What Are Waveguide Calibration Kits?

Picture this: You're a microwave engineer working on a critical satellite communication system. Your measurements show inconsistent results, and you're unsure whether the problem lies in your equipment or the system under test. Without proper calibration, even the most sophisticated Vector Network Analyzer becomes unreliable, potentially leading to costly system failures and project delays. Waveguide Calibration Kits are precision tools that eliminate these uncertainties by providing reference standards to calibrate measurement systems, ensuring accurate and repeatable results in microwave and millimeter-wave applications. These essential instruments serve as the foundation for reliable RF testing, enabling engineers to distinguish between measurement errors and actual system performance issues.

Understanding Waveguide Calibration Kit Fundamentals

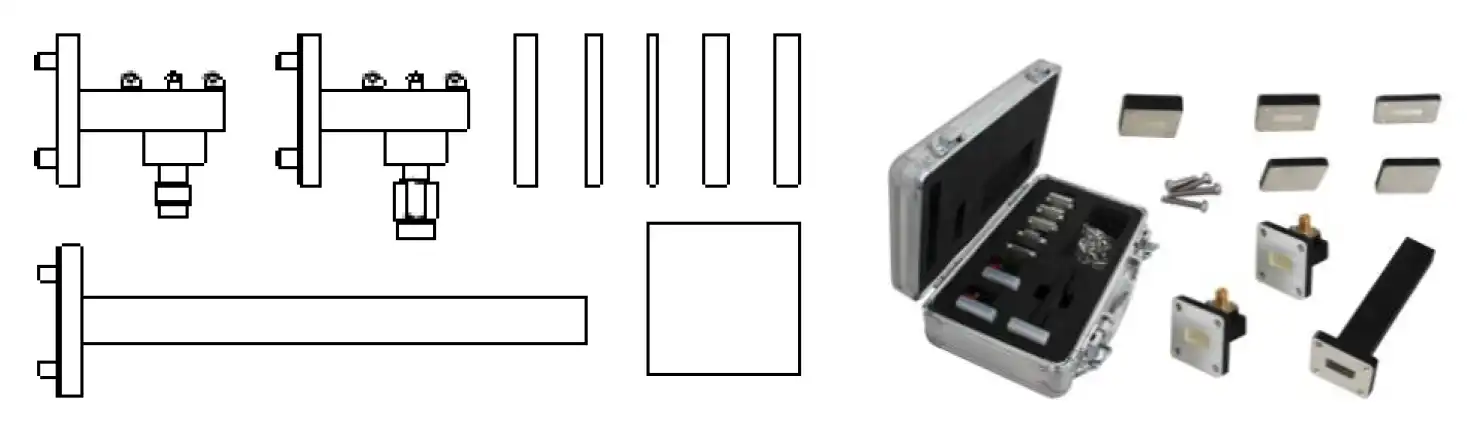

Waveguide Calibration Kits represent sophisticated measurement tools designed specifically for calibrating Vector Network Analyzers and other microwave test equipment operating at high frequencies. These kits contain a comprehensive set of precision-manufactured standards that serve as reference points for measurement systems, enabling accurate characterization of microwave components and systems. The fundamental principle behind Waveguide Calibration Kits lies in their ability to provide known impedance and transmission characteristics that can be mathematically removed from subsequent measurements, revealing the true performance of the device under test. The architecture of modern Waveguide Calibration Kits typically incorporates multiple impedance standards including short circuits, offset shorts, and matched loads, along with transmission standards such as through connections or line standards. This combination allows for comprehensive two-port calibration procedures that can eliminate systematic errors inherent in measurement systems. Advanced Microwave's waveguide calibration kits include a set of precision components that technicians can use to calibrate and verify waveguide assemblies, ensuring signal integrity and system reliability across frequencies ranging from 0.5 to 110 GHz.

Essential Components and Standards

The core components within Waveguide Calibration Kits serve specific mathematical functions in the calibration process. Short circuit standards provide perfect reflection with zero phase shift, while offset short circuits introduce known phase shifts typically at 1/8 lambda and 3/8 lambda intervals. These offset shorts effectively replace open circuit standards in waveguide systems, where true open circuits are difficult to achieve due to fringing fields and radiation effects. Matched load standards present theoretically perfect impedance matching, absorbing all incident energy without reflection. Transmission standards complete the calibration suite by providing known insertion loss and phase shift characteristics. These components enable the measurement system to distinguish between losses introduced by the test setup versus those inherent in the device under test. The precision manufacturing of these standards ensures repeatability and accuracy across multiple measurement sessions, critical for maintaining measurement integrity in production environments and research applications.

Technical Specifications and Performance Characteristics

Modern Waveguide Calibration Kits demonstrate remarkable technical capabilities that address the demanding requirements of contemporary microwave applications. The frequency coverage extends from traditional microwave bands through millimeter-wave frequencies, with some systems supporting operations up to 110 GHz and beyond. This extensive frequency range accommodates everything from legacy communication systems to cutting-edge 5G and emerging 6G technologies that operate at increasingly higher frequencies. The precision characteristics of these calibration kits directly impact measurement accuracy and system performance. High-quality Waveguide Calibration Kits achieve return loss specifications exceeding 40 dB for matched loads, while short circuit standards maintain reflection coefficients within 0.01 dB of ideal performance. Phase accuracy typically remains within ±2 degrees across the specified frequency range, enabling precise characterization of phase-sensitive components such as filters, amplifiers, and antenna systems.

Material Selection and Durability Features

The materials used in constructing Waveguide Calibration Kits significantly influence their long-term stability and measurement repeatability. Premium kits utilize high-grade brass or aluminum alloys with specialized surface treatments to minimize oxidation and maintain stable electrical characteristics over time. Contact surfaces often incorporate gold plating to ensure low-resistance connections and prevent corrosion that could degrade measurement accuracy. Mechanical precision plays an equally important role in kit performance. Manufacturing tolerances for critical dimensions typically remain within micrometers, ensuring consistent electromagnetic behavior across multiple connect-disconnect cycles. This mechanical stability becomes particularly important in production environments where calibration kits experience frequent use and handling. Advanced Microwave Technologies Co., Ltd ensures our calibration kits are manufactured to the highest standards, incorporating durable materials that withstand harsh environments while maintaining optimal performance and reliability.

Industry Applications and Use Cases

The versatility of Waveguide Calibration Kits enables their deployment across numerous industries and application areas. In telecommunications, these kits play crucial roles in base station development, satellite communication system testing, and network infrastructure validation. The ability to accurately characterize filters, amplifiers, and antenna systems directly impacts system performance, coverage area, and signal quality for end users. Aerospace and defense applications represent another significant market for Waveguide Calibration Kits. Radar systems, electronic warfare equipment, and missile guidance technologies all require precise calibration to ensure proper operation in critical scenarios. The high-frequency capabilities of modern calibration kits support the development of advanced radar systems operating in millimeter-wave bands, where traditional calibration methods become inadequate.

Research and Development Applications

Research institutions and advanced technology companies rely heavily on Waveguide Calibration Kits for developing next-generation microwave and millimeter-wave technologies. These applications often push the boundaries of frequency coverage, requiring calibration standards that maintain accuracy at the limits of current technology. Universities conducting electromagnetic research, companies developing 5G and 6G communication systems, and organizations working on advanced radar technologies all depend on precise calibration capabilities. The customization potential of Waveguide Calibration Kits enables support for specialized research applications. Custom frequency bands, non-standard waveguide sizes, and specialized connector interfaces can be accommodated to meet specific research requirements. This flexibility proves essential for exploring new frequency bands and developing innovative measurement techniques that advance the overall field of microwave engineering.

Advanced Measurement Techniques and Calibration Procedures

The implementation of Waveguide Calibration Kits involves sophisticated measurement procedures that maximize accuracy and minimize uncertainty. The most common approach utilizes the Short-Offset Short-Load-Through (SOSLT) technique, which adapts traditional coaxial calibration methods to waveguide environments. This technique accounts for the unique propagation characteristics of waveguide systems while maintaining mathematical rigor in error correction. Advanced calibration procedures incorporate multiple offset short positions to improve calibration robustness and reduce sensitivity to manufacturing tolerances. The use of multiple offset positions provides redundancy in the calibration process, enabling statistical analysis of measurement uncertainty and identification of potential systematic errors. Modern Vector Network Analyzers automatically implement these advanced calibration algorithms, simplifying the calibration process for operators while maintaining mathematical precision.

Quality Assurance and Verification Methods

Maintaining calibration kit accuracy requires comprehensive quality assurance procedures that verify standard performance over time. Regular verification measurements using independent reference standards help identify drift in calibration kit characteristics, ensuring continued measurement accuracy. These verification procedures typically involve cross-checking with national standards laboratories or using automated verification systems that continuously monitor calibration kit performance. The traceability chain for Waveguide Calibration Kits extends to national measurement institutes, providing confidence in measurement results and supporting regulatory compliance requirements. This traceability becomes particularly important in aerospace, defense, and telecommunications applications where measurement accuracy directly impacts system safety and performance. Advanced Microwave Technologies Co., Ltd maintains rigorous quality control procedures throughout the manufacturing process, ensuring each calibration kit meets strict performance specifications and maintains long-term stability.

Conclusion

Waveguide Calibration Kits serve as indispensable tools for ensuring measurement accuracy in microwave and millimeter-wave applications. Their precision-engineered components enable reliable calibration of test equipment across frequencies extending to 110 GHz, supporting applications from telecommunications to aerospace. The combination of technical sophistication and practical utility makes these kits essential for any organization working with high-frequency electromagnetic systems.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd stands as a leading China Waveguide Calibration Kits manufacturer and China Waveguide Calibration Kits supplier with over 20 years of expertise in microwave technology. As a trusted China Waveguide Calibration Kits factory, we offer China Waveguide Calibration Kits wholesale solutions alongside premium Waveguide Calibration Kits for sale. Our High Quality Waveguide Calibration Kits feature competitive Waveguide Calibration Kits price points backed by our state-of-the-art 24m Microwave Darkroom and ISO certifications. Our perfect supply chain system, rich production experience, and professional technical R&D team ensure fast delivery with strict quality control. Whether you need prototyping, technical support, or customized OEM solutions, our expert engineers provide comprehensive assistance from installation guidance to troubleshooting support. Ready to enhance your microwave testing capabilities? Contact us at craig@admicrowave.com for personalized consultation and competitive quotes. Bookmark this page for future reference and stay ahead in microwave technology!

FAQ

Q: What frequency range do waveguide calibration kits typically cover?

A: Modern waveguide calibration kits cover frequencies from 0.5 GHz up to 110 GHz, supporting applications from traditional microwave to millimeter-wave systems.

Q: How often should waveguide calibration kits be recalibrated?

A: Calibration kits should typically be verified annually or according to your quality management system requirements, with more frequent checks for high-usage environments.

Q: What components are included in a standard waveguide calibration kit?

A: Standard kits include short circuits, offset shorts at 1/8 and 3/8 wavelength positions, matched loads, and through connections for comprehensive two-port calibration.

Q: Can waveguide calibration kits be customized for specific applications?

A: Yes, calibration kits can be customized for specific frequency bands, waveguide sizes, materials, and connector interfaces to meet specialized application requirements.

References

1. "RF and Microwave Circuit Design for Wireless Communications" by Lawrence E. Larson, 2nd Edition, Artech House Publishers

2. "Microwave Engineering" by David M. Pozar, 4th Edition, John Wiley & Sons

3. "Network Analyzer Error Models and Calibration Methods" by Roger B. Marks, National Institute of Standards and Technology Technical Note 1364

4. "Waveguide Handbook" by Nathan Marcuvitz, Institution of Engineering and Technology

YOU MAY LIKE

VIEW MOREDouble Ridge Straight Waveguide

VIEW MOREDouble Ridge Straight Waveguide VIEW MOREDouble Ridge Waveguide Transition

VIEW MOREDouble Ridge Waveguide Transition VIEW MOREDouble Ridged Flexible Waveguide

VIEW MOREDouble Ridged Flexible Waveguide VIEW MOREDouble Ridge Waveguide Load

VIEW MOREDouble Ridge Waveguide Load VIEW MOREDouble Ridge Waveguide Rotary Joint

VIEW MOREDouble Ridge Waveguide Rotary Joint VIEW MOREDouble-Ridged Waveguide Broadwall Directional Coupler

VIEW MOREDouble-Ridged Waveguide Broadwall Directional Coupler VIEW MOREWaveguide Flange Gasket

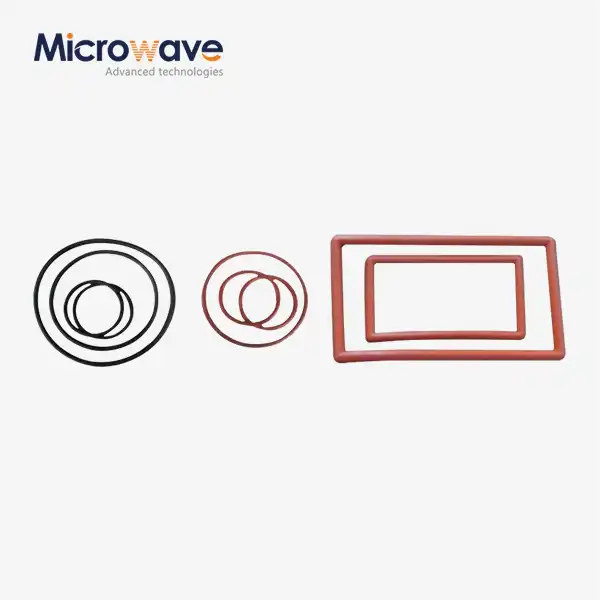

VIEW MOREWaveguide Flange Gasket VIEW MOREWaveguide Adjustable Support

VIEW MOREWaveguide Adjustable Support