What is an H-Plane Waveguide Tee?

Are you struggling with signal distribution challenges in your microwave system, experiencing power losses that compromise performance in critical satellite communications or radar applications? Understanding H-Plane Tee technology is essential for engineers who demand precise signal routing and minimal insertion loss in high-frequency applications. An H-Plane Tee is a three-port waveguide junction where the auxiliary arm connects to the narrow wall of the main waveguide, creating a shunt connection that enables efficient power division or combination while maintaining excellent phase characteristics and signal integrity across wide frequency ranges.

Understanding H-Plane Tee Fundamentals and Configuration

The H-Plane Tee represents a sophisticated approach to microwave signal management, fundamentally designed to address the complex requirements of high-frequency systems. This waveguide component operates by creating a junction where the side arm connects perpendicular to the narrow wall of the main rectangular waveguide, establishing what engineers refer to as a shunt connection. The terminology "H-Plane" derives from the magnetic field orientation within the waveguide structure, where the junction occurs parallel to the magnetic field lines. This configuration ensures that signals entering the main ports combine in-phase at the side arm, making it invaluable for applications requiring coherent signal combination or precise power division. The H-Plane Tee differs significantly from its E-Plane counterpart in that it maintains phase coherence between outputs, whereas E-Plane configurations introduce 180-degree phase differences. Advanced Microwave Technologies manufactures H-Plane Tees with precision-engineered junctions that optimize signal flow characteristics, ensuring minimal reflection and maximum power transfer efficiency across operational frequency ranges.

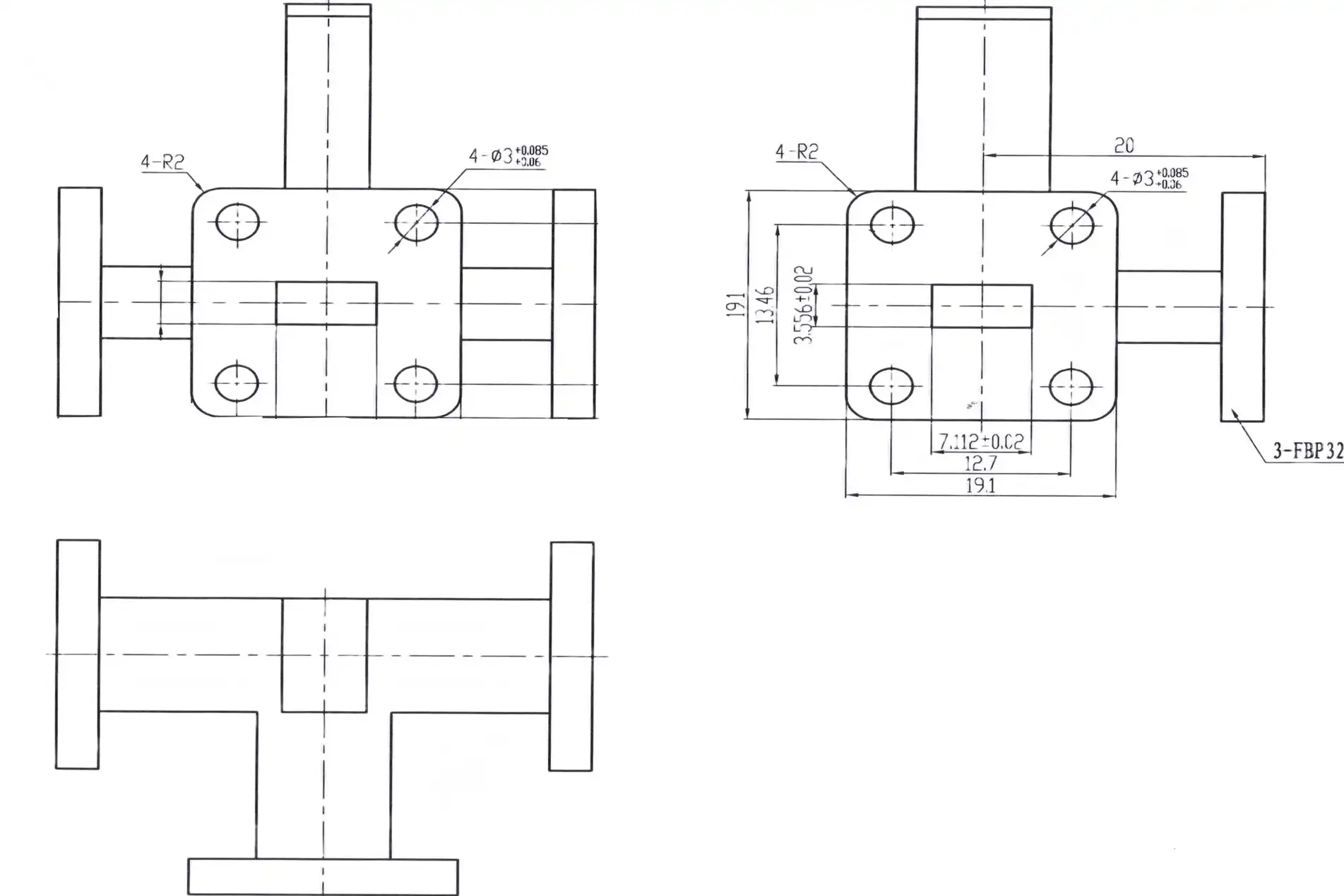

Physical Structure and Design Principles

The physical construction of an H-Plane Tee involves careful consideration of electromagnetic field distributions and impedance matching requirements. The junction geometry must be precisely calculated to minimize discontinuities that could cause unwanted reflections or signal degradation. When electromagnetic energy propagates through the main waveguide ports, the H-Plane Tee structure allows for seamless field coupling into the auxiliary arm. The narrow wall connection ensures that the magnetic field components remain continuous across the junction, while the electric field patterns adapt to maintain proper impedance characteristics. Manufacturing tolerances become critical at higher frequencies, where dimensional variations can significantly impact performance. Advanced Microwave Technologies employs state-of-the-art machining techniques and quality control processes to ensure that each H-Plane Tee meets stringent specifications for dimensional accuracy and surface finish quality.

Electromagnetic Field Behavior in H-Plane Configurations

Understanding the electromagnetic field behavior within H-Plane Tee structures provides insights into their superior performance characteristics. When signals propagate through the main waveguide, the dominant TE10 mode maintains specific field patterns that must be preserved across the junction. The H-Plane Tee configuration allows the magnetic field lines to flow naturally around the junction without significant disruption, while the electric field components adjust to accommodate the new boundary conditions. This field behavior explains why H-Plane Tees maintain phase coherence between signals, as the magnetic field coupling mechanism preserves the fundamental mode structure. The auxiliary arm connection point is strategically positioned to maximize field coupling efficiency while minimizing parasitic modes that could degrade performance. Advanced simulation tools and measurement techniques validate these electromagnetic principles, ensuring that manufactured H-Plane Tees deliver predictable and consistent performance across their specified frequency ranges.

H-Plane Tee Applications and Performance Characteristics

H-Plane Tee applications span numerous critical industries where reliable microwave signal management is paramount. In satellite communications systems, these components enable efficient signal distribution from single sources to multiple receivers, or conversely, combine multiple signals for transmission through single channels. The aerospace and defense sectors rely heavily on H-Plane Tees for radar systems, electronic warfare applications, and communication networks where signal integrity cannot be compromised. Telecommunications infrastructure utilizes these components in base station configurations, microwave link systems, and testing equipment where precise signal routing is essential. Advanced Microwave Technologies' H-Plane Tees excel in these demanding environments, offering superior performance characteristics including low insertion loss, high power handling capabilities, and excellent port-to-port isolation. The components support frequency ranges from DC to 40 GHz, accommodating diverse application requirements from legacy systems to cutting-edge 5G and emerging 6G technologies.

Power Handling and Frequency Response

The power handling capabilities of H-Plane Tees depend on several factors including frequency, waveguide size, construction materials, and thermal management considerations. Advanced Microwave Technologies designs H-Plane Tees capable of handling power levels up to 100 watts, depending on the specific model and operational conditions. The frequency response characteristics remain flat across wide bandwidths, ensuring consistent performance from low-frequency applications through millimeter-wave frequencies. Power handling limitations typically arise from peak electric field concentrations at the junction discontinuities, where careful design optimization minimizes these effects. Thermal considerations become increasingly important at higher power levels, where material selection and heat dissipation mechanisms influence overall system reliability. The company's engineering team conducts extensive power testing and thermal analysis to verify that each H-Plane Tee design meets or exceeds specified power handling requirements across its entire operational frequency range.

Signal Integrity and Phase Performance

Signal integrity represents a critical performance parameter for H-Plane Tees, particularly in applications requiring coherent signal processing or precise phase relationships. The in-phase combining characteristic of H-Plane Tees makes them ideal for applications where signals must maintain specific phase relationships, such as phased array antenna systems or coherent signal processing architectures. Phase stability across temperature variations and frequency changes ensures consistent performance in demanding operational environments. Advanced Microwave Technologies incorporates sophisticated design techniques to minimize phase variations and maintain excellent signal integrity across all operational conditions. The company's 24-meter microwave darkroom facility enables precise measurement of phase characteristics and signal integrity parameters, ensuring that manufactured components meet stringent performance specifications required by critical applications.

Advanced Manufacturing and Quality Assurance

The manufacturing process for high-performance H-Plane Tees requires sophisticated machining capabilities, precision tooling, and comprehensive quality control procedures. Advanced Microwave Technologies employs computer-numerical-control machining centers capable of maintaining tight dimensional tolerances essential for consistent electromagnetic performance. Material selection plays a crucial role in determining component reliability and performance characteristics, with options including aluminum, brass, and stainless steel depending on application requirements and environmental conditions. The junction geometry requires particular attention to surface finish quality and dimensional accuracy, as these parameters directly influence electrical performance and power handling capabilities. Quality assurance procedures include dimensional inspection, electrical performance testing, and environmental stress screening to ensure that each component meets or exceeds customer specifications and industry standards.

Testing and Validation Procedures

Comprehensive testing procedures verify that each H-Plane Tee meets performance specifications across its entire operational envelope. Advanced Microwave Technologies' measurement capabilities extend from DC to 110 GHz, enabling thorough characterization of electrical parameters including insertion loss, return loss, isolation, and phase characteristics. The company's Antenna Plane Near and Far Field Measuring Recombination Chamber provides advanced measurement capabilities for complex electromagnetic characterization. Environmental testing validates component performance across temperature ranges, humidity conditions, and mechanical stress environments typical of real-world applications. Power testing verifies component reliability at specified power levels, while long-term stability testing ensures consistent performance over extended operational periods. These comprehensive validation procedures guarantee that customers receive components that deliver reliable performance in their most demanding applications.

Customization and Engineering Support

Advanced Microwave Technologies recognizes that different applications require specific performance characteristics and physical configurations. The company's engineering team provides comprehensive customization services, tailoring H-Plane Tee designs to meet unique customer requirements including frequency response, power handling, connector types, and mechanical interfaces. Custom material selection addresses specific environmental requirements such as corrosion resistance, temperature stability, or weight constraints. The design process incorporates advanced electromagnetic simulation tools to optimize performance characteristics before manufacturing begins, reducing development time and ensuring first-pass success. Engineering support extends beyond initial design to include installation guidance, troubleshooting assistance, and performance optimization recommendations. This comprehensive support approach ensures that customers achieve optimal system performance while minimizing integration challenges and development risks.

Industry Standards and Compliance Requirements

Modern microwave component manufacturing must comply with numerous industry standards and regulatory requirements to ensure product quality, environmental sustainability, and workplace safety. Advanced Microwave Technologies maintains ISO 9001:2015 certification, demonstrating commitment to comprehensive quality management systems throughout all organizational processes. The ISO 14001:2015 environmental management standard reflects the company's dedication to minimizing environmental impact through responsible manufacturing practices, waste reduction programs, and energy conservation initiatives. ISO 45001:2018 certification ensures that employee health and safety remain paramount priorities in all manufacturing operations. RoHS compliance guarantees that manufactured components meet restrictions on hazardous substances, enabling use in environmentally sensitive applications and markets with stringent regulatory requirements. These certifications and compliance measures provide customers with confidence that Advanced Microwave Technologies products meet the highest standards for quality, environmental responsibility, and safety.

International Quality Standards Implementation

The implementation of international quality standards requires comprehensive documentation, process control, and continuous improvement initiatives throughout the organization. Advanced Microwave Technologies has integrated these standards into every aspect of operations, from initial design concepts through final product delivery and after-sales support. Quality management systems include detailed procedures for supplier qualification, incoming material inspection, manufacturing process control, and final product testing. Document control systems ensure that all personnel work with current specifications, procedures, and quality requirements. Regular internal audits and management reviews verify continued compliance and identify opportunities for process improvements. Customer feedback integration ensures that quality systems remain aligned with evolving market requirements and application needs. This systematic approach to quality management provides the foundation for consistent product excellence and customer satisfaction.

Conclusion

H-Plane Tees represent essential components in modern microwave systems, offering superior signal management capabilities through their unique shunt connection configuration. These precision-engineered devices provide reliable power division and combination while maintaining excellent phase characteristics and minimal insertion losses. Advanced manufacturing techniques and comprehensive quality assurance procedures ensure consistent performance across demanding applications in satellite communications, defense, aerospace, and telecommunications sectors.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Partner with Advanced Microwave Technologies Co., Ltd., your trusted China H-Plane Tee manufacturer and China H-Plane Tee supplier, for superior microwave solutions. As a leading China H-Plane Tee factory offering China H-Plane Tee wholesale services, we provide High Quality H-Plane Tees for sale at competitive H-Plane Tee prices. With over 20 years of experience, our ISO-certified facility delivers custom solutions backed by our 24m microwave darkroom testing capabilities. Our perfect supply chain system, professional R&D team, and fast delivery ensure your project success. Whether you need prototyping, technical support, or volume orders, our engineering excellence guarantees optimal performance. Contact craig@admicrowave.com today for your inquiry and discover why industry leaders trust our microwave expertise.

FAQ

Q: What is the main difference between H-Plane and E-Plane Tees?

A: H-Plane Tees provide in-phase signal combination at the junction, while E-Plane Tees produce 180-degree phase differences between outputs.

Q: What frequency range do H-Plane Tees typically support?

A: Modern H-Plane Tees support frequencies from DC to 40 GHz, with specialized designs extending to 110 GHz for millimeter-wave applications.

Q: How much power can H-Plane Tees handle?

A: Power handling capabilities vary by design and frequency, typically ranging up to 100 watts depending on the specific model and operational conditions.

Q: What are the primary applications for H-Plane Tees?

A: H-Plane Tees are widely used in satellite communications, radar systems, telecommunications infrastructure, aerospace applications, and microwave test equipment.

References

1. "Microwave Engineering: Fundamentals and Applications" by David M. Pozar, covering comprehensive waveguide tee theory and applications.

2. "RF Circuit Design: Theory and Practice" by Reinhold Ludwig and Pavel Bretchko, detailing microwave component design principles.

3. "Microwave Filters, Impedance-Matching Networks, and Coupling Structures" by George L. Matthaei, Leo Young, and E.M.T. Jones, providing detailed analysis of waveguide junction theory.

4. "Handbook of Microwave Component Measurements" by Joel P. Dunsmore, covering measurement techniques for microwave components including waveguide tees.