What is a guide to buy a coaxial fixed attenuator for RF applications?

When your RF system performance falls short of expectations due to signal level mismatches, component overload, or measurement inaccuracies, the right Coaxial Fixed Attenuator can transform your entire system operation. Navigating the complex world of RF components can be overwhelming, especially when precision and reliability are paramount for your application success. This comprehensive guide will walk you through every critical consideration for selecting the ideal Coaxial Fixed Attenuator, from understanding technical specifications to evaluating manufacturer capabilities, ensuring you make an informed decision that delivers optimal system performance and long-term reliability.

Understanding Coaxial Fixed Attenuator Fundamentals

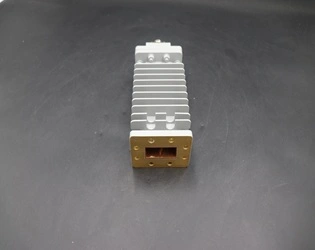

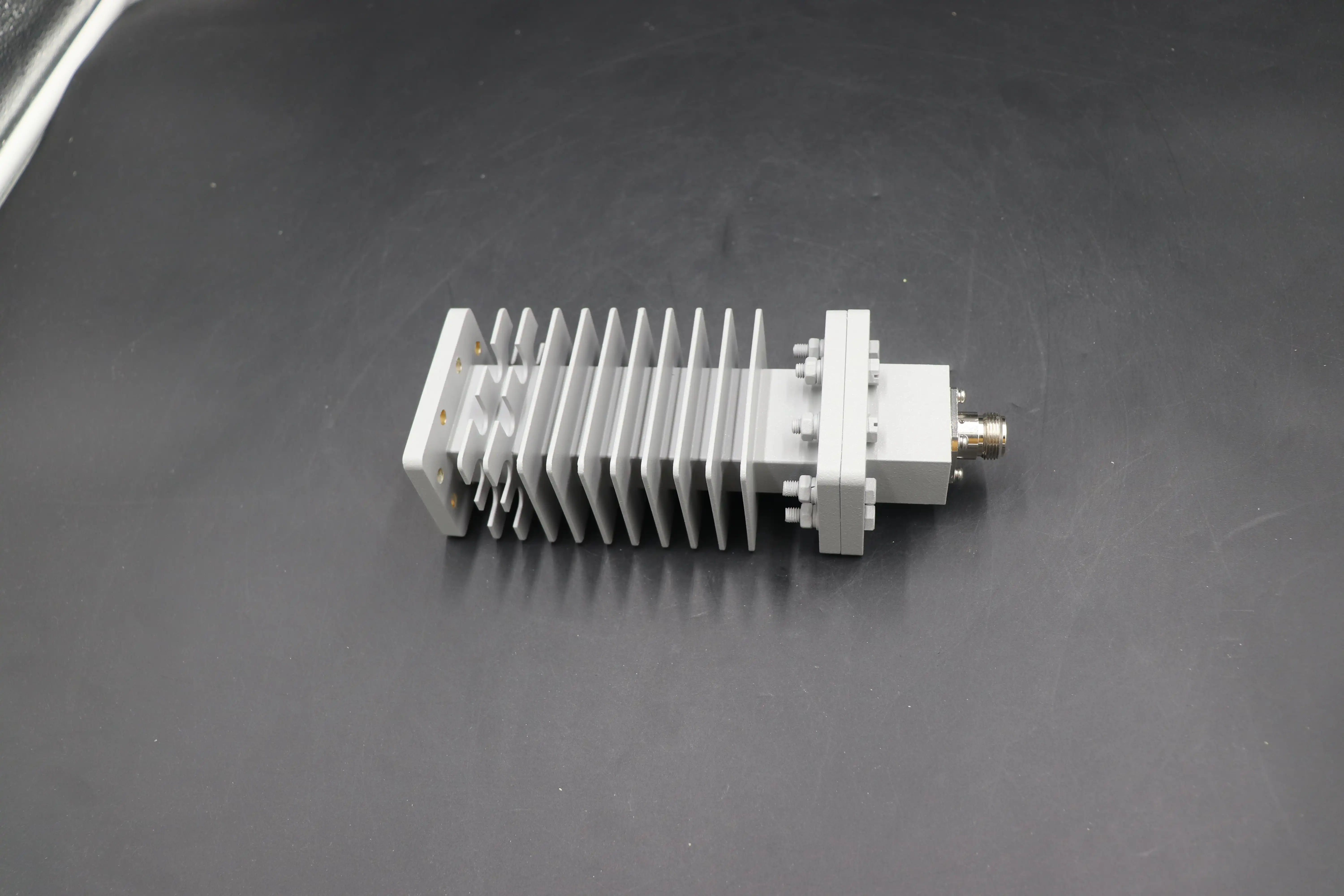

A Coaxial Fixed Attenuator represents one of the most essential components in RF and microwave systems, designed to reduce signal power by a predetermined amount while maintaining signal integrity and impedance matching. These passive devices serve as crucial building blocks in telecommunications, aerospace, defense, and measurement applications where precise signal control is paramount. The fundamental principle behind every Coaxial Fixed Attenuator involves controlled signal power reduction through carefully engineered resistive networks that absorb excess energy while preserving the characteristic impedance of the transmission line. Unlike variable attenuators, fixed units provide consistent attenuation values that remain stable across temperature variations and extended operational periods, making them ideal for applications requiring predictable performance. Modern Coaxial Fixed Attenuator designs incorporate advanced materials and manufacturing techniques to achieve exceptional frequency response characteristics. These components typically feature precision-machined housings, gold-plated contacts, and specialized dielectric materials that ensure minimal signal reflection and maximum power handling capability. The internal resistive elements are often fabricated using thin-film technology, providing superior stability and repeatability compared to traditional carbon or wire-wound resistors.

Key Performance Parameters

Voltage Standing Wave Ratio (VSWR) represents one of the most critical specifications for any Coaxial Fixed Attenuator, as it directly impacts signal integrity and system efficiency. A low VSWR indicates minimal signal reflection, typically achieved through precise impedance matching and high-quality connector interfaces. Professional-grade attenuators maintain VSWR values below 1.25:1 across their specified frequency range. Power handling capability determines the maximum continuous and peak power levels that the attenuator can safely manage without degradation or failure. This specification becomes particularly crucial in high-power applications such as broadcast transmitters, radar systems, and industrial heating applications. Thermal management through proper heat dissipation design ensures reliable operation under demanding conditions. Frequency response characteristics define the operational bandwidth over which the attenuator maintains specified performance parameters. Broadband designs covering DC to 26.5 GHz or higher frequencies require sophisticated engineering to minimize parasitic effects and maintain flat attenuation across the entire spectrum.

Essential Selection Criteria for RF Coaxial Fixed Attenuators

Frequency range compatibility stands as the primary consideration when selecting any Coaxial Fixed Attenuator for your specific application. Different frequency bands impose unique design challenges and material requirements, with higher frequencies demanding increasingly precise mechanical tolerances and specialized connector technologies. Understanding your system's operational bandwidth helps narrow down suitable options and prevents costly specification mismatches. Attenuation value selection requires careful analysis of your system's signal levels, component sensitivities, and measurement requirements. Common attenuation values include 3, 6, 10, 20, 30, and 40 dB, each serving specific purposes in signal conditioning and system optimization. The choice depends on factors such as transmitter output power, receiver input sensitivity, and dynamic range requirements. Power rating considerations encompass both average and peak power handling capabilities, which directly influence component longevity and system reliability. Environmental operating conditions, including temperature extremes, humidity, and vibration, further impact power derating requirements. Understanding these factors ensures proper component selection and prevents premature failure in demanding applications. Connector compatibility represents another crucial selection criterion, as mismatched interfaces can introduce significant signal degradation and mechanical reliability issues. Popular connector types include N-type, SMA, TNC, and specialized precision connectors like APC-3.5, each offering different performance characteristics and mechanical advantages.

Environmental and Mechanical Considerations

Operating temperature range significantly affects Coaxial Fixed Attenuator performance, particularly in aerospace, automotive, and industrial applications where extreme conditions are common. Temperature coefficients for attenuation and VSWR specify how these parameters change across the operational temperature range, helping predict system behavior under varying conditions. Mechanical construction quality impacts both electrical performance and long-term reliability. Robust housing materials, precision-machined connector interfaces, and proper environmental sealing ensure consistent performance in challenging environments. Vibration and shock resistance become critical factors for mobile and aerospace applications. Size and weight constraints often influence component selection, particularly in space-limited applications such as portable equipment and satellite systems. Miniaturized designs must balance performance requirements with physical constraints while maintaining thermal management capabilities.

Technical Specifications and Performance Metrics

Insertion loss represents the total signal loss introduced by the Coaxial Fixed Attenuator, combining the desired attenuation with any additional losses from connectors, internal transitions, and dielectric materials. High-quality attenuators minimize parasitic losses while maintaining precise attenuation values, ensuring accurate system calculations and optimal performance. Return loss specifications quantify the amount of signal reflected back toward the source, directly related to VSWR measurements. Excellent return loss performance indicates superior impedance matching and minimal system disruption, particularly important in sensitive measurement applications and high-frequency systems. Phase linearity characteristics become increasingly important in applications requiring precise timing relationships or coherent signal processing. Non-linear phase response can introduce signal distortion and measurement errors, making this parameter crucial for radar, communications, and instrumentation applications. Temperature stability specifications define how attenuation values change with temperature variations, typically expressed as temperature coefficients in dB per degree Celsius. Superior temperature stability ensures consistent system performance across varying environmental conditions without requiring frequent recalibration.

Power Handling and Thermal Management

Average power ratings specify the continuous power level that the Coaxial Fixed Attenuator can safely handle under specified environmental conditions. These ratings typically assume specific ambient temperatures and may require derating for higher temperature operations or restricted airflow conditions. Peak power handling capability addresses short-duration, high-power pulses common in radar and pulsed communication systems. This specification includes pulse width and duty cycle limitations that prevent thermal damage while accommodating typical operational requirements. Thermal resistance specifications help predict component temperature rise under various power dissipation levels, enabling proper thermal management design. Understanding these characteristics prevents overheating and ensures reliable long-term operation in demanding applications.

Advanced Coaxial Fixed Attenuator Technologies

Modern Coaxial Fixed Attenuator designs incorporate sophisticated materials and manufacturing processes to achieve superior performance characteristics. Thin-film resistive elements provide exceptional stability and precision compared to traditional technologies, while specialized substrate materials optimize high-frequency performance and thermal management. Surface mount technology (SMT) variants offer significant advantages in compact systems and automated manufacturing processes. These miniaturized components maintain excellent electrical performance while reducing size and weight requirements, making them ideal for modern telecommunications and portable equipment applications. Waveguide-to-coaxial transition attenuators address unique requirements in millimeter-wave applications where traditional coaxial interfaces become impractical. These specialized components enable seamless integration between different transmission line technologies while maintaining precise attenuation control.

Integration and System Considerations

Impedance matching requirements extend beyond the attenuator itself to include connecting cables, adapters, and system interfaces. Proper system design ensures minimal reflections and optimal power transfer throughout the signal path, maximizing overall system efficiency and performance. Calibration and traceability considerations become critical in measurement applications where accuracy and repeatability are paramount. Understanding calibration procedures and maintaining traceability to national standards ensures reliable measurement results and regulatory compliance. Electromagnetic compatibility (EMC) requirements may impose additional constraints on attenuator selection and system design. Proper shielding, grounding, and filtering techniques prevent interference and ensure compliance with relevant regulations and standards.

Quality Assessment and Manufacturer Evaluation

Manufacturing quality indicators include ISO certifications, quality control procedures, and testing methodologies employed by the manufacturer. Advanced Microwave Technologies Co., Ltd maintains ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications, demonstrating commitment to quality, environmental responsibility, and workplace safety. Testing and validation procedures ensure that each Coaxial Fixed Attenuator meets specified performance requirements across its operational envelope. Swept-frequency testing, power testing, and environmental stress screening identify potential issues before components reach end users, minimizing field failures and system downtime. Technical support capabilities and engineering expertise significantly impact successful component integration and long-term system success. Manufacturers with extensive application experience and responsive technical support teams provide valuable assistance throughout the product lifecycle.

Supply Chain and Delivery Considerations

Production capacity and lead time management become crucial factors in project planning and inventory management. Understanding manufacturer capabilities helps prevent delays and ensures adequate component availability for production schedules and maintenance requirements. Global distribution networks and logistics capabilities affect component availability and delivery schedules, particularly for international projects or remote installations. Reliable supply chains minimize project risks and ensure timely component delivery. Customization capabilities enable optimization for specific application requirements that may not be addressed by standard product offerings. OEM services and custom design capabilities provide flexibility for unique applications while maintaining cost-effectiveness and delivery schedules.

Cost-Effectiveness and Value Analysis

Total cost of ownership extends beyond initial component cost to include installation, maintenance, and replacement expenses throughout the system lifecycle. Higher-quality components may command premium pricing but often provide superior long-term value through reduced maintenance requirements and extended operational life. Performance-to-cost ratios help evaluate different options and identify optimal solutions for specific application requirements. Understanding the relationship between specifications and pricing enables informed decisions that balance performance needs with budget constraints. Volume pricing and long-term agreements can significantly reduce component costs for large-scale projects or ongoing production requirements. Many manufacturers offer attractive pricing structures for customers with substantial volume commitments or strategic partnerships.

Return on Investment Considerations

Reliability improvements and reduced downtime provide tangible benefits that often justify higher component costs. Superior components reduce maintenance expenses, minimize system failures, and improve overall operational efficiency, contributing to positive return on investment. Performance improvements enabled by high-quality Coaxial Fixed Attenuators can enhance system capabilities and competitive positioning. Better signal control, reduced interference, and improved measurement accuracy provide direct operational benefits that support business objectives. Future-proofing considerations ensure that selected components remain viable as system requirements evolve and technology advances. Choosing components with superior specifications and proven reliability helps extend system lifecycles and protect investment value.

Conclusion

Selecting the ideal Coaxial Fixed Attenuator for RF applications requires careful consideration of technical specifications, environmental requirements, and long-term reliability needs. Success depends on understanding your specific application requirements, evaluating manufacturer capabilities, and balancing performance needs with cost constraints to achieve optimal system performance.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd stands as your trusted China Coaxial Fixed Attenuator manufacturer with over 20 years of proven expertise in microwave components. Our comprehensive product portfolio includes high-quality Coaxial Fixed Attenuators designed for demanding RF applications, backed by our state-of-the-art 24m Microwave Darkroom and testing capabilities up to 110 GHz.

As a leading China Coaxial Fixed Attenuator supplier, we offer competitive pricing without compromising quality, making us your preferred China Coaxial Fixed Attenuator wholesale partner. Our ISO-certified manufacturing processes ensure every High Quality Coaxial Fixed Attenuator meets international standards, while our global distribution network provides reliable Coaxial Fixed Attenuator for sale worldwide.

Contact our expert team at craig@admicrowave.com to discuss your specific requirements and receive personalized quotes for our Coaxial Fixed Attenuator price options. Bookmark this guide for future reference and connect with us to experience the Advanced Microwave Technologies difference in RF component excellence.

FAQ

Q: What frequency range should I consider for my Coaxial Fixed Attenuator?

A: Choose based on your system's operational bandwidth, with common ranges from DC to 18 GHz or higher for modern applications.

Q: How do I determine the correct attenuation value for my application?

A: Calculate based on your signal levels, component sensitivities, and measurement requirements, with common values being 3, 6, 10, 20, 30, and 40 dB.

Q: What power rating should I select for safe operation?

A: Choose ratings well above your maximum operating power, considering both average and peak power requirements with appropriate derating factors.

Q: Which connector types are most suitable for RF applications?

A: N-type, SMA, and TNC connectors are most common, with selection based on frequency range, power handling, and mechanical requirements.

References

1. "RF Circuit Design: Theory & Applications" by Reinhold Ludwig and Gene Bogdanov - Comprehensive coverage of RF component theory and practical applications

2. "Microwave Engineering" by David M. Pozar - Fundamental principles of microwave components including attenuators and transmission lines

3. "RF and Microwave Passive and Active Technologies" by Mike Golio and Janet Golio - Detailed analysis of passive RF components and their applications

4. "High-Frequency Electronics Design Handbook" by John Fielding - Practical guidance for RF system design and component selection

YOU MAY LIKE

VIEW MORERight Angle Double Ridged WG To Coaxial Adapter

VIEW MORERight Angle Double Ridged WG To Coaxial Adapter VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter

VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter VIEW MORERight Angle Waveguide to Microstrip Adapter

VIEW MORERight Angle Waveguide to Microstrip Adapter VIEW MOREWG Termination

VIEW MOREWG Termination VIEW MOREDouble Ridge Waveguide Termination

VIEW MOREDouble Ridge Waveguide Termination VIEW MOREWaveguide Power Divider

VIEW MOREWaveguide Power Divider VIEW MOREE-Plane Tee

VIEW MOREE-Plane Tee VIEW MORECrossguide Directional Coupler

VIEW MORECrossguide Directional Coupler