High Power Waveguide Isolators - Reliable RF Solutions

Picture this: You've invested hundreds of thousands in sensitive radar equipment, only to watch it fail catastrophically from reflected power surges. Your satellite ground station loses critical signal integrity during peak transmission hours. Your defense system's reliability is compromised by unexpected signal reflections. These nightmares are all too real in high-power RF applications, but they don't have to be. High Power Waveguide Isolator technology provides the protective barrier your mission-critical systems desperately need, ensuring reflected power never reaches your valuable transmitter components while maintaining exceptional signal quality across demanding operational environments.

Understanding High Power Waveguide Isolator Technology in Modern RF Systems

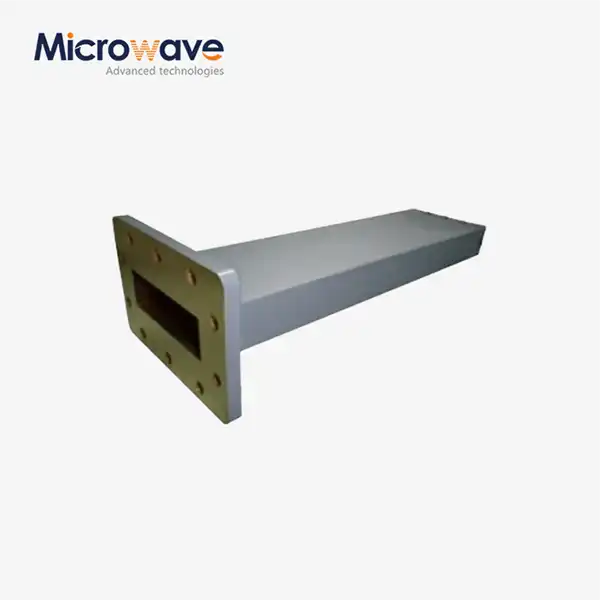

In today's demanding RF and microwave landscape, High Power Waveguide Isolator devices serve as essential guardians of system integrity. These non-reciprocal passive components function as unidirectional valves for electromagnetic energy, permitting signals to flow freely in one direction while blocking reflections that travel backward toward sensitive source equipment. The fundamental operating principle relies on ferrite materials combined with precisely engineered magnetic fields to create differential phase shifts depending on propagation direction. When forward-traveling signals pass through the High Power Waveguide Isolator, they experience minimal attenuation, typically around 0.3 dB insertion loss. However, reflected signals encounter substantial isolation, often exceeding 20 dB, effectively preventing them from reaching and potentially damaging high-power amplifiers, transmitters, or other vulnerable components. The physical construction of waveguide isolators differs significantly from coaxial alternatives, offering superior power handling capabilities essential for high-power applications. Rectangular or circular waveguide structures fabricated from aluminum or copper alloys provide robust mechanical platforms that efficiently dissipate heat generated during high-power operation. Advanced Microwave Technologies Co., Ltd manufactures High Power Waveguide Isolator products optimized for reliability, cost-effectiveness, and manufacturability from the initial design stage, ensuring customers receive components that perform flawlessly in real-world conditions rather than just laboratory specifications.

Critical Performance Parameters for High Power Applications

Successful deployment of High Power Waveguide Isolator technology requires careful consideration of multiple interrelated performance specifications. Forward power handling represents perhaps the most critical parameter, determining the maximum continuous or peak power the device can safely process without thermal damage or performance degradation. Advanced Microwave's isolators support forward power levels up to 1000 watts maximum, accommodating the demanding requirements of radar transmitters, satellite communication uplinks, and industrial heating applications. The bandwidth specification of 800 MHz ensures broad frequency coverage within assigned operating bands, providing flexibility for wideband communication systems and frequency-agile radar installations. Isolation performance directly impacts system protection effectiveness. With typical isolation values of 20 dB, these High Power Waveguide Isolator components effectively reduce reflected power to just one percent of its original magnitude, providing substantial safety margins for sensitive transmitter stages. Insertion loss, maintaining values around 0.3 dB typical, ensures minimal signal degradation during forward transmission, preserving precious transmit power and maintaining link budgets in communication systems. The VSWR (Voltage Standing Wave Ratio) specification further characterizes impedance matching quality, with superior designs achieving VSWR values better than 1.2:1, minimizing additional reflections generated by the isolator itself.

Material Selection and Environmental Durability

The harsh operating environments encountered in aerospace, defense, and satellite applications demand exceptional material performance from High Power Waveguide Isolator components. Advanced Microwave Technologies utilizes aluminum and copper alloys for waveguide housing construction, materials selected for their excellent electrical conductivity, thermal management properties, and favorable strength-to-weight ratios. These materials undergo precision CNC machining to achieve tight dimensional tolerances essential for optimal electromagnetic performance across the specified frequency range. Internal ferrite elements, the functional heart of isolation performance, are carefully selected and magnetized to provide stable characteristics across temperature and power variations. Environmental specifications reveal the robust nature of professional-grade High Power Waveguide Isolator designs. Operating temperature ranges from -40°C to +70°C accommodate everything from Arctic installations to desert deployments without performance compromise. This thermal stability results from careful thermal design, proper material selection, and comprehensive environmental testing during product development. RoHS compliance and ISO 9001:2015 certification demonstrate Advanced Microwave's commitment to environmental responsibility and consistent quality management, providing customers confidence that every High Power Waveguide Isolator meets stringent international standards for manufacturing excellence and environmental stewardship.

High Power Waveguide Isolator Applications Across Critical Industries

The versatility of High Power Waveguide Isolator technology enables deployment across an impressive spectrum of mission-critical applications. In satellite communication ground stations, these components protect expensive high-power amplifiers from antenna mismatch reflections caused by weather-related impedance variations, ice accumulation, or mechanical pointing errors. The isolators ensure continuous operation during critical communication windows, preventing system failures that could result in lost revenue, missed scientific data collection, or compromised military operations. For feeder systems connecting transmitters to antenna arrays, High Power Waveguide Isolator components provide essential protection while maintaining signal quality through their exceptionally low insertion loss characteristics. Air traffic control radar systems depend heavily on High Power Waveguide Isolator protection to maintain operational reliability in all weather conditions. These systems transmit substantial RF power to achieve necessary detection ranges, making them particularly vulnerable to damage from reflected energy caused by precipitation, birds, or nearby structures. By isolating the magnetron or solid-state transmitter from these unpredictable reflections, the isolator extends equipment lifespan dramatically while reducing maintenance costs and unplanned downtime. Weather monitoring radar installations similarly benefit from this protection, ensuring meteorologists receive uninterrupted data streams essential for accurate forecasting and severe weather warnings.

Defense and Aerospace System Integration

Military surveillance radar and electronic warfare systems operate under particularly demanding conditions where equipment reliability directly impacts mission success and personnel safety. High Power Waveguide Isolator components from Advanced Microwave Technologies provide the protection these systems require, handling peak power levels while maintaining isolation performance across wide temperature ranges and severe environmental conditions. Defense contractors specify these isolators for applications ranging from airborne early warning radar to ground-based air defense systems, where component failure simply isn't acceptable. The compact design and optimized space utilization allow integration into size-constrained platforms including unmanned aerial vehicles and shipboard installations. Aerospace navigation systems represent another critical application domain for High Power Waveguide Isolator technology. Precision landing systems, satellite navigation ground stations, and aircraft communication transceivers all benefit from the protection and signal integrity these components provide. The ability to operate reliably at altitude, withstand vibration and shock loads, and maintain performance across extreme temperature cycles makes properly designed isolators indispensable for aerospace applications. Advanced Microwave's ISO 45001:2018 certification for occupational health and safety management, combined with comprehensive quality systems, ensures components meet or exceed the rigorous reliability requirements aerospace applications demand.

Test and Measurement Equipment Requirements

Beyond operational systems, test and measurement applications frequently require High Power Waveguide Isolator protection to safeguard expensive instrumentation from damage caused by device under test mismatches or failures. Network analyzer calibration standards, power meter calibration systems, and antenna measurement facilities all benefit from strategically placed isolators that prevent reflected power from corrupting measurements or damaging sensitive receiver components. Advanced Microwave's 24-meter microwave darkroom facility, equipped with an Antenna Plane Near and Far Field Measuring Recombination Chamber, relies on precision High Power Waveguide Isolator components to ensure measurement accuracy and equipment protection throughout the 0.5 to 110 GHz frequency range.

Customization Capabilities and OEM Services for High Power Waveguide Isolators

Recognition that standard catalog components cannot address every application challenge drives Advanced Microwave Technologies' comprehensive OEM and customization services for High Power Waveguide Isolator products. Engineering teams work directly with customers to understand specific requirements including non-standard frequency bands, enhanced power handling, specialized flange configurations, or integrated cooling systems for extreme power density applications. The design process leverages decades of microwave engineering expertise combined with sophisticated electromagnetic simulation tools to optimize performance before manufacturing begins, reducing development time and ensuring first-pass design success. Frequency range customization represents a particularly common customer requirement, as operational bands vary widely across different applications and geographic regions. While standard High Power Waveguide Isolator designs cover widely used frequency allocations, custom designs can target narrow bands for optimized performance or cover extended bandwidths for frequency-agile systems. Advanced Microwave's comprehensive test capabilities, extending to 110 GHz, enable thorough characterization of custom designs across their entire operating range, providing customers detailed performance data that validates design specifications. This testing rigor, backed by ISO 9001:2015 quality management systems, ensures custom High Power Waveguide Isolator components meet or exceed promised performance specifications.

Fast Prototyping and Production Scalability

Time-to-market pressures in competitive technology sectors demand rapid prototyping capabilities for custom High Power Waveguide Isolator designs. Advanced Microwave Technologies maintains streamlined processes that compress the timeline from initial concept to functional prototype, allowing customers to evaluate performance in their specific application context quickly. Rapid prototyping doesn't compromise quality or performance; rather, it reflects efficient engineering workflows, established design methodologies, and responsive manufacturing capabilities that prioritize customer needs. Following prototype approval, production scaling proceeds smoothly, leveraging established supply chain relationships and proven manufacturing processes to deliver production quantities with consistent quality and on-time delivery. The company's perfect supply chain system and rich production experience enable cost advantages that benefit customers without sacrificing quality or performance. Strategic material sourcing, efficient manufacturing processes, and continuous improvement initiatives translate to competitive pricing even for specialized custom High Power Waveguide Isolator configurations. This cost leadership, combined with technical excellence and responsive customer service, positions Advanced Microwave Technologies as an ideal partner for both small-scale R&D projects and large-volume production programs. Professional technical R&D teams remain engaged throughout the product lifecycle, providing ongoing support for design optimization, application guidance, and troubleshooting assistance when needed.

Quality Assurance and International Certification Standards

Stringent quality control measures govern every stage of High Power Waveguide Isolator manufacturing at Advanced Microwave Technologies, from incoming material inspection through final test and shipment preparation. ISO 9001:2015 certification establishes comprehensive quality management systems that ensure consistent product quality through documented procedures, regular audits, and continuous improvement processes. Every High Power Waveguide Isolator undergoes rigorous testing to verify electrical performance specifications including insertion loss, isolation, VSWR, and power handling across the specified frequency range and operating temperature extremes. Automated test equipment combined with experienced technicians ensures measurement accuracy and repeatability while maintaining efficient throughput. Environmental management commitment demonstrated through ISO 14001:2015 certification reflects corporate responsibility extending beyond product performance alone. Manufacturing processes for High Power Waveguide Isolator components incorporate waste minimization, energy conservation, and emissions reduction strategies that minimize environmental impact while maintaining production efficiency. This environmental stewardship resonates with customers increasingly focused on supply chain sustainability and corporate social responsibility. RoHS compliance ensures High Power Waveguide Isolator products meet European Union restrictions on hazardous substances, facilitating export to global markets and demonstrating commitment to environmental protection and worker safety throughout the manufacturing process.

Workplace Safety and Technical Excellence

ISO 45001:2018 certification for occupational health and safety management systems underscores Advanced Microwave Technologies' commitment to employee wellbeing and workplace safety. Highly trained engineers and technicians operate sophisticated test equipment and precision manufacturing tools within environments designed to protect their health while enabling peak productivity. Proper training, protective equipment, and established safety protocols create a workplace culture where technical excellence and employee safety advance together rather than competing priorities. This focus on people directly benefits customers through reduced turnover, accumulated expertise, and consistent execution of complex manufacturing and test processes essential for High Power Waveguide Isolator quality. The combination of international certifications, advanced test capabilities, and experienced personnel positions Advanced Microwave Technologies as a trusted partner for customers with demanding requirements. Whether supporting telecommunications infrastructure, enabling defense systems, advancing aerospace technology, or facilitating scientific research, High Power Waveguide Isolator components from Advanced Microwave deliver the reliability, performance, and value that critical applications demand. Strong after-sales capability ensures customers receive ongoing support throughout product lifecycles, from initial selection and integration through long-term operation and potential future upgrades or modifications.

Conclusion

High Power Waveguide Isolator technology represents essential protection for valuable RF systems across satellite communications, defense, aerospace, and telecommunications industries, combining robust power handling with exceptional isolation performance and minimal insertion loss.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Partner with Advanced Microwave Technologies Co., Ltd, your premier China High Power Waveguide Isolator manufacturer, China High Power Waveguide Isolator supplier, and China High Power Waveguide Isolator factory offering competitive High Power Waveguide Isolator price without compromising High Quality High Power Waveguide Isolator standards. With over 20 years of expertise, ISO certifications, and comprehensive OEM services, we deliver China High Power Waveguide Isolator wholesale solutions backed by rapid prototyping, technical excellence, and superior after-sales support. Browse our High Power Waveguide Isolator for sale catalog, bookmark this resource for future reference, and contact craig@admicrowave.com today to discuss your custom requirements. Let our experienced team transform your RF protection challenges into optimized solutions that exceed performance expectations while meeting delivery timelines and budget constraints.

References

1. Baden Fuller, A.J. "Ferrites at Microwave Frequencies." Peter Peregrinus Ltd., London, Institution of Electrical Engineers Electromagnetic Waves Series.

2. Helszajn, J. "Nonreciprocal Microwave Junctions and Circulators." John Wiley & Sons, New York.

3. Linkhart, Douglas K. "Microwave Circulator Design." Artech House Microwave Library, Second Edition.

4. Pozar, David M. "Microwave Engineering." John Wiley & Sons, Fourth Edition.

YOU MAY LIKE

VIEW MOREHigh Power Waveguide to Coaxial Adapter

VIEW MOREHigh Power Waveguide to Coaxial Adapter VIEW MOREWaveguide Loop Coupler

VIEW MOREWaveguide Loop Coupler VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter

VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter VIEW MOREEnd Launch Waveguide to Microstrip Adapter

VIEW MOREEnd Launch Waveguide to Microstrip Adapter VIEW MOREWaveguide Sliding Termination

VIEW MOREWaveguide Sliding Termination VIEW MOREWaveguide Unmatched Termination

VIEW MOREWaveguide Unmatched Termination VIEW MOREMagic Hybrid Tee

VIEW MOREMagic Hybrid Tee VIEW MOREH-Plane Tee

VIEW MOREH-Plane Tee