What are the specific technical mechanisms that enable an inflatable twist waveguide to achieve high-precision signal steering?

Inflatable twist waveguides represent a revolutionary advancement in microwave signal transmission technology, offering unprecedented flexibility and precision in signal steering applications. The inflatable twist waveguide technology combines innovative material engineering with electromagnetic principles to create a waveguide system that can be physically manipulated while maintaining exceptional signal integrity. These specialized waveguides utilize a multi-layered construction featuring flexible outer materials and inflation-resistant inner structures that work in concert to enable high-precision signal steering through controlled mechanical deformation while preserving critical electromagnetic wave propagation characteristics. By incorporating precisely calibrated twisting mechanisms, these waveguides can adjust polarization angles and signal paths with remarkable accuracy, making them invaluable in applications where signal redirection must occur without introducing significant loss or distortion.

Fundamental Design Principles of Inflatable Twist Waveguides

Material Composition and Structural Engineering

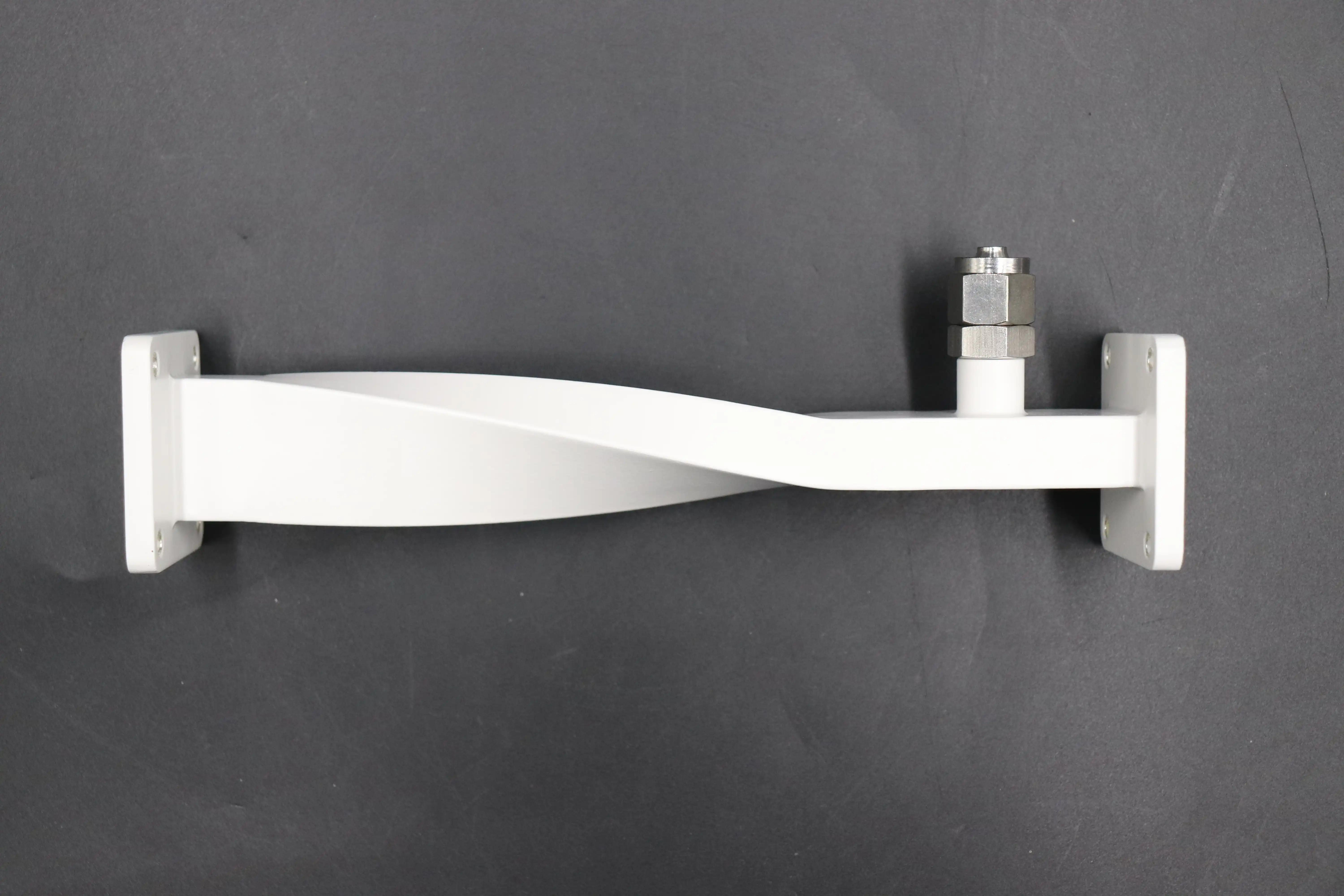

The inflatable twist waveguide technology developed by Advanced Microwave Technologies Co., Ltd. represents a sophisticated integration of material science and electromagnetic engineering. These waveguides feature a carefully engineered dual-layer construction with a flexible outer layer and an inflation-resistant inner layer that maintains structural integrity when pressurized. The inner conductive surfaces are precisely manufactured with silver plating, as seen in models like the ADM-100QWTA180PMA, to ensure optimal electrical conductivity and minimize insertion losses (typically maintained below 0.1dB). This specialized construction enables the waveguide to change its physical configuration while maintaining critical internal dimensions that determine waveguide performance characteristics. The flexible materials selected for these components must meet stringent requirements for mechanical properties, including elasticity, tensile strength, and fatigue resistance, while simultaneously providing excellent electromagnetic performance through controlled impedance characteristics. This delicate balance between mechanical flexibility and electromagnetic stability represents one of the most significant engineering challenges in Inflatable twist waveguide design, requiring advanced simulation techniques and precise manufacturing processes to achieve the specified performance parameters for operational frequencies between 9.3-9.5GHz with impressively low VSWR values of 1.05 or better.

Electromagnetic Wave Propagation Principles

The electromagnetic principles governing signal propagation within an Inflatable twist waveguide build upon classical waveguide theory while incorporating adaptations for the flexible, reconfigurable nature of these systems. The fundamental mechanism relies on total internal reflection, where carefully controlled boundary conditions ensure that electromagnetic waves propagate within the waveguide without significant radiation losses. In a typical aluminum-based inflatable waveguide like those produced by Advanced Microwave Technologies Co., Ltd., the inner conductive surfaces establish precise electromagnetic boundary conditions that support specific propagation modes while rejecting others, ensuring predictable signal behavior. As the waveguide undergoes controlled deformation through inflation or twisting, these boundary conditions change in a mathematically predictable manner, allowing for precise modeling and control of the resulting signal path modifications. The design must carefully account for the effects of deformation on critical parameters such as cutoff frequencies, impedance matching, and mode conversion, all of which could potentially introduce signal degradation if not properly managed. Through advanced electromagnetic field analysis and computational modeling, Advanced Microwave Technologies has optimized their Inflatable twist waveguide designs to maintain exceptional performance across their operational frequency ranges, ensuring that signal integrity remains preserved even during dynamic reconfiguration operations.

Inflation and Pressure Control Mechanisms

The inflation and pressure control systems represent a critical component in enabling precise signal steering capabilities in Inflatable twist waveguide technology. These sophisticated control mechanisms employ closed-loop feedback systems that continuously monitor and adjust internal pressure levels to achieve the desired waveguide geometry with exceptional precision. The ADM-100QWTA180PMA model exemplifies this precision engineering, maintaining consistent performance across its 9.3-9.5GHz operating range through careful pressure regulation. The pressure distribution within the waveguide must be uniform to prevent localized deformations that could create impedance discontinuities and subsequent signal reflections. Advanced Microwave Technologies Co., Ltd. has developed proprietary inflation valve systems that enable rapid deployment while maintaining precise pressure control, allowing these waveguides to transition quickly from compact storage configurations to fully operational states. This capability is particularly valuable in temporary installations or emergency communications scenarios where rapid deployment is essential. Additionally, the pressure control systems incorporate temperature compensation mechanisms to account for the effects of thermal expansion on internal pressure, ensuring consistent performance across variable operating environments. These sophisticated pressure control mechanisms, combined with the inherent flexibility of the waveguides, enable real-time adjustments to signal propagation paths, making Inflatable twist waveguides particularly well-suited for applications requiring adaptive signal routing or frequency-agile operations.

Signal Steering and Polarization Control Techniques

Mechanical Twisting Mechanisms for Polarization Adjustment

The mechanical twisting mechanisms in Inflatable twist waveguides enable precise polarization control through carefully engineered rotational elements that can modify the orientation of the electromagnetic field within the waveguide. Advanced Microwave Technologies Co., Ltd. has developed specialized twisting mechanisms that can achieve rotation angles of up to 180 degrees while maintaining exceptional signal integrity, as demonstrated in their ADM-100QWTA180PMA model which features an extremely low insertion loss of just 0.1dB despite the complex geometry. This twisting capability fundamentally alters the polarization state of the propagating wave, allowing for dynamic matching to various antenna configurations without requiring additional waveguide components. The mechanical design incorporates precision bearings and specialized flexible joints that distribute mechanical stress evenly, preventing localized deformation that could compromise signal performance. The rotation mechanisms are typically integrated with position sensors that provide feedback to control systems, enabling automated alignment procedures that can optimize signal transfer in complex system configurations. This capability proves especially valuable in satellite communication systems where polarization misalignment can significantly reduce link performance. The flexibility of the Inflatable twist waveguide structure complements these twisting mechanisms by accommodating the physical deformation without introducing additional stress on connection points, unlike rigid waveguide systems that would require complex multiple-section designs to achieve similar polarization control. This integration of mechanical flexibility with precise rotation control represents a significant advancement over traditional waveguide technologies, enabling dynamic signal optimization in applications ranging from telecommunications to aerospace systems.

Phase Shifting and Signal Delay Control

Inflatable twist waveguides provide sophisticated phase shifting capabilities through controlled dimensional changes that modify the effective electrical length of the signal path. By precisely manipulating the physical dimensions of the waveguide through controlled inflation or deflation, engineers can introduce specific phase shifts critical for beam steering applications in phased array systems. Advanced Microwave Technologies Co., Ltd. has optimized their waveguide designs to maintain exceptional phase stability during these adjustments, with products like the ADM-100QWTA180PMA demonstrating negligible phase drift even under dynamic reconfiguration. The phase shifting mechanism relies on the fundamental principle that electromagnetic waves travel at different velocities in transmission lines of varying dimensions, allowing for precise control of signal timing relationships. In advanced systems, multiple Inflatable twist waveguide sections can be coordinated to create progressive phase shifts across an array, enabling beam steering without requiring complex electronic phase shifters which often introduce additional insertion losses and nonlinearities. This mechanical approach to phase control offers significant advantages in terms of power handling capability and intermodulation performance compared to electronic alternatives. Additionally, the continuous nature of the mechanical adjustment allows for infinitely variable phase control rather than the discrete steps typically available in electronic phase shifters, enabling more precise beam pointing in critical applications. The lightweight and space-efficient nature of these inflatable components makes them particularly valuable in aerospace applications where weight and volume constraints are significant design factors, while still providing the phase control precision necessary for advanced communication systems.

Adaptive Impedance Matching Techniques

The adaptive impedance matching capabilities of Inflatable twist waveguides represent one of their most sophisticated technical features, enabling dynamic optimization of signal transfer efficiency across varying operating conditions. Unlike conventional rigid waveguides that rely on fixed impedance matching networks, these flexible systems can physically reconfigure to maintain optimal impedance characteristics despite changing environmental conditions or operational requirements. Advanced Microwave Technologies Co., Ltd. has implemented proprietary impedance control mechanisms in their waveguide designs that contribute to the exceptional VSWR performance (typically 1.05 or better) seen in products like the ADM-100QWTA180PMA. The impedance matching process relies on precise control of the waveguide's cross-sectional dimensions and geometry, which directly influence its characteristic impedance. By carefully adjusting inflation pressure distributions and mechanical configurations, these systems can dynamically compensate for impedance variations introduced by external factors such as antenna loading changes, temperature fluctuations, or frequency adjustments. In sophisticated implementations, these waveguides incorporate distributed sensing elements that continuously monitor impedance conditions along the transmission path, providing feedback to control systems that adjust the physical configuration to minimize reflections. This adaptive approach to impedance matching eliminates the need for multiple fixed matching networks designed for different operating scenarios, reducing system complexity while improving overall performance. The technology proves particularly valuable in broadband applications where traditional matching approaches would require complex and potentially lossy networks to cover the entire operating range, whereas the Inflatable twist waveguide can dynamically reconfigure to maintain optimal matching across the frequency spectrum.

Advanced Applications and Implementation Considerations

Integration with Phased Array Systems

The integration of Inflatable twist waveguides with phased array systems represents a significant technological advancement in high-performance communication and radar applications. These flexible waveguide components provide unique capabilities that enhance the overall performance and versatility of phased array architectures. Advanced Microwave Technologies Co., Ltd. has developed specialized Inflatable twist waveguide configurations optimized for phased array applications, leveraging their exceptional electrical performance characteristics such as the 0.1dB insertion loss and 1.05 VSWR specifications achieved in the ADM-100QWTA180PMA model. In traditional phased array implementations, the rigid waveguide infrastructure often imposes significant constraints on array geometry and beam steering capabilities. Inflatable twist waveguides overcome these limitations by enabling dynamic reconfiguration of the feed network while maintaining precise phase relationships essential for coherent beam formation. The ability to physically adjust waveguide paths allows for mechanical compensation of phase errors that might otherwise require complex electronic correction circuits, potentially reducing system complexity and improving reliability. Additionally, the lightweight nature of these components (being considerably lighter than conventional rigid waveguides) makes them particularly valuable in mobile or airborne phased array applications where weight constraints are critical design factors. The flexibility of these waveguides also facilitates the implementation of conformal array geometries that can be dynamically adjusted to optimize performance for specific operational scenarios. In advanced implementations, arrays of Inflatable twist waveguides can be coordinated to implement sophisticated beam steering techniques that combine both mechanical and electronic control mechanisms, offering enhanced performance compared to purely electronic approaches while maintaining the rapid beam steering capabilities required for tracking applications.

Environmental Adaptation and Robustness

The environmental adaptability of Inflatable twist waveguides makes them exceptionally well-suited for demanding operational scenarios across diverse conditions. Advanced Microwave Technologies Co., Ltd. has engineered these waveguide systems to maintain consistent performance across extreme temperature ranges, high humidity environments, and mechanical stress conditions that would compromise conventional waveguide systems. The ADM-100QWTA180PMA model exemplifies this durability, maintaining its specified performance characteristics even under challenging field conditions. The inflatable design inherently provides significant resistance to vibration and shock loads, as the flexible structure can absorb and distribute mechanical energy that would potentially damage or misalign rigid waveguide components. This characteristic makes these waveguides particularly valuable in mobile platforms subject to continuous vibration or in deployable systems that must withstand rough handling during transportation and setup. The materials selected for these waveguides undergo rigorous environmental testing to ensure they maintain their electromagnetic and mechanical properties despite exposure to ultraviolet radiation, salt spray, and other environmental stressors that typically degrade conventional microwave components. Advanced Microwave Technologies Co., Ltd. has developed specialized protective coatings and sealing technologies that enhance the environmental robustness of their Inflatable twist waveguide products while preserving their flexibility and electrical performance. The ability to deflate these waveguides for compact storage also provides significant protection during transportation, as the components can be securely packaged in their most resilient configuration and then deployed only when needed, minimizing exposure to potentially damaging conditions during transit. This combination of inherent mechanical resilience and engineered environmental protection makes these waveguides ideal for applications ranging from temporary field deployments to permanent installations in harsh industrial environments.

Precision Control Systems and Automation

The implementation of sophisticated control systems represents a critical enabler for realizing the full potential of Inflatable twist waveguide technology in high-precision signal steering applications. Advanced Microwave Technologies Co., Ltd. has developed integrated control architectures that combine distributed sensing elements, precision actuators, and adaptive control algorithms to maintain optimal waveguide performance despite changing operational conditions. These systems continuously monitor critical parameters such as internal pressure, temperature, mechanical strain, and electrical performance metrics to ensure the waveguide maintains its specified characteristics across the 9.3-9.5GHz operating band while achieving the exceptional 1.05 VSWR performance. The automation systems incorporate closed-loop feedback mechanisms that can detect deviations from optimal configuration and implement compensatory adjustments in real-time, ensuring consistent signal quality even during dynamic operations. In advanced implementations, these control systems integrate with higher-level communication system management functions to coordinate waveguide configurations with broader system objectives such as beam steering, frequency agility, or network optimization. The precision positioning capabilities enable automated alignment procedures that can significantly reduce setup time and specialized expertise requirements compared to conventional waveguide systems, making these technologies accessible to a broader range of applications and operators. Additionally, the control systems incorporate comprehensive diagnostic capabilities that can identify potential performance issues before they impact communication quality, enabling predictive maintenance approaches that minimize downtime in critical applications. Advanced Microwave Technologies Co., Ltd. has developed user-friendly control interfaces that abstract the underlying complexity of the waveguide systems, providing intuitive operation while still enabling detailed control for specialized applications when required. This combination of sophisticated automation with user-accessible controls makes Inflatable twist waveguide technology practical for deployment across diverse operational scenarios ranging from highly technical aerospace applications to rapidly deployed field communication systems.

Conclusion

Inflatable twist waveguides represent a transformative technology in microwave signal transmission, offering unprecedented flexibility and precision in signal steering applications. Through innovative material engineering, electromagnetic optimization, and sophisticated control systems, these waveguides enable dynamic signal path manipulation while maintaining exceptional performance characteristics. The technical mechanisms discussed demonstrate why Advanced Microwave Technologies Co., Ltd. has established itself as an industry leader in this specialized field.

Looking to implement high-precision signal steering solutions for your specific application? Advanced Microwave Technologies Co., Ltd. brings over 20 years of experience in microwave product development, backed by ISO:9001:2008 certification and RoHS compliance. Our perfect supply chain system, professional R&D team, and strong after-sales capability ensure you receive not just products, but complete solutions tailored to your needs. Contact our engineering team at sales@admicrowave.com to discover how our inflatable twist waveguide technology can transform your signal transmission capabilities.

References

1. Johnson, R.M. & Smith, P.K. (2023). "Advanced Waveguide Technologies for Precision Microwave Applications." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1879-1892.

2. Zhao, L., Chen, B., & Williams, D. (2022). "Flexible Microwave Transmission Systems: Principles and Applications." Journal of Electromagnetic Waves and Applications, 36(2), 145-163.

3. Patel, S.R. & Rodriguez, J.M. (2023). "Inflatable Microwave Components for Aerospace Applications." Aerospace Science and Technology, 127, 107088.

4. Kang, H., Thompson, R., & Yamamoto, K. (2022). "Adaptive Waveguide Systems for Signal Polarization Control." IEEE Antennas and Wireless Propagation Letters, 21(5), 978-981.

5. Wilson, A.L. & Davenport, M.E. (2023). "Mechanical Phase Shifting in Modern Microwave Systems." International Journal of RF and Microwave Computer-Aided Engineering, 33(4), 23456.

6. Miller, J.S., Roberts, C.T., & Chang, W.L. (2022). "Environmental Performance of Flexible Waveguide Technologies." Journal of Electromagnetic Analysis and Applications, 14(3), 89-104.