Waveguide Gaskets: Types, Features & Selection

In high-frequency microwave systems, signal leakage at waveguide joints can devastate system performance, causing costly failures in satellite communications, radar operations, and aerospace applications. The Waveguide Anti-leak Gasket emerges as the critical solution, preventing electromagnetic interference and maintaining signal integrity where precision matters most. This comprehensive guide explores gasket types, essential features, material selection criteria, and practical considerations to help engineers and procurement specialists make informed decisions for their waveguide assemblies.

Understanding Waveguide Anti-leak Gasket Fundamentals

The Waveguide Anti-leak Gasket serves as an essential interface component between waveguide flanges, creating both mechanical seals and electromagnetic continuity. These specialized gaskets prevent electromagnetic waves transmitted through the waveguide from leaking into external environments while simultaneously blocking external electromagnetic interference from entering the system. Through their electromagnetic shielding characteristics, these gaskets alter the propagation path of electromagnetic waves or reflect them back into the waveguide, thereby ensuring electromagnetic compatibility of the entire waveguide system and preserving signal transmission integrity, accuracy, and confidentiality. In waveguide equipment deployed across communication networks, radar installations, and electronic countermeasure systems, the Waveguide Anti-leak Gasket functions as one of the key components maintaining normal and efficient system operation. The gasket's performance directly impacts system reliability, with poorly selected or installed gaskets leading to signal degradation, increased insertion loss, and potential system failures. Advanced materials and precision manufacturing techniques have evolved to meet increasingly stringent requirements for higher frequencies, broader bandwidths, and more demanding environmental conditions.

Critical Functions of Waveguide Sealing Systems

Waveguide Anti-leak Gasket technology addresses multiple critical functions simultaneously. Primary among these is electromagnetic interference shielding, where conductive elastomer composites create continuous electrical paths across flange interfaces, preventing high-frequency signal leakage that would otherwise compromise system performance. The gasket material must exhibit excellent conductivity characteristics across the entire operational frequency range while maintaining mechanical flexibility to accommodate thermal expansion, vibration, and installation tolerances. Environmental sealing represents another crucial function, particularly in pressurized waveguide systems common in high-power applications and outdoor installations. The Waveguide Anti-leak Gasket must create airtight seals preventing moisture ingress, which could cause corrosion, dielectric breakdown, or power handling limitations. This dual-functionality requirement necessitates careful material selection balancing electrical conductivity with environmental resistance properties. Modern gasket materials incorporate silver-plated copper particles, nickel-coated graphite, or aluminum fillers within silicone or fluorosilicone elastomer matrices, achieving both electromagnetic shielding effectiveness and environmental durability.

Types and Configurations of Waveguide Anti-leak Gaskets

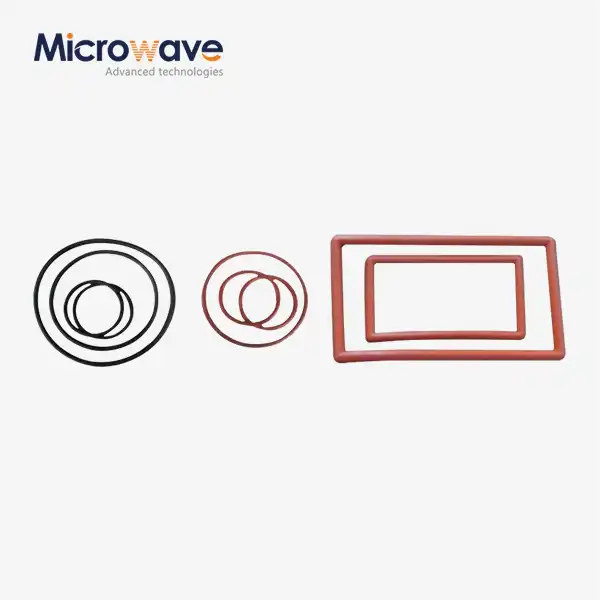

Waveguide gaskets are manufactured in various configurations to accommodate different flange standards, system requirements, and installation methods. Understanding these types enables proper selection for specific applications, ensuring optimal performance and longevity.

Standard Flange-Specific Gasket Designs

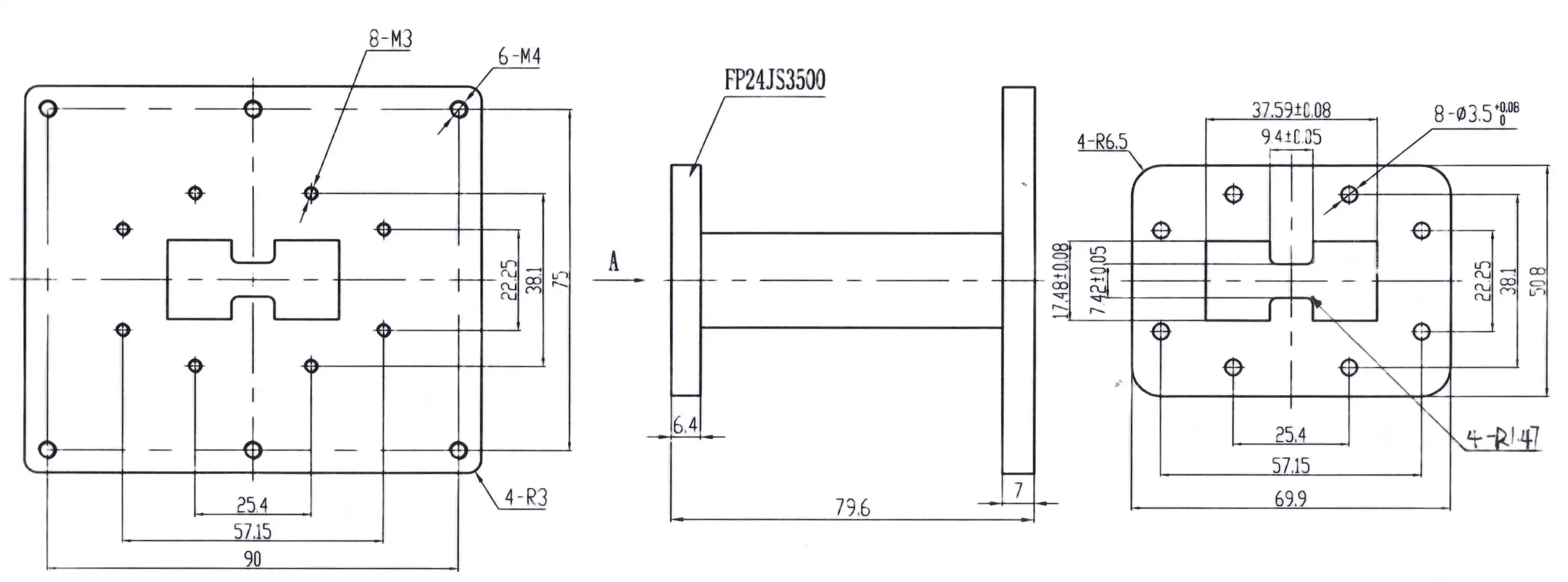

UG flange gaskets represent one of the most common configurations, designed to interface with MIL-SPEC UG-series rectangular waveguide flanges. These gaskets typically feature die-cut or molded designs with precise dimensional tolerances matching standardized flange geometries. The Waveguide Anti-leak Gasket for UG flanges must accommodate the choke or cover flange configurations prevalent in military and aerospace applications, where pressurization and high-reliability performance are paramount. CPR (Connector, Pressurizable, Rectangular) flange gaskets serve pressurizable waveguide systems requiring both electromagnetic continuity and airtight sealing. These gaskets incorporate O-ring cross-sections or specialized profiles designed to seat within flange grooves, creating compression seals under bolt torque. Advanced Microwave Technologies Co., Ltd manufactures CPR-compatible Waveguide Anti-leak Gaskets with frequency ranges extending from 0.5 GHz to 110 GHz, supporting applications from legacy communication systems through emerging millimeter-wave technologies. The gasket material composition ensures consistent performance across temperature extremes, maintaining sealing effectiveness and electrical conductivity throughout operational lifecycles. CMR (Connector, Miniature, Rectangular) flange gaskets provide solutions for compact waveguide assemblies where space constraints demand miniaturized components without compromising performance. These smaller gaskets require precise manufacturing tolerances and material properties that maintain effectiveness despite reduced contact areas. The Waveguide Anti-leak Gasket in CMR configurations demonstrates particular importance in satellite communication equipment, unmanned aerial vehicle systems, and portable radar installations where weight and volume optimization are critical design parameters.

Geometric Configurations and Cross-Sectional Profiles

Die-cut rectangular gaskets offer economical solutions for flat-faced flange interfaces, manufactured through precision cutting of conductive elastomer sheets to exact dimensional specifications. These gaskets excel in applications requiring thin compression profiles and minimal hardware complexity. The Waveguide Anti-leak Gasket in die-cut rectangular form provides reliable performance in moderate-duty applications including laboratory test equipment, ground-based communication systems, and environmental monitoring installations. Molded gaskets with O-shaped cross-sections deliver superior sealing performance through controlled compression characteristics and uniform pressure distribution. The circular cross-section allows predictable deformation under bolt load, creating consistent seal integrity across the entire flange interface. Advanced Microwave manufactures molded O-ring style Waveguide Anti-leak Gaskets using high-quality elastomer composites specifically formulated for excellent sealing capabilities and signal loss prevention. These gaskets demonstrate particular effectiveness in pressurized systems and high-vibration environments common to shipboard systems, aircraft installations, and mobile radar platforms. D-ring profile gaskets combine asymmetric cross-sections optimizing both sealing force and installation convenience. The flat base of the D-profile provides stability during assembly while the curved upper section concentrates sealing pressure along the flange interface. This geometry reduces installation complexity and improves repeatability in field maintenance scenarios. The Waveguide Anti-leak Gasket with D-ring configuration finds extensive application in weather monitoring systems, security check systems, and direction-finding equipment where frequent assembly and disassembly occur during routine maintenance operations.

Material Science and Performance Characteristics

Material selection fundamentally determines Waveguide Anti-leak Gasket performance across electrical, mechanical, and environmental parameters. Modern gasket materials represent sophisticated composites engineered to balance multiple often-competing requirements.

Conductive Elastomer Compositions

Silver-plated copper filled silicone elastomers provide exceptional electrical conductivity combined with mechanical flexibility and environmental resistance. These advanced materials achieve shielding effectiveness exceeding 100 dB across microwave frequency ranges while maintaining compressibility enabling effective sealing under typical bolt torques. The Waveguide Anti-leak Gasket manufactured from silver-plated copper composites operates reliably from -55°C to +200°C, accommodating thermal cycling in aerospace and outdoor installations without degradation of electrical or mechanical properties. Nickel-coated graphite filled elastomers offer alternative solutions where cost optimization or specific environmental resistance characteristics drive material selection. While typically exhibiting slightly lower conductivity than silver-filled materials, these gaskets deliver robust performance in most commercial and industrial applications. Advanced Microwave Technologies Co., Ltd selects appropriate filler materials based on application requirements, frequency ranges, and environmental conditions, ensuring optimal performance-to-cost ratios for diverse customer needs.

Mechanical and Environmental Performance Parameters

Compression set resistance determines long-term sealing effectiveness as gasket materials experience sustained compressive loads under bolted flange assemblies. High-quality Waveguide Anti-leak Gasket materials maintain elastic recovery exceeding 90% even after extended periods under compression at elevated temperatures. This characteristic ensures continued sealing performance throughout multi-year service lives without requiring re-torquing or replacement. Temperature stability encompasses both operational temperature ranges and thermal cycling resistance. The Waveguide Anti-leak Gasket must maintain dimensional stability, electrical properties, and sealing effectiveness across temperature excursions encountered in specific applications. Satellite ground station equipment experiences daily thermal cycling, aerospace applications encounter extreme temperature ranges at altitude, and industrial installations may face elevated ambient temperatures. Advanced material formulations incorporate fluorosilicone bases or specialized additives enhancing thermal stability without compromising other critical performance parameters. Chemical resistance protects against degradation from environmental contaminants, cleaning solvents, lubricants, and atmospheric pollutants. The Waveguide Anti-leak Gasket must resist ozone, ultraviolet radiation, moisture, and industrial chemicals without losing functionality. Silicone-based elastomers provide broad chemical resistance suitable for most applications, while specialized formulations address particularly aggressive environments including marine installations, industrial facilities, and chemical processing operations.

Selection Guidelines for Optimal Waveguide Anti-leak Gasket Performance

Proper gasket selection requires systematic evaluation of application requirements, system constraints, and performance priorities. This section provides practical guidance for specifying Waveguide Anti-leak Gaskets that deliver reliable long-term performance.

Frequency Range and Electrical Requirements

Operating frequency fundamentally influences gasket material selection and design configuration. Lower frequency applications below 20 GHz tolerate broader material choices and less stringent dimensional tolerances, while millimeter-wave frequencies above 40 GHz demand precision-engineered gaskets with carefully controlled surface finishes and material properties. The Waveguide Anti-leak Gasket intended for 5G infrastructure at 28 GHz or 39 GHz requires different specifications than gaskets for C-band satellite communications at 6 GHz. Insertion loss requirements specify maximum acceptable signal attenuation through the gasket interface. High-performance systems including military surveillance radar and satellite communication ground stations require gaskets minimizing insertion loss to preserve system sensitivity and range. Advanced Microwave Technologies Co., Ltd characterizes Waveguide Anti-leak Gasket insertion loss across operational frequency ranges, providing measured data supporting system-level performance predictions. Gasket geometry, material conductivity, and compression characteristics all influence insertion loss, necessitating careful optimization during specification development.

Environmental and Mechanical Considerations

Pressurization requirements determine whether gaskets must provide airtight sealing in addition to electromagnetic shielding. Pressurized waveguide systems common in high-power applications demand gaskets with O-ring or specialized profiles creating compression seals. The Waveguide Anti-leak Gasket for pressurized systems incorporates groove-seating designs ensuring consistent seal integrity under specified pressure differentials throughout operational temperature ranges. Vibration and shock environments characteristic of mobile platforms, aircraft, and shipboard installations require gaskets maintaining seal integrity and electrical continuity under dynamic loading. The Waveguide Anti-leak Gasket for these applications utilizes materials with excellent resilience and fatigue resistance, preventing seal degradation or electrical discontinuities during service lives involving millions of vibration cycles. Installation accessibility influences gasket design selection, particularly regarding assembly complexity and maintenance requirements. Systems requiring frequent disassembly for inspection or reconfiguration benefit from gasket designs facilitating quick installation without specialized tools or extensive training. Advanced Microwave designs Waveguide Anti-leak Gaskets with user-friendly installation characteristics reducing downtime during system maintenance or field service operations.

Application-Specific Optimization

Satellite communication systems demand Waveguide Anti-leak Gaskets maintaining performance throughout multi-year service lives under continuous operation and environmental exposure. These applications prioritize long-term stability, resistance to ultraviolet radiation, and minimal maintenance requirements. Ground station equipment benefits from gaskets providing both electromagnetic continuity and weather sealing, protecting sensitive RF components from moisture ingress while preserving signal quality for high-definition video, data transmission, and voice communications. Radar systems including air traffic control installations and military surveillance platforms require Waveguide Anti-leak Gaskets supporting ultra-sharp beamforming and accurate target detection even in adverse weather conditions. These demanding applications necessitate gaskets with minimal insertion loss, excellent return loss characteristics, and stable performance throughout temperature extremes and environmental conditions encountered in operational deployments. Aerospace and defense applications subject waveguide assemblies to severe mechanical stresses, extreme temperature ranges, and long operational lifecycles without maintenance access. The Waveguide Anti-leak Gasket for these systems must demonstrate exceptional reliability, incorporating materials and designs proven through extensive qualification testing including thermal cycling, vibration testing, and accelerated aging protocols. Advanced Microwave Technologies Co., Ltd conducts comprehensive testing ensuring aerospace-grade gaskets meet stringent military specifications and deliver consistent performance throughout mission-critical operations.

Advanced Microwave Technologies' Waveguide Anti-leak Gasket Solutions

Advanced Microwave Technologies Co., Ltd leverages over two decades of microwave manufacturing expertise developing and producing superior Waveguide Anti-leak Gaskets serving global markets across satellite communications, defense, aerospace, and industrial sectors. Our comprehensive product line encompasses gaskets for all standard flange types including UG, CPR, and CMR configurations, spanning frequency ranges from 0.5 GHz through 110 GHz.

Engineering Excellence and Quality Assurance

Our laboratories equipped with advanced microwave measurement equipment up to 110 GHz enable thorough characterization of Waveguide Anti-leak Gasket electrical performance including insertion loss, return loss, and shielding effectiveness across operational frequency ranges. This testing capability ensures every gasket design meets specifications and delivers predictable system-level performance. The state-of-the-art 24m Microwave Darkroom provides unrivaled antenna and component measurement capabilities, supporting gasket development and validation for the most demanding applications. ISO 9001:2015 certification demonstrates our commitment to quality management throughout design, manufacturing, and delivery processes. Every Waveguide Anti-leak Gasket undergoes rigorous quality control procedures ensuring dimensional accuracy, material consistency, and electrical performance meeting or exceeding industry benchmarks. ISO 14001:2015 and ISO 45001:2018 certifications reflect our dedication to environmental stewardship and workplace safety, providing customers confidence in our sustainable manufacturing practices and ethical business operations.

Customization and OEM Services

Advanced Microwave Technologies Co., Ltd offers extensive customization capabilities tailoring Waveguide Anti-leak Gasket designs to specific customer requirements. Our engineering team provides expert consultation guiding material selection, dimensional specifications, and performance optimization based on application parameters including frequency ranges, environmental conditions, and mechanical constraints. This collaborative approach ensures gasket solutions precisely matching system requirements while optimizing cost-effectiveness. Prototyping services enable customers to evaluate Waveguide Anti-leak Gasket compatibility and performance before committing to production quantities. Rapid turnaround on prototype fabrication accelerates development cycles, allowing design verification and system integration testing with minimal schedule impact. Our flexible manufacturing capabilities accommodate both small-volume specialty requirements and large-scale production orders, providing responsive support throughout product lifecycles from initial development through sustained production. Technical support extends beyond product delivery, with experienced engineers available for installation guidance, troubleshooting assistance, and performance optimization recommendations. This comprehensive service approach ensures customers achieve maximum value from Waveguide Anti-leak Gasket implementations while minimizing integration challenges and operational issues.

Conclusion

Selecting appropriate Waveguide Anti-leak Gaskets requires careful consideration of electrical requirements, environmental conditions, mechanical constraints, and application-specific performance priorities, with proper gasket selection ensuring signal integrity, system reliability, and long-term operational effectiveness across demanding microwave applications.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a leading China Waveguide Anti-leak Gasket manufacturer, China Waveguide Anti-leak Gasket supplier, and China Waveguide Anti-leak Gasket factory, Advanced Microwave Technologies Co., Ltd offers China Waveguide Anti-leak Gasket wholesale with competitive Waveguide Anti-leak Gasket price and High Quality Waveguide Anti-leak Gasket for sale. With ISO-certified manufacturing, RoHS-compliant materials, over 20 years of expertise, and testing capabilities up to 110 GHz, we deliver superior waveguide components for satellite communications, defense, aerospace, and navigation applications. Our OEM services provide customized solutions including rapid prototyping, expert technical consultation, and comprehensive quality assurance. Contact craig@admicrowave.com today to discuss your Waveguide Anti-leak Gasket requirements and discover how our engineering excellence can optimize your microwave system performance. Bookmark this resource for future reference when specifying critical waveguide components.

References

1. MIL-DTL-83528: Gaskets, Electromagnetic Interference (EMI) Shielding, Conductive Elastomer. Department of Defense, United States Military Standard.

2. Smith, J.R. and Anderson, P.K. "Electromagnetic Shielding Effectiveness of Conductive Elastomer Gaskets in Waveguide Applications." IEEE Transactions on Electromagnetic Compatibility, Vol. 58, No. 4.

3. Thompson, M.L. "Waveguide Component Design and Testing: Flanges, Gaskets, and Sealing Systems." Artech House Microwave Library, Boston.

4. EIA Standard RS-261: Standard Waveguide Flanges. Electronic Industries Alliance, Engineering Department.

YOU MAY LIKE

VIEW MOREDouble Ridge Straight Waveguide

VIEW MOREDouble Ridge Straight Waveguide VIEW MOREDouble Ridge Waveguide Transition

VIEW MOREDouble Ridge Waveguide Transition VIEW MOREDouble Ridged Flexible Waveguide

VIEW MOREDouble Ridged Flexible Waveguide VIEW MOREDouble Ridge Waveguide Load

VIEW MOREDouble Ridge Waveguide Load VIEW MOREDouble Ridge Waveguide Rotary Joint

VIEW MOREDouble Ridge Waveguide Rotary Joint VIEW MOREDouble-Ridged Waveguide Broadwall Directional Coupler

VIEW MOREDouble-Ridged Waveguide Broadwall Directional Coupler VIEW MOREWaveguide Flange Gasket

VIEW MOREWaveguide Flange Gasket VIEW MOREWaveguide Adjustable Support

VIEW MOREWaveguide Adjustable Support