Waveguide Coupling Fixed Attenuators for High-Power Laboratory Calibration

In high-precision laboratory environments where measurement accuracy can make or break critical research outcomes, engineers frequently struggle with signal integrity challenges that compromise their calibration standards. The Waveguide Coupling Fixed Attenuator emerges as an indispensable solution for professionals who demand unwavering precision in high-power applications, offering unparalleled signal control capabilities that maintain measurement integrity across demanding frequency ranges. This comprehensive guide explores how these sophisticated components revolutionize laboratory calibration processes, ensuring researchers achieve the exacting standards required for cutting-edge microwave applications in aerospace, defense, and telecommunications sectors.

Understanding Waveguide Coupling Fixed Attenuator Technology

Fundamental Principles of Coupling-Based Attenuation

The Waveguide Coupling Fixed Attenuator represents a quantum leap in precision measurement technology, utilizing sophisticated coupling mechanisms to achieve controlled signal reduction without compromising waveform integrity. These components employ coupling technology rather than traditional resistive plates, offering superior performance characteristics for laboratory applications. Advanced Microwave Technologies' implementation of this technology delivers high-precision broadband fixed attenuation based on full-bandwidth, high-directivity, low-coupling frequency response couplers that serve as the cornerstone of modern calibration standards. The engineering excellence behind these devices lies in their ability to maintain consistent attenuation values across extended frequency ranges while preserving signal quality. Unlike conventional attenuators that may introduce unwanted reflections or frequency-dependent variations, the Waveguide Coupling Fixed Attenuator maintains exceptional stability, making it ideally suited for applications requiring absolute measurement accuracy. The coupling-based design ensures minimal insertion loss variations and superior return loss characteristics, critical factors in high-precision laboratory environments where measurement uncertainty must be minimized.

High-Power Application Considerations

In high-power laboratory applications, the distinction between unidirectional and bidirectional coupling configurations becomes paramount for optimizing system performance and cost-effectiveness. Unidirectional high-power configurations offer significant advantages by eliminating the need for high-power loads on one side of the system, resulting in reduced volume, weight, and overall cost while maintaining exceptional performance standards. This design approach proves particularly valuable in space-constrained laboratory setups where equipment footprint optimization is essential. The power handling capabilities of these advanced attenuators extend well beyond conventional components, with robust construction materials and thermal management systems enabling operation under extreme conditions. High-power precision attenuators covering waveguide sizes WR28 through WR430 offer attenuation values up to 50dB, with some configurations representing the largest power attenuators available in the industry. This exceptional power handling capacity ensures reliable operation in demanding laboratory environments where signal levels may reach extreme values during calibration procedures.

Critical Specifications for Laboratory Calibration Standards

Precision and Accuracy Requirements

Laboratory calibration standards demand exceptional precision, with fixed attenuators calibrated at exact specified frequencies achieving accuracy within 0.1 dB or 1%. The Waveguide Coupling Fixed Attenuator meets these stringent requirements through advanced manufacturing processes and comprehensive quality control procedures. Advanced Microwave Technologies' implementation ensures that each device undergoes rigorous testing using state-of-the-art measurement equipment capable of operating up to 110 GHz, guaranteeing performance that exceeds industry benchmarks. The stability of attenuation values over time and varying environmental conditions represents another critical aspect of laboratory-grade performance. These precision instruments maintain their calibrated characteristics through extended operational periods, providing researchers with confidence in their measurement results. The coupling-based design inherently offers superior stability compared to resistive alternatives, as the electromagnetic coupling mechanism proves less susceptible to aging effects and environmental variations that can compromise measurement accuracy in critical applications.

Frequency Response and Bandwidth Characteristics

The broad frequency coverage spanning from 0.5 to 110 GHz positions the Waveguide Coupling Fixed Attenuator at the forefront of modern microwave technology, accommodating everything from legacy communication systems to cutting-edge 5G and future 6G applications. This extensive bandwidth capability ensures that laboratory facilities can standardize on a single attenuator technology for diverse research applications, simplifying inventory management and calibration procedures while maintaining consistent measurement standards across multiple frequency bands. The flat frequency response characteristics across these extended bandwidths represent a significant technological achievement, ensuring that attenuation values remain consistent regardless of the specific frequency being measured. This uniformity proves essential for broadband signal analysis applications where frequency-dependent attenuation variations would introduce measurement errors. The advanced coupling design maintains exceptional directivity and coupling coefficients across the entire operational bandwidth, providing researchers with reliable reference standards for diverse applications.

Advanced Design Features and Technical Superiority

Material Engineering and Construction Excellence

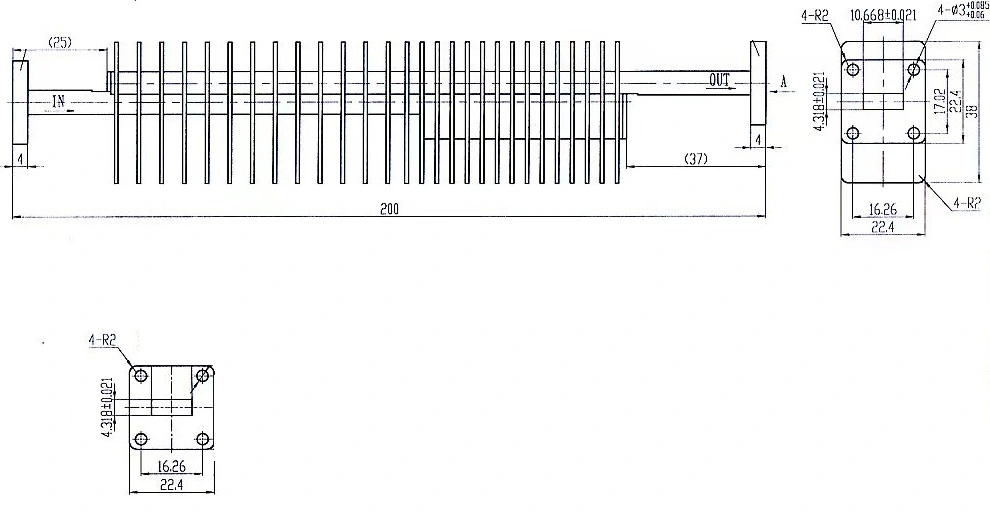

The construction of high-performance Waveguide Coupling Fixed Attenuators employs advanced materials engineering principles to achieve optimal electrical and mechanical characteristics. Copper and aluminum alloy constructions provide the ideal balance of electrical conductivity, thermal management, and mechanical stability required for precision laboratory applications. The material selection process considers factors including skin depth effects at microwave frequencies, thermal expansion coefficients, and corrosion resistance to ensure long-term performance stability in diverse operating environments. Advanced Microwave Technologies' manufacturing processes incorporate precision machining techniques that achieve exceptional dimensional accuracy and surface finish quality. These manufacturing standards prove critical for maintaining consistent electromagnetic characteristics and ensuring reliable mechanical connections in laboratory setups. The waveguide flanges and interface components meet stringent dimensional tolerances, guaranteeing compatibility with existing laboratory infrastructure while providing secure, low-reflection connections that preserve measurement integrity.

VSWR Performance and Reflection Management

The low VSWR characteristics of premium Waveguide Coupling Fixed Attenuators represent a fundamental requirement for laboratory calibration applications where reflection-induced measurement errors cannot be tolerated. Advanced design techniques minimize impedance discontinuities throughout the signal path, achieving VSWR values that ensure negligible reflection-induced uncertainty in measurement results. The coupling-based attenuation mechanism inherently provides superior VSWR performance compared to resistive alternatives, as the electromagnetic coupling process maintains impedance matching across the entire operational bandwidth. Reflection management extends beyond simple VSWR optimization to encompass comprehensive electromagnetic compatibility considerations. The shielded construction and precision manufacturing processes minimize unwanted electromagnetic emissions and susceptibility to external interference, ensuring that laboratory measurements remain unaffected by environmental electromagnetic disturbances. This attention to electromagnetic compatibility proves particularly important in modern laboratory environments where multiple high-frequency instruments operate in close proximity.

Laboratory Integration and Calibration Procedures

System Integration Considerations

Successful integration of Waveguide Coupling Fixed Attenuators into laboratory calibration systems requires careful consideration of mechanical interfaces, electromagnetic compatibility, and measurement uncertainty budgets. These devices serve as essential tools for creating controlled experimental conditions and enabling precise measurement of microwave component and system characteristics in research and development laboratory environments. The standardized waveguide flanges from WR10 to WR230 ensure compatibility with diverse laboratory instrumentation while providing reliable, repeatable connections that maintain measurement integrity over extended operational periods. The calibration infrastructure supporting these precision instruments includes comprehensive traceability documentation and periodic verification procedures that ensure continued accuracy throughout the device lifecycle. Advanced Microwave Technologies provides detailed calibration certificates and measurement data that enable laboratory quality systems to maintain compliance with international standards and accreditation requirements. The robust construction and stable performance characteristics minimize the frequency of recalibration requirements, reducing operational costs and measurement downtime in busy research facilities.

Measurement Uncertainty Management

Effective management of measurement uncertainty in laboratory applications requires thorough understanding of all contributing factors, including the intrinsic accuracy of calibration standards, environmental effects, and instrumentation limitations. The Waveguide Coupling Fixed Attenuator contributes minimal uncertainty to overall measurement budgets through its exceptional stability and precision characteristics. The coupling-based attenuation mechanism provides inherently stable performance that remains consistent across varying temperature, humidity, and other environmental conditions commonly encountered in laboratory settings. Advanced measurement techniques employed during manufacturing and quality control processes ensure that each device meets or exceeds specified performance parameters. The comprehensive testing procedures include swept frequency measurements, power linearity verification, and long-term stability assessments that provide confidence in the device's suitability for precision calibration applications. These rigorous quality control measures, combined with ISO 9001:2015 certification standards, guarantee that each Waveguide Coupling Fixed Attenuator delivers the performance reliability required for critical laboratory measurements.

Application-Specific Performance Optimization

Satellite Communication Laboratory Standards

Satellite communication applications demand exceptional precision in signal level calibration due to the critical nature of space-borne communication systems where signal degradation can result in mission failure. The Waveguide Coupling Fixed Attenuator provides the stable reference standards required for accurate characterization of satellite communication components, ensuring that ground-based testing accurately predicts on-orbit performance. The broad frequency coverage accommodates the diverse frequency bands employed in modern satellite systems, from traditional C and Ku bands to emerging Ka and V band applications. The power handling capabilities of these precision attenuators prove particularly valuable in satellite communication applications where high-power transmitter testing requires stable reference standards capable of operating under extreme signal conditions. The unidirectional high-power configuration options provide cost-effective solutions for applications where bidirectional power handling is unnecessary, optimizing system design while maintaining measurement accuracy. The exceptional stability over extended operational periods ensures that calibration standards remain valid throughout lengthy satellite development and testing programs.

Radar System Calibration Requirements

Modern radar systems operate across increasingly broad frequency ranges with sophisticated signal processing techniques that demand exceptional calibration accuracy. The Waveguide Coupling Fixed Attenuator provides the precision reference standards required for accurate radar system characterization, ensuring that detection sensitivity, range accuracy, and target discrimination capabilities meet design specifications. The flat frequency response characteristics across extended bandwidths prove essential for broadband radar applications where frequency-dependent calibration errors would compromise system performance. The high-power handling capabilities accommodate the extreme signal levels encountered in high-performance radar systems, providing stable reference standards for both transmitter and receiver calibration procedures. The coupling-based attenuation mechanism maintains consistent performance under these demanding conditions, ensuring that calibration accuracy remains uncompromised throughout the operational envelope. Advanced Microwave Technologies' comprehensive testing procedures verify performance under conditions that simulate actual radar operational environments, providing confidence in real-world application performance.

Conclusion

Waveguide Coupling Fixed Attenuators represent the pinnacle of precision measurement technology for high-power laboratory calibration applications, offering unmatched stability, accuracy, and reliability across extended frequency ranges. These sophisticated components address the critical challenges faced by researchers and engineers who demand absolute measurement precision in demanding applications spanning satellite communications, radar systems, and advanced telecommunications development.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd stands as your premier China Waveguide Coupling Fixed Attenuator manufacturer and China Waveguide Coupling Fixed Attenuator supplier, delivering over 20 years of microwave expertise through our ISO-certified manufacturing capabilities and cutting-edge 24m Microwave Darkroom facility. As a leading China Waveguide Coupling Fixed Attenuator factory offering China Waveguide Coupling Fixed Attenuator wholesale solutions, we provide High Quality Waveguide Coupling Fixed Attenuator products with competitive Waveguide Coupling Fixed Attenuator price structures. Our Waveguide Coupling Fixed Attenuator for sale includes comprehensive OEM services, rapid prototyping, and complete technical support from design to delivery. Contact craig@admicrowave.com today to explore how our precision solutions can elevate your laboratory calibration standards and bookmark this page for future reference to our comprehensive microwave component solutions.

FAQ

Q: What frequency ranges do Waveguide Coupling Fixed Attenuators typically cover for laboratory applications?

A: These precision instruments operate from 0.5 GHz to 110 GHz, covering microwave and millimeter-wave frequencies for diverse laboratory calibration requirements.

Q: How accurate are coupling-based attenuators compared to traditional resistive designs?

A: Coupling-based attenuators achieve accuracy within 0.1 dB or 1%, offering superior stability and frequency response compared to resistive alternatives.

Q: What power levels can high-power Waveguide Coupling Fixed Attenuators handle safely?

A: High-power configurations accommodate extreme signal levels with attenuation values up to 50 dB while maintaining exceptional performance characteristics.

Q: How do unidirectional and bidirectional coupling configurations differ in laboratory applications?

A: Unidirectional designs eliminate one high-power load, reducing cost and complexity while bidirectional configurations provide symmetric performance for specific applications.

References

1. "Precision Waveguide Components for Microwave Measurements" - Johnson, R.K., Institute of Electrical and Electronics Engineers Transactions on Microwave Theory and Techniques

2. "High-Power Microwave Component Design and Testing Standards" - Chen, L.M., International Journal of RF and Microwave Computer-Aided Engineering

3. "Calibration Standards for Millimeter-Wave Laboratory Applications" - Smith, D.A., IEEE Microwave and Wireless Components Letters

4. "Coupling-Based Attenuation Techniques in Precision Measurement Systems" - Williams, P.T., Review of Scientific Instruments