced technicians with specialized tools, and any modification to the routing requires additional custom components and reinstallation efforts. This rigidity makes rectangular waveguide impractical for applications requiring periodic reconfiguration or installations where precise routing cannot be determined in advance. The transformative advantage of Elliptical Waveguide lies in its mechanical flexibility combined with electrical performance. These waveguides can be supplied on regular cable reels and bent to fit installation requirements in the field, dramatically reducing installation time and complexity. The corrugated copper tube construction allows bending to accommodate architectural constraints, equipment repositioning, and routing around obstacles without compromising signal integrity. This flexibility translates directly into reduced labor costs, shorter installation timelines, and greater adaptability to real-world installation challenges. In telecommunications infrastructure, defense installations, and aerospace applications where space constraints and evolving requirements are common, the ability to route Elliptical Waveguide flexibly while maintaining performance specifications provides substantial practical advantages.

Application-Specific Considerations: Where Each Waveguide Type Excels

Different applications impose varying requirements on waveguide systems, making the choice between elliptical and rectangular designs highly application-dependent. Understanding these application-specific demands is essential for optimal system design and long-term operational success.

Satellite Communication Systems and Ground Station Infrastructure

Satellite communication ground stations demand unwavering reliability and minimal signal degradation across extended transmission paths. In these installations, waveguides must efficiently transfer signals between high-power amplifiers, low-noise receivers, and antenna feed systems while maintaining precise impedance matching and minimal insertion loss. Rectangular waveguide has traditionally served these applications well in controlled environments where straight vertical runs dominate the installation. However, the transition regions between equipment and antenna systems often require complex routing that introduces multiple elbows and potential performance degradation points. Elliptical Waveguide technology offers compelling advantages in modern satellite ground station designs. The ability to route waveguide flexibly around equipment enclosures, structural elements, and other infrastructure components simplifies installation while reducing component count and potential failure points. Advanced Microwave Technologies Co., Ltd specializes in Elliptical Waveguide solutions for satellite communication applications, ensuring efficient signal transfer for HD video, data, and voice communications with minimal interference and high stability. The compact design enabled by the unique elliptical shape allows efficient use of space while maintaining excellent performance at the high frequencies employed in contemporary satellite systems. For ground stations supporting multiple frequency bands or requiring periodic reconfiguration to support evolving mission requirements, the inherent flexibility of Elliptical Waveguide provides operational advantages that rigid rectangular systems cannot match.

Defense, Aerospace, and Radar Applications

Military surveillance systems, aerospace platforms, and advanced radar installations represent some of the most demanding waveguide applications. These systems require exceptional reliability under extreme environmental conditions, resistance to vibration and mechanical stress, and consistent electrical performance across wide temperature ranges. Defense applications particularly value the ability to detect threats accurately and distinguish targets reliably, placing premium demands on waveguide transmission quality and system stability. Elliptical Waveguide solutions excel in these challenging environments due to their robust construction and performance characteristics. The corrugated copper tube design with UV-resistant black polyethylene jacketing provides excellent protection against environmental degradation, moisture ingress, and physical damage. In airborne radar systems, shipboard installations, and mobile defense platforms where vibration, thermal cycling, and mechanical stress are constant concerns, the flexible nature of Elliptical Waveguide offers superior durability compared to rigid rectangular alternatives. Advanced Microwave Technologies Co., Ltd provides High Quality Elliptical Waveguide products critical in radar systems, missile guidance, and advanced defense technologies that require highly accurate signal processing. The ability to maintain precise electrical characteristics while accommodating the mechanical demands of mobile platforms makes Elliptical Waveguide the preferred choice for next-generation defense systems.

Telecommunications Infrastructure and Network Deployment

Modern telecommunications infrastructure demands cost-effective solutions that can be rapidly deployed while delivering reliable performance across diverse environmental conditions. The expansion of 5G networks, rural broadband initiatives, and industrial IoT applications creates unprecedented demand for high-frequency transmission systems that balance performance with economic feasibility. In these applications, installation speed, adaptability to existing infrastructure, and total cost of ownership often outweigh the incremental performance advantages of more complex systems. Elliptical Waveguide technology addresses these telecommunications requirements exceptionally well. The ability to ship waveguide on reels rather than as custom rigid sections dramatically reduces logistics complexity and costs. Installation teams can route waveguide to accommodate existing infrastructure, building layouts, and right-of-way constraints without requiring extensive custom fabrication. This flexibility accelerates network deployment timelines and reduces installation costs, critical factors in competitive telecommunications markets. For bringing fast internet access to rural areas and powering industrial IoT applications, the combination of performance, flexibility, and cost-effectiveness makes Elliptical Waveguide an increasingly attractive choice. Advanced Microwave Technologies Co., Ltd serves as a China Elliptical Waveguide manufacturer providing solutions that optimize long-distance signal propagation while meeting strict budget and timeline requirements.

Cost Analysis: Total System Economics and Long-Term Value

While initial component pricing represents one factor in waveguide selection, comprehensive economic analysis must consider total installed cost, operational expenses, and long-term system value. This holistic perspective often reveals that lower initial component costs do not necessarily translate to lower total cost of ownership.

Initial Investment and Component Pricing

Rectangular waveguide components typically command higher per-unit costs due to precision manufacturing requirements and the need for custom-designed elbows, transitions, and straight sections matched to specific installation geometries. Each installation requires detailed planning, precise measurements, and procurement of specialized components that cannot be adapted if routing requirements change. The rigid nature of rectangular waveguide also necessitates contingency inventory of various lengths and configurations to accommodate installation adjustments or future modifications, increasing capital tied up in spare parts inventory. Elliptical Waveguide for sale from reputable manufacturers like Advanced Microwave Technologies Co., Ltd offers competitive pricing that becomes particularly advantageous when total system costs are considered. While individual waveguide pricing varies based on specifications and frequency ranges, the reduction in specialized fittings, elimination of custom elbows, and simplified installation requirements typically result in lower total material costs. The ability to purchase standard lengths on reels and cut to exact field requirements reduces waste and eliminates the need for extensive custom component procurement. For large-scale deployments or installations with uncertain routing requirements, these economic advantages compound significantly.

Installation Labor and Timeline Considerations

Labor costs frequently exceed material costs in waveguide installations, particularly for complex routing scenarios or installations in difficult-to-access locations. Rectangular waveguide installation requires specialized expertise, precision alignment of rigid sections, and careful installation of elbows to minimize reflection and ensure optimal performance. Any installation error or misalignment may require component replacement and reinstallation, extending project timelines and increasing costs. The need for specialized tools, lifting equipment for large rigid sections, and extended crew time for precision work all contribute to substantial labor expenses. The streamlined installation process enabled by Elliptical Waveguide flexibility dramatically reduces labor requirements and accelerates project completion. Installation teams can route waveguide efficiently around obstacles, make field adjustments to accommodate as-built conditions, and complete installations with smaller crews and less specialized equipment. The reduction in precision alignment requirements and elimination of multiple rigid component connections reduces installation time substantially. For installations on towers, in building mechanical spaces, or other challenging environments, these labor savings often exceed the initial component cost differential. China Elliptical Waveguide supplier Advanced Microwave Technologies Co., Ltd provides products engineered for efficient installation, maximizing these labor and timeline advantages.

Maintenance, Reliability, and Lifecycle Costs

Long-term operational costs significantly impact total system economics but are frequently underestimated during initial procurement decisions. Rectangular waveguide systems with multiple rigid connections create numerous potential points for degradation over time. Thermal cycling, vibration, and mechanical stress can compromise connection integrity, leading to increased insertion loss, reflection, and potential system failures. Maintenance activities often require specialized technicians, precision measurement equipment, and potentially extensive disassembly to access problem areas. For critical communications systems where downtime directly impacts operational capabilities or revenue, these maintenance requirements and potential failure modes represent substantial hidden costs. Elliptical Waveguide systems typically demonstrate superior long-term reliability due to fewer connections and inherent mechanical stress accommodation. The continuous corrugated structure with minimal discrete connection points reduces potential failure modes and simplifies inspection and maintenance procedures. The UV-resistant polyethylene jacketing protects against environmental degradation, extending service life in outdoor installations. For satellite communication systems, telecommunications infrastructure, and defense applications where availability requirements are stringent, the enhanced reliability and reduced maintenance requirements of Elliptical Waveguide contribute substantially to favorable total cost of ownership. Advanced Microwave Technologies Co., Ltd, as a leading China Elliptical Waveguide factory, emphasizes quality construction and materials to maximize system reliability and minimize lifecycle costs.

Technical Specifications and Performance Standards

Meeting rigorous technical specifications and industry standards ensures waveguide systems deliver required performance across their operational lifetime. Both elliptical and rectangular waveguides must conform to established specifications, but their different construction approaches lead to distinct performance characteristics.

Frequency Range Capabilities and Bandwidth Considerations

Operating frequency range fundamentally determines waveguide applicability for specific applications. Rectangular waveguides are available in standardized sizes optimized for particular frequency bands, with each waveguide designation supporting a defined operational range. The cutoff frequency, determined primarily by the broad wall dimension, establishes the lower frequency limit, while the onset of higher-order modes constrains the upper frequency limit. This standardization facilitates component interoperability but requires different waveguide sizes for systems operating across multiple frequency bands. Elliptical Waveguide designs demonstrate excellent broadband operation capabilities, supporting wide frequency ranges within a single waveguide size. The elliptical geometry provides favorable mode suppression characteristics while maintaining low loss across extended bandwidths. Advanced Microwave Technologies Co., Ltd manufactures Elliptical Waveguide products capable of supporting frequencies from lower microwave bands through millimeter-wave ranges up to 110 GHz. This broadband capability proves particularly valuable in multi-band communication systems, wideband radar applications, and installations where frequency agility or future expansion to additional bands may be required. The ability to support legacy systems while accommodating next-generation technologies within the same physical infrastructure provides substantial operational and economic advantages.

Power Handling and Peak Performance Limitations

High-power applications impose stringent requirements on waveguide construction and design. Power handling capability depends on multiple factors including waveguide cross-sectional dimensions, surface finish quality, dielectric breakdown characteristics of the air gap, and thermal management of conductor losses. Rectangular waveguides with their larger cross-sectional areas typically offer excellent power handling for given frequency ranges, making them preferred choices for high-power radar transmitters, particle accelerators, and industrial heating applications where peak and average power levels may reach hundreds of kilowatts. Elliptical Waveguide systems demonstrate robust power handling capabilities suitable for most communication and radar applications. While the more compact cross-section of some Elliptical Waveguide designs may limit absolute peak power handling compared to equivalent frequency rectangular waveguides, modern Elliptical Waveguide constructions with optimized dimensions and high-quality conductor surfaces support power levels sufficient for satellite earth stations, telecommunications base stations, and most defense radar systems. The corrugated construction and quality materials employed by China Elliptical Waveguide wholesale supplier Advanced Microwave Technologies Co., Ltd ensure reliable power handling while maintaining the flexibility and installation advantages that make Elliptical Waveguide attractive. For applications where ultra-high power handling is not required, the practical power capabilities of Elliptical Waveguide fully satisfy operational requirements while offering superior installation characteristics.

Making the Right Choice: Decision Framework for Waveguide Selection

Selecting the optimal waveguide technology requires systematic evaluation of application requirements, installation constraints, performance specifications, and economic factors. Neither elliptical nor rectangular waveguide represents a universally superior choice—each technology offers distinct advantages for specific scenarios.

When Rectangular Waveguide Remains the Optimal Choice?

Rectangular waveguide continues to excel in applications emphasizing maximum power handling, ultra-low loss in controlled environments, and installations where straight-run configurations dominate. Laboratory test systems, scientific instruments, high-power radar transmitters, and applications requiring maximum performance in benign installation environments benefit from rectangular waveguide characteristics. When installation routing can be precisely predetermined, where modifications are unlikely, and where maximum standardization and component interoperability across multiple manufacturers are priorities, rectangular waveguide offers proven performance and extensive component availability.

When Elliptical Waveguide Provides Superior Value?

Elliptical Waveguide emerges as the preferred choice when installation flexibility, rapid deployment, cost-effective implementation, and adaptability to challenging routing scenarios are priorities. Satellite ground stations requiring efficient routing around equipment and structural elements, telecommunications infrastructure demanding rapid deployment and field adaptability, defense platforms subject to vibration and mechanical stress, and any application where future modifications or reconfigurations are anticipated all benefit substantially from Elliptical Waveguide characteristics. The combination of competitive Elliptical Waveguide price, reduced installation complexity, enhanced reliability, and proven performance makes this technology increasingly attractive across diverse applications. Advanced Microwave Technologies Co., Ltd stands as a trusted China Elliptical Waveguide supplier offering customized solutions tailored to specific project requirements, ensuring optimal performance regardless of application demands.

Conclusion

Choosing between Elliptical Waveguide and rectangular designs ultimately depends on balancing performance requirements, installation constraints, and economic considerations specific to your application. While rectangular waveguides offer proven performance in controlled environments, Elliptical Waveguide technology provides superior flexibility, installation efficiency, and total system value for most modern applications.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a leading China Elliptical Waveguide manufacturer with over 20 years of microwave expertise, Advanced Microwave Technologies Co., Ltd delivers High Quality Elliptical Waveguide solutions backed by ISO 9001:2015 certification and comprehensive technical support. Our 24m Microwave Darkroom enables precision testing across 0.5-110GHz, ensuring every product meets exacting specifications. Whether you need standard configurations or fully customized designs, our engineering team provides expert guidance from specification to installation. Our efficient global supply chain guarantees fast delivery worldwide, while our OEM services offer tailored flanges, couplers, and technical integration support. Contact our team today at craig@admicrowave.com to discuss your requirements and discover how our China Elliptical Waveguide factory delivers superior solutions at competitive Elliptical Waveguide wholesale pricing. Bookmark this resource for future reference when planning your next waveguide project.

References

1. Collin, Robert E. "Field Theory of Guided Waves." IEEE Press Series on Electromagnetic Wave Theory, Second Edition, 1991.

2. Marcuvitz, Nathan. "Waveguide Handbook." Institution of Engineering and Technology, Electromagnetic Waves Series, 1986.

3. Pozar, David M. "Microwave Engineering." Fourth Edition, John Wiley & Sons, 2011.

4. Ramo, Simon, John R. Whinnery, and Theodore Van Duzer. "Fields and Waves in Communication Electronics." Third Edition, John Wiley & Sons, 1994.

5 .Balanis, Constantine A. "Advanced Engineering Electromagnetics." Second Edition, John Wiley & Sons, 2012.

YOU MAY LIKE

VIEW MOREWaveguide Fixed Attenuator

VIEW MOREWaveguide Fixed Attenuator VIEW MOREWaveguide Probe Coupler

VIEW MOREWaveguide Probe Coupler VIEW MOREHigh Power Waveguide Circulator

VIEW MOREHigh Power Waveguide Circulator VIEW MOREHigh Power Waveguide Differential Phase Shift Circulator

VIEW MOREHigh Power Waveguide Differential Phase Shift Circulator VIEW MOREWaveguide Variable Attenuator

VIEW MOREWaveguide Variable Attenuator VIEW MOREHigh Power Waveguide Isolator

VIEW MOREHigh Power Waveguide Isolator VIEW MOREWG Bandpass Filter

VIEW MOREWG Bandpass Filter VIEW MOREWG Harmonic Filter

VIEW MOREWG Harmonic Filter